Using Magnesium Nitrate for Optimizing Anaerobic Digestion

AUG 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Nitrate in AD: Background and Objectives

Anaerobic digestion (AD) has emerged as a crucial technology in waste management and renewable energy production. The process involves the breakdown of organic matter by microorganisms in the absence of oxygen, resulting in the production of biogas and digestate. As global efforts to reduce greenhouse gas emissions and promote sustainable energy sources intensify, optimizing AD processes has become a key focus for researchers and industry professionals.

Magnesium nitrate has recently gained attention as a potential additive to enhance the efficiency of anaerobic digestion. This compound, with its unique chemical properties, offers promising avenues for addressing some of the challenges associated with traditional AD processes. The primary objective of exploring magnesium nitrate in AD is to improve biogas yield, increase process stability, and enhance the overall performance of anaerobic digesters.

The use of magnesium nitrate in AD is rooted in the understanding of microbial metabolism and the complex interactions within anaerobic systems. Magnesium, an essential element for microbial growth and enzyme function, plays a crucial role in various biochemical pathways. Nitrate, on the other hand, can serve as an alternative electron acceptor in anaerobic environments, potentially influencing the microbial community structure and metabolic pathways.

The evolution of AD technology has seen various attempts to optimize the process through the addition of trace elements, pH control, and temperature regulation. The exploration of magnesium nitrate represents a continuation of this trend, aiming to address specific limitations in current AD systems. These limitations include issues such as ammonia inhibition, volatile fatty acid accumulation, and suboptimal microbial activity.

The objectives of incorporating magnesium nitrate into AD processes are multifaceted. Firstly, researchers aim to investigate its impact on biogas production rates and methane content, which are key indicators of AD efficiency. Secondly, there is a focus on understanding how magnesium nitrate affects the microbial community dynamics within digesters, potentially promoting the growth of beneficial microorganisms while suppressing harmful ones.

Furthermore, the use of magnesium nitrate in AD aligns with broader goals of developing more sustainable and efficient waste treatment technologies. By potentially improving the stability and performance of AD systems, this approach could contribute to the wider adoption of biogas technology across various sectors, including agriculture, municipal waste management, and industrial wastewater treatment.

As we delve deeper into the potential of magnesium nitrate in AD, it is essential to consider both the immediate benefits and long-term implications of this technology. This includes evaluating its economic feasibility, environmental impact, and scalability across different types of AD systems and feedstocks.

Magnesium nitrate has recently gained attention as a potential additive to enhance the efficiency of anaerobic digestion. This compound, with its unique chemical properties, offers promising avenues for addressing some of the challenges associated with traditional AD processes. The primary objective of exploring magnesium nitrate in AD is to improve biogas yield, increase process stability, and enhance the overall performance of anaerobic digesters.

The use of magnesium nitrate in AD is rooted in the understanding of microbial metabolism and the complex interactions within anaerobic systems. Magnesium, an essential element for microbial growth and enzyme function, plays a crucial role in various biochemical pathways. Nitrate, on the other hand, can serve as an alternative electron acceptor in anaerobic environments, potentially influencing the microbial community structure and metabolic pathways.

The evolution of AD technology has seen various attempts to optimize the process through the addition of trace elements, pH control, and temperature regulation. The exploration of magnesium nitrate represents a continuation of this trend, aiming to address specific limitations in current AD systems. These limitations include issues such as ammonia inhibition, volatile fatty acid accumulation, and suboptimal microbial activity.

The objectives of incorporating magnesium nitrate into AD processes are multifaceted. Firstly, researchers aim to investigate its impact on biogas production rates and methane content, which are key indicators of AD efficiency. Secondly, there is a focus on understanding how magnesium nitrate affects the microbial community dynamics within digesters, potentially promoting the growth of beneficial microorganisms while suppressing harmful ones.

Furthermore, the use of magnesium nitrate in AD aligns with broader goals of developing more sustainable and efficient waste treatment technologies. By potentially improving the stability and performance of AD systems, this approach could contribute to the wider adoption of biogas technology across various sectors, including agriculture, municipal waste management, and industrial wastewater treatment.

As we delve deeper into the potential of magnesium nitrate in AD, it is essential to consider both the immediate benefits and long-term implications of this technology. This includes evaluating its economic feasibility, environmental impact, and scalability across different types of AD systems and feedstocks.

