Use of Magnesium Nitrate in Modifying Textile Wetting Properties

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate Textile Modification Background

The use of magnesium nitrate in modifying textile wetting properties represents a significant advancement in the field of textile engineering and surface modification. This technology has evolved from the broader context of textile finishing and surface treatment methods, which have been integral to the textile industry for decades. The primary goal of this technique is to alter the surface characteristics of textiles, particularly their wetting behavior, to enhance their performance in various applications.

Historically, textile modification techniques have focused on improving properties such as water repellency, moisture wicking, and stain resistance. The introduction of magnesium nitrate as a modifying agent marks a shift towards more sophisticated and targeted approaches to textile surface engineering. This development is driven by the increasing demand for high-performance textiles in sectors ranging from sportswear to technical textiles used in industrial applications.

The use of magnesium nitrate builds upon the principles of surface chemistry and material science. It leverages the unique properties of magnesium ions and their interaction with textile fibers to create controlled changes in surface energy and wettability. This approach offers several advantages over traditional methods, including improved durability of the treatment, enhanced control over the degree of modification, and potential for environmentally friendly processing.

The evolution of this technology is closely tied to advancements in nanotechnology and green chemistry. As the textile industry moves towards more sustainable practices, the use of magnesium nitrate aligns with efforts to develop eco-friendly textile treatments. This technique potentially reduces the need for harsh chemicals and energy-intensive processes commonly used in conventional textile finishing.

Research in this area aims to achieve precise control over textile surface properties, enabling the creation of fabrics with tailored wetting characteristics. This could lead to textiles that can selectively repel or absorb different types of liquids, opening up new possibilities in protective clothing, medical textiles, and smart fabrics.

The development of magnesium nitrate-based textile modification also intersects with broader trends in material science, such as the creation of stimuli-responsive materials. This synergy could potentially lead to textiles that can dynamically alter their wetting properties in response to environmental changes or external stimuli, further expanding the functional capabilities of treated fabrics.

As research in this field progresses, the focus is on optimizing the application process, understanding the long-term stability of the treatment, and exploring the full range of potential applications across different textile types and end-uses. The ultimate goal is to develop a versatile, efficient, and sustainable method for tailoring textile wetting properties to meet diverse and evolving market needs.

Historically, textile modification techniques have focused on improving properties such as water repellency, moisture wicking, and stain resistance. The introduction of magnesium nitrate as a modifying agent marks a shift towards more sophisticated and targeted approaches to textile surface engineering. This development is driven by the increasing demand for high-performance textiles in sectors ranging from sportswear to technical textiles used in industrial applications.

The use of magnesium nitrate builds upon the principles of surface chemistry and material science. It leverages the unique properties of magnesium ions and their interaction with textile fibers to create controlled changes in surface energy and wettability. This approach offers several advantages over traditional methods, including improved durability of the treatment, enhanced control over the degree of modification, and potential for environmentally friendly processing.

The evolution of this technology is closely tied to advancements in nanotechnology and green chemistry. As the textile industry moves towards more sustainable practices, the use of magnesium nitrate aligns with efforts to develop eco-friendly textile treatments. This technique potentially reduces the need for harsh chemicals and energy-intensive processes commonly used in conventional textile finishing.

Research in this area aims to achieve precise control over textile surface properties, enabling the creation of fabrics with tailored wetting characteristics. This could lead to textiles that can selectively repel or absorb different types of liquids, opening up new possibilities in protective clothing, medical textiles, and smart fabrics.

The development of magnesium nitrate-based textile modification also intersects with broader trends in material science, such as the creation of stimuli-responsive materials. This synergy could potentially lead to textiles that can dynamically alter their wetting properties in response to environmental changes or external stimuli, further expanding the functional capabilities of treated fabrics.

As research in this field progresses, the focus is on optimizing the application process, understanding the long-term stability of the treatment, and exploring the full range of potential applications across different textile types and end-uses. The ultimate goal is to develop a versatile, efficient, and sustainable method for tailoring textile wetting properties to meet diverse and evolving market needs.

Market Analysis for Modified Textiles

The market for modified textiles, particularly those with enhanced wetting properties, has shown significant growth in recent years. This trend is driven by increasing demand across various industries, including apparel, sportswear, medical textiles, and industrial applications. The use of magnesium nitrate in modifying textile wetting properties has emerged as a promising technique, attracting attention from both manufacturers and consumers.

In the apparel sector, there is a growing consumer preference for fabrics with improved moisture management capabilities. This demand is particularly strong in the sportswear and activewear segments, where consumers seek clothing that can effectively wick away sweat and provide comfort during physical activities. The global sportswear market, which heavily relies on such functional textiles, is projected to continue its upward trajectory, creating substantial opportunities for modified textiles.

