Activated Carbon Adsorption: GAC Vs PAC, Contactors And Residual Management

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Activated Carbon Technology Evolution and Objectives

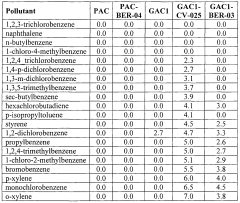

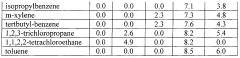

Activated carbon adsorption technology has evolved significantly since its initial applications in water treatment during the early 20th century. The fundamental principle of utilizing carbon's porous structure to capture contaminants through adsorption has remained consistent, while the implementation methods and efficiency have dramatically improved. Initially, activated carbon was primarily used for taste and odor control in drinking water, but its applications have expanded to address a wide range of organic contaminants, including volatile organic compounds (VOCs), pesticides, industrial chemicals, and emerging contaminants such as pharmaceuticals and personal care products.

The evolution of activated carbon technology has been marked by several key developments. In the 1960s and 1970s, granular activated carbon (GAC) systems became more widespread in municipal water treatment. The 1980s saw significant advancements in powdered activated carbon (PAC) applications, particularly for addressing seasonal taste and odor issues. By the 1990s, activated carbon had become an essential component in multi-barrier treatment approaches for drinking water.

Recent technological advancements have focused on enhancing the performance characteristics of activated carbon materials. This includes developing carbons with specialized pore size distributions to target specific contaminants, improving regeneration techniques to extend carbon life, and creating novel contactors that maximize adsorption efficiency while minimizing operational costs. The development of biological activated carbon (BAC) processes has also emerged as a significant innovation, combining adsorption with biological degradation mechanisms.

The primary objectives of current activated carbon technology research and development center around several key areas. First is improving adsorption capacity and selectivity for emerging contaminants, particularly per- and polyfluoroalkyl substances (PFAS), which have become a major public health concern. Second is enhancing the sustainability of activated carbon production and use, including developing more environmentally friendly activation processes and improving regeneration efficiency.

Another critical objective is optimizing the integration of activated carbon systems within comprehensive water treatment trains, particularly in addressing the comparative advantages of GAC versus PAC in different scenarios. Additionally, there is significant focus on developing more efficient contactor designs that maximize treatment effectiveness while minimizing energy consumption and carbon usage.

The technology also aims to address challenges in spent carbon management, including more effective regeneration techniques and environmentally responsible disposal methods. As regulatory standards for water quality become increasingly stringent worldwide, activated carbon technology continues to evolve to meet these demands while maintaining cost-effectiveness and operational simplicity.

The evolution of activated carbon technology has been marked by several key developments. In the 1960s and 1970s, granular activated carbon (GAC) systems became more widespread in municipal water treatment. The 1980s saw significant advancements in powdered activated carbon (PAC) applications, particularly for addressing seasonal taste and odor issues. By the 1990s, activated carbon had become an essential component in multi-barrier treatment approaches for drinking water.

Recent technological advancements have focused on enhancing the performance characteristics of activated carbon materials. This includes developing carbons with specialized pore size distributions to target specific contaminants, improving regeneration techniques to extend carbon life, and creating novel contactors that maximize adsorption efficiency while minimizing operational costs. The development of biological activated carbon (BAC) processes has also emerged as a significant innovation, combining adsorption with biological degradation mechanisms.

The primary objectives of current activated carbon technology research and development center around several key areas. First is improving adsorption capacity and selectivity for emerging contaminants, particularly per- and polyfluoroalkyl substances (PFAS), which have become a major public health concern. Second is enhancing the sustainability of activated carbon production and use, including developing more environmentally friendly activation processes and improving regeneration efficiency.

Another critical objective is optimizing the integration of activated carbon systems within comprehensive water treatment trains, particularly in addressing the comparative advantages of GAC versus PAC in different scenarios. Additionally, there is significant focus on developing more efficient contactor designs that maximize treatment effectiveness while minimizing energy consumption and carbon usage.

