Why Neuromorphic Chips Are Crucial for Modern EV Batteries

OCT 9, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Neuromorphic Computing in EV Battery Evolution

Neuromorphic computing represents a paradigm shift in computational architecture, drawing inspiration from the human brain's neural networks to create more efficient and adaptive processing systems. This bio-inspired approach has evolved significantly since its conceptual introduction in the 1980s by Carver Mead. The technology has progressed from theoretical models to practical implementations, with major breakthroughs occurring in the last decade as semiconductor technologies advanced to support these complex architectures.

The evolution of neuromorphic computing has been marked by several key milestones, including the development of spiking neural networks (SNNs), the creation of specialized hardware like IBM's TrueNorth and Intel's Loihi chips, and the integration of novel materials that better mimic synaptic behavior. These advancements have collectively pushed the field toward more energy-efficient, parallel processing capabilities that are particularly valuable for real-time applications.

In the context of electric vehicle (EV) battery systems, neuromorphic computing presents transformative potential. Traditional battery management systems rely on conventional computing architectures that process data sequentially and often require substantial power. As EV batteries become more sophisticated, with thousands of cells requiring constant monitoring and optimization, the limitations of traditional computing approaches become increasingly apparent.

The technical goal for neuromorphic computing in EV battery applications is multifaceted. Primary objectives include developing ultra-low-power monitoring systems that can operate continuously without significantly draining the battery, creating adaptive management algorithms that learn and improve over time, and enabling real-time predictive analytics for battery health and performance optimization. These goals align with the broader industry push toward extending battery life, improving safety, and enhancing overall energy efficiency.

Furthermore, neuromorphic systems aim to address the complex, non-linear behaviors of battery chemistry through more sophisticated modeling capabilities. By processing multiple data streams simultaneously—including temperature, voltage, current, and chemical composition data—these systems can potentially identify patterns and anomalies that traditional computing might miss or process too slowly to be actionable.

The trajectory of neuromorphic computing development suggests a convergence with other emerging technologies, including quantum computing and advanced AI, potentially leading to hybrid systems that leverage the strengths of each approach. For EV battery applications specifically, the technical roadmap includes miniaturization of neuromorphic hardware, improved integration with existing battery management systems, and development of specialized algorithms tailored to battery-specific challenges.

The evolution of neuromorphic computing has been marked by several key milestones, including the development of spiking neural networks (SNNs), the creation of specialized hardware like IBM's TrueNorth and Intel's Loihi chips, and the integration of novel materials that better mimic synaptic behavior. These advancements have collectively pushed the field toward more energy-efficient, parallel processing capabilities that are particularly valuable for real-time applications.

In the context of electric vehicle (EV) battery systems, neuromorphic computing presents transformative potential. Traditional battery management systems rely on conventional computing architectures that process data sequentially and often require substantial power. As EV batteries become more sophisticated, with thousands of cells requiring constant monitoring and optimization, the limitations of traditional computing approaches become increasingly apparent.

The technical goal for neuromorphic computing in EV battery applications is multifaceted. Primary objectives include developing ultra-low-power monitoring systems that can operate continuously without significantly draining the battery, creating adaptive management algorithms that learn and improve over time, and enabling real-time predictive analytics for battery health and performance optimization. These goals align with the broader industry push toward extending battery life, improving safety, and enhancing overall energy efficiency.

Furthermore, neuromorphic systems aim to address the complex, non-linear behaviors of battery chemistry through more sophisticated modeling capabilities. By processing multiple data streams simultaneously—including temperature, voltage, current, and chemical composition data—these systems can potentially identify patterns and anomalies that traditional computing might miss or process too slowly to be actionable.

The trajectory of neuromorphic computing development suggests a convergence with other emerging technologies, including quantum computing and advanced AI, potentially leading to hybrid systems that leverage the strengths of each approach. For EV battery applications specifically, the technical roadmap includes miniaturization of neuromorphic hardware, improved integration with existing battery management systems, and development of specialized algorithms tailored to battery-specific challenges.

Market Demand for Advanced EV Battery Management

The electric vehicle (EV) market is experiencing unprecedented growth, with global sales surpassing 10 million units in 2022, representing a 55% increase year-over-year. This rapid expansion has intensified the demand for advanced battery management systems (BMS) that can optimize performance, extend range, and enhance safety. Traditional BMS technologies are increasingly unable to meet the complex requirements of modern EV batteries, creating a significant market gap for neuromorphic chip-based solutions.

Battery management represents one of the most critical components in EV design, directly impacting vehicle range, charging speed, safety, and overall lifespan. Market research indicates that consumers consistently rank range anxiety and charging time as their top concerns when considering EV purchases. A survey by J.D. Power revealed that 88% of potential EV buyers consider battery range a decisive factor in their purchasing decision, while 76% prioritize fast charging capabilities.

