Activated Carbon Adsorption: Particle Strength, Attrition And Hydraulic Performance

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Activated Carbon Adsorption Technology Background and Objectives

Activated carbon adsorption technology has evolved significantly since its initial applications in water treatment during the early 20th century. Originally derived from charcoal, modern activated carbon materials represent a sophisticated class of adsorbents with highly developed internal pore structures and surface areas exceeding 1000 m²/g. This remarkable surface area enables exceptional adsorption capacity for removing contaminants from liquid and gas streams, making it a cornerstone technology in environmental remediation and industrial purification processes.

The historical trajectory of activated carbon technology shows continuous refinement in manufacturing processes, raw material selection, and activation methods. From traditional thermal activation to more recent chemical activation techniques, each advancement has aimed to enhance the material's fundamental properties while maintaining economic viability. The industry has progressively shifted focus from merely increasing surface area to optimizing specific performance characteristics including particle strength, attrition resistance, and hydraulic behavior.

Current technological trends indicate growing emphasis on understanding the mechanical integrity of activated carbon particles under operational conditions. This focus stems from recognition that particle degradation during service significantly impacts system performance, maintenance requirements, and operational costs. The interrelationship between particle strength and hydraulic performance represents a critical frontier in activated carbon research, as these factors directly influence adsorption efficiency, pressure drop characteristics, and overall system reliability.

The global push toward more stringent environmental regulations and sustainable water treatment solutions has accelerated research into optimized activated carbon systems. Particularly in drinking water treatment, wastewater remediation, and industrial process purification, there is increasing demand for activated carbon materials that maintain structural integrity while delivering consistent hydraulic performance under variable operating conditions.

The primary technical objectives in this field now center on developing comprehensive understanding of the factors affecting particle strength and attrition resistance, quantifying the relationship between particle degradation and hydraulic performance, and establishing predictive models for system optimization. These objectives align with broader industry goals of extending media service life, reducing replacement frequency, minimizing operational disruptions, and lowering total treatment costs.

Additionally, researchers aim to establish standardized testing protocols for evaluating activated carbon mechanical properties that correlate meaningfully with real-world performance. This standardization would enable more effective comparison between different carbon products and support evidence-based selection for specific applications. The ultimate goal is to develop activated carbon materials and systems that balance adsorptive capacity, mechanical durability, and hydraulic efficiency across diverse operational scenarios.

The historical trajectory of activated carbon technology shows continuous refinement in manufacturing processes, raw material selection, and activation methods. From traditional thermal activation to more recent chemical activation techniques, each advancement has aimed to enhance the material's fundamental properties while maintaining economic viability. The industry has progressively shifted focus from merely increasing surface area to optimizing specific performance characteristics including particle strength, attrition resistance, and hydraulic behavior.

Current technological trends indicate growing emphasis on understanding the mechanical integrity of activated carbon particles under operational conditions. This focus stems from recognition that particle degradation during service significantly impacts system performance, maintenance requirements, and operational costs. The interrelationship between particle strength and hydraulic performance represents a critical frontier in activated carbon research, as these factors directly influence adsorption efficiency, pressure drop characteristics, and overall system reliability.

The global push toward more stringent environmental regulations and sustainable water treatment solutions has accelerated research into optimized activated carbon systems. Particularly in drinking water treatment, wastewater remediation, and industrial process purification, there is increasing demand for activated carbon materials that maintain structural integrity while delivering consistent hydraulic performance under variable operating conditions.

The primary technical objectives in this field now center on developing comprehensive understanding of the factors affecting particle strength and attrition resistance, quantifying the relationship between particle degradation and hydraulic performance, and establishing predictive models for system optimization. These objectives align with broader industry goals of extending media service life, reducing replacement frequency, minimizing operational disruptions, and lowering total treatment costs.

Additionally, researchers aim to establish standardized testing protocols for evaluating activated carbon mechanical properties that correlate meaningfully with real-world performance. This standardization would enable more effective comparison between different carbon products and support evidence-based selection for specific applications. The ultimate goal is to develop activated carbon materials and systems that balance adsorptive capacity, mechanical durability, and hydraulic efficiency across diverse operational scenarios.