The technology also aims to address challenges in spent carbon management, including more effective regeneration techniques and environmentally responsible disposal methods. As regulatory standards for water quality become increasingly stringent worldwide, activated carbon technology continues to evolve to meet these demands while maintaining cost-effectiveness and operational simplicity.

Market Analysis for Carbon Adsorption Applications

The global activated carbon market has demonstrated robust growth, valued at approximately $3.4 billion in 2022 and projected to reach $5.8 billion by 2028, with a compound annual growth rate of 9.3%. This growth is primarily driven by increasing water and air purification demands across industrial, municipal, and residential sectors.

Water treatment applications represent the largest market segment, accounting for nearly 45% of total activated carbon consumption. Within this segment, municipal drinking water treatment dominates, followed by wastewater treatment and industrial process water applications. The stringent regulations regarding water quality standards, particularly in North America and Europe, have significantly boosted the demand for both Granular Activated Carbon (GAC) and Powdered Activated Carbon (PAC) systems.

Air purification applications constitute approximately 30% of the market, with industrial emission control and indoor air quality improvement being the primary drivers. The remaining market share is distributed among food and beverage processing, pharmaceutical manufacturing, and specialty applications such as gold recovery and catalyst support.

Regionally, North America leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate at 11.2% annually, primarily due to rapid industrialization in China and India, coupled with increasingly stringent environmental regulations.

The GAC segment currently dominates the market, representing approximately 60% of total activated carbon sales. This dominance is attributed to GAC's reusability, lower operational costs over time, and suitability for continuous flow systems. However, the PAC segment is growing at a faster rate due to its lower initial capital investment requirements and flexibility in application.

Market dynamics are significantly influenced by raw material availability and pricing. Coal-based activated carbon remains the most common (65% of production), though coconut shell-based products are gaining market share due to their superior hardness and micropore structure, particularly valuable for certain contaminant removal applications.

The competitive landscape features both global corporations and regional specialists. Major players include Calgon Carbon Corporation (Kuraray), Cabot Corporation, Jacobi Carbons, and Haycarb PLC, collectively controlling approximately 45% of the global market. These companies are increasingly focusing on product differentiation through enhanced adsorption capacities, specialized contactor designs, and improved regeneration technologies to maintain competitive advantages.

Water treatment applications represent the largest market segment, accounting for nearly 45% of total activated carbon consumption. Within this segment, municipal drinking water treatment dominates, followed by wastewater treatment and industrial process water applications. The stringent regulations regarding water quality standards, particularly in North America and Europe, have significantly boosted the demand for both Granular Activated Carbon (GAC) and Powdered Activated Carbon (PAC) systems.

Air purification applications constitute approximately 30% of the market, with industrial emission control and indoor air quality improvement being the primary drivers. The remaining market share is distributed among food and beverage processing, pharmaceutical manufacturing, and specialty applications such as gold recovery and catalyst support.

Regionally, North America leads the market with approximately 35% share, followed by Europe (28%) and Asia-Pacific (25%). However, the Asia-Pacific region is experiencing the fastest growth rate at 11.2% annually, primarily due to rapid industrialization in China and India, coupled with increasingly stringent environmental regulations.

The GAC segment currently dominates the market, representing approximately 60% of total activated carbon sales. This dominance is attributed to GAC's reusability, lower operational costs over time, and suitability for continuous flow systems. However, the PAC segment is growing at a faster rate due to its lower initial capital investment requirements and flexibility in application.

Market dynamics are significantly influenced by raw material availability and pricing. Coal-based activated carbon remains the most common (65% of production), though coconut shell-based products are gaining market share due to their superior hardness and micropore structure, particularly valuable for certain contaminant removal applications.

The competitive landscape features both global corporations and regional specialists. Major players include Calgon Carbon Corporation (Kuraray), Cabot Corporation, Jacobi Carbons, and Haycarb PLC, collectively controlling approximately 45% of the global market. These companies are increasingly focusing on product differentiation through enhanced adsorption capacities, specialized contactor designs, and improved regeneration technologies to maintain competitive advantages.

