Activated Carbon Adsorption: Multi-Bed Swing Operation, Pressure Drop And Energy

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Activated Carbon Adsorption Technology Evolution and Objectives

Activated carbon adsorption technology has evolved significantly over the past century, transforming from simple charcoal filters to sophisticated multi-bed adsorption systems. The earliest applications date back to the early 1900s when activated carbon was primarily used for water purification and gas masks. By the mid-20th century, industrial applications expanded to include solvent recovery and air purification, though these systems were characterized by simple fixed-bed designs with limited efficiency and high energy consumption.

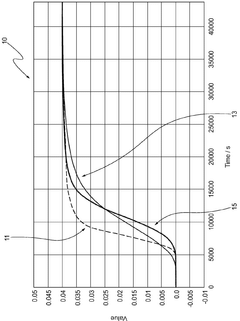

The 1970s marked a turning point with the introduction of thermal swing adsorption (TSA) systems, allowing for regeneration of carbon beds and continuous operation. This period also saw the first attempts at pressure swing adsorption (PSA) with activated carbon, though the technology was primarily applied with zeolites and other adsorbents. The 1980s and 1990s witnessed significant advancements in understanding adsorption kinetics and the development of mathematical models to predict breakthrough curves and pressure drop across carbon beds.

The early 2000s brought increased focus on energy efficiency and process intensification, leading to the development of multi-bed swing operation systems. These configurations allowed for continuous adsorption while individual beds underwent regeneration, significantly improving throughput and reducing energy consumption. Concurrently, computational fluid dynamics (CFD) modeling enabled more precise prediction of pressure drop phenomena, which had previously been a major limitation in system design and scaling.

Recent technological developments have centered on optimizing the balance between adsorption capacity, pressure drop, and energy consumption. Advanced carbon materials with tailored pore structures have emerged, offering improved selectivity and reduced pressure drop. Vacuum pressure swing adsorption (VPSA) and temperature-vacuum swing adsorption (TVSA) have been developed as hybrid approaches to further reduce energy requirements while maintaining separation efficiency.

The primary objectives in this field now focus on several key areas: developing carbon materials with optimized pore structures to minimize pressure drop while maximizing adsorption capacity; creating more sophisticated multi-bed configurations that reduce energy consumption during regeneration cycles; implementing advanced control systems that can dynamically adjust operating parameters based on feed conditions; and integrating renewable energy sources to power the thermal or pressure swing operations.

Additionally, there is growing interest in developing predictive models that can accurately simulate the complex interplay between adsorption kinetics, pressure drop, and energy consumption in multi-bed systems. These models aim to enable more efficient system design and operation, ultimately reducing the carbon footprint of adsorption-based separation processes while improving their economic viability across various industrial applications.

The 1970s marked a turning point with the introduction of thermal swing adsorption (TSA) systems, allowing for regeneration of carbon beds and continuous operation. This period also saw the first attempts at pressure swing adsorption (PSA) with activated carbon, though the technology was primarily applied with zeolites and other adsorbents. The 1980s and 1990s witnessed significant advancements in understanding adsorption kinetics and the development of mathematical models to predict breakthrough curves and pressure drop across carbon beds.

The early 2000s brought increased focus on energy efficiency and process intensification, leading to the development of multi-bed swing operation systems. These configurations allowed for continuous adsorption while individual beds underwent regeneration, significantly improving throughput and reducing energy consumption. Concurrently, computational fluid dynamics (CFD) modeling enabled more precise prediction of pressure drop phenomena, which had previously been a major limitation in system design and scaling.

Recent technological developments have centered on optimizing the balance between adsorption capacity, pressure drop, and energy consumption. Advanced carbon materials with tailored pore structures have emerged, offering improved selectivity and reduced pressure drop. Vacuum pressure swing adsorption (VPSA) and temperature-vacuum swing adsorption (TVSA) have been developed as hybrid approaches to further reduce energy requirements while maintaining separation efficiency.

The primary objectives in this field now focus on several key areas: developing carbon materials with optimized pore structures to minimize pressure drop while maximizing adsorption capacity; creating more sophisticated multi-bed configurations that reduce energy consumption during regeneration cycles; implementing advanced control systems that can dynamically adjust operating parameters based on feed conditions; and integrating renewable energy sources to power the thermal or pressure swing operations.