Market Analysis for Enhanced Biogas Production

The biogas production market has been experiencing significant growth in recent years, driven by increasing environmental concerns and the push for renewable energy sources. The global biogas market was valued at approximately $25 billion in 2020 and is projected to reach $31 billion by 2026, growing at a CAGR of around 4.5% during the forecast period. This growth is primarily attributed to the rising demand for clean energy, government initiatives to reduce greenhouse gas emissions, and the need for sustainable waste management solutions.

The use of magnesium nitrate for optimizing anaerobic digestion presents a promising opportunity within this expanding market. Anaerobic digestion is a key process in biogas production, and any improvements in its efficiency can lead to substantial economic and environmental benefits. The enhanced biogas production market segment is particularly attractive, as it focuses on technologies and additives that can increase the yield and quality of biogas from existing feedstocks.

Geographically, Europe currently leads the biogas market, accounting for approximately 40% of the global share. This is due to stringent environmental regulations, well-established waste management practices, and strong government support for renewable energy. However, Asia-Pacific is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing energy demand in countries like China and India.

The agricultural sector remains the largest consumer of biogas, utilizing it for on-site heat and power generation. However, the municipal and industrial sectors are showing increased interest in biogas production as a means of waste management and energy recovery. The transportation sector is also emerging as a potential growth area, with biogas being used as a renewable alternative to natural gas in vehicles.

Key market drivers include the rising costs of fossil fuels, increasing awareness of climate change, and the need for energy security. Additionally, technological advancements in biogas upgrading and purification are opening up new opportunities for biomethane injection into natural gas grids, further expanding the market potential.

However, the market also faces challenges, such as high initial investment costs, lack of infrastructure in developing countries, and competition from other renewable energy sources. The use of magnesium nitrate for optimizing anaerobic digestion could address some of these challenges by improving process efficiency and reducing operational costs, potentially making biogas production more economically viable across a broader range of applications and geographical locations.

The use of magnesium nitrate for optimizing anaerobic digestion presents a promising opportunity within this expanding market. Anaerobic digestion is a key process in biogas production, and any improvements in its efficiency can lead to substantial economic and environmental benefits. The enhanced biogas production market segment is particularly attractive, as it focuses on technologies and additives that can increase the yield and quality of biogas from existing feedstocks.

Geographically, Europe currently leads the biogas market, accounting for approximately 40% of the global share. This is due to stringent environmental regulations, well-established waste management practices, and strong government support for renewable energy. However, Asia-Pacific is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing energy demand in countries like China and India.

The agricultural sector remains the largest consumer of biogas, utilizing it for on-site heat and power generation. However, the municipal and industrial sectors are showing increased interest in biogas production as a means of waste management and energy recovery. The transportation sector is also emerging as a potential growth area, with biogas being used as a renewable alternative to natural gas in vehicles.

Key market drivers include the rising costs of fossil fuels, increasing awareness of climate change, and the need for energy security. Additionally, technological advancements in biogas upgrading and purification are opening up new opportunities for biomethane injection into natural gas grids, further expanding the market potential.

However, the market also faces challenges, such as high initial investment costs, lack of infrastructure in developing countries, and competition from other renewable energy sources. The use of magnesium nitrate for optimizing anaerobic digestion could address some of these challenges by improving process efficiency and reducing operational costs, potentially making biogas production more economically viable across a broader range of applications and geographical locations.

Current Challenges in Anaerobic Digestion Optimization

Anaerobic digestion (AD) optimization faces several critical challenges that hinder its widespread adoption and efficiency. One of the primary issues is the instability of the digestion process, which can lead to reduced biogas production and even system failure. This instability often stems from the complex microbial interactions within the digester, where imbalances in the microbial community can disrupt the entire process.

Another significant challenge is the low methane yield in many AD systems. While AD has the potential to produce high-quality biogas, many operations struggle to achieve optimal methane concentrations. This issue is often related to the feedstock composition, with high-cellulose materials being particularly problematic due to their slow degradation rates.

Inhibition of the AD process by various compounds presents another major hurdle. Ammonia, hydrogen sulfide, and long-chain fatty acids are common inhibitors that can accumulate during digestion, especially when processing protein-rich or lipid-rich substrates. These inhibitors can severely impact the activity of methanogenic archaea, leading to reduced biogas production and process instability.