The medical textile industry represents another key market for fabrics with enhanced wetting properties. Hospital gowns, bedding, and wound dressings benefit from improved liquid absorption and distribution characteristics. As healthcare expenditures rise globally and the importance of infection control becomes more pronounced, the demand for advanced medical textiles is expected to increase.

Industrial applications of modified textiles also contribute significantly to market growth. Sectors such as filtration, automotive, and agriculture utilize fabrics with specific wetting properties for various purposes. For instance, in agriculture, textiles with controlled water retention capabilities are used in crop protection and irrigation systems.

The market for modified textiles is influenced by broader trends in sustainability and eco-friendliness. Consumers are increasingly conscious of the environmental impact of textile production and are seeking products that are both functional and sustainable. This has led to research into environmentally friendly methods of modifying textile properties, including the use of magnesium nitrate, which is generally considered less harmful than some alternative chemical treatments.

Geographically, the market for modified textiles shows varying levels of development. Developed regions such as North America and Europe have been early adopters of advanced textile technologies, driven by high consumer awareness and stringent performance standards. However, emerging economies in Asia-Pacific, particularly China and India, are expected to be key growth drivers in the coming years, fueled by expanding manufacturing capabilities and rising domestic demand.

The competitive landscape of the modified textile market is characterized by a mix of established textile manufacturers and innovative startups. Large textile companies are investing in research and development to enhance their product offerings, while smaller, specialized firms are focusing on niche applications and novel modification techniques. This dynamic is fostering innovation and driving the overall market forward.

In the apparel sector, there is a growing consumer preference for fabrics with improved moisture management capabilities. This demand is particularly strong in the sportswear and activewear segments, where consumers seek clothing that can effectively wick away sweat and provide comfort during physical activities. The global sportswear market, which heavily relies on such functional textiles, is projected to continue its upward trajectory, creating substantial opportunities for modified textiles.

The medical textile industry represents another key market for fabrics with enhanced wetting properties. Hospital gowns, bedding, and wound dressings benefit from improved liquid absorption and distribution characteristics. As healthcare expenditures rise globally and the importance of infection control becomes more pronounced, the demand for advanced medical textiles is expected to increase.

Industrial applications of modified textiles also contribute significantly to market growth. Sectors such as filtration, automotive, and agriculture utilize fabrics with specific wetting properties for various purposes. For instance, in agriculture, textiles with controlled water retention capabilities are used in crop protection and irrigation systems.

The market for modified textiles is influenced by broader trends in sustainability and eco-friendliness. Consumers are increasingly conscious of the environmental impact of textile production and are seeking products that are both functional and sustainable. This has led to research into environmentally friendly methods of modifying textile properties, including the use of magnesium nitrate, which is generally considered less harmful than some alternative chemical treatments.

Geographically, the market for modified textiles shows varying levels of development. Developed regions such as North America and Europe have been early adopters of advanced textile technologies, driven by high consumer awareness and stringent performance standards. However, emerging economies in Asia-Pacific, particularly China and India, are expected to be key growth drivers in the coming years, fueled by expanding manufacturing capabilities and rising domestic demand.

The competitive landscape of the modified textile market is characterized by a mix of established textile manufacturers and innovative startups. Large textile companies are investing in research and development to enhance their product offerings, while smaller, specialized firms are focusing on niche applications and novel modification techniques. This dynamic is fostering innovation and driving the overall market forward.

Current Challenges in Textile Wetting Modification

The modification of textile wetting properties using magnesium nitrate faces several significant challenges in the current landscape. One of the primary obstacles is achieving consistent and uniform application of magnesium nitrate across various textile materials. Different fabrics possess distinct surface characteristics and chemical compositions, making it difficult to develop a standardized application process that works effectively for all types of textiles.

Another challenge lies in the durability of the modified wetting properties. While magnesium nitrate can initially alter the surface tension and wetting behavior of textiles, maintaining these properties over time, especially after repeated washing and wear, remains a considerable hurdle. The longevity of the treatment is crucial for practical applications in clothing and industrial textiles.

The environmental impact of using magnesium nitrate in textile modification is also a growing concern. As sustainability becomes increasingly important in the textile industry, there is a need to ensure that the use of magnesium nitrate does not lead to harmful environmental effects, either during the application process or when the treated textiles are disposed of at the end of their lifecycle.

Furthermore, the scalability of magnesium nitrate treatments presents challenges in industrial settings. Developing cost-effective and efficient methods for large-scale application of magnesium nitrate to textiles, while maintaining quality and consistency, is essential for widespread adoption in the textile industry.

The interaction between magnesium nitrate and other textile treatments or finishes is another area of concern. Many textiles undergo multiple treatments to enhance various properties, and ensuring compatibility between magnesium nitrate and other chemical treatments without compromising their respective functionalities is a complex task.