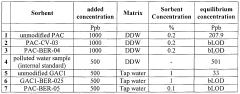

GAC vs PAC: Technical Comparison and Challenges

Granular Activated Carbon (GAC) and Powdered Activated Carbon (PAC) represent the two primary forms of activated carbon used in water treatment processes. GAC consists of irregularly shaped particles with sizes ranging from 0.2 to 5 mm, while PAC particles are significantly smaller, typically less than 0.18 mm in diameter. This fundamental difference in particle size leads to distinct performance characteristics and application scenarios.

GAC systems typically operate as fixed-bed adsorbers where water flows through a stationary bed of carbon granules. This configuration allows for longer contact times, resulting in more effective removal of organic compounds, particularly those with lower molecular weights. GAC systems demonstrate superior performance in removing taste and odor compounds, synthetic organic chemicals, and disinfection byproducts. Additionally, GAC beds can serve as biological filters when operated continuously, enhancing removal efficiency through biological degradation mechanisms.

In contrast, PAC is directly added to water as a slurry and requires subsequent separation through sedimentation or filtration processes. PAC offers advantages in terms of dosing flexibility, allowing treatment facilities to adjust carbon doses in response to fluctuating contaminant levels or seasonal water quality changes. This adaptability makes PAC particularly valuable for addressing periodic taste and odor events or managing intermittent contaminant spikes.

The economic considerations between these technologies present complex tradeoffs. GAC systems require significant initial capital investment for contactors and supporting infrastructure but offer lower operational costs over time. PAC systems feature minimal capital requirements but incur higher ongoing operational expenses due to continuous carbon consumption and the need for precise dosing equipment.

Technical challenges for GAC systems include bed fouling, channeling, and the need for periodic regeneration or replacement. Backwashing requirements and head loss management also present operational complexities. GAC contactors must be carefully designed to ensure proper flow distribution and minimize short-circuiting that could reduce treatment efficiency.

PAC systems face different challenges, primarily related to achieving adequate mixing and contact time. The fine carbon particles can cause downstream operational issues including membrane fouling in filtration systems, increased sludge production, and potential interference with disinfection processes. Precise dosing control represents another significant challenge, as underdosing reduces treatment efficacy while overdosing increases operational costs unnecessarily.

Both technologies present distinct residual management challenges. Spent GAC requires periodic removal and either regeneration or disposal, with thermal regeneration being energy-intensive and potentially creating air quality concerns. PAC residuals become incorporated into water treatment sludge, potentially complicating sludge management and disposal options due to adsorbed contaminants.

GAC systems typically operate as fixed-bed adsorbers where water flows through a stationary bed of carbon granules. This configuration allows for longer contact times, resulting in more effective removal of organic compounds, particularly those with lower molecular weights. GAC systems demonstrate superior performance in removing taste and odor compounds, synthetic organic chemicals, and disinfection byproducts. Additionally, GAC beds can serve as biological filters when operated continuously, enhancing removal efficiency through biological degradation mechanisms.

In contrast, PAC is directly added to water as a slurry and requires subsequent separation through sedimentation or filtration processes. PAC offers advantages in terms of dosing flexibility, allowing treatment facilities to adjust carbon doses in response to fluctuating contaminant levels or seasonal water quality changes. This adaptability makes PAC particularly valuable for addressing periodic taste and odor events or managing intermittent contaminant spikes.

The economic considerations between these technologies present complex tradeoffs. GAC systems require significant initial capital investment for contactors and supporting infrastructure but offer lower operational costs over time. PAC systems feature minimal capital requirements but incur higher ongoing operational expenses due to continuous carbon consumption and the need for precise dosing equipment.

Technical challenges for GAC systems include bed fouling, channeling, and the need for periodic regeneration or replacement. Backwashing requirements and head loss management also present operational complexities. GAC contactors must be carefully designed to ensure proper flow distribution and minimize short-circuiting that could reduce treatment efficiency.