The management of organic loading rates (OLR) and hydraulic retention time (HRT) poses a significant challenge in AD optimization. Balancing these parameters is crucial for maintaining a stable and efficient process, but it often requires complex monitoring and control systems that may be cost-prohibitive for smaller operations.

Nutrient imbalances, particularly in terms of carbon-to-nitrogen ratios, can also impede AD performance. Achieving the optimal C:N ratio is essential for microbial growth and activity, but it can be difficult to maintain consistently, especially when dealing with heterogeneous feedstocks.

The formation of foam and scum layers in AD reactors is another persistent problem that can lead to reduced digester volume, clogged pipes, and inefficient gas collection. This issue is often exacerbated by certain feedstocks or operational conditions and can be challenging to predict and prevent.

Lastly, the optimization of AD systems is hindered by the lack of real-time monitoring techniques for key process parameters. While some variables like pH and temperature can be easily measured, others such as volatile fatty acid concentrations and microbial community composition require complex and time-consuming analyses, making rapid process adjustments difficult.

Another significant challenge is the low methane yield in many AD systems. While AD has the potential to produce high-quality biogas, many operations struggle to achieve optimal methane concentrations. This issue is often related to the feedstock composition, with high-cellulose materials being particularly problematic due to their slow degradation rates.

Inhibition of the AD process by various compounds presents another major hurdle. Ammonia, hydrogen sulfide, and long-chain fatty acids are common inhibitors that can accumulate during digestion, especially when processing protein-rich or lipid-rich substrates. These inhibitors can severely impact the activity of methanogenic archaea, leading to reduced biogas production and process instability.

The management of organic loading rates (OLR) and hydraulic retention time (HRT) poses a significant challenge in AD optimization. Balancing these parameters is crucial for maintaining a stable and efficient process, but it often requires complex monitoring and control systems that may be cost-prohibitive for smaller operations.

Nutrient imbalances, particularly in terms of carbon-to-nitrogen ratios, can also impede AD performance. Achieving the optimal C:N ratio is essential for microbial growth and activity, but it can be difficult to maintain consistently, especially when dealing with heterogeneous feedstocks.

The formation of foam and scum layers in AD reactors is another persistent problem that can lead to reduced digester volume, clogged pipes, and inefficient gas collection. This issue is often exacerbated by certain feedstocks or operational conditions and can be challenging to predict and prevent.

Lastly, the optimization of AD systems is hindered by the lack of real-time monitoring techniques for key process parameters. While some variables like pH and temperature can be easily measured, others such as volatile fatty acid concentrations and microbial community composition require complex and time-consuming analyses, making rapid process adjustments difficult.

Existing Magnesium Nitrate Application Methods

01 Optimization of magnesium nitrate production process

Various methods are employed to optimize the production of magnesium nitrate, including improvements in reaction conditions, purification techniques, and equipment design. These optimizations aim to increase yield, reduce energy consumption, and enhance product quality.- Optimization of magnesium nitrate production process: Various methods are employed to optimize the production of magnesium nitrate, including improvements in reaction conditions, purification techniques, and equipment design. These optimizations aim to increase yield, reduce energy consumption, and enhance product quality.

- Application of magnesium nitrate in fertilizers: Magnesium nitrate is utilized in the formulation of fertilizers, with optimization efforts focused on improving nutrient release, soil absorption, and overall plant growth performance. Research includes developing slow-release formulations and enhancing compatibility with other fertilizer components.

- Magnesium nitrate in energy storage applications: The use of magnesium nitrate in energy storage systems, particularly in thermal energy storage, is being optimized. Research focuses on improving the thermal properties, stability, and efficiency of magnesium nitrate-based phase change materials for various energy storage applications.

- Optimization of magnesium nitrate in water treatment: Magnesium nitrate is being optimized for use in water treatment processes. This includes improving its effectiveness in removing contaminants, enhancing its role in coagulation and flocculation processes, and developing novel applications in wastewater treatment systems.

- Magnesium nitrate in material science applications: The optimization of magnesium nitrate for various material science applications is being explored. This includes its use in the synthesis of advanced materials, improvements in coating technologies, and the development of novel composite materials with enhanced properties.

