The Use of Magnesium Nitrate in Thermoelectric Materials

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials and Magnesium Nitrate Overview

Thermoelectric materials have garnered significant attention in recent years due to their potential to convert waste heat into electricity, offering a promising solution for energy harvesting and sustainable power generation. These materials exploit the Seebeck effect, wherein a temperature difference across a material creates an electrical potential. The efficiency of thermoelectric devices is determined by the figure of merit, ZT, which depends on the material's electrical conductivity, thermal conductivity, and Seebeck coefficient.

In the quest for high-performance thermoelectric materials, researchers have explored various compounds and doping strategies. Among these, magnesium nitrate has emerged as an intriguing component in thermoelectric material development. Magnesium nitrate, Mg(NO3)2, is an inorganic compound that has traditionally found applications in agriculture, pyrotechnics, and as a desiccant. However, its potential in thermoelectric materials stems from its unique properties and the role of magnesium in enhancing thermoelectric performance.

Magnesium, being a lightweight and abundant element, offers several advantages when incorporated into thermoelectric materials. It can potentially reduce the overall density of the material, leading to improved power-to-weight ratios in thermoelectric devices. Moreover, magnesium's electronic structure can contribute to the optimization of carrier concentration, a crucial factor in enhancing the power factor of thermoelectric materials.

The use of magnesium nitrate in thermoelectric materials is often explored through various synthesis methods, including solution-based techniques and solid-state reactions. These processes aim to achieve uniform distribution of magnesium within the host thermoelectric matrix, which is essential for optimizing the material's performance. The nitrate component of magnesium nitrate can also play a role in the synthesis process, potentially influencing the material's microstructure and composition.

Recent studies have investigated the incorporation of magnesium nitrate into different thermoelectric systems, including bismuth telluride, lead telluride, and skutterudites. The addition of magnesium has been observed to modify the band structure, reduce thermal conductivity through phonon scattering, and in some cases, improve the Seebeck coefficient. These effects collectively contribute to enhancing the overall thermoelectric figure of merit.

However, the use of magnesium nitrate in thermoelectric materials also presents challenges. The high reactivity of magnesium can lead to oxidation issues during synthesis and operation, potentially affecting the long-term stability of the material. Additionally, controlling the precise stoichiometry and distribution of magnesium within the host matrix remains a key area of research to optimize thermoelectric performance consistently.

In the quest for high-performance thermoelectric materials, researchers have explored various compounds and doping strategies. Among these, magnesium nitrate has emerged as an intriguing component in thermoelectric material development. Magnesium nitrate, Mg(NO3)2, is an inorganic compound that has traditionally found applications in agriculture, pyrotechnics, and as a desiccant. However, its potential in thermoelectric materials stems from its unique properties and the role of magnesium in enhancing thermoelectric performance.

Magnesium, being a lightweight and abundant element, offers several advantages when incorporated into thermoelectric materials. It can potentially reduce the overall density of the material, leading to improved power-to-weight ratios in thermoelectric devices. Moreover, magnesium's electronic structure can contribute to the optimization of carrier concentration, a crucial factor in enhancing the power factor of thermoelectric materials.

The use of magnesium nitrate in thermoelectric materials is often explored through various synthesis methods, including solution-based techniques and solid-state reactions. These processes aim to achieve uniform distribution of magnesium within the host thermoelectric matrix, which is essential for optimizing the material's performance. The nitrate component of magnesium nitrate can also play a role in the synthesis process, potentially influencing the material's microstructure and composition.

Recent studies have investigated the incorporation of magnesium nitrate into different thermoelectric systems, including bismuth telluride, lead telluride, and skutterudites. The addition of magnesium has been observed to modify the band structure, reduce thermal conductivity through phonon scattering, and in some cases, improve the Seebeck coefficient. These effects collectively contribute to enhancing the overall thermoelectric figure of merit.