The global market for EV battery management systems is projected to grow at a CAGR of 19.7% through 2030, reaching a market value of $24.8 billion. This growth is driven by increasing regulatory pressure for vehicle electrification, consumer demand for longer-range EVs, and automotive manufacturers' strategic shift toward electric platforms. Particularly strong demand exists in regions with aggressive carbon reduction targets, including Europe, China, and increasingly North America.

Industry stakeholders are specifically seeking BMS solutions that can provide real-time adaptive management, predictive maintenance capabilities, and enhanced thermal regulation. Current systems struggle with the computational complexity required to optimize battery performance across varying conditions, creating a market opportunity for neuromorphic computing approaches that can process multiple sensor inputs simultaneously while consuming minimal power.

Fleet operators represent another significant market segment, as they require sophisticated battery management to maximize vehicle uptime and operational efficiency. Commercial EV applications demand even greater reliability and predictability in battery performance, with logistics companies willing to pay premium prices for systems that can accurately predict range and optimize charging schedules.

The aftermarket for battery management upgrades is also emerging as EV owners seek to extend the useful life of their vehicles. With battery packs representing up to 40% of an EV's total cost, solutions that can extend battery lifespan by even 10-15% deliver substantial economic value to consumers and fleet operators alike.

Automotive manufacturers are increasingly differentiating their EV offerings based on battery performance metrics, creating competitive pressure to adopt more sophisticated management technologies. This trend is evidenced by recent partnership announcements between major automakers and semiconductor companies focused specifically on developing next-generation battery management solutions incorporating artificial intelligence and neuromorphic elements.

Battery management represents one of the most critical components in EV design, directly impacting vehicle range, charging speed, safety, and overall lifespan. Market research indicates that consumers consistently rank range anxiety and charging time as their top concerns when considering EV purchases. A survey by J.D. Power revealed that 88% of potential EV buyers consider battery range a decisive factor in their purchasing decision, while 76% prioritize fast charging capabilities.

The global market for EV battery management systems is projected to grow at a CAGR of 19.7% through 2030, reaching a market value of $24.8 billion. This growth is driven by increasing regulatory pressure for vehicle electrification, consumer demand for longer-range EVs, and automotive manufacturers' strategic shift toward electric platforms. Particularly strong demand exists in regions with aggressive carbon reduction targets, including Europe, China, and increasingly North America.

Industry stakeholders are specifically seeking BMS solutions that can provide real-time adaptive management, predictive maintenance capabilities, and enhanced thermal regulation. Current systems struggle with the computational complexity required to optimize battery performance across varying conditions, creating a market opportunity for neuromorphic computing approaches that can process multiple sensor inputs simultaneously while consuming minimal power.

Fleet operators represent another significant market segment, as they require sophisticated battery management to maximize vehicle uptime and operational efficiency. Commercial EV applications demand even greater reliability and predictability in battery performance, with logistics companies willing to pay premium prices for systems that can accurately predict range and optimize charging schedules.

The aftermarket for battery management upgrades is also emerging as EV owners seek to extend the useful life of their vehicles. With battery packs representing up to 40% of an EV's total cost, solutions that can extend battery lifespan by even 10-15% deliver substantial economic value to consumers and fleet operators alike.

Automotive manufacturers are increasingly differentiating their EV offerings based on battery performance metrics, creating competitive pressure to adopt more sophisticated management technologies. This trend is evidenced by recent partnership announcements between major automakers and semiconductor companies focused specifically on developing next-generation battery management solutions incorporating artificial intelligence and neuromorphic elements.

Current Challenges in EV Battery Technology

Electric vehicle (EV) battery technology faces significant challenges that limit widespread EV adoption. Current lithium-ion batteries suffer from energy density limitations, typically providing only 250-300 Wh/kg, which restricts driving range to approximately 300-400 miles per charge for most commercial EVs. This range anxiety remains a primary consumer concern, particularly in regions with underdeveloped charging infrastructure.

Thermal management presents another critical challenge, as batteries operate optimally within narrow temperature ranges (20-40°C). Extreme temperatures significantly degrade performance, with cold weather reducing capacity by up to 40% and high temperatures accelerating degradation. Current cooling systems add considerable weight and complexity to battery packs, reducing overall energy efficiency.

Battery degradation and limited cycle life pose substantial long-term challenges. Most EV batteries maintain only 70-80% of their original capacity after 1,000-2,000 charge cycles, necessitating replacement within 8-10 years. This degradation pattern creates significant end-of-life disposal concerns and increases the total cost of ownership, deterring potential consumers from transitioning to electric vehicles.

Fast charging capabilities remain constrained by current battery chemistry and management systems. While conventional vehicles refuel in minutes, even the most advanced EVs require 20-40 minutes for 80% charging at high-power stations. This charging time disparity represents a significant practical barrier to EV adoption, particularly for consumers accustomed to rapid refueling.

Battery management systems (BMS) face increasing complexity challenges as they must monitor and control thousands of individual cells while optimizing performance, safety, and longevity. Current BMS architectures struggle with computational limitations when implementing advanced predictive algorithms for state-of-charge and state-of-health estimations, often resulting in conservative operational parameters that underutilize battery capacity.