Additionally, there is growing interest in developing predictive models that can accurately simulate the complex interplay between adsorption kinetics, pressure drop, and energy consumption in multi-bed systems. These models aim to enable more efficient system design and operation, ultimately reducing the carbon footprint of adsorption-based separation processes while improving their economic viability across various industrial applications.

Market Demand Analysis for Multi-Bed Swing Adsorption Systems

The global market for multi-bed swing adsorption systems has been experiencing significant growth, driven primarily by increasing environmental regulations and the growing need for efficient gas separation and purification technologies. The market value for activated carbon adsorption systems was estimated at $3.2 billion in 2022, with multi-bed swing operations representing approximately 28% of this segment. Industry analysts project a compound annual growth rate of 6.7% through 2030.

Industrial sectors including petrochemical processing, natural gas purification, and hydrogen production constitute the largest market segments for multi-bed swing adsorption systems. These industries require high-purity gas streams and efficient removal of contaminants, creating sustained demand for advanced adsorption technologies. The natural gas processing sector alone accounts for nearly 35% of the total market demand, as stringent specifications for pipeline-quality gas necessitate effective removal of CO2, H2S, and moisture.

Environmental applications represent the fastest-growing segment, with air purification and carbon capture systems showing increased adoption rates of 9.3% annually. This growth is directly linked to tightening emission standards worldwide and corporate sustainability initiatives. The pharmaceutical and food processing industries are also emerging as significant consumers of multi-bed swing adsorption technology, particularly for solvent recovery and air quality control applications.

Geographically, North America and Europe currently dominate the market with a combined share of 58%, attributed to stringent environmental regulations and mature industrial infrastructure. However, the Asia-Pacific region is witnessing the highest growth rate at 8.5% annually, driven by rapid industrialization in China and India, along with increasing environmental awareness and regulatory frameworks.

A key market trend is the growing demand for energy-efficient adsorption systems with optimized pressure drop characteristics. End-users are increasingly focused on total cost of ownership rather than initial capital expenditure, creating market pull for innovations that reduce operational energy consumption. Systems that can demonstrate 15-20% energy savings compared to conventional designs command premium pricing and faster market acceptance.

The market also shows increasing demand for modular, skid-mounted multi-bed systems that offer flexibility in capacity and reduced installation costs. This trend is particularly strong in emerging markets where capital constraints and space limitations are significant factors in technology adoption decisions. Additionally, there is growing interest in hybrid systems that combine activated carbon with other adsorbents to achieve enhanced performance for specific applications.

Industrial sectors including petrochemical processing, natural gas purification, and hydrogen production constitute the largest market segments for multi-bed swing adsorption systems. These industries require high-purity gas streams and efficient removal of contaminants, creating sustained demand for advanced adsorption technologies. The natural gas processing sector alone accounts for nearly 35% of the total market demand, as stringent specifications for pipeline-quality gas necessitate effective removal of CO2, H2S, and moisture.

Environmental applications represent the fastest-growing segment, with air purification and carbon capture systems showing increased adoption rates of 9.3% annually. This growth is directly linked to tightening emission standards worldwide and corporate sustainability initiatives. The pharmaceutical and food processing industries are also emerging as significant consumers of multi-bed swing adsorption technology, particularly for solvent recovery and air quality control applications.

Geographically, North America and Europe currently dominate the market with a combined share of 58%, attributed to stringent environmental regulations and mature industrial infrastructure. However, the Asia-Pacific region is witnessing the highest growth rate at 8.5% annually, driven by rapid industrialization in China and India, along with increasing environmental awareness and regulatory frameworks.

A key market trend is the growing demand for energy-efficient adsorption systems with optimized pressure drop characteristics. End-users are increasingly focused on total cost of ownership rather than initial capital expenditure, creating market pull for innovations that reduce operational energy consumption. Systems that can demonstrate 15-20% energy savings compared to conventional designs command premium pricing and faster market acceptance.

The market also shows increasing demand for modular, skid-mounted multi-bed systems that offer flexibility in capacity and reduced installation costs. This trend is particularly strong in emerging markets where capital constraints and space limitations are significant factors in technology adoption decisions. Additionally, there is growing interest in hybrid systems that combine activated carbon with other adsorbents to achieve enhanced performance for specific applications.

Current Challenges in Activated Carbon Multi-Bed Operations

Despite significant advancements in activated carbon adsorption technology, multi-bed swing operations continue to face several critical challenges that limit their efficiency and widespread industrial adoption. One of the primary concerns is the substantial pressure drop across activated carbon beds, which directly impacts energy consumption and operational costs. As gas flows through the packed carbon beds, the resistance creates pressure differentials that require additional energy input to maintain desired flow rates, particularly in high-throughput industrial applications.

The optimization of bed geometry presents another significant challenge. Current designs often struggle to balance the competing requirements of sufficient contact time for adsorption and minimizing pressure drop. Beds that are too densely packed enhance adsorption efficiency but exacerbate pressure losses, while loosely packed configurations reduce pressure drop but compromise adsorption performance.

Energy consumption during regeneration cycles remains problematic, especially in temperature swing adsorption (TSA) systems. The thermal energy required to desorb captured compounds from activated carbon is substantial, and current heat recovery systems are often inadequate, resulting in poor overall energy efficiency. This challenge is particularly acute in applications requiring frequent regeneration cycles.

Bed fouling and degradation over multiple adsorption-desorption cycles represent another persistent issue. Irreversible adsorption of certain compounds, particularly high-molecular-weight organics and some inorganic contaminants, gradually reduces the active surface area of carbon beds. This necessitates more frequent replacement of the adsorbent material, increasing operational costs and system downtime.

Control system limitations also hinder optimal performance in multi-bed operations. Current automated control systems often lack the sophistication to dynamically adjust operational parameters in response to changing inlet conditions, resulting in sub-optimal performance during variable load conditions. The integration of real-time monitoring with predictive control algorithms remains underdeveloped in commercial systems.

Scale-up challenges persist when transitioning from laboratory or pilot-scale systems to full industrial implementation. The non-linear scaling of pressure drop and mass transfer phenomena often leads to unexpected performance issues in larger systems that weren't apparent in smaller test units.

Additionally, the trade-off between adsorption capacity and selectivity continues to challenge system designers. Carbon beds optimized for high capacity often show reduced selectivity for target compounds in mixed gas streams, while highly selective configurations may demonstrate lower overall capacity, necessitating more frequent regeneration cycles.

The optimization of bed geometry presents another significant challenge. Current designs often struggle to balance the competing requirements of sufficient contact time for adsorption and minimizing pressure drop. Beds that are too densely packed enhance adsorption efficiency but exacerbate pressure losses, while loosely packed configurations reduce pressure drop but compromise adsorption performance.

Energy consumption during regeneration cycles remains problematic, especially in temperature swing adsorption (TSA) systems. The thermal energy required to desorb captured compounds from activated carbon is substantial, and current heat recovery systems are often inadequate, resulting in poor overall energy efficiency. This challenge is particularly acute in applications requiring frequent regeneration cycles.

Bed fouling and degradation over multiple adsorption-desorption cycles represent another persistent issue. Irreversible adsorption of certain compounds, particularly high-molecular-weight organics and some inorganic contaminants, gradually reduces the active surface area of carbon beds. This necessitates more frequent replacement of the adsorbent material, increasing operational costs and system downtime.

Control system limitations also hinder optimal performance in multi-bed operations. Current automated control systems often lack the sophistication to dynamically adjust operational parameters in response to changing inlet conditions, resulting in sub-optimal performance during variable load conditions. The integration of real-time monitoring with predictive control algorithms remains underdeveloped in commercial systems.

Scale-up challenges persist when transitioning from laboratory or pilot-scale systems to full industrial implementation. The non-linear scaling of pressure drop and mass transfer phenomena often leads to unexpected performance issues in larger systems that weren't apparent in smaller test units.

Additionally, the trade-off between adsorption capacity and selectivity continues to challenge system designers. Carbon beds optimized for high capacity often show reduced selectivity for target compounds in mixed gas streams, while highly selective configurations may demonstrate lower overall capacity, necessitating more frequent regeneration cycles.

Current Multi-Bed Swing Operation Technical Solutions

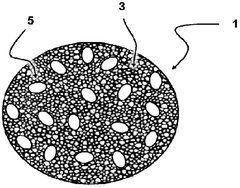

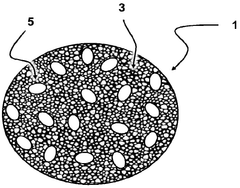

01 Activated carbon structure optimization for reduced pressure drop

The physical structure of activated carbon can be optimized to reduce pressure drop in adsorption systems. This includes designing specific pore size distributions, particle shapes, and bed configurations that allow for efficient gas flow while maintaining high adsorption capacity. Honeycomb structures, monolithic carbon forms, and specially shaped granules can significantly reduce resistance to flow through the carbon bed while maintaining effective contaminant removal.- Activated carbon structure optimization for pressure drop reduction: The structure of activated carbon can be optimized to reduce pressure drop in adsorption systems. This includes designing specific pore structures, particle sizes, and bed configurations that minimize resistance to flow while maintaining adsorption efficiency. Honeycomb structures, monolithic carbon forms, and optimized particle size distributions can significantly reduce pressure drop across carbon beds while ensuring effective contaminant removal.

- Energy-efficient regeneration methods for activated carbon: Various energy-efficient methods can be employed for regenerating spent activated carbon. These include thermal swing adsorption with heat recovery systems, microwave-assisted regeneration, steam regeneration, and pressure swing techniques. These methods aim to reduce the overall energy consumption during the regeneration process while maintaining the adsorption capacity of the activated carbon for subsequent use cycles.

- Flow distribution systems to minimize pressure drop: Specialized flow distribution systems can be implemented to minimize pressure drop across activated carbon beds. These include uniform flow distributors, baffles, and channeling prevention mechanisms that ensure even distribution of the fluid stream through the carbon bed. By optimizing flow patterns, these systems reduce localized high-velocity regions that contribute to increased pressure drop and energy consumption.

- Composite and modified activated carbon materials: Composite and modified activated carbon materials can be developed to address pressure drop and energy efficiency concerns. These include carbon-polymer composites, surface-modified carbons, and hybrid materials that combine the adsorption properties of activated carbon with improved flow characteristics. These materials can be engineered to provide lower resistance to flow while maintaining or enhancing adsorption capacity.

- System design and operational parameters optimization: The overall system design and operational parameters can be optimized to balance pressure drop and energy consumption in activated carbon adsorption systems. This includes determining optimal bed depths, flow rates, operating temperatures, and pressure conditions. Advanced control systems can dynamically adjust these parameters based on real-time monitoring to minimize energy usage while maintaining treatment objectives and extending carbon service life.

02 Energy-efficient regeneration methods for activated carbon

Various techniques can be employed to reduce energy consumption during the regeneration of spent activated carbon. These include low-temperature thermal desorption, microwave-assisted regeneration, steam regeneration, and pressure swing processes. These methods aim to remove adsorbed contaminants while minimizing the energy required compared to conventional high-temperature thermal regeneration, thereby improving the overall energy efficiency of activated carbon adsorption systems.Expand Specific Solutions03 Flow distribution systems to minimize pressure drop

Specialized flow distribution systems can be implemented to optimize gas or liquid flow through activated carbon beds, reducing pressure drop while maintaining adsorption efficiency. These systems include baffles, distribution plates, radial flow arrangements, and multi-stage configurations that ensure uniform flow distribution across the carbon bed. By preventing channeling and ensuring even utilization of the adsorbent, these systems minimize pressure drop and energy consumption while maximizing contaminant removal.Expand Specific Solutions04 Composite and modified activated carbon materials

Composite and modified activated carbon materials can be engineered to provide improved adsorption performance with lower pressure drop. These materials include carbon-polymer composites, carbon-ceramic hybrids, and surface-modified carbons with enhanced hydrophobic or hydrophilic properties. By tailoring the material properties to specific applications, these advanced carbons can achieve higher adsorption capacity and selectivity while requiring less energy for fluid to pass through the adsorption bed.Expand Specific Solutions05 Pressure drop prediction and system optimization

Mathematical models and simulation techniques can be used to predict pressure drop across activated carbon beds