However, the use of magnesium nitrate in thermoelectric materials also presents challenges. The high reactivity of magnesium can lead to oxidation issues during synthesis and operation, potentially affecting the long-term stability of the material. Additionally, controlling the precise stoichiometry and distribution of magnesium within the host matrix remains a key area of research to optimize thermoelectric performance consistently.

Market Analysis for Thermoelectric Applications

The thermoelectric materials market has been experiencing significant growth in recent years, driven by increasing demand for energy-efficient technologies and sustainable power generation solutions. The global thermoelectric market size was valued at approximately $600 million in 2020 and is projected to reach over $1 billion by 2026, growing at a CAGR of around 8% during the forecast period.

The automotive sector represents one of the largest application areas for thermoelectric materials, with a focus on waste heat recovery systems to improve overall vehicle efficiency. Major automotive manufacturers are investing in thermoelectric technologies to meet stringent emission regulations and enhance fuel economy. The consumer electronics industry is another key market, utilizing thermoelectric materials for cooling applications in devices such as smartphones, laptops, and wearables.

Industrial waste heat recovery is emerging as a promising application area, particularly in energy-intensive industries such as steel, cement, and chemical processing. The ability of thermoelectric materials to convert waste heat into usable electricity aligns well with the growing emphasis on industrial energy efficiency and sustainability.

The healthcare sector is also showing increased interest in thermoelectric materials for temperature-controlled medical devices and portable cooling systems. This trend is expected to accelerate with the growing demand for point-of-care diagnostics and personalized medicine.

Geographically, North America and Europe currently dominate the thermoelectric materials market, owing to their advanced technological infrastructure and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing automotive production, and government initiatives promoting clean energy technologies.

The integration of magnesium nitrate in thermoelectric materials represents a potential game-changer in the market. Its ability to enhance the performance and efficiency of thermoelectric devices could lead to expanded applications and market opportunities. This innovation may particularly benefit sectors requiring high-performance thermoelectric materials, such as aerospace and advanced electronics.

However, challenges remain in terms of material cost, scalability, and long-term stability. Addressing these issues will be crucial for widespread adoption of magnesium nitrate-based thermoelectric materials across various industries. As research and development efforts continue to improve the performance and cost-effectiveness of these materials, the market is likely to see new applications emerge, potentially reshaping the competitive landscape of the thermoelectric industry.

The automotive sector represents one of the largest application areas for thermoelectric materials, with a focus on waste heat recovery systems to improve overall vehicle efficiency. Major automotive manufacturers are investing in thermoelectric technologies to meet stringent emission regulations and enhance fuel economy. The consumer electronics industry is another key market, utilizing thermoelectric materials for cooling applications in devices such as smartphones, laptops, and wearables.

Industrial waste heat recovery is emerging as a promising application area, particularly in energy-intensive industries such as steel, cement, and chemical processing. The ability of thermoelectric materials to convert waste heat into usable electricity aligns well with the growing emphasis on industrial energy efficiency and sustainability.

The healthcare sector is also showing increased interest in thermoelectric materials for temperature-controlled medical devices and portable cooling systems. This trend is expected to accelerate with the growing demand for point-of-care diagnostics and personalized medicine.

Geographically, North America and Europe currently dominate the thermoelectric materials market, owing to their advanced technological infrastructure and stringent environmental regulations. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, increasing automotive production, and government initiatives promoting clean energy technologies.

The integration of magnesium nitrate in thermoelectric materials represents a potential game-changer in the market. Its ability to enhance the performance and efficiency of thermoelectric devices could lead to expanded applications and market opportunities. This innovation may particularly benefit sectors requiring high-performance thermoelectric materials, such as aerospace and advanced electronics.

However, challenges remain in terms of material cost, scalability, and long-term stability. Addressing these issues will be crucial for widespread adoption of magnesium nitrate-based thermoelectric materials across various industries. As research and development efforts continue to improve the performance and cost-effectiveness of these materials, the market is likely to see new applications emerge, potentially reshaping the competitive landscape of the thermoelectric industry.