Market Demand Analysis for High-Performance Activated Carbon

The global market for high-performance activated carbon continues to experience robust growth, driven primarily by increasing environmental regulations and growing industrial applications. Current market assessments value the high-performance activated carbon sector at approximately 3.5 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 8.2% through 2030.

Water treatment represents the largest application segment, accounting for nearly 40% of market demand. This is largely attributed to stringent water quality standards implemented across developed and developing nations alike. Municipal water treatment facilities are increasingly adopting advanced activated carbon systems with superior particle strength and reduced attrition rates to minimize maintenance costs and improve operational efficiency.

Air purification applications constitute the second-largest market segment at 25%, with particular growth observed in industrial emission control systems and indoor air quality management. In these applications, the hydraulic performance of activated carbon systems directly impacts energy consumption and overall operational costs, driving demand for optimized products.

The industrial sector demonstrates accelerating demand for specialized activated carbon solutions, particularly in pharmaceutical manufacturing, food and beverage processing, and chemical production. These industries require activated carbon with exceptional particle strength to withstand high-pressure operations while maintaining adsorption efficiency.

Geographically, North America and Europe currently dominate market consumption, collectively representing 55% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate at 10.5% annually, driven by rapid industrialization, urbanization, and increasingly stringent environmental regulations in China, India, and Southeast Asian nations.

Consumer preferences are shifting toward activated carbon products that offer extended service life and reduced replacement frequency. This trend directly correlates with the technical parameters of particle strength and attrition resistance, as these properties significantly impact the operational lifespan of activated carbon installations.

Market research indicates that customers are willing to pay a premium of 15-30% for activated carbon products demonstrating superior hydraulic performance and mechanical durability. This price elasticity reflects the total cost of ownership calculation, where higher initial investment is offset by reduced maintenance requirements and extended replacement intervals.

Emerging applications in energy storage, particularly in supercapacitor technology, are creating new market opportunities for specialized activated carbon with precise pore structure and exceptional mechanical integrity. While currently representing only 5% of the market, this segment is projected to grow at 18% annually through 2030.

Water treatment represents the largest application segment, accounting for nearly 40% of market demand. This is largely attributed to stringent water quality standards implemented across developed and developing nations alike. Municipal water treatment facilities are increasingly adopting advanced activated carbon systems with superior particle strength and reduced attrition rates to minimize maintenance costs and improve operational efficiency.

Air purification applications constitute the second-largest market segment at 25%, with particular growth observed in industrial emission control systems and indoor air quality management. In these applications, the hydraulic performance of activated carbon systems directly impacts energy consumption and overall operational costs, driving demand for optimized products.

The industrial sector demonstrates accelerating demand for specialized activated carbon solutions, particularly in pharmaceutical manufacturing, food and beverage processing, and chemical production. These industries require activated carbon with exceptional particle strength to withstand high-pressure operations while maintaining adsorption efficiency.

Geographically, North America and Europe currently dominate market consumption, collectively representing 55% of global demand. However, the Asia-Pacific region is experiencing the fastest growth rate at 10.5% annually, driven by rapid industrialization, urbanization, and increasingly stringent environmental regulations in China, India, and Southeast Asian nations.

Consumer preferences are shifting toward activated carbon products that offer extended service life and reduced replacement frequency. This trend directly correlates with the technical parameters of particle strength and attrition resistance, as these properties significantly impact the operational lifespan of activated carbon installations.

Market research indicates that customers are willing to pay a premium of 15-30% for activated carbon products demonstrating superior hydraulic performance and mechanical durability. This price elasticity reflects the total cost of ownership calculation, where higher initial investment is offset by reduced maintenance requirements and extended replacement intervals.

Emerging applications in energy storage, particularly in supercapacitor technology, are creating new market opportunities for specialized activated carbon with precise pore structure and exceptional mechanical integrity. While currently representing only 5% of the market, this segment is projected to grow at 18% annually through 2030.

Current Challenges in Particle Strength and Attrition Resistance

Despite significant advancements in activated carbon technology, several persistent challenges remain in the realm of particle strength and attrition resistance that limit optimal performance in industrial applications. The mechanical integrity of activated carbon particles represents a critical concern, as these materials must withstand various physical stresses during handling, transportation, and operational conditions without significant degradation.