PAC systems face different challenges, primarily related to achieving adequate mixing and contact time. The fine carbon particles can cause downstream operational issues including membrane fouling in filtration systems, increased sludge production, and potential interference with disinfection processes. Precise dosing control represents another significant challenge, as underdosing reduces treatment efficacy while overdosing increases operational costs unnecessarily.

Both technologies present distinct residual management challenges. Spent GAC requires periodic removal and either regeneration or disposal, with thermal regeneration being energy-intensive and potentially creating air quality concerns. PAC residuals become incorporated into water treatment sludge, potentially complicating sludge management and disposal options due to adsorbed contaminants.

Contactor Design Solutions and Implementation Strategies

01 Factors affecting GAC and PAC adsorption efficiency

Various factors influence the adsorption efficiency of Granular Activated Carbon (GAC) and Powdered Activated Carbon (PAC) systems. These include contact time, carbon particle size, pH levels, temperature, and initial contaminant concentration. Optimizing these parameters can significantly enhance the adsorption capacity and removal efficiency of target pollutants. The surface area and pore structure of activated carbon also play crucial roles in determining adsorption performance.- Factors affecting GAC and PAC adsorption efficiency: Various factors influence the adsorption efficiency of Granular Activated Carbon (GAC) and Powdered Activated Carbon (PAC). These include particle size, contact time, pH level, temperature, and initial contaminant concentration. Smaller particle sizes generally provide greater surface area for adsorption, while longer contact times allow for more complete adsorption. The pH of the solution can affect the charge of both the adsorbent and adsorbate, impacting adsorption efficiency. Temperature changes can alter adsorption kinetics, with most adsorption processes being exothermic in nature.

- Modification techniques to enhance adsorption capacity: Various modification techniques can be applied to activated carbon to enhance its adsorption efficiency. These include chemical activation using acids, bases, or salts; physical activation through steam or CO2 treatment; and impregnation with metal ions or nanoparticles. Surface functionalization can introduce specific functional groups that target particular contaminants. Heat treatment can also alter pore structure and surface chemistry, potentially increasing adsorption capacity for specific pollutants. These modifications can significantly improve the performance of both GAC and PAC in water and air purification applications.

- Comparative performance of GAC versus PAC: Granular Activated Carbon (GAC) and Powdered Activated Carbon (PAC) exhibit different adsorption efficiencies based on their physical characteristics and application methods. PAC typically offers higher adsorption rates due to its smaller particle size and larger surface area, making it more efficient for rapid removal of contaminants. However, GAC provides advantages in fixed-bed applications with longer service life and easier separation from treated media. PAC is generally more effective for short-term or emergency treatment scenarios, while GAC is preferred for continuous flow systems. The choice between GAC and PAC depends on specific treatment objectives, system design, and economic considerations.

- Regeneration methods to restore adsorption efficiency: Activated carbon regeneration methods are crucial for restoring adsorption efficiency and extending the useful life of the adsorbent. Thermal regeneration involves heating spent carbon to high temperatures (800-1000°C) to desorb and decompose adsorbed contaminants. Chemical regeneration uses solvents, acids, bases, or oxidizing agents to extract or destroy adsorbed compounds. Biological regeneration employs microorganisms to degrade organic contaminants on the carbon surface. Steam regeneration can effectively remove volatile organic compounds. Each method offers different advantages in terms of carbon recovery rate, energy consumption, and environmental impact, with the optimal choice depending on the specific application and contaminant type.

- Novel system designs for optimizing adsorption efficiency: Innovative system designs can significantly enhance the adsorption efficiency of activated carbon treatments. Multi-stage adsorption systems allow for more complete contaminant removal by providing sequential treatment steps. Fluidized bed reactors improve contact between adsorbent and contaminants by maintaining carbon particles in suspension. Hybrid systems combining activated carbon with other treatment technologies (such as membrane filtration, advanced oxidation, or biological treatment) can address a broader range of contaminants. Pulse flow systems optimize contact time and reduce channeling effects. Automated monitoring and control systems adjust operational parameters in real-time to maintain optimal adsorption conditions despite variations in influent quality.