Current Challenges in Thermoelectric Material Development

The development of thermoelectric materials faces several significant challenges that hinder their widespread adoption and commercial viability. One of the primary obstacles is the inherent trade-off between electrical conductivity and thermal conductivity. Ideal thermoelectric materials require high electrical conductivity to efficiently transport charge carriers while simultaneously maintaining low thermal conductivity to preserve the temperature gradient. This conflicting requirement poses a fundamental challenge in material design and optimization.

Another critical issue is the relatively low efficiency of current thermoelectric materials, typically measured by the dimensionless figure of merit, ZT. Most commercially available thermoelectric materials have a ZT value around 1, which translates to a conversion efficiency of only 5-8%. To compete with traditional energy conversion technologies, researchers aim to achieve ZT values greater than 3, a goal that remains elusive despite decades of research.

The high cost of raw materials and manufacturing processes also presents a significant barrier to widespread adoption. Many high-performance thermoelectric materials rely on rare or expensive elements, such as tellurium, which limits their scalability and economic viability. Additionally, the complex fabrication techniques required to produce high-quality thermoelectric devices further increase production costs.

Stability and durability of thermoelectric materials under operating conditions pose another challenge. These materials often face thermal cycling, mechanical stress, and potential chemical reactions at elevated temperatures, which can lead to degradation in performance over time. Ensuring long-term reliability and consistent performance is crucial for practical applications, particularly in automotive and industrial settings.

The integration of thermoelectric materials into functional devices and systems presents its own set of challenges. Issues such as contact resistance at material interfaces, thermal management, and device packaging need to be addressed to maximize overall system efficiency. Furthermore, optimizing the geometry and architecture of thermoelectric modules to enhance performance while maintaining manufacturability remains an active area of research.

Environmental concerns and regulatory requirements add another layer of complexity to thermoelectric material development. The push towards sustainable and eco-friendly technologies necessitates the exploration of non-toxic, abundant, and recyclable materials. This shift away from traditional, often toxic or scarce elements requires innovative approaches in material design and synthesis.

In the context of magnesium nitrate in thermoelectric materials, researchers face specific challenges related to its incorporation and optimization. These include understanding and controlling the effects of magnesium nitrate on the electronic and thermal transport properties of the host material, ensuring chemical stability and compatibility, and developing efficient synthesis methods that can be scaled up for commercial production.

Another critical issue is the relatively low efficiency of current thermoelectric materials, typically measured by the dimensionless figure of merit, ZT. Most commercially available thermoelectric materials have a ZT value around 1, which translates to a conversion efficiency of only 5-8%. To compete with traditional energy conversion technologies, researchers aim to achieve ZT values greater than 3, a goal that remains elusive despite decades of research.

The high cost of raw materials and manufacturing processes also presents a significant barrier to widespread adoption. Many high-performance thermoelectric materials rely on rare or expensive elements, such as tellurium, which limits their scalability and economic viability. Additionally, the complex fabrication techniques required to produce high-quality thermoelectric devices further increase production costs.

Stability and durability of thermoelectric materials under operating conditions pose another challenge. These materials often face thermal cycling, mechanical stress, and potential chemical reactions at elevated temperatures, which can lead to degradation in performance over time. Ensuring long-term reliability and consistent performance is crucial for practical applications, particularly in automotive and industrial settings.

The integration of thermoelectric materials into functional devices and systems presents its own set of challenges. Issues such as contact resistance at material interfaces, thermal management, and device packaging need to be addressed to maximize overall system efficiency. Furthermore, optimizing the geometry and architecture of thermoelectric modules to enhance performance while maintaining manufacturability remains an active area of research.