One primary challenge is the inherent trade-off between adsorption capacity and mechanical strength. Highly porous activated carbons with extensive surface areas typically demonstrate superior adsorption capabilities but often exhibit compromised structural integrity. This inverse relationship creates a significant engineering dilemma, particularly in applications requiring both high adsorption efficiency and durability.

Manufacturing inconsistencies further complicate the situation, as variations in raw materials and production parameters can lead to unpredictable mechanical properties across different batches. This inconsistency makes quality control challenging and affects the reliability of activated carbon systems in long-term operations.

The attrition resistance of activated carbon particles under hydraulic stress presents another substantial challenge. In fluid-based applications, particularly in fluidized bed systems, the continuous movement and collision of particles result in gradual erosion and fragmentation. This attrition process not only reduces the effective lifespan of the carbon but also generates fine particles that can cause downstream operational problems, including filter clogging and pressure drop increases.

Environmental factors such as temperature fluctuations, chemical exposure, and moisture content significantly impact particle strength. Activated carbon used in water treatment facilities, for instance, must maintain structural integrity despite constant exposure to various contaminants and hydraulic forces. The degradation mechanisms under these complex conditions remain incompletely understood, hindering the development of more resilient materials.

Current testing methodologies for particle strength and attrition resistance lack standardization across the industry. Different manufacturers employ various testing protocols, making direct comparisons between products difficult and creating uncertainty for end-users when selecting appropriate materials for specific applications.

The economic implications of these challenges are substantial. Premature particle breakdown necessitates more frequent replacement of activated carbon media, increasing operational costs and system downtime. Additionally, the environmental footprint expands due to increased waste generation and resource consumption associated with more frequent carbon replacement cycles.

One primary challenge is the inherent trade-off between adsorption capacity and mechanical strength. Highly porous activated carbons with extensive surface areas typically demonstrate superior adsorption capabilities but often exhibit compromised structural integrity. This inverse relationship creates a significant engineering dilemma, particularly in applications requiring both high adsorption efficiency and durability.

Manufacturing inconsistencies further complicate the situation, as variations in raw materials and production parameters can lead to unpredictable mechanical properties across different batches. This inconsistency makes quality control challenging and affects the reliability of activated carbon systems in long-term operations.

The attrition resistance of activated carbon particles under hydraulic stress presents another substantial challenge. In fluid-based applications, particularly in fluidized bed systems, the continuous movement and collision of particles result in gradual erosion and fragmentation. This attrition process not only reduces the effective lifespan of the carbon but also generates fine particles that can cause downstream operational problems, including filter clogging and pressure drop increases.

Environmental factors such as temperature fluctuations, chemical exposure, and moisture content significantly impact particle strength. Activated carbon used in water treatment facilities, for instance, must maintain structural integrity despite constant exposure to various contaminants and hydraulic forces. The degradation mechanisms under these complex conditions remain incompletely understood, hindering the development of more resilient materials.

Current testing methodologies for particle strength and attrition resistance lack standardization across the industry. Different manufacturers employ various testing protocols, making direct comparisons between products difficult and creating uncertainty for end-users when selecting appropriate materials for specific applications.

The economic implications of these challenges are substantial. Premature particle breakdown necessitates more frequent replacement of activated carbon media, increasing operational costs and system downtime. Additionally, the environmental footprint expands due to increased waste generation and resource consumption associated with more frequent carbon replacement cycles.

Current Solutions for Improving Hydraulic Performance

01 Particle strength enhancement methods

Various methods can be employed to enhance the strength of activated carbon particles, reducing breakage during handling and use. These methods include specific binding agents, heat treatment processes, and composite material formulations that improve the mechanical integrity of the particles. Enhanced particle strength leads to longer service life and better performance in filtration systems, as stronger particles resist crushing and degradation under pressure.- Particle strength enhancement methods for activated carbon: Various methods can be employed to enhance the strength of activated carbon particles, reducing breakage during handling and use. These include specific binding agents, controlled carbonization processes, and surface treatments that improve mechanical stability. Enhanced particle strength leads to longer service life and reduced replacement frequency in adsorption systems.