02 Modified activated carbon for enhanced adsorption

Chemical and physical modifications of activated carbon can improve its adsorption efficiency. Techniques include acid/base treatment, metal impregnation, and surface functionalization to create specific binding sites for target contaminants. These modifications can enhance selectivity and capacity for particular pollutants such as heavy metals, organic compounds, or specific industrial contaminants. Modified activated carbons demonstrate superior performance compared to conventional activated carbon in many applications.Expand Specific Solutions03 Regeneration and reuse of activated carbon

Methods for regenerating spent activated carbon to restore its adsorption efficiency include thermal regeneration, chemical regeneration, biological regeneration, and electrochemical processes. These techniques remove adsorbed contaminants and restore active sites, extending the carbon's useful life and improving cost-effectiveness. Regeneration processes must be optimized to minimize carbon loss while maximizing restoration of adsorption capacity.Expand Specific Solutions04 Advanced activated carbon adsorption systems

Innovative system designs improve the efficiency of activated carbon adsorption processes. These include multi-stage filtration systems, fluidized bed reactors, fixed-bed columns with optimized flow patterns, and hybrid systems combining activated carbon with other treatment technologies. Advanced monitoring and control systems help maintain optimal operating conditions, while novel reactor configurations enhance mass transfer and reduce energy consumption.Expand Specific Solutions05 Application-specific activated carbon formulations

Specialized activated carbon formulations are developed for specific applications such as drinking water treatment, wastewater purification, air pollution control, and industrial process streams. These formulations are tailored with specific surface characteristics, pore size distributions, and functional groups to target particular contaminants. The source material (coconut shell, coal, wood, etc.) and activation process are selected based on the intended application to maximize adsorption efficiency for specific pollutants.Expand Specific Solutions

Leading Manufacturers and Industry Landscape

The activated carbon adsorption market is in a growth phase, with increasing demand driven by stringent water quality regulations and rising environmental concerns. The market is segmented between Granular Activated Carbon (GAC) and Powdered Activated Carbon (PAC) technologies, with GAC systems gaining preference for their reusability and efficiency. Key industry players include established water treatment specialists like Evoqua Water Technologies and Aqua-Aerobic Systems, alongside innovative companies such as ToxSorb and Cyclopure developing proprietary adsorption technologies. Academic institutions including Nanyang Technological University and California Institute of Technology are advancing research in contactor design and residual management. The technology is reaching maturity in conventional applications, while innovations in carbon materials, regeneration methods, and PFAS removal represent emerging growth opportunities.

Evoqua Water Technologies LLC

Technical Solution: Evoqua Water Technologies has developed comprehensive activated carbon adsorption solutions featuring both Granular Activated Carbon (GAC) and Powdered Activated Carbon (PAC) technologies. Their GAC systems utilize advanced contactor designs including fixed-bed, moving bed, and fluidized bed configurations that optimize contact time and adsorption efficiency[1]. For municipal water treatment, Evoqua's SORB™ series offers modular pressure vessels with specialized media distribution systems ensuring uniform flow and minimizing channeling effects. Their proprietary reactivation facilities allow for sustainable carbon management, processing spent GAC to restore adsorption capacity while reducing waste disposal costs by approximately 30%[3]. For PAC applications, Evoqua has engineered automated dosing systems with real-time monitoring capabilities that adjust carbon addition rates based on influent contaminant concentrations, achieving up to 25% reduction in carbon usage compared to conventional systems.

Strengths: Industry-leading carbon reactivation infrastructure providing closed-loop sustainability; proprietary contactor designs with optimized hydraulics for maximum utilization of carbon capacity; comprehensive service network for carbon exchange and residuals management. Weaknesses: Higher capital costs compared to basic treatment systems; reactivation process may not be suitable for all contaminant types, particularly those containing heavy metals or certain persistent organic pollutants.

The Water & Carbon Group Pty Ltd.