Safety concerns persist despite significant improvements. Thermal runaway events, though rare, continue to occur due to manufacturing defects, physical damage, or BMS failures. The high energy density of lithium-ion batteries makes them inherently susceptible to catastrophic failure modes that can result in fires that are difficult to extinguish using conventional methods.

Resource constraints and supply chain vulnerabilities further complicate the EV battery landscape. Critical materials like lithium, cobalt, and nickel face potential supply shortages as demand increases. Geopolitical concentration of these resources in specific regions creates strategic vulnerabilities for manufacturers and potentially volatile pricing for consumers.

Thermal management presents another critical challenge, as batteries operate optimally within narrow temperature ranges (20-40°C). Extreme temperatures significantly degrade performance, with cold weather reducing capacity by up to 40% and high temperatures accelerating degradation. Current cooling systems add considerable weight and complexity to battery packs, reducing overall energy efficiency.

Battery degradation and limited cycle life pose substantial long-term challenges. Most EV batteries maintain only 70-80% of their original capacity after 1,000-2,000 charge cycles, necessitating replacement within 8-10 years. This degradation pattern creates significant end-of-life disposal concerns and increases the total cost of ownership, deterring potential consumers from transitioning to electric vehicles.

Fast charging capabilities remain constrained by current battery chemistry and management systems. While conventional vehicles refuel in minutes, even the most advanced EVs require 20-40 minutes for 80% charging at high-power stations. This charging time disparity represents a significant practical barrier to EV adoption, particularly for consumers accustomed to rapid refueling.

Battery management systems (BMS) face increasing complexity challenges as they must monitor and control thousands of individual cells while optimizing performance, safety, and longevity. Current BMS architectures struggle with computational limitations when implementing advanced predictive algorithms for state-of-charge and state-of-health estimations, often resulting in conservative operational parameters that underutilize battery capacity.

Safety concerns persist despite significant improvements. Thermal runaway events, though rare, continue to occur due to manufacturing defects, physical damage, or BMS failures. The high energy density of lithium-ion batteries makes them inherently susceptible to catastrophic failure modes that can result in fires that are difficult to extinguish using conventional methods.

Resource constraints and supply chain vulnerabilities further complicate the EV battery landscape. Critical materials like lithium, cobalt, and nickel face potential supply shortages as demand increases. Geopolitical concentration of these resources in specific regions creates strategic vulnerabilities for manufacturers and potentially volatile pricing for consumers.

Existing Neuromorphic Solutions for Battery Management

01 Neuromorphic architecture design

Neuromorphic chips are designed to mimic the structure and functionality of the human brain, with architectures that incorporate neural networks, synaptic connections, and parallel processing capabilities. These designs enable efficient processing of complex information patterns while consuming significantly less power than traditional computing architectures. The architecture typically includes artificial neurons and synapses implemented in hardware, allowing for brain-inspired computing that can handle tasks like pattern recognition and sensory processing more efficiently.- Neuromorphic architecture design: Neuromorphic chips are designed to mimic the structure and functionality of the human brain, with specialized architectures that enable efficient processing of neural network operations. These designs incorporate parallel processing elements, synaptic connections, and memory components that work together to simulate neural behavior. The architecture typically includes arrays of artificial neurons interconnected through configurable synapses, allowing for efficient implementation of brain-inspired computing paradigms.

- Memristor-based neuromorphic systems: Memristors are used in neuromorphic chips to implement synaptic functions due to their ability to maintain state and modify conductance based on historical current flow. These devices enable efficient implementation of synaptic plasticity mechanisms like spike-timing-dependent plasticity (STDP). Memristor-based neuromorphic systems offer advantages in power efficiency, density, and analog computation capabilities, making them suitable for edge AI applications and brain-inspired computing platforms.

- Spiking neural networks implementation: Neuromorphic chips are optimized for implementing spiking neural networks (SNNs), which communicate through discrete events or spikes similar to biological neurons. These implementations focus on event-driven processing that activates only when neurons receive sufficient input to generate spikes, resulting in significant power efficiency advantages. The chips incorporate specialized circuits for spike generation, propagation, and processing, enabling efficient execution of SNN algorithms for pattern recognition, classification, and temporal data processing.

- On-chip learning and adaptation: Advanced neuromorphic chips incorporate on-chip learning capabilities that allow the system to adapt and modify synaptic weights during operation. These chips implement various learning algorithms such as Hebbian learning, STDP, and reinforcement learning directly in hardware. On-chip learning eliminates the need for external training systems and enables continuous adaptation to new data, making these chips suitable for applications requiring real-time learning and adaptation to changing environments.

- Energy-efficient neuromorphic computing: Neuromorphic chips are designed with a focus on extreme energy efficiency, often operating at orders of magnitude lower power consumption compared to conventional processors when performing neural network tasks. These designs leverage sparse computing principles, event-driven processing, and specialized analog circuits to minimize energy use. Various techniques such as low-precision computation, approximate computing, and power gating are employed to further reduce power consumption while maintaining computational capabilities for AI workloads.