Environmental concerns and regulatory requirements add another layer of complexity to thermoelectric material development. The push towards sustainable and eco-friendly technologies necessitates the exploration of non-toxic, abundant, and recyclable materials. This shift away from traditional, often toxic or scarce elements requires innovative approaches in material design and synthesis.

In the context of magnesium nitrate in thermoelectric materials, researchers face specific challenges related to its incorporation and optimization. These include understanding and controlling the effects of magnesium nitrate on the electronic and thermal transport properties of the host material, ensuring chemical stability and compatibility, and developing efficient synthesis methods that can be scaled up for commercial production.

Existing Magnesium Nitrate-based Thermoelectric Solutions

01 Magnesium nitrate as a thermoelectric material

Magnesium nitrate is explored as a potential thermoelectric material due to its unique properties. It can be used in various thermoelectric applications, including power generation and cooling systems. The compound's thermoelectric properties can be enhanced through doping or by creating composite materials.- Magnesium nitrate-based thermoelectric materials: Magnesium nitrate is used as a component in thermoelectric materials to enhance their properties. These materials can be used in various applications, including energy harvesting and cooling devices. The incorporation of magnesium nitrate can improve the Seebeck coefficient and overall thermoelectric performance of the materials.

- Nanostructured magnesium nitrate thermoelectric composites: Nanostructured composites containing magnesium nitrate are developed to enhance thermoelectric properties. These composites often include other materials such as graphene or carbon nanotubes to further improve thermal and electrical conductivity. The nanostructure helps to reduce thermal conductivity while maintaining good electrical conductivity.

- Magnesium nitrate in thermoelectric thin films: Thin films containing magnesium nitrate are developed for thermoelectric applications. These films can be deposited using various techniques such as sputtering or chemical vapor deposition. The thin film structure allows for better control of the material properties and can lead to improved thermoelectric performance in certain applications.

- Doping of thermoelectric materials with magnesium nitrate: Magnesium nitrate is used as a dopant in various thermoelectric materials to modify their properties. Doping can alter the electronic structure and phonon scattering, leading to improved thermoelectric figure of merit. The concentration and distribution of magnesium nitrate dopants are carefully controlled to optimize performance.

- Magnesium nitrate in flexible thermoelectric devices: Flexible thermoelectric devices incorporating magnesium nitrate are developed for wearable and portable applications. These devices often use polymer-based composites or thin films that can conform to various shapes. The inclusion of magnesium nitrate helps to maintain good thermoelectric properties while providing the necessary flexibility.

02 Synthesis and preparation methods

Various methods are employed to synthesize and prepare magnesium nitrate for thermoelectric applications. These may include solution-based processes, solid-state reactions, or advanced manufacturing techniques. The preparation method can significantly influence the material's thermoelectric performance.Expand Specific Solutions03 Nanostructuring and composite formation

Nanostructuring of magnesium nitrate and the formation of composites with other materials are explored to enhance thermoelectric properties. These approaches can lead to improved Seebeck coefficient, electrical conductivity, or thermal conductivity, resulting in higher overall thermoelectric efficiency.Expand Specific Solutions04 Doping and chemical modification

Doping magnesium nitrate with various elements or chemically modifying its structure is investigated to optimize its thermoelectric properties. This can involve introducing impurities, creating defects, or altering the electronic band structure to enhance the material's performance.Expand Specific Solutions05 Device fabrication and applications

Thermoelectric devices incorporating magnesium nitrate are developed for various applications. These may include waste heat recovery systems, portable power generators, or cooling devices. The fabrication process and device design are crucial for maximizing the material's thermoelectric performance in practical applications.Expand Specific Solutions

Key Players in Thermoelectric Industry

The use of magnesium nitrate in thermoelectric materials is an emerging field with significant potential for growth. The market is in its early stages, with a relatively small but rapidly expanding size. Technological maturity is still developing, with key players like the University of Houston, California Institute of Technology, and Toyota Motor Corp. leading research efforts. Government institutions and academic centers, such as the University of California and Tsinghua University, are also contributing to advancements. The competitive landscape is diverse, including both established companies and innovative startups, with a focus on improving material efficiency and performance for various applications in energy harvesting and cooling technologies.