Additionally, the regulatory landscape surrounding the use of magnesium nitrate in textile modification is evolving. Compliance with safety standards and regulations, particularly in applications involving direct skin contact or specialized uses like medical textiles, requires ongoing research and adaptation of treatment processes.

Lastly, optimizing the concentration and application methods of magnesium nitrate to achieve desired wetting properties without negatively impacting other textile characteristics, such as strength, color, or feel, remains a delicate balancing act. This challenge necessitates continuous research and development to fine-tune the treatment process for different textile applications.

Another challenge lies in the durability of the modified wetting properties. While magnesium nitrate can initially alter the surface tension and wetting behavior of textiles, maintaining these properties over time, especially after repeated washing and wear, remains a considerable hurdle. The longevity of the treatment is crucial for practical applications in clothing and industrial textiles.

The environmental impact of using magnesium nitrate in textile modification is also a growing concern. As sustainability becomes increasingly important in the textile industry, there is a need to ensure that the use of magnesium nitrate does not lead to harmful environmental effects, either during the application process or when the treated textiles are disposed of at the end of their lifecycle.

Furthermore, the scalability of magnesium nitrate treatments presents challenges in industrial settings. Developing cost-effective and efficient methods for large-scale application of magnesium nitrate to textiles, while maintaining quality and consistency, is essential for widespread adoption in the textile industry.

The interaction between magnesium nitrate and other textile treatments or finishes is another area of concern. Many textiles undergo multiple treatments to enhance various properties, and ensuring compatibility between magnesium nitrate and other chemical treatments without compromising their respective functionalities is a complex task.

Additionally, the regulatory landscape surrounding the use of magnesium nitrate in textile modification is evolving. Compliance with safety standards and regulations, particularly in applications involving direct skin contact or specialized uses like medical textiles, requires ongoing research and adaptation of treatment processes.

Lastly, optimizing the concentration and application methods of magnesium nitrate to achieve desired wetting properties without negatively impacting other textile characteristics, such as strength, color, or feel, remains a delicate balancing act. This challenge necessitates continuous research and development to fine-tune the treatment process for different textile applications.

Existing Magnesium Nitrate Application Methods

01 Magnesium nitrate as a wetting agent

Magnesium nitrate is used as an effective wetting agent in various applications. It enhances the spreading and penetration of liquids on surfaces, improving the overall wetting properties of solutions. This property makes it useful in agricultural, industrial, and chemical processes where improved surface contact is desired.- Magnesium nitrate as a wetting agent: Magnesium nitrate is used as an effective wetting agent in various applications. It enhances the spreading and penetration of liquids on surfaces, improving the overall wetting properties of solutions. This property makes it useful in agricultural, industrial, and chemical processes where improved surface contact is desired.

- Hygroscopic properties of magnesium nitrate: Magnesium nitrate exhibits strong hygroscopic properties, allowing it to absorb moisture from the surrounding environment. This characteristic makes it useful in humidity control applications, desiccants, and as a moisture-retaining agent in various products. The hygroscopic nature also contributes to its wetting properties by attracting and retaining water molecules.

- Magnesium nitrate in fire retardant formulations: Magnesium nitrate is utilized in fire retardant formulations due to its wetting properties and ability to form a protective layer on surfaces. When exposed to heat, it releases water molecules, which helps in cooling and suppressing flames. This makes it an effective component in fire-fighting chemicals and flame-retardant coatings.

- Magnesium nitrate in agricultural applications: The wetting properties of magnesium nitrate make it valuable in agricultural applications. It is used in fertilizers to improve nutrient absorption by plants, enhancing the spread and penetration of the fertilizer solution in soil. Additionally, it can be used in foliar sprays to improve the adhesion and coverage of pesticides or other agricultural chemicals on plant surfaces.

- Magnesium nitrate in industrial processes: Magnesium nitrate's wetting properties are utilized in various industrial processes. It is used in the production of ceramics, catalysts, and as a component in chemical reactions where improved surface contact or liquid dispersion is required. Its ability to lower surface tension and promote spreading makes it valuable in processes such as metal surface treatment, printing, and textile manufacturing.