Technical Solution: The Water & Carbon Group has pioneered integrated activated carbon solutions specifically designed for decentralized water treatment applications. Their technology combines biological treatment with activated carbon adsorption in what they term "Bio-Activated Carbon" systems. These systems utilize specialized GAC contactors with controlled hydraulic retention times that promote both biological degradation and physical adsorption mechanisms[2]. Their patented ACTIFLOW™ technology incorporates upflow GAC contactors with optimized backwashing protocols that extend carbon life by up to 40% compared to conventional downflow systems. For PAC applications, they've developed the CARBONDOSE™ system featuring precision slurry preparation and injection with advanced mixing technology that achieves uniform distribution throughout treatment tanks. Their residuals management approach includes innovative dewatering techniques for spent PAC and regeneration partnerships that reduce disposal volumes by approximately 75%[4]. The company has also developed specialized carbon blends tailored for specific contaminant profiles in various water matrices.

Strengths: Specialized expertise in decentralized and small-scale applications; innovative hybrid biological-physical treatment approach extending carbon life; custom-engineered solutions for specific water quality challenges. Weaknesses: More limited global presence compared to larger competitors; regeneration capabilities dependent on third-party partnerships in some regions; systems may require more operator attention than fully automated large-scale installations.

Breakthrough Patents in Activated Carbon Adsorption

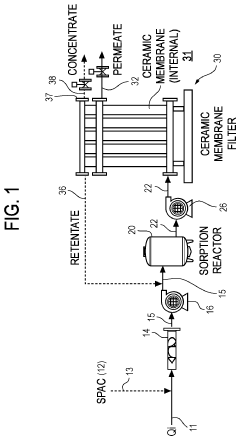

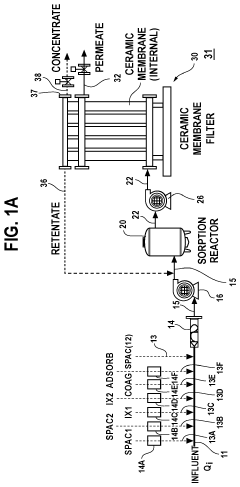

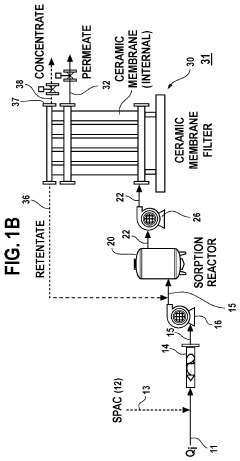

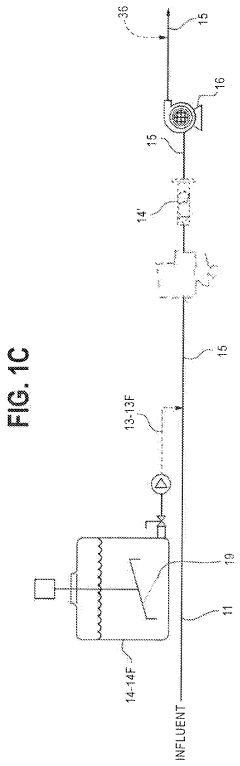

System and method for removal of multiple recalcitrant organic compounds from water

PatentPendingUS20240051847A1

Innovation

- The use of sub-micron powdered activated carbon (SPAC) in conjunction with ceramic membrane filtration and multiple adsorbents within a single reactor, allowing for enhanced adsorption and concentration of PFAS and other recalcitrant organic compounds, along with coagulants, to improve removal efficiency and reduce disposal burdens.

Modified activated carbon as adsorbent for anionic and cationic inorganic pollutants

PatentWO2009053972A1

Innovation

- Modified activated carbon sorbents, treated with cationic or anionic modifiers such as organic dyes or chelating agents, enhance the adsorption capacity for inorganic pollutants like chromate, arsenate, and heavy metals, while maintaining organic pollutant removal capabilities, and can be regenerated for extended use.

Environmental Impact and Sustainability Considerations

The environmental footprint of activated carbon adsorption systems represents a critical consideration in their implementation. Both Granular Activated Carbon (GAC) and Powdered Activated Carbon (PAC) systems generate distinct environmental impacts throughout their lifecycle, from raw material sourcing to disposal.