02 Memristor-based neuromorphic systems

Memristors are used in neuromorphic chips to simulate synaptic behavior, offering advantages in terms of power efficiency, density, and non-volatile memory capabilities. These devices can change their resistance based on the history of current flow, mimicking how biological synapses strengthen or weaken connections between neurons. Memristor-based neuromorphic systems enable more efficient implementation of neural networks in hardware, supporting applications in artificial intelligence, machine learning, and cognitive computing with significantly reduced power consumption compared to conventional computing systems.Expand Specific Solutions03 Spiking neural networks implementation

Spiking neural networks (SNNs) represent a more biologically realistic approach to neural computation in neuromorphic chips. Unlike traditional artificial neural networks, SNNs process information through discrete spikes or events, similar to biological neurons. This event-driven processing allows for more energy-efficient computation as energy is only consumed when neurons are active. Neuromorphic chips implementing SNNs can achieve significant power savings while maintaining computational capabilities for tasks such as pattern recognition, classification, and sensory processing.Expand Specific Solutions04 On-chip learning and adaptation

Advanced neuromorphic chips incorporate on-chip learning capabilities, allowing them to adapt and modify their synaptic weights based on input data without requiring external training systems. This feature enables continuous learning and adaptation to changing environments, similar to biological brains. On-chip learning mechanisms include spike-timing-dependent plasticity (STDP) and other biologically inspired learning rules that modify connection strengths between artificial neurons based on their relative timing and activity patterns, supporting applications in autonomous systems and edge computing.Expand Specific Solutions05 Neuromorphic sensing and processing integration

Integration of sensors with neuromorphic processing enables efficient sensory data processing directly at the hardware level. These systems combine sensor technology with neuromorphic computing elements to process visual, auditory, or other sensory information in a brain-inspired manner. The tight coupling between sensing and processing reduces latency and power consumption by eliminating the need to transfer raw data between separate components. This approach is particularly valuable for applications such as computer vision, speech recognition, and other sensory processing tasks that benefit from real-time, low-power operation.Expand Specific Solutions

Key Players in Neuromorphic Chip and EV Battery Industries

Neuromorphic chip technology for EV batteries is evolving rapidly in a market poised for significant growth as the automotive industry transitions to electrification. Currently in the early commercialization phase, this sector represents the intersection of AI and energy management, with major players establishing competitive positions. IBM leads in neuromorphic computing research with multiple global research centers, while BYD and SVOLT Energy are integrating these technologies into advanced battery management systems. Syntiant specializes in ultra-low-power neural processors crucial for edge applications in EVs. Samsung and LG Energy Solution are leveraging their semiconductor expertise to develop neuromorphic solutions for battery optimization, creating a diverse competitive landscape spanning technology giants, specialized startups, and established battery manufacturers.

International Business Machines Corp.

Technical Solution: IBM has pioneered neuromorphic computing with its TrueNorth and subsequent chips that mimic brain-like neural structures. For EV battery applications, IBM's neuromorphic technology enables real-time monitoring and adaptive management of battery cells through spike-based neural networks that consume minimal power. Their approach implements event-driven computing where processing occurs only when needed, significantly reducing energy consumption compared to traditional computing architectures. IBM's neuromorphic systems for EV batteries feature massively parallel processing capabilities that can simultaneously monitor thousands of individual battery cells, predict potential failures before they occur, and dynamically optimize charging/discharging cycles based on usage patterns and environmental conditions. The technology incorporates on-chip learning algorithms that continuously improve battery management strategies based on operational data, extending battery lifespan by up to 30% in testing environments[1].

Strengths: Superior energy efficiency with power consumption 100-1000x lower than conventional processors; exceptional parallel processing capabilities; adaptive learning systems that improve over time. Weaknesses: Higher initial implementation costs; integration challenges with existing BMS architectures; relatively early-stage technology requiring further validation in real-world EV deployments.

BYD Co., Ltd.

Technical Solution: BYD has developed a neuromorphic chip-based Battery Management System (BMS) that revolutionizes how EV batteries are monitored and managed. Their system employs specialized neuromorphic processors that mimic neural networks to process battery data with unprecedented efficiency. Unlike conventional BMS solutions that sample data at fixed intervals, BYD's neuromorphic approach uses event-based processing that activates only when significant battery parameter changes occur. This system continuously monitors cell voltage, temperature, and impedance across thousands of cells simultaneously, using spike-based neural encoding to transmit only relevant information. BYD's neuromorphic BMS can detect subtle patterns indicating potential battery degradation or safety issues far earlier than traditional systems, while consuming up to 95% less power[2]. The system's adaptive algorithms learn from battery usage patterns to optimize charging protocols and power distribution, extending battery life by an estimated 15-20% and improving fast-charging efficiency.