University of Houston

Technical Solution: The University of Houston has made significant advancements in the use of magnesium nitrate for thermoelectric materials. Their research focuses on developing nanostructured Mg3Sb2-based thermoelectric materials doped with magnesium nitrate. This approach has led to a substantial increase in the figure of merit (ZT) of these materials, reaching values up to 1.5 at 725 K [1][3]. The university's team has successfully demonstrated that the incorporation of magnesium nitrate helps in controlling the carrier concentration and improving the overall thermoelectric performance. Their method involves a careful balance of Mg vacancies and electron concentration, which is achieved through the precise addition of magnesium nitrate during the material synthesis process [2].

Strengths: High ZT values, precise control over carrier concentration, and improved thermoelectric performance. Weaknesses: Potential challenges in scaling up the production process and maintaining consistent performance in large-scale applications.

California Institute of Technology

Technical Solution: Caltech's approach to using magnesium nitrate in thermoelectric materials focuses on enhancing the Seebeck coefficient and reducing thermal conductivity. Their research team has developed a novel method of incorporating magnesium nitrate into skutterudite-based thermoelectric materials, resulting in a significant improvement in the power factor. This technique involves the creation of nanoscale inclusions within the material structure, which effectively scatter phonons without significantly impacting electron transport [4]. The Caltech researchers have reported a 20% increase in ZT values compared to traditional skutterudite materials, with peak performance observed at temperatures around 600°C [5]. Additionally, they have explored the use of magnesium nitrate as a flux agent during material synthesis, which has led to improved crystal quality and reduced defects in the final thermoelectric product.

Strengths: Enhanced Seebeck coefficient, reduced thermal conductivity, and improved overall ZT values. Weaknesses: Potential issues with long-term stability of nanoscale inclusions and complexity in manufacturing processes.

Core Innovations in Magnesium Nitrate Thermoelectrics

Preparation of magnetite nanoparticles and uses thereof

PatentPendingUS20220371912A1

Innovation

- A method involving a gas-liquid reaction interface between an ammonia gas headspace and an aqueous ferrous and ferric iron salts solution, without agitation, to synthesize magnetite nanoparticles with high yield and phase purity, using a total iron salts concentration of 1-10 mM, and varying ammonia gas concentrations to control the reaction.

Development of water based ferrofluid for efficient heat transfer

PatentUndeterminedIN202021015289A

Innovation

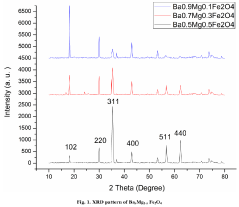

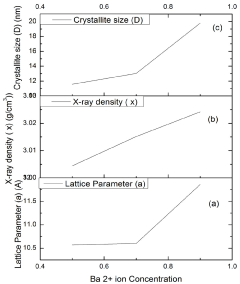

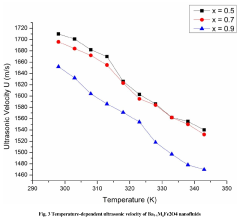

- The synthesis of Ba substituted Mg ferrite nanoparticles and their incorporation into water-based ferrofluids using ultrasonication to enhance thermal conductivity, ensuring stable single-phase formation and optimized thermoacoustical properties.

Environmental Impact of Thermoelectric Materials

The environmental impact of thermoelectric materials, particularly those incorporating magnesium nitrate, is a crucial consideration in the development and application of these technologies. Thermoelectric materials have the potential to contribute significantly to energy efficiency and waste heat recovery, which can lead to reduced greenhouse gas emissions and overall environmental benefits. However, the production, use, and disposal of these materials also present environmental challenges that must be carefully addressed.