02 Magnesium nitrate in fire retardant compositions

Magnesium nitrate is incorporated into fire retardant compositions due to its wetting properties. It helps in the even distribution of the fire retardant solution on surfaces, enhancing its effectiveness. The wetting ability of magnesium nitrate ensures better coverage and adhesion of the fire retardant material to the protected surfaces.Expand Specific Solutions03 Magnesium nitrate in agricultural formulations

The wetting properties of magnesium nitrate are utilized in agricultural formulations. It improves the spread and absorption of fertilizers and pesticides on plant surfaces. This enhanced wetting ability leads to better nutrient uptake and more effective pest control, contributing to improved crop yields and plant health.Expand Specific Solutions04 Magnesium nitrate in moisture retention applications

Magnesium nitrate's hygroscopic nature and wetting properties make it suitable for moisture retention applications. It is used in products designed to maintain humidity levels or prevent drying out. This property is beneficial in various industries, including food preservation, construction materials, and chemical processing.Expand Specific Solutions05 Magnesium nitrate in surface treatment processes

The wetting properties of magnesium nitrate are exploited in surface treatment processes. It enhances the interaction between treatment solutions and the surfaces being processed. This improved wetting leads to more uniform and effective surface treatments, which is particularly useful in metal finishing, textile processing, and other industrial applications.Expand Specific Solutions

Key Players in Textile Chemical Industry

The use of magnesium nitrate in modifying textile wetting properties is an emerging area in the textile industry, currently in its early development stage. The market size is relatively small but growing, driven by increasing demand for functional textiles. The technology is still evolving, with varying levels of maturity across different applications. Key players like Donghua University and Wuhan Textile University are leading academic research, while companies such as Acticell GmbH and Shanxi Jiaocheng Hongxing Chemicals Co. Ltd. are developing commercial applications. Industry leaders like Asahi Kasei Corp. and Lu Thai Textile Co., Ltd. are also exploring this technology to enhance their product offerings, indicating its potential for widespread adoption in the near future.

Donghua University

Technical Solution: Donghua University has developed an innovative approach to modifying textile wetting properties using magnesium nitrate. Their research focuses on a sol-gel method to create a durable superhydrophobic coating on cotton fabrics[1]. The process involves preparing a sol solution containing magnesium nitrate, tetraethyl orthosilicate (TEOS), and fluoroalkylsilane (FAS). The cotton fabric is then immersed in this solution and subjected to a curing process. This treatment results in the formation of a hierarchical micro-nano structure on the fabric surface, which significantly enhances its water repellency[2]. The magnesium nitrate plays a crucial role in creating the rough surface morphology necessary for superhydrophobicity. Additionally, the university has explored the combination of magnesium nitrate with other compounds to achieve multifunctional properties, such as flame retardancy and UV protection, alongside water repellency[3].

Strengths: Achieves durable superhydrophobicity, potential for multifunctional coatings. Weaknesses: May alter fabric feel, complex application process requiring specialized equipment.

Wuhan Textile University

Technical Solution: Wuhan Textile University has developed a novel approach to modifying textile wetting properties using magnesium nitrate in combination with other compounds. Their research focuses on creating a multifunctional coating that not only enhances water repellency but also imparts flame retardant properties to textiles[1]. The process involves preparing a solution containing magnesium nitrate, phosphorus-based compounds, and silica precursors. This solution is then applied to the fabric using a pad-dry-cure method. The magnesium nitrate acts as a synergist in the flame retardant system while also contributing to the formation of a water-repellent surface structure[2]. The university has conducted extensive studies on the durability of this treatment, showing that the modified textiles maintain their properties even after multiple wash cycles. Furthermore, they have explored the use of this technology on various fabric types, including cotton, polyester, and their blends, demonstrating its versatility[3]. Recent advancements in their research have also focused on incorporating environmentally friendly components to make the process more sustainable.

Strengths: Multifunctional coating providing both water repellency and flame retardancy, applicable to various fabric types. Weaknesses: May require optimization for different fabric compositions, potential environmental concerns with some flame retardant compounds.