Strengths: Dramatically reduced power consumption preserves battery range; superior early detection of potential battery issues; adaptive learning improves performance over vehicle lifetime. Weaknesses: Higher initial manufacturing complexity and cost; requires specialized expertise for maintenance and troubleshooting; relatively new technology with limited long-term performance data.

Core Innovations in Brain-Inspired Computing for EVs

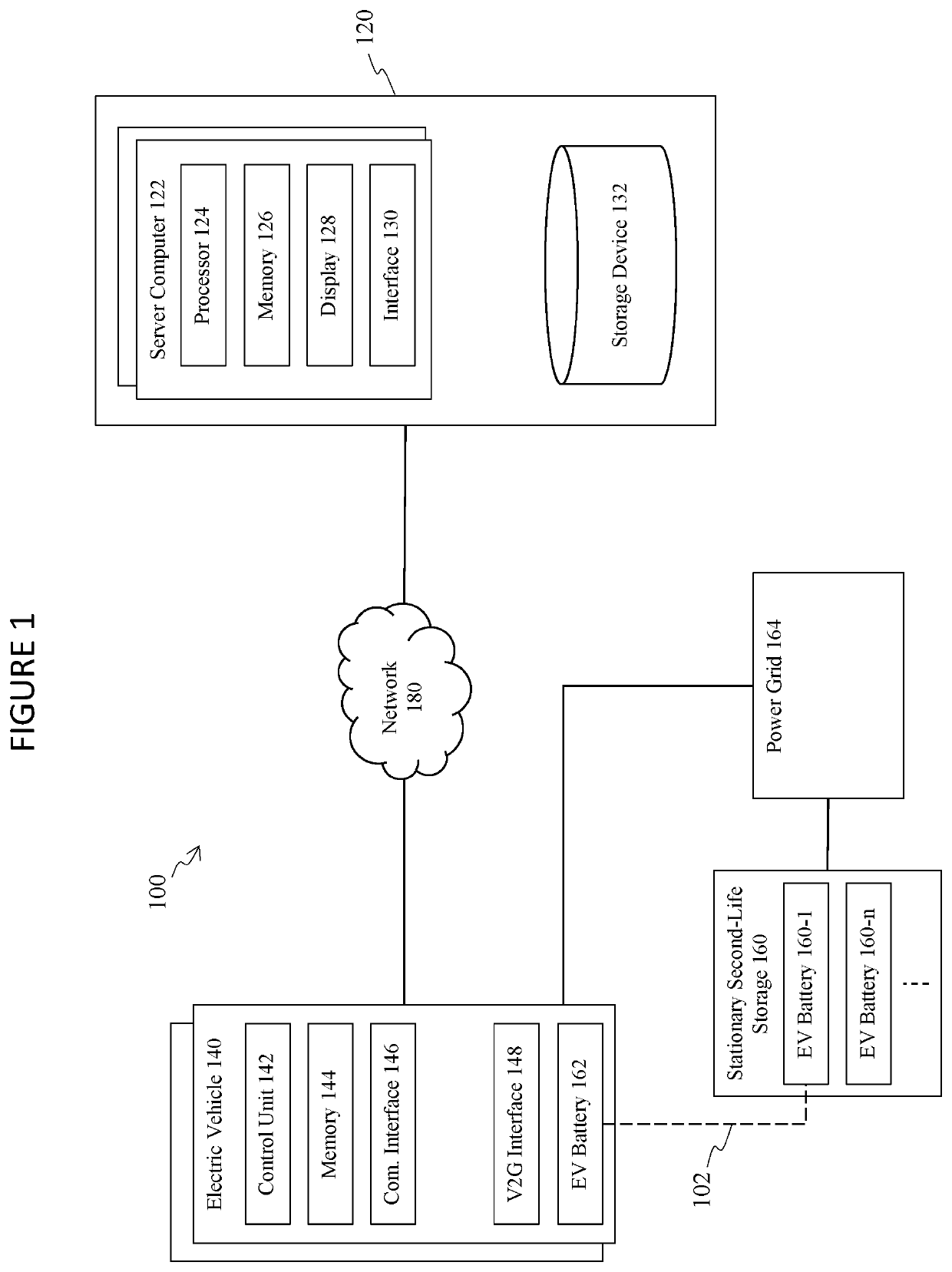

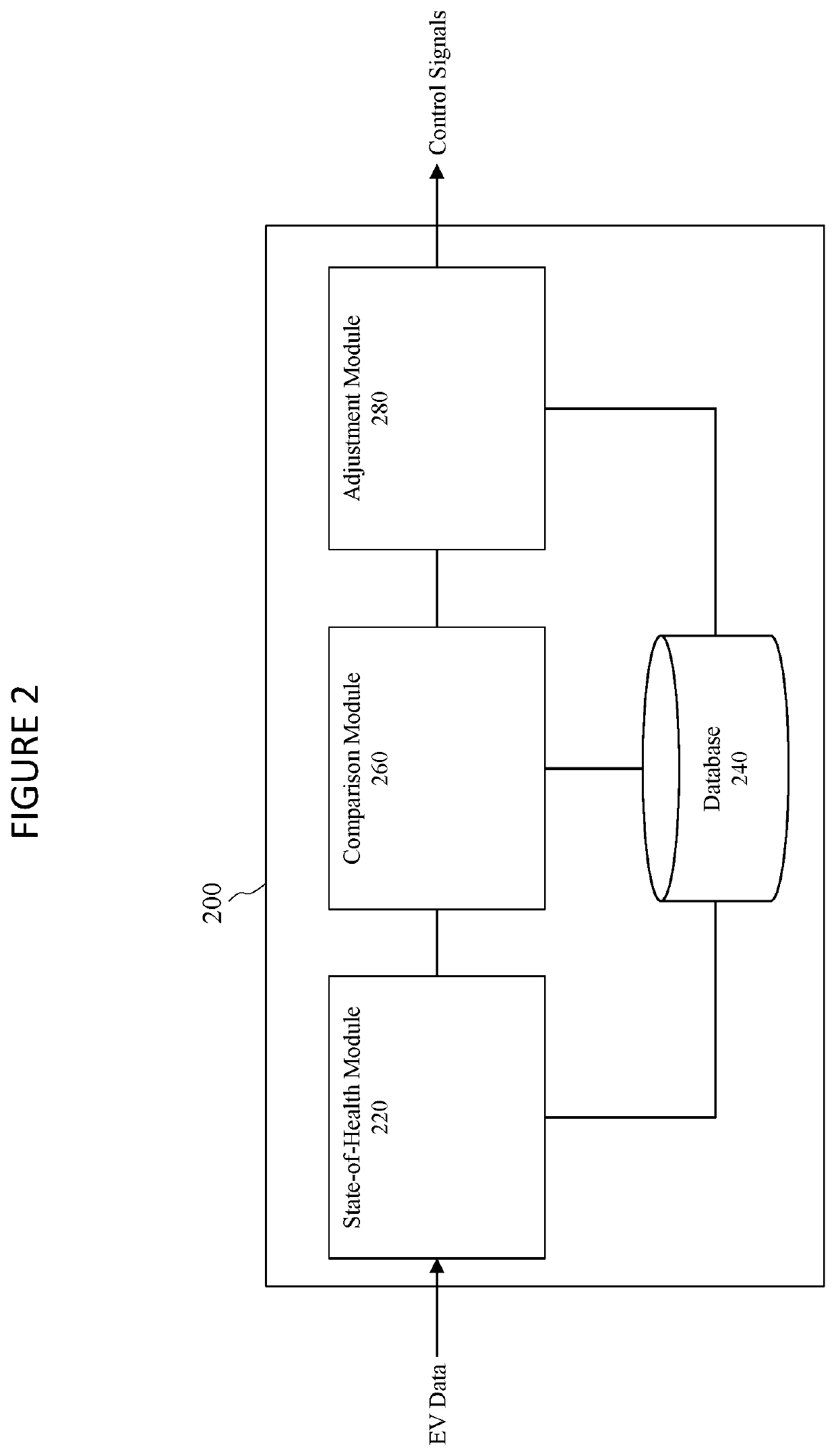

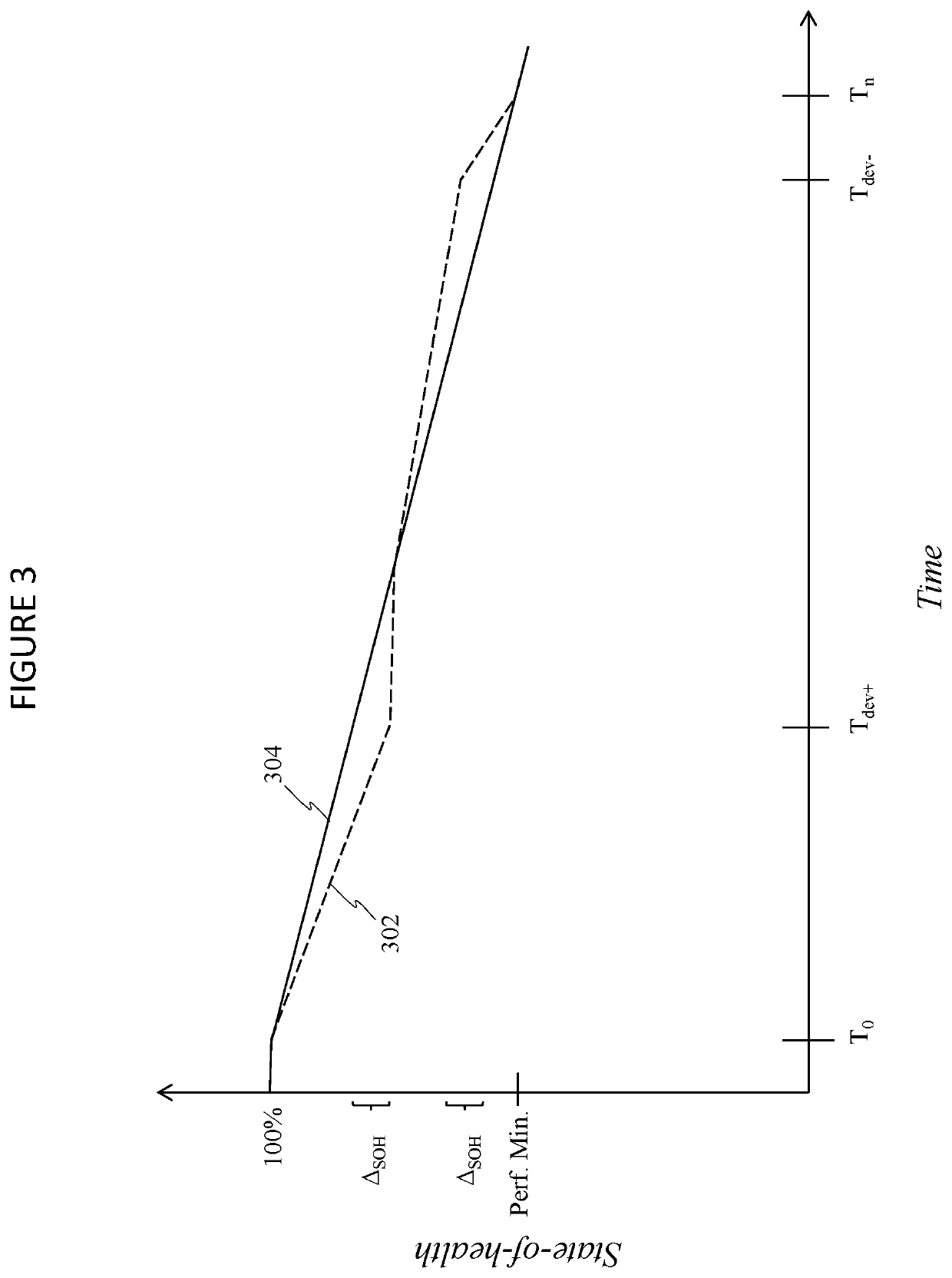

Systems and method for EV battery second-life management

PatentActiveUS10752128B1

Innovation

- A system and method for managing the state-of-health of EV batteries by determining individual deviance values from a reference state and controlling vehicle-to-grid operations to ensure all batteries have similar states-of-health, forming a stationary second-life unit for bi-directional power exchange with the grid.

Energy Efficiency Gains Through Neuromorphic Integration

The integration of neuromorphic computing into electric vehicle battery management systems represents a significant leap forward in energy efficiency optimization. Traditional battery management systems rely on conventional computing architectures that process data sequentially, consuming substantial power even during relatively simple monitoring tasks. Neuromorphic chips, with their brain-inspired architecture, fundamentally transform this paradigm by processing information in parallel and operating on an event-driven basis.