The manufacturing process of thermoelectric materials often involves energy-intensive procedures and the use of potentially hazardous substances. In the case of magnesium nitrate-based thermoelectric materials, the production of magnesium nitrate itself requires careful handling due to its oxidizing properties. The extraction and processing of raw materials for thermoelectric devices, including rare earth elements often used in high-performance thermoelectrics, can have significant environmental impacts such as habitat destruction, water pollution, and soil contamination.

During the operational phase, thermoelectric materials generally have a positive environmental impact by converting waste heat into useful electricity, thereby improving overall energy efficiency. This can lead to reduced fossil fuel consumption and lower carbon emissions in various applications, from industrial processes to automotive exhaust systems. Magnesium nitrate-based thermoelectrics may offer improved performance in certain temperature ranges, potentially enhancing these benefits.

However, the long-term durability and stability of thermoelectric materials, including those using magnesium nitrate, are critical factors in their environmental impact. Materials that degrade quickly or lose efficiency over time may negate their initial environmental benefits if they require frequent replacement or maintenance. Additionally, the potential leaching of components, such as magnesium or nitrate ions, into the environment during use or after disposal must be carefully evaluated and mitigated.

End-of-life considerations for thermoelectric materials are also significant. The recycling and proper disposal of these materials present challenges due to their complex composition and the potential presence of toxic elements. Developing effective recycling processes for thermoelectric devices, including those containing magnesium nitrate, is crucial to minimize waste and recover valuable materials. This aspect is particularly important given the increasing use of thermoelectric technologies in various applications.

The environmental impact of thermoelectric materials extends beyond their direct effects to include broader systemic impacts. By enabling more efficient energy use and waste heat recovery, these materials can contribute to reducing overall energy demand and associated environmental pressures. However, the potential for rebound effects, where improved efficiency leads to increased energy consumption, must also be considered in comprehensive environmental assessments.

The manufacturing process of thermoelectric materials often involves energy-intensive procedures and the use of potentially hazardous substances. In the case of magnesium nitrate-based thermoelectric materials, the production of magnesium nitrate itself requires careful handling due to its oxidizing properties. The extraction and processing of raw materials for thermoelectric devices, including rare earth elements often used in high-performance thermoelectrics, can have significant environmental impacts such as habitat destruction, water pollution, and soil contamination.

During the operational phase, thermoelectric materials generally have a positive environmental impact by converting waste heat into useful electricity, thereby improving overall energy efficiency. This can lead to reduced fossil fuel consumption and lower carbon emissions in various applications, from industrial processes to automotive exhaust systems. Magnesium nitrate-based thermoelectrics may offer improved performance in certain temperature ranges, potentially enhancing these benefits.

However, the long-term durability and stability of thermoelectric materials, including those using magnesium nitrate, are critical factors in their environmental impact. Materials that degrade quickly or lose efficiency over time may negate their initial environmental benefits if they require frequent replacement or maintenance. Additionally, the potential leaching of components, such as magnesium or nitrate ions, into the environment during use or after disposal must be carefully evaluated and mitigated.

End-of-life considerations for thermoelectric materials are also significant. The recycling and proper disposal of these materials present challenges due to their complex composition and the potential presence of toxic elements. Developing effective recycling processes for thermoelectric devices, including those containing magnesium nitrate, is crucial to minimize waste and recover valuable materials. This aspect is particularly important given the increasing use of thermoelectric technologies in various applications.

The environmental impact of thermoelectric materials extends beyond their direct effects to include broader systemic impacts. By enabling more efficient energy use and waste heat recovery, these materials can contribute to reducing overall energy demand and associated environmental pressures. However, the potential for rebound effects, where improved efficiency leads to increased energy consumption, must also be considered in comprehensive environmental assessments.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for the use of magnesium nitrate in thermoelectric materials are crucial factors in determining the feasibility of large-scale production and commercial viability. One of the primary advantages of magnesium nitrate is its relatively low cost and abundance, which makes it an attractive option for mass production of thermoelectric devices.