The production of activated carbon requires significant energy inputs, particularly during the activation process which typically involves temperatures exceeding 800°C. GAC production generally consumes between 5-10 kWh per kilogram, while PAC may require slightly less energy due to the reduced particle size. This energy consumption translates directly to carbon emissions, with approximately 2-4 kg CO2 equivalent per kilogram of activated carbon produced, depending on the energy source utilized.

Raw material sourcing presents another environmental dimension. Sustainable sources such as coconut shells, wood, or agricultural waste offer renewable alternatives to coal-based carbons. Life cycle assessments indicate that biobased activated carbons can reduce environmental impact by 30-45% compared to mineral-based counterparts, primarily through reduced mining impacts and partial carbon sequestration.

Water consumption during manufacturing and regeneration processes represents a significant environmental concern. GAC regeneration facilities typically consume 3-5 cubic meters of water per ton of carbon processed, while also generating wastewater containing trace contaminants that require additional treatment before discharge.

The management of spent activated carbon presents particular challenges. While GAC offers the advantage of regeneration, this process itself consumes substantial energy and produces emissions. Thermal regeneration of GAC typically recovers 70-90% of adsorption capacity but generates approximately 1.5-2.5 kg CO2 equivalent per kilogram regenerated. PAC, being generally non-regenerable, creates greater solid waste challenges, though innovative applications in cement manufacturing and soil remediation are emerging as disposal alternatives.

Transportation impacts vary significantly between GAC and PAC systems. GAC's longer service life reduces replacement frequency and associated transportation emissions, while PAC's lower bulk density may increase the carbon footprint of its distribution. Regional sourcing can reduce these impacts by up to 40% compared to international supply chains.

Recent innovations in sustainable activated carbon technologies include development of lower-temperature activation processes, increased use of renewable energy in production, and enhanced regeneration techniques that preserve carbon structure while reducing energy requirements. These advances are gradually improving the overall sustainability profile of activated carbon adsorption systems across various applications.

The production of activated carbon requires significant energy inputs, particularly during the activation process which typically involves temperatures exceeding 800°C. GAC production generally consumes between 5-10 kWh per kilogram, while PAC may require slightly less energy due to the reduced particle size. This energy consumption translates directly to carbon emissions, with approximately 2-4 kg CO2 equivalent per kilogram of activated carbon produced, depending on the energy source utilized.

Raw material sourcing presents another environmental dimension. Sustainable sources such as coconut shells, wood, or agricultural waste offer renewable alternatives to coal-based carbons. Life cycle assessments indicate that biobased activated carbons can reduce environmental impact by 30-45% compared to mineral-based counterparts, primarily through reduced mining impacts and partial carbon sequestration.

Water consumption during manufacturing and regeneration processes represents a significant environmental concern. GAC regeneration facilities typically consume 3-5 cubic meters of water per ton of carbon processed, while also generating wastewater containing trace contaminants that require additional treatment before discharge.

The management of spent activated carbon presents particular challenges. While GAC offers the advantage of regeneration, this process itself consumes substantial energy and produces emissions. Thermal regeneration of GAC typically recovers 70-90% of adsorption capacity but generates approximately 1.5-2.5 kg CO2 equivalent per kilogram regenerated. PAC, being generally non-regenerable, creates greater solid waste challenges, though innovative applications in cement manufacturing and soil remediation are emerging as disposal alternatives.

Transportation impacts vary significantly between GAC and PAC systems. GAC's longer service life reduces replacement frequency and associated transportation emissions, while PAC's lower bulk density may increase the carbon footprint of its distribution. Regional sourcing can reduce these impacts by up to 40% compared to international supply chains.

Recent innovations in sustainable activated carbon technologies include development of lower-temperature activation processes, increased use of renewable energy in production, and enhanced regeneration techniques that preserve carbon structure while reducing energy requirements. These advances are gradually improving the overall sustainability profile of activated carbon adsorption systems across various applications.