- Attrition resistance improvements in activated carbon: Techniques to improve attrition resistance focus on reducing particle breakdown during fluidization and movement. These include specialized coating technologies, composite structures, and optimized particle morphology. Improved attrition resistance maintains consistent particle size distribution and prevents the formation of fines that could cause pressure drops or escape filtration systems.

- Hydraulic performance optimization in activated carbon systems: Optimizing hydraulic performance involves designing activated carbon systems with appropriate flow distribution, bed configuration, and particle size gradation. This includes considerations for pressure drop, flow uniformity, and contact time. Enhanced hydraulic performance ensures efficient utilization of the adsorption capacity while minimizing energy requirements for fluid movement through the carbon bed.

- Particle size and shape control for balanced performance: Controlling the size and shape of activated carbon particles creates a balance between adsorption efficiency, mechanical strength, and hydraulic properties. Uniform particle size distribution prevents channeling in fixed beds, while optimized shapes can increase surface area without compromising strength. These parameters are critical for applications requiring both high adsorption capacity and good mechanical durability.

- Testing and quality control methods for activated carbon performance: Standardized testing methods are essential for evaluating activated carbon's mechanical strength, attrition resistance, and hydraulic performance. These include ball pan hardness tests, attrition indices measurement, pressure drop analysis, and accelerated wear testing. Quality control procedures ensure consistent performance across batches and help predict service life in various application conditions.

02 Attrition resistance improvements

Techniques to improve attrition resistance of activated carbon focus on surface treatments and structural modifications that minimize particle breakdown during fluid flow. These include specialized coating processes, particle shape optimization, and hardening treatments that reduce friction-based wear. Improved attrition resistance ensures consistent performance in water treatment systems and prevents the release of carbon fines that could contaminate treated water.Expand Specific Solutions03 Hydraulic performance optimization

Optimizing the hydraulic performance of activated carbon systems involves particle size distribution control, bed configuration design, and flow pattern engineering. These factors affect pressure drop, contact time, and adsorption efficiency. Properly designed systems balance the need for sufficient contact time with minimized pressure drop, allowing for efficient contaminant removal while maintaining adequate flow rates through the carbon bed.Expand Specific Solutions04 Manufacturing processes affecting physical properties

The manufacturing processes used to produce activated carbon significantly impact its physical properties including strength, porosity, and hydraulic characteristics. Activation temperature, carbonization time, raw material selection, and post-treatment methods all influence the final product's performance. Controlled manufacturing conditions can yield activated carbon with optimized strength-to-surface area ratios, balancing adsorption capacity with mechanical durability.Expand Specific Solutions05 Testing and quality control methods

Standardized testing and quality control methods are essential for evaluating activated carbon's particle strength, attrition resistance, and hydraulic performance. These include ball pan hardness tests, attrition indices measurement, pressure drop testing, and accelerated wear simulations. Comprehensive quality control ensures that activated carbon products meet application-specific requirements and perform consistently under operational conditions.Expand Specific Solutions

Key Industry Players in Activated Carbon Production

Activated carbon adsorption technology is currently in a mature development phase with a global market size estimated at over $3 billion annually, growing at 8-10% CAGR. The competitive landscape features established chemical manufacturers like Kuraray Co., Ltd. and its subsidiary Kuraray Chemical Co., Ltd., who lead in high-performance activated carbon development with superior particle strength characteristics. Companies such as BASF Corp. and Nippon Shokubai focus on hydraulic performance optimization, while Toyota Motor Corp. and Honda Motor apply this technology in automotive emission control systems. Research institutions including Tongji University and AIST are advancing attrition resistance innovations. The technology has reached commercial maturity in water treatment and air purification, with emerging applications in energy storage and carbon capture being developed by innovative players like Climeworks AG.

Kuraray Co., Ltd.