Core Innovations in Magnesium Nitrate Usage

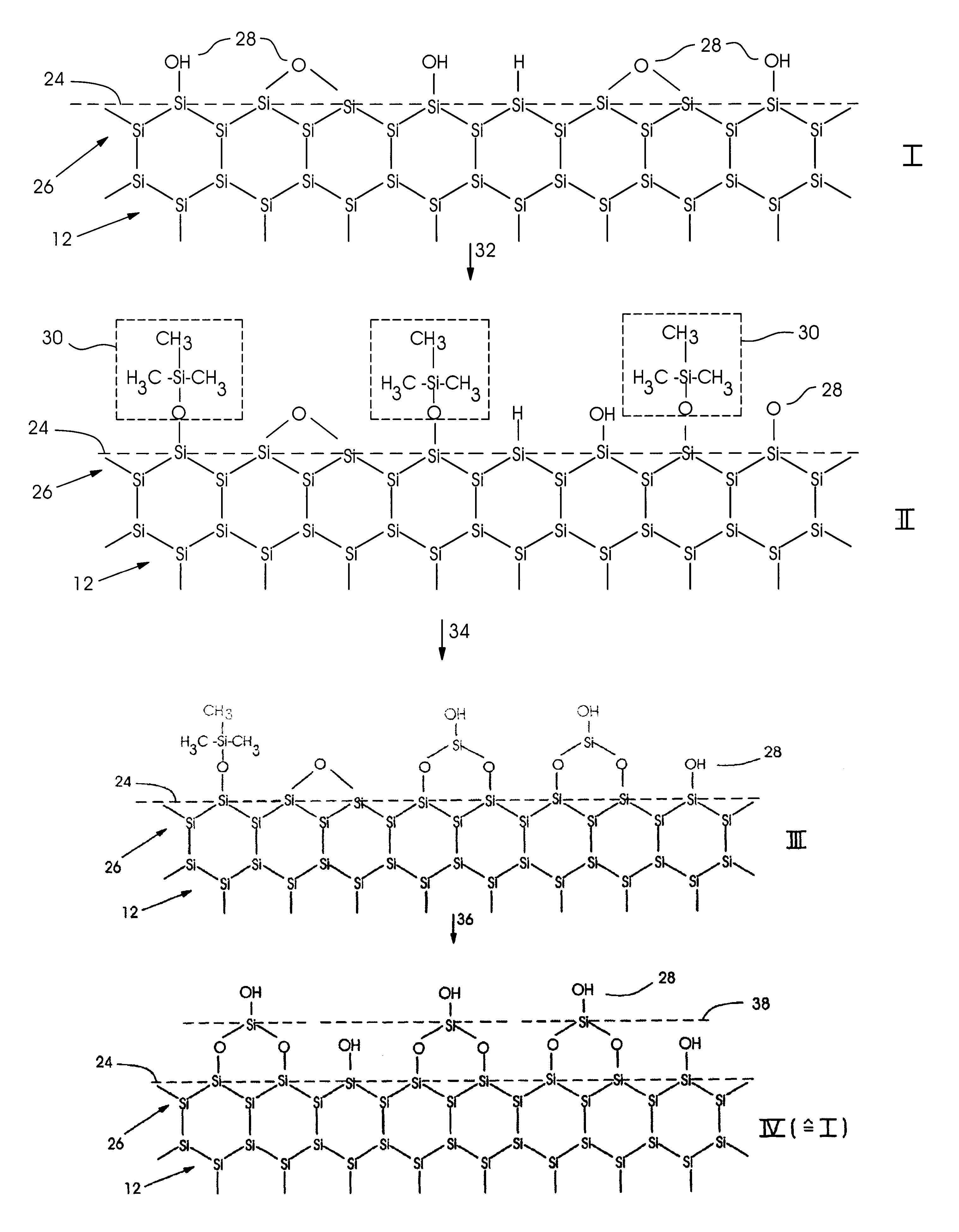

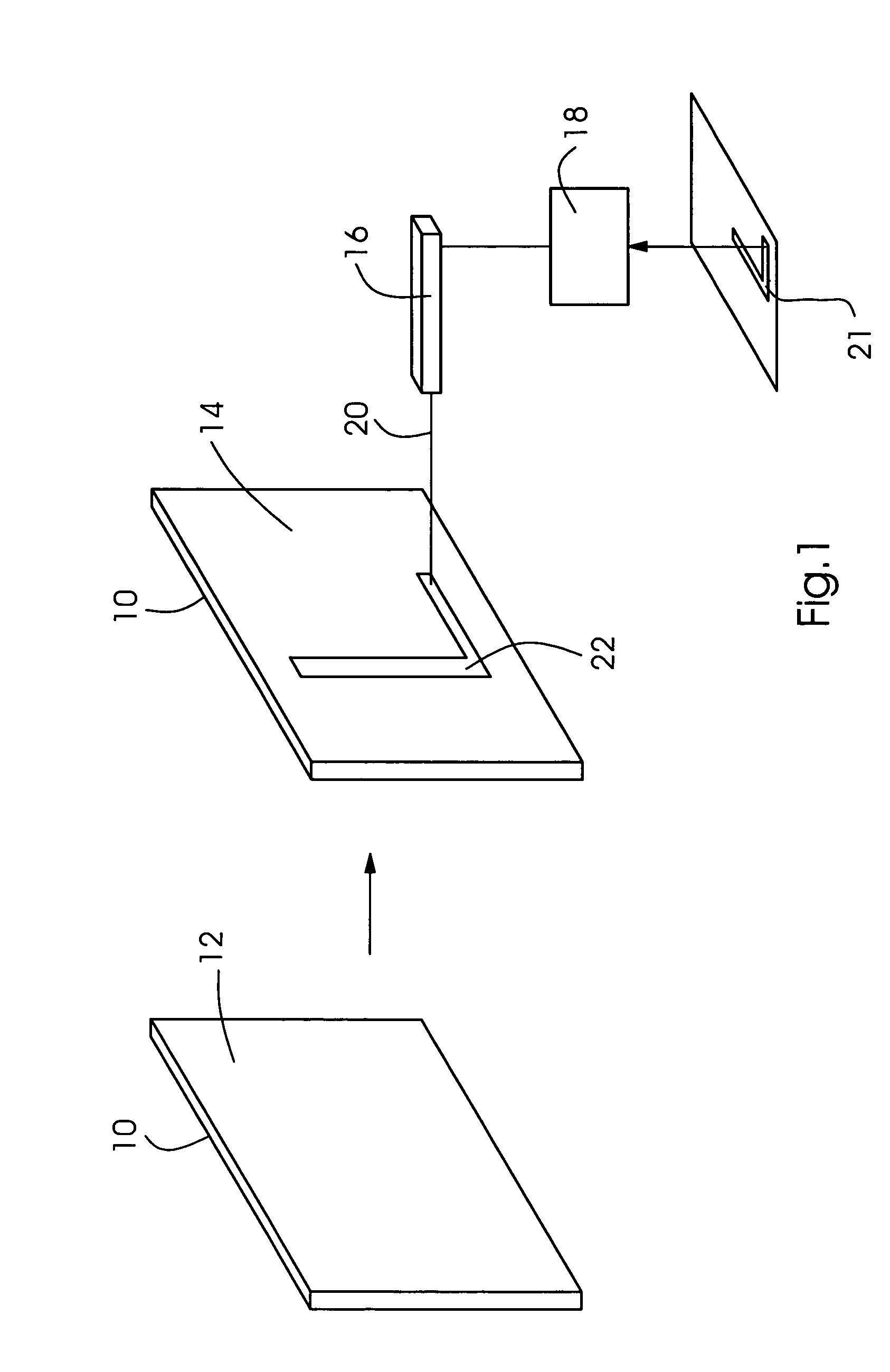

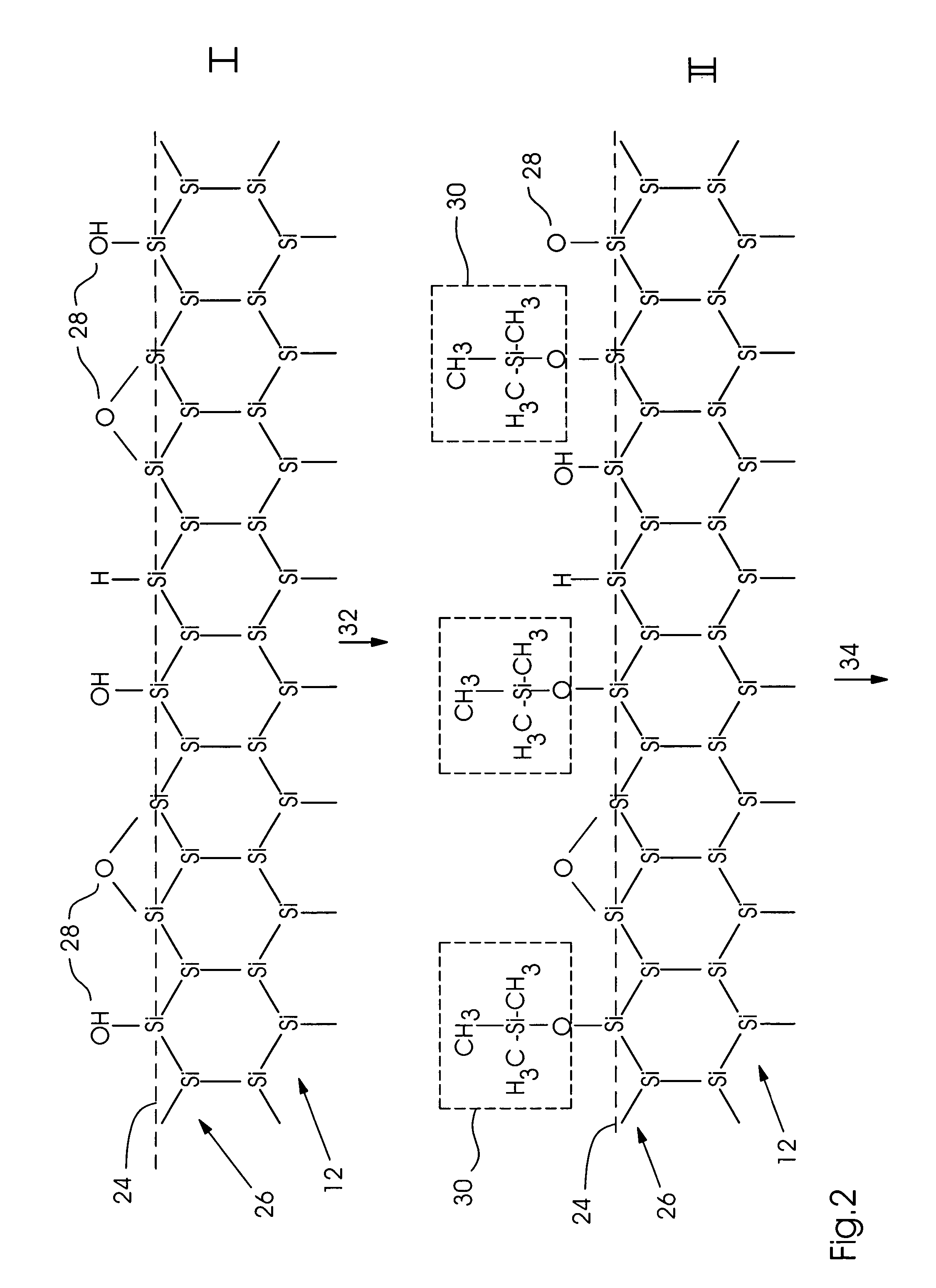

Printing form and method for modifying its wetting properties

PatentInactiveUS7152530B2

Innovation

- A printing form with a surface composed of hydrophilic and hydrophobic regions, where silicon atoms are substituted with specific organic terminal groups, allowing for localized modification of wetting properties using controlled light sources, enabling the creation of pronounced hydrophobic regions and varying wetting contrasts.

Environmental Impact Assessment

The use of magnesium nitrate in modifying textile wetting properties has potential environmental implications that warrant careful consideration. The application of this chemical compound in textile processing can lead to both positive and negative environmental impacts throughout the product lifecycle. One of the primary concerns is the release of nitrates into water systems during the manufacturing process or through subsequent washing of treated textiles. Elevated nitrate levels in water bodies can contribute to eutrophication, causing algal blooms and disrupting aquatic ecosystems.

However, the use of magnesium nitrate may also offer environmental benefits when compared to alternative textile treatments. Its effectiveness in modifying wetting properties could potentially reduce the need for other, more harmful chemicals in textile production. This substitution effect might lead to a net reduction in overall environmental impact, particularly if it results in decreased use of persistent organic pollutants or other substances with known ecological risks.