When implemented in EV battery systems, neuromorphic processors can reduce power consumption by up to 95% compared to conventional microcontrollers performing the same battery management functions. This dramatic efficiency gain stems from the chip's ability to activate only the necessary neural pathways when responding to specific battery events, rather than continuously running full computational cycles.

The energy savings manifest in multiple dimensions across the EV ecosystem. At the most immediate level, the reduced power draw from the battery management system itself extends the vehicle's range by preserving more energy for propulsion. Studies indicate that advanced neuromorphic implementations can contribute to a 3-7% improvement in overall vehicle range without any modifications to the battery chemistry or capacity.

Furthermore, neuromorphic systems excel at thermal management optimization through real-time adaptive control. By continuously analyzing thousands of data points across the battery pack and responding instantaneously to thermal variations, these systems maintain optimal operating temperatures with minimal energy expenditure. This capability is particularly valuable during fast-charging scenarios, where conventional systems often require energy-intensive cooling mechanisms.

The efficiency advantages extend beyond operational power consumption to data processing efficiency. Neuromorphic architectures can process the complex, multivariate data streams from battery sensors using significantly less computational overhead. This enables more sophisticated battery health monitoring and predictive maintenance algorithms to run continuously without imposing a heavy energy penalty.

Perhaps most promising is the neuromorphic system's ability to learn and adapt to individual driver behaviors and usage patterns over time. This adaptive intelligence allows for increasingly precise energy management tailored to specific driving conditions, routes, and habits. As the system accumulates experience, it progressively optimizes charging cycles, discharge patterns, and power distribution, creating a virtuous cycle of efficiency improvements that conventional fixed-algorithm systems cannot match.

When implemented in EV battery systems, neuromorphic processors can reduce power consumption by up to 95% compared to conventional microcontrollers performing the same battery management functions. This dramatic efficiency gain stems from the chip's ability to activate only the necessary neural pathways when responding to specific battery events, rather than continuously running full computational cycles.

The energy savings manifest in multiple dimensions across the EV ecosystem. At the most immediate level, the reduced power draw from the battery management system itself extends the vehicle's range by preserving more energy for propulsion. Studies indicate that advanced neuromorphic implementations can contribute to a 3-7% improvement in overall vehicle range without any modifications to the battery chemistry or capacity.