Technical Solution: Kuraray has developed advanced activated carbon technologies through their GG series products, focusing on optimized particle strength and hydraulic performance for liquid-phase applications. Their manufacturing process involves a proprietary pre-treatment of coal-based raw materials followed by controlled activation that creates a balanced micropore/mesopore structure while maintaining particle integrity. Kuraray's activated carbon features exceptional hardness (>95% on the ball-pan hardness scale) and low attrition rates (<0.5% mass loss per 1000 hours of operation in moving bed systems). The company has pioneered a unique particle shaping technology that produces uniform granules with optimized sphericity (>0.85 sphericity factor), significantly enhancing hydraulic performance by reducing pressure drop by approximately 25-30% compared to conventional irregular granules. Their activated carbon undergoes a specialized post-activation treatment that strengthens the carbon matrix while preserving adsorption capacity (typically 1000-1200 m²/g BET surface area). Kuraray's products feature carefully controlled particle size distribution (uniformity coefficient <1.6) that optimizes bed packing and flow distribution.

Strengths: Superior mechanical durability in high-stress applications; excellent hydraulic performance with minimal channeling; consistent quality control across production batches. Weaknesses: Premium pricing compared to standard activated carbons; specialized manufacturing process requires longer production cycles; limited raw material flexibility.

BLÜCHER GmbH

Technical Solution: BLÜCHER has developed a revolutionary spherical activated carbon technology that addresses traditional challenges in particle strength and hydraulic performance. Their patented SARATECH® process creates perfectly spherical activated carbon beads with controlled diameter (0.3-1.5mm) and exceptional uniformity (>95% within target size range). The manufacturing process involves a unique polymer-based precursor that undergoes controlled pyrolysis and activation, resulting in activated carbon with superior mechanical strength (crush strength >200N per particle) while maintaining high surface area (1100-1400 m²/g). BLÜCHER's spherical particles demonstrate exceptional attrition resistance with loss rates below 0.1% annually in fixed-bed applications. The uniform spherical shape creates ideal hydraulic conditions with predictable pressure drop characteristics (typically 30-40% lower than conventional granular activated carbon) and superior bed permeability. Their technology includes a proprietary surface treatment process that enhances adsorption kinetics while preserving the structural integrity of the carbon particles.

Strengths: Exceptional hydraulic performance with minimal pressure drop; superior mechanical durability with virtually no dust formation; uniform particle size distribution enabling optimal bed utilization and flow distribution. Weaknesses: Higher production costs compared to traditional activated carbons; limited raw material flexibility as process requires specific polymer precursors; specialized manufacturing equipment requirements limit production capacity.

Critical Patents in Particle Strength Enhancement

Method of making activated carbon bodies having improved adsorption properties

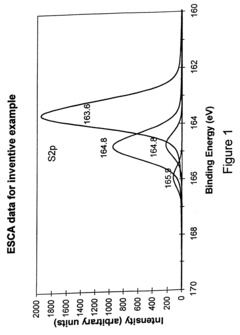

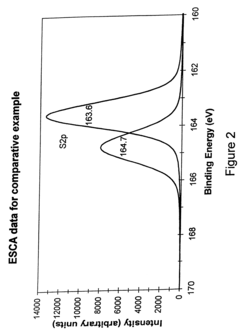

PatentInactiveUS6187713B1

Innovation

- The use of synthetic, non-polycyclic aromatic carbon precursors, such as thermosetting resins, treated with additives like sulfur, phosphoric acid, or oils that are non-miscible and non-reactive, to enhance adsorption properties through curing, carbonization, and activation, resulting in a continuous graphitic structure with improved porosity.

Active carbon with high adsorption capacity and low residual phosphoric content, its preparation and uses

PatentInactiveEP1236681A1

Innovation

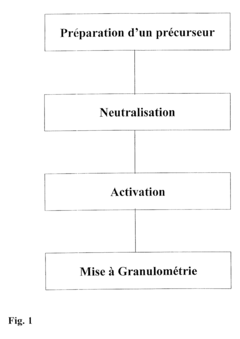

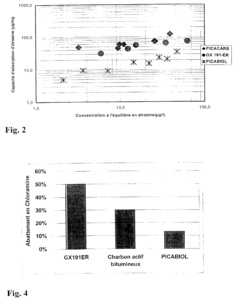

- A new activated carbon with improved characteristics, including a CCl4 index between 120% and 190%, P2O5 content less than 2%, extraction pH greater than 7, and lower electrical resistivity, is developed through a process involving chemical activation with phosphoric acid, neutralization with urea or ammonia, and thermal activation at 800-1000°C, reducing residual P2O5 and enhancing porosity and adsorption capacity.