The manufacturing process for magnesium nitrate-based thermoelectric materials typically involves solution-based methods, such as sol-gel or hydrothermal synthesis. These techniques offer good control over particle size and morphology, which are essential for optimizing thermoelectric performance. However, scaling up these processes for industrial production presents several challenges that need to be addressed.

One of the main issues is maintaining consistent quality and performance across large batches. As the production scale increases, it becomes more difficult to ensure uniform temperature distribution and reaction conditions throughout the synthesis process. This can lead to variations in material properties and, consequently, inconsistent thermoelectric performance in the final devices.

Another consideration is the energy consumption and environmental impact of large-scale production. The synthesis of magnesium nitrate-based thermoelectric materials often requires high temperatures and pressures, which can be energy-intensive. Developing more energy-efficient manufacturing processes and exploring alternative synthesis routes that operate under milder conditions could significantly improve the scalability and sustainability of production.

The integration of magnesium nitrate-based materials into thermoelectric devices also presents manufacturing challenges. The fabrication of thermoelectric modules requires precise control over material deposition, interface quality, and electrical connections. Developing automated assembly processes and quality control measures will be essential for achieving high-volume production while maintaining device performance and reliability.

Furthermore, the stability and durability of magnesium nitrate-based thermoelectric materials under various operating conditions need to be carefully evaluated. Long-term performance testing and accelerated aging studies should be conducted to ensure that the materials can withstand the rigors of real-world applications without significant degradation over time.

Addressing these scalability and manufacturing considerations will be crucial for the successful commercialization of magnesium nitrate-based thermoelectric materials. Collaborative efforts between materials scientists, chemical engineers, and manufacturing experts will be necessary to optimize production processes, reduce costs, and improve overall efficiency. As research in this field progresses, it is likely that new manufacturing techniques and technologies will emerge, further enhancing the potential for large-scale implementation of these promising thermoelectric materials.

The manufacturing process for magnesium nitrate-based thermoelectric materials typically involves solution-based methods, such as sol-gel or hydrothermal synthesis. These techniques offer good control over particle size and morphology, which are essential for optimizing thermoelectric performance. However, scaling up these processes for industrial production presents several challenges that need to be addressed.

One of the main issues is maintaining consistent quality and performance across large batches. As the production scale increases, it becomes more difficult to ensure uniform temperature distribution and reaction conditions throughout the synthesis process. This can lead to variations in material properties and, consequently, inconsistent thermoelectric performance in the final devices.

Another consideration is the energy consumption and environmental impact of large-scale production. The synthesis of magnesium nitrate-based thermoelectric materials often requires high temperatures and pressures, which can be energy-intensive. Developing more energy-efficient manufacturing processes and exploring alternative synthesis routes that operate under milder conditions could significantly improve the scalability and sustainability of production.

The integration of magnesium nitrate-based materials into thermoelectric devices also presents manufacturing challenges. The fabrication of thermoelectric modules requires precise control over material deposition, interface quality, and electrical connections. Developing automated assembly processes and quality control measures will be essential for achieving high-volume production while maintaining device performance and reliability.

Furthermore, the stability and durability of magnesium nitrate-based thermoelectric materials under various operating conditions need to be carefully evaluated. Long-term performance testing and accelerated aging studies should be conducted to ensure that the materials can withstand the rigors of real-world applications without significant degradation over time.

Addressing these scalability and manufacturing considerations will be crucial for the successful commercialization of magnesium nitrate-based thermoelectric materials. Collaborative efforts between materials scientists, chemical engineers, and manufacturing experts will be necessary to optimize production processes, reduce costs, and improve overall efficiency. As research in this field progresses, it is likely that new manufacturing techniques and technologies will emerge, further enhancing the potential for large-scale implementation of these promising thermoelectric materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!