Regulatory Framework for Water Treatment Technologies

The regulatory landscape governing activated carbon adsorption technologies in water treatment is complex and multifaceted, spanning federal, state, and local jurisdictions. At the federal level, the U.S. Environmental Protection Agency (EPA) establishes baseline standards through the Safe Drinking Water Act (SDWA) and the Clean Water Act (CWA), which directly impact the implementation of both Granular Activated Carbon (GAC) and Powdered Activated Carbon (PAC) systems.

The EPA's National Primary Drinking Water Regulations (NPDWRs) set enforceable Maximum Contaminant Levels (MCLs) for various organic compounds, many of which are specifically targeted by activated carbon treatment. These regulations have increasingly recognized GAC as a Best Available Technology (BAT) for removing synthetic organic chemicals, disinfection byproducts, and emerging contaminants of concern.

Regulatory frameworks also address operational parameters for carbon contactors, with standards for Empty Bed Contact Time (EBCT), hydraulic loading rates, and breakthrough monitoring. For GAC systems, regulations typically mandate regular performance monitoring through sampling protocols that assess contaminant breakthrough and treatment efficiency. PAC applications face different regulatory considerations, particularly regarding dosing limits and residual management in finished water.

The disposal and management of spent activated carbon falls under the Resource Conservation and Recovery Act (RCRA), with classification requirements based on the adsorbed contaminants. Spent carbon containing certain hazardous substances may require special handling, regeneration protocols, or disposal methods compliant with hazardous waste regulations.

International standards, including those from the World Health Organization (WHO) and the European Union's Drinking Water Directive, provide additional frameworks that influence global best practices. These standards often establish stricter limits for certain contaminants, driving innovation in carbon adsorption technologies and application methodologies.

Recent regulatory trends show increasing focus on per- and polyfluoroalkyl substances (PFAS), with several states implementing their own MCLs ahead of federal action. This regulatory evolution has positioned GAC as a preferred treatment technology, though compliance requirements continue to evolve as scientific understanding advances.

Certification programs such as NSF/ANSI Standards 61 and 53 provide additional regulatory oversight by verifying that activated carbon products meet safety and performance criteria for drinking water applications. These third-party certifications often become de facto requirements for municipal water treatment facilities seeking regulatory approval for new carbon adsorption systems.

The EPA's National Primary Drinking Water Regulations (NPDWRs) set enforceable Maximum Contaminant Levels (MCLs) for various organic compounds, many of which are specifically targeted by activated carbon treatment. These regulations have increasingly recognized GAC as a Best Available Technology (BAT) for removing synthetic organic chemicals, disinfection byproducts, and emerging contaminants of concern.

Regulatory frameworks also address operational parameters for carbon contactors, with standards for Empty Bed Contact Time (EBCT), hydraulic loading rates, and breakthrough monitoring. For GAC systems, regulations typically mandate regular performance monitoring through sampling protocols that assess contaminant breakthrough and treatment efficiency. PAC applications face different regulatory considerations, particularly regarding dosing limits and residual management in finished water.

The disposal and management of spent activated carbon falls under the Resource Conservation and Recovery Act (RCRA), with classification requirements based on the adsorbed contaminants. Spent carbon containing certain hazardous substances may require special handling, regeneration protocols, or disposal methods compliant with hazardous waste regulations.

International standards, including those from the World Health Organization (WHO) and the European Union's Drinking Water Directive, provide additional frameworks that influence global best practices. These standards often establish stricter limits for certain contaminants, driving innovation in carbon adsorption technologies and application methodologies.

Recent regulatory trends show increasing focus on per- and polyfluoroalkyl substances (PFAS), with several states implementing their own MCLs ahead of federal action. This regulatory evolution has positioned GAC as a preferred treatment technology, though compliance requirements continue to evolve as scientific understanding advances.

Certification programs such as NSF/ANSI Standards 61 and 53 provide additional regulatory oversight by verifying that activated carbon products meet safety and performance criteria for drinking water applications. These third-party certifications often become de facto requirements for municipal water treatment facilities seeking regulatory approval for new carbon adsorption systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!