The production and disposal of magnesium nitrate-treated textiles also require assessment. The manufacturing process of magnesium nitrate itself should be evaluated for energy consumption and emissions. Additionally, the end-of-life disposal of treated textiles may introduce magnesium and nitrate compounds into landfills or incineration systems, necessitating an analysis of potential soil and atmospheric impacts.

Water usage is another critical factor to consider. If the application of magnesium nitrate allows for more efficient dyeing or finishing processes, it could lead to reduced water consumption in textile manufacturing. This potential water-saving benefit must be weighed against the risk of water pollution from nitrate runoff.

The long-term environmental persistence of magnesium nitrate-treated textiles is an area that requires further study. Research should focus on the stability of the treatment under various environmental conditions and its potential for leaching during use and disposal. Understanding these factors is crucial for accurately assessing the cumulative environmental impact over the full lifecycle of treated textiles.

Regulatory compliance and industry standards also play a significant role in the environmental impact assessment. As environmental regulations become more stringent, the use of magnesium nitrate in textile processing must be evaluated against current and anticipated future environmental protection guidelines. This includes considerations for worker safety, air and water quality standards, and waste management protocols.

In conclusion, a comprehensive environmental impact assessment of magnesium nitrate use in textile wetting property modification must balance potential benefits against risks. It should encompass the entire lifecycle of treated textiles, from raw material extraction to final disposal, and consider both local and global environmental effects. Such an assessment will be crucial in determining the overall sustainability of this textile treatment method and guiding future research and development efforts in eco-friendly textile processing technologies.

However, the use of magnesium nitrate may also offer environmental benefits when compared to alternative textile treatments. Its effectiveness in modifying wetting properties could potentially reduce the need for other, more harmful chemicals in textile production. This substitution effect might lead to a net reduction in overall environmental impact, particularly if it results in decreased use of persistent organic pollutants or other substances with known ecological risks.

The production and disposal of magnesium nitrate-treated textiles also require assessment. The manufacturing process of magnesium nitrate itself should be evaluated for energy consumption and emissions. Additionally, the end-of-life disposal of treated textiles may introduce magnesium and nitrate compounds into landfills or incineration systems, necessitating an analysis of potential soil and atmospheric impacts.

Water usage is another critical factor to consider. If the application of magnesium nitrate allows for more efficient dyeing or finishing processes, it could lead to reduced water consumption in textile manufacturing. This potential water-saving benefit must be weighed against the risk of water pollution from nitrate runoff.

The long-term environmental persistence of magnesium nitrate-treated textiles is an area that requires further study. Research should focus on the stability of the treatment under various environmental conditions and its potential for leaching during use and disposal. Understanding these factors is crucial for accurately assessing the cumulative environmental impact over the full lifecycle of treated textiles.