Environmental Impact and Sustainability Considerations

The environmental impact of activated carbon adsorption systems extends beyond their primary function of contaminant removal. These systems, while effective for purification processes, present several sustainability challenges that must be addressed in comprehensive technology assessments.

The production of activated carbon requires significant energy input, particularly during the activation process which typically involves temperatures of 600-900°C. This energy consumption contributes substantially to the carbon footprint of the material before it even enters service. Additionally, raw material sourcing—whether from coal, coconut shells, wood, or other carbon-rich precursors—raises questions about resource depletion and land use impacts.

Particle attrition in activated carbon systems creates environmental concerns through the generation of fine carbon particles that may escape into effluent streams. These particles can carry adsorbed contaminants and potentially introduce them into receiving water bodies. The hydraulic performance of adsorption systems directly influences their environmental efficiency—poor distribution leading to channeling increases waste generation and reduces treatment effectiveness.

Spent activated carbon management represents a critical environmental consideration. Traditional disposal methods involve landfilling, which contradicts circular economy principles and wastes valuable resources. Thermal regeneration, while allowing carbon reuse, consumes significant energy and produces greenhouse gas emissions. Chemical regeneration alternatives may introduce additional pollutants if not properly managed.

Water consumption during backwashing operations presents another sustainability challenge, particularly in water-scarce regions. Systems optimized for particle strength and hydraulic performance can reduce backwashing frequency, thereby conserving water resources. Similarly, energy requirements for pumping and pressure maintenance in adsorption systems contribute to ongoing operational environmental impacts.

Recent sustainability innovations include developing activated carbons from waste biomass, implementing energy-efficient regeneration technologies, and designing systems with reduced attrition rates to extend service life. Life cycle assessment studies indicate that improvements in particle strength and hydraulic design can significantly reduce the overall environmental footprint of activated carbon technologies through reduced replacement frequency and more efficient contaminant removal.

The regulatory landscape increasingly emphasizes sustainability metrics in water and air treatment technologies, with emerging standards addressing not only treatment efficacy but also resource efficiency, waste generation, and energy consumption throughout the technology lifecycle.

The production of activated carbon requires significant energy input, particularly during the activation process which typically involves temperatures of 600-900°C. This energy consumption contributes substantially to the carbon footprint of the material before it even enters service. Additionally, raw material sourcing—whether from coal, coconut shells, wood, or other carbon-rich precursors—raises questions about resource depletion and land use impacts.

Particle attrition in activated carbon systems creates environmental concerns through the generation of fine carbon particles that may escape into effluent streams. These particles can carry adsorbed contaminants and potentially introduce them into receiving water bodies. The hydraulic performance of adsorption systems directly influences their environmental efficiency—poor distribution leading to channeling increases waste generation and reduces treatment effectiveness.

Spent activated carbon management represents a critical environmental consideration. Traditional disposal methods involve landfilling, which contradicts circular economy principles and wastes valuable resources. Thermal regeneration, while allowing carbon reuse, consumes significant energy and produces greenhouse gas emissions. Chemical regeneration alternatives may introduce additional pollutants if not properly managed.

Water consumption during backwashing operations presents another sustainability challenge, particularly in water-scarce regions. Systems optimized for particle strength and hydraulic performance can reduce backwashing frequency, thereby conserving water resources. Similarly, energy requirements for pumping and pressure maintenance in adsorption systems contribute to ongoing operational environmental impacts.

Recent sustainability innovations include developing activated carbons from waste biomass, implementing energy-efficient regeneration technologies, and designing systems with reduced attrition rates to extend service life. Life cycle assessment studies indicate that improvements in particle strength and hydraulic design can significantly reduce the overall environmental footprint of activated carbon technologies through reduced replacement frequency and more efficient contaminant removal.