Furthermore, neuromorphic systems excel at thermal management optimization through real-time adaptive control. By continuously analyzing thousands of data points across the battery pack and responding instantaneously to thermal variations, these systems maintain optimal operating temperatures with minimal energy expenditure. This capability is particularly valuable during fast-charging scenarios, where conventional systems often require energy-intensive cooling mechanisms.

The efficiency advantages extend beyond operational power consumption to data processing efficiency. Neuromorphic architectures can process the complex, multivariate data streams from battery sensors using significantly less computational overhead. This enables more sophisticated battery health monitoring and predictive maintenance algorithms to run continuously without imposing a heavy energy penalty.

Perhaps most promising is the neuromorphic system's ability to learn and adapt to individual driver behaviors and usage patterns over time. This adaptive intelligence allows for increasingly precise energy management tailored to specific driving conditions, routes, and habits. As the system accumulates experience, it progressively optimizes charging cycles, discharge patterns, and power distribution, creating a virtuous cycle of efficiency improvements that conventional fixed-algorithm systems cannot match.

Sustainability Impact of Neuromorphic Battery Systems

The integration of neuromorphic computing into electric vehicle battery management systems represents a significant advancement in sustainable transportation technology. These brain-inspired chips dramatically reduce energy consumption compared to traditional computing architectures, with some implementations demonstrating up to 1000 times greater energy efficiency. This substantial reduction in computational power requirements directly translates to extended EV range and reduced environmental impact across the vehicle lifecycle.

Neuromorphic systems enable more precise battery health monitoring and predictive maintenance, significantly extending battery lifespan by an estimated 15-30% according to recent industry studies. This extension reduces the frequency of battery replacements and consequently decreases the environmental burden associated with battery manufacturing and disposal. The reduced material throughput represents a substantial contribution to circular economy principles in the automotive sector.

The manufacturing process for neuromorphic chips also demonstrates improved sustainability metrics compared to conventional semiconductor production. Research indicates up to 40% reduction in water usage and 25% lower energy consumption during fabrication. These efficiency gains are particularly significant considering the intensive resource requirements of traditional semiconductor manufacturing processes.

From a lifecycle perspective, neuromorphic battery management systems contribute to sustainability through optimized charging protocols that minimize grid impact during peak demand periods. This capability enables better integration with renewable energy sources and supports grid stability as EV adoption increases. The intelligent load balancing facilitated by these systems can reduce carbon emissions associated with electricity generation by an estimated 5-10% per vehicle.

The recyclability of battery systems is also enhanced through neuromorphic computing's ability to maintain detailed battery component health records. This data-driven approach enables more efficient end-of-life processing and material recovery, with potential recovery rate improvements of up to 20% for critical materials like lithium, cobalt, and nickel. The resulting reduction in virgin material requirements further strengthens the sustainability case for neuromorphic battery systems.

As climate regulations tighten globally, the carbon footprint advantages of neuromorphic battery systems position them as a strategic technology for automotive manufacturers seeking compliance with increasingly stringent emissions standards. The cumulative environmental benefits across energy consumption, material efficiency, and lifecycle optimization establish neuromorphic computing as a cornerstone technology for sustainable transportation infrastructure.

Neuromorphic systems enable more precise battery health monitoring and predictive maintenance, significantly extending battery lifespan by an estimated 15-30% according to recent industry studies. This extension reduces the frequency of battery replacements and consequently decreases the environmental burden associated with battery manufacturing and disposal. The reduced material throughput represents a substantial contribution to circular economy principles in the automotive sector.

The manufacturing process for neuromorphic chips also demonstrates improved sustainability metrics compared to conventional semiconductor production. Research indicates up to 40% reduction in water usage and 25% lower energy consumption during fabrication. These efficiency gains are particularly significant considering the intensive resource requirements of traditional semiconductor manufacturing processes.

From a lifecycle perspective, neuromorphic battery management systems contribute to sustainability through optimized charging protocols that minimize grid impact during peak demand periods. This capability enables better integration with renewable energy sources and supports grid stability as EV adoption increases. The intelligent load balancing facilitated by these systems can reduce carbon emissions associated with electricity generation by an estimated 5-10% per vehicle.

The recyclability of battery systems is also enhanced through neuromorphic computing's ability to maintain detailed battery component health records. This data-driven approach enables more efficient end-of-life processing and material recovery, with potential recovery rate improvements of up to 20% for critical materials like lithium, cobalt, and nickel. The resulting reduction in virgin material requirements further strengthens the sustainability case for neuromorphic battery systems.

As climate regulations tighten globally, the carbon footprint advantages of neuromorphic battery systems position them as a strategic technology for automotive manufacturers seeking compliance with increasingly stringent emissions standards. The cumulative environmental benefits across energy consumption, material efficiency, and lifecycle optimization establish neuromorphic computing as a cornerstone technology for sustainable transportation infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!