Regulatory compliance and industry standards also play a significant role in the environmental impact assessment. As environmental regulations become more stringent, the use of magnesium nitrate in textile processing must be evaluated against current and anticipated future environmental protection guidelines. This includes considerations for worker safety, air and water quality standards, and waste management protocols.

In conclusion, a comprehensive environmental impact assessment of magnesium nitrate use in textile wetting property modification must balance potential benefits against risks. It should encompass the entire lifecycle of treated textiles, from raw material extraction to final disposal, and consider both local and global environmental effects. Such an assessment will be crucial in determining the overall sustainability of this textile treatment method and guiding future research and development efforts in eco-friendly textile processing technologies.

Textile Performance Testing Standards

Textile performance testing standards play a crucial role in evaluating the effectiveness of magnesium nitrate in modifying textile wetting properties. These standards provide a systematic approach to assess the impact of this chemical treatment on various aspects of fabric performance, particularly in relation to moisture management and wettability.

The American Association of Textile Chemists and Colorists (AATCC) has developed several key test methods that are relevant to this application. AATCC Test Method 79 is widely used to measure the absorbency of textiles, which is directly influenced by the use of magnesium nitrate. This test involves placing a drop of water on the fabric surface and measuring the time it takes for the drop to be completely absorbed. The modification of textile wetting properties through magnesium nitrate treatment can be quantified using this method.

Another important standard is AATCC Test Method 195, which evaluates the liquid moisture management properties of fabrics. This test assesses the movement of liquid moisture in multiple directions, providing insights into how magnesium nitrate treatment affects the fabric's ability to transport moisture away from the skin. The test measures parameters such as wetting time, absorption rate, and spreading speed, all of which can be influenced by the application of magnesium nitrate.

The International Organization for Standardization (ISO) also offers relevant standards for assessing textile wetting properties. ISO 4920 is a water repellency test that can be used to evaluate how magnesium nitrate treatment affects the fabric's resistance to surface wetting. This test involves spraying water onto the fabric surface and assessing the degree of wetting visually.

For more specific evaluation of surface wettability, contact angle measurements are often employed. While not a standardized test method, the technique is widely accepted in the scientific community. It involves measuring the angle formed between a liquid droplet and the textile surface, providing quantitative data on the hydrophobicity or hydrophilicity of the treated fabric.

Performance testing also extends to durability aspects, as it is crucial to assess how long the modified wetting properties persist after repeated washing and wear. AATCC Test Method 61 simulates accelerated laundering conditions and can be used to evaluate the durability of the magnesium nitrate treatment. This test helps determine whether the modified wetting properties are maintained over the expected lifetime of the textile product.

In addition to these specific tests, broader performance standards such as those related to comfort and breathability should be considered. The use of magnesium nitrate to modify wetting properties may impact these characteristics, necessitating comprehensive testing to ensure that overall fabric performance is not compromised.

The American Association of Textile Chemists and Colorists (AATCC) has developed several key test methods that are relevant to this application. AATCC Test Method 79 is widely used to measure the absorbency of textiles, which is directly influenced by the use of magnesium nitrate. This test involves placing a drop of water on the fabric surface and measuring the time it takes for the drop to be completely absorbed. The modification of textile wetting properties through magnesium nitrate treatment can be quantified using this method.

Another important standard is AATCC Test Method 195, which evaluates the liquid moisture management properties of fabrics. This test assesses the movement of liquid moisture in multiple directions, providing insights into how magnesium nitrate treatment affects the fabric's ability to transport moisture away from the skin. The test measures parameters such as wetting time, absorption rate, and spreading speed, all of which can be influenced by the application of magnesium nitrate.

The International Organization for Standardization (ISO) also offers relevant standards for assessing textile wetting properties. ISO 4920 is a water repellency test that can be used to evaluate how magnesium nitrate treatment affects the fabric's resistance to surface wetting. This test involves spraying water onto the fabric surface and assessing the degree of wetting visually.

For more specific evaluation of surface wettability, contact angle measurements are often employed. While not a standardized test method, the technique is widely accepted in the scientific community. It involves measuring the angle formed between a liquid droplet and the textile surface, providing quantitative data on the hydrophobicity or hydrophilicity of the treated fabric.

Performance testing also extends to durability aspects, as it is crucial to assess how long the modified wetting properties persist after repeated washing and wear. AATCC Test Method 61 simulates accelerated laundering conditions and can be used to evaluate the durability of the magnesium nitrate treatment. This test helps determine whether the modified wetting properties are maintained over the expected lifetime of the textile product.

In addition to these specific tests, broader performance standards such as those related to comfort and breathability should be considered. The use of magnesium nitrate to modify wetting properties may impact these characteristics, necessitating comprehensive testing to ensure that overall fabric performance is not compromised.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!