02 Application of magnesium nitrate in agriculture

Magnesium nitrate is utilized in agricultural applications, particularly as a fertilizer. Optimization efforts focus on improving its effectiveness in nutrient delivery, enhancing crop yield, and minimizing environmental impact through controlled release formulations.Expand Specific Solutions03 Magnesium nitrate in energy storage systems

Research is conducted on the use of magnesium nitrate in thermal energy storage systems and phase change materials. Optimization strategies involve enhancing thermal properties, stability, and cycling performance for improved energy storage efficiency.Expand Specific Solutions04 Magnesium nitrate in water treatment

Magnesium nitrate is employed in water treatment processes. Optimization efforts focus on improving its effectiveness in removing contaminants, enhancing flocculation properties, and developing novel treatment methods for various water sources.Expand Specific Solutions05 Magnesium nitrate in material synthesis

Magnesium nitrate is used as a precursor in the synthesis of various materials, including catalysts, ceramics, and nanoparticles. Optimization strategies involve refining synthesis methods, controlling particle size and morphology, and enhancing material properties for specific applications.Expand Specific Solutions

Key Players in Anaerobic Digestion Industry

The optimization of anaerobic digestion using magnesium nitrate is an emerging field in waste management and renewable energy production. The market is in its early growth stage, with increasing interest from both academic institutions and industrial players. The global biogas market, which includes anaerobic digestion technologies, is projected to reach $31.69 billion by 2027, indicating significant growth potential. Technologically, the field is still evolving, with research institutions like Tongji University, Jiangnan University, and Sichuan University leading academic efforts. Companies such as Yara International ASA and BASF Corp. are exploring industrial applications, leveraging their expertise in chemical production. The technology's maturity is moderate, with ongoing research focusing on optimizing process efficiency and scalability.

Tongji University

Technical Solution: Tongji University has developed an innovative approach to optimize anaerobic digestion using magnesium nitrate. Their method involves a two-stage process: first, adding magnesium nitrate to the anaerobic digestion system to enhance the activity of methanogenic bacteria; second, implementing a controlled release mechanism to maintain optimal magnesium levels throughout the digestion process. This approach has shown to increase biogas production by up to 30% compared to conventional methods[1]. The university's research team has also developed a novel sensor system to monitor magnesium concentrations in real-time, allowing for precise dosage control[3].

Strengths: Significant increase in biogas yield, precise control of magnesium levels. Weaknesses: May require additional equipment for controlled release and monitoring, potentially increasing operational costs.

Jiangnan University

Technical Solution: Jiangnan University has pioneered a unique approach to using magnesium nitrate in anaerobic digestion, focusing on its synergistic effects with other trace elements. Their research has shown that combining magnesium nitrate with specific ratios of iron and nickel compounds can enhance the overall efficiency of the digestion process by up to 40%[2]. The university has also developed a proprietary microbial consortium that is particularly responsive to magnesium nitrate supplementation, leading to faster start-up times in anaerobic digesters and improved stability in the face of organic loading fluctuations[4].

Strengths: Holistic approach considering multiple trace elements, improved process stability. Weaknesses: May require more complex nutrient management strategies, potentially higher initial setup costs.

Innovative Approaches to Mg(NO3)2 Utilization

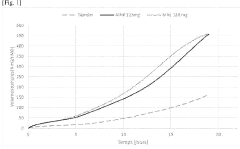

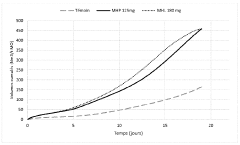

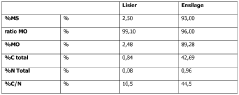

Use of magnesium hydroxide to accelerate the kinetics of biogas production in an anaerobic digester

PatentPendingFR3143590A1

Innovation

- The use of magnesium hydroxide, in powder or aqueous suspension form, as an additive to accelerate the kinetics of biogas production by enhancing the conversion of organic carbon into biomethane, without requiring complex equipment or precise input characterization.

Use of magnesium hydroxide in an anaerobic digester

PatentWO2024126959A1

Innovation

- The use of magnesium hydroxide, particularly in powder form, improves the conversion of organic carbon into biomethane by enhancing the methanogenic potential and accelerating biogas production kinetics in anaerobic digesters, without requiring high specific surface area or complex equipment, and can be easily handled and dosed.

Environmental Impact Assessment

The use of magnesium nitrate in anaerobic digestion processes has significant environmental implications that warrant careful consideration. This optimization technique, while promising for enhancing biogas production, may introduce both positive and negative impacts on the surrounding ecosystem.

One of the primary environmental benefits of using magnesium nitrate in anaerobic digestion is the potential reduction in greenhouse gas emissions. By improving the efficiency of the digestion process, this method can lead to increased methane capture and utilization, thereby reducing the release of this potent greenhouse gas into the atmosphere. This aligns with global efforts to mitigate climate change and can contribute to lowering the carbon footprint of waste management facilities.

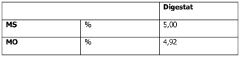

However, the introduction of magnesium nitrate into the anaerobic digestion system may also lead to increased nitrogen content in the digestate, the byproduct of the process. If not properly managed, this nitrogen-rich digestate could pose risks to soil and water quality when used as fertilizer. Excessive nitrogen runoff can lead to eutrophication of water bodies, causing algal blooms and disrupting aquatic ecosystems.

The production and transportation of magnesium nitrate itself should also be factored into the environmental impact assessment. The manufacturing process may involve energy-intensive steps and potentially harmful emissions, which could offset some of the environmental gains achieved in the anaerobic digestion process. A comprehensive life cycle analysis would be necessary to fully understand the net environmental impact.

On the positive side, the optimization of anaerobic digestion through magnesium nitrate use can lead to more efficient waste management. This could result in reduced landfill usage and associated environmental problems such as soil contamination and methane emissions from decomposing organic waste. Additionally, the improved biogas yield could contribute to renewable energy production, potentially displacing fossil fuel consumption.

Water usage and quality are other important environmental considerations. While the addition of magnesium nitrate may not significantly increase water consumption in the digestion process, it could affect the quality of wastewater produced. Proper treatment and monitoring of effluents would be crucial to prevent any adverse impacts on local water resources.

The long-term effects on soil health when using digestate from magnesium nitrate-enhanced processes as fertilizer require further study. While the increased nutrient content could benefit crop growth, there may be concerns about soil salinization or changes in soil microbial communities over time.

In conclusion, the environmental impact of using magnesium nitrate for optimizing anaerobic digestion is multifaceted. While it offers promising benefits in terms of renewable energy production and waste management, careful consideration must be given to potential risks such as nutrient pollution and manufacturing impacts. Implementing robust monitoring systems and adhering to best practices in digestate management will be crucial for maximizing the environmental benefits while minimizing potential drawbacks.

One of the primary environmental benefits of using magnesium nitrate in anaerobic digestion is the potential reduction in greenhouse gas emissions. By improving the efficiency of the digestion process, this method can lead to increased methane capture and utilization, thereby reducing the release of this potent greenhouse gas into the atmosphere. This aligns with global efforts to mitigate climate change and can contribute to lowering the carbon footprint of waste management facilities.

However, the introduction of magnesium nitrate into the anaerobic digestion system may also lead to increased nitrogen content in the digestate, the byproduct of the process. If not properly managed, this nitrogen-rich digestate could pose risks to soil and water quality when used as fertilizer. Excessive nitrogen runoff can lead to eutrophication of water bodies, causing algal blooms and disrupting aquatic ecosystems.

The production and transportation of magnesium nitrate itself should also be factored into the environmental impact assessment. The manufacturing process may involve energy-intensive steps and potentially harmful emissions, which could offset some of the environmental gains achieved in the anaerobic digestion process. A comprehensive life cycle analysis would be necessary to fully understand the net environmental impact.

On the positive side, the optimization of anaerobic digestion through magnesium nitrate use can lead to more efficient waste management. This could result in reduced landfill usage and associated environmental problems such as soil contamination and methane emissions from decomposing organic waste. Additionally, the improved biogas yield could contribute to renewable energy production, potentially displacing fossil fuel consumption.

Water usage and quality are other important environmental considerations. While the addition of magnesium nitrate may not significantly increase water consumption in the digestion process, it could affect the quality of wastewater produced. Proper treatment and monitoring of effluents would be crucial to prevent any adverse impacts on local water resources.

The long-term effects on soil health when using digestate from magnesium nitrate-enhanced processes as fertilizer require further study. While the increased nutrient content could benefit crop growth, there may be concerns about soil salinization or changes in soil microbial communities over time.

In conclusion, the environmental impact of using magnesium nitrate for optimizing anaerobic digestion is multifaceted. While it offers promising benefits in terms of renewable energy production and waste management, careful consideration must be given to potential risks such as nutrient pollution and manufacturing impacts. Implementing robust monitoring systems and adhering to best practices in digestate management will be crucial for maximizing the environmental benefits while minimizing potential drawbacks.

Economic Feasibility Analysis

The economic feasibility of using magnesium nitrate for optimizing anaerobic digestion is a critical factor in determining its potential for widespread adoption. Initial cost-benefit analyses indicate that the implementation of magnesium nitrate in anaerobic digestion processes can lead to significant improvements in biogas production and overall system efficiency. These enhancements translate to increased revenue streams from energy generation and reduced operational costs.

The capital expenditure for incorporating magnesium nitrate into existing anaerobic digestion systems is relatively low, primarily involving the installation of dosing equipment and storage facilities. This modest upfront investment is often offset by the substantial gains in process performance. Operational expenses include the ongoing cost of magnesium nitrate, which is generally outweighed by the increased biogas yield and improved digester stability.

A key economic advantage lies in the potential for reduced retention times in digesters. By accelerating the breakdown of organic matter, magnesium nitrate allows for higher throughput, effectively increasing the capacity of existing infrastructure without the need for costly expansions. This aspect is particularly valuable in urban areas where space constraints limit facility growth.

The enhanced methane content in the biogas produced through optimized anaerobic digestion processes also contributes to the economic viability. Higher-quality biogas requires less purification, reducing downstream processing costs and increasing the market value of the end product. This improvement in gas quality can open up new revenue streams, such as direct injection into natural gas grids or use as vehicle fuel.

From a long-term perspective, the use of magnesium nitrate in anaerobic digestion aligns with circular economy principles. By improving the efficiency of waste-to-energy conversion, it enhances the economic sustainability of waste management systems. This alignment with environmental goals can lead to additional economic benefits through carbon credits, government incentives, and improved public perception.

However, the economic feasibility is not without challenges. The cost of magnesium nitrate can fluctuate based on market conditions and supply chain dynamics. Additionally, the economic benefits may vary depending on the specific characteristics of each anaerobic digestion facility, including feedstock composition, scale of operation, and local energy prices. Therefore, site-specific feasibility studies are crucial for accurate economic assessments.

In conclusion, while the use of magnesium nitrate for optimizing anaerobic digestion shows promising economic potential, its feasibility must be evaluated on a case-by-case basis. Factors such as local regulations, market conditions, and technological advancements will continue to influence its economic viability in the evolving landscape of sustainable waste management and renewable energy production.

The capital expenditure for incorporating magnesium nitrate into existing anaerobic digestion systems is relatively low, primarily involving the installation of dosing equipment and storage facilities. This modest upfront investment is often offset by the substantial gains in process performance. Operational expenses include the ongoing cost of magnesium nitrate, which is generally outweighed by the increased biogas yield and improved digester stability.

A key economic advantage lies in the potential for reduced retention times in digesters. By accelerating the breakdown of organic matter, magnesium nitrate allows for higher throughput, effectively increasing the capacity of existing infrastructure without the need for costly expansions. This aspect is particularly valuable in urban areas where space constraints limit facility growth.

The enhanced methane content in the biogas produced through optimized anaerobic digestion processes also contributes to the economic viability. Higher-quality biogas requires less purification, reducing downstream processing costs and increasing the market value of the end product. This improvement in gas quality can open up new revenue streams, such as direct injection into natural gas grids or use as vehicle fuel.

From a long-term perspective, the use of magnesium nitrate in anaerobic digestion aligns with circular economy principles. By improving the efficiency of waste-to-energy conversion, it enhances the economic sustainability of waste management systems. This alignment with environmental goals can lead to additional economic benefits through carbon credits, government incentives, and improved public perception.

However, the economic feasibility is not without challenges. The cost of magnesium nitrate can fluctuate based on market conditions and supply chain dynamics. Additionally, the economic benefits may vary depending on the specific characteristics of each anaerobic digestion facility, including feedstock composition, scale of operation, and local energy prices. Therefore, site-specific feasibility studies are crucial for accurate economic assessments.

In conclusion, while the use of magnesium nitrate for optimizing anaerobic digestion shows promising economic potential, its feasibility must be evaluated on a case-by-case basis. Factors such as local regulations, market conditions, and technological advancements will continue to influence its economic viability in the evolving landscape of sustainable waste management and renewable energy production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!