The regulatory landscape increasingly emphasizes sustainability metrics in water and air treatment technologies, with emerging standards addressing not only treatment efficacy but also resource efficiency, waste generation, and energy consumption throughout the technology lifecycle.

Regeneration Technologies and Economic Feasibility

Regeneration of activated carbon is essential for sustainable operation in adsorption systems, as it restores adsorption capacity and extends carbon life cycles. Thermal regeneration remains the most widely adopted technology, involving heating spent carbon to 800-900°C in controlled atmospheres to desorb contaminants. This process typically recovers 90-95% of original adsorption capacity with a mass loss of 5-10% per cycle, necessitating periodic fresh carbon addition to maintain system performance.

Steam regeneration offers a lower-temperature alternative (250-400°C), particularly suitable for volatile organic compounds. While less energy-intensive than thermal methods, it achieves lower regeneration efficiency (70-85%) and may be insufficient for strongly adsorbed compounds or complex mixtures.

Chemical regeneration employs solvents or reactive agents to extract adsorbates without significant heating. Solvents like methanol or acetone can effectively remove organic contaminants, while acids or bases target specific pollutants. This approach preserves particle strength by avoiding thermal stress but generates secondary waste streams requiring treatment.

Biological regeneration represents an emerging technology utilizing microorganisms to degrade adsorbed contaminants. Though environmentally friendly and energy-efficient, it remains limited to biodegradable compounds and requires extended regeneration times (days to weeks) compared to conventional methods.

Economic feasibility analysis reveals thermal regeneration costs typically range from $0.50-1.20 per kg carbon, with energy consumption representing 40-60% of operational expenses. On-site regeneration becomes economically viable for facilities processing >500 kg carbon monthly, while smaller operations benefit from centralized regeneration services despite transportation costs.

Life cycle assessment indicates regeneration reduces carbon footprint by 60-80% compared to virgin carbon production. Most facilities achieve economic break-even after 3-5 regeneration cycles, with subsequent cycles generating significant cost savings. The regeneration frequency directly impacts hydraulic performance, as each cycle incrementally reduces particle strength and increases attrition rates by 1-3%.

Emerging technologies include microwave-assisted regeneration, which offers 30-40% energy savings through selective heating, and supercritical fluid regeneration using CO₂, which preserves particle integrity but requires high-pressure equipment. These advanced methods show promise for improving economic feasibility while maintaining hydraulic performance in activated carbon systems.

Steam regeneration offers a lower-temperature alternative (250-400°C), particularly suitable for volatile organic compounds. While less energy-intensive than thermal methods, it achieves lower regeneration efficiency (70-85%) and may be insufficient for strongly adsorbed compounds or complex mixtures.

Chemical regeneration employs solvents or reactive agents to extract adsorbates without significant heating. Solvents like methanol or acetone can effectively remove organic contaminants, while acids or bases target specific pollutants. This approach preserves particle strength by avoiding thermal stress but generates secondary waste streams requiring treatment.

Biological regeneration represents an emerging technology utilizing microorganisms to degrade adsorbed contaminants. Though environmentally friendly and energy-efficient, it remains limited to biodegradable compounds and requires extended regeneration times (days to weeks) compared to conventional methods.

Economic feasibility analysis reveals thermal regeneration costs typically range from $0.50-1.20 per kg carbon, with energy consumption representing 40-60% of operational expenses. On-site regeneration becomes economically viable for facilities processing >500 kg carbon monthly, while smaller operations benefit from centralized regeneration services despite transportation costs.

Life cycle assessment indicates regeneration reduces carbon footprint by 60-80% compared to virgin carbon production. Most facilities achieve economic break-even after 3-5 regeneration cycles, with subsequent cycles generating significant cost savings. The regeneration frequency directly impacts hydraulic performance, as each cycle incrementally reduces particle strength and increases attrition rates by 1-3%.

Emerging technologies include microwave-assisted regeneration, which offers 30-40% energy savings through selective heating, and supercritical fluid regeneration using CO₂, which preserves particle integrity but requires high-pressure equipment. These advanced methods show promise for improving economic feasibility while maintaining hydraulic performance in activated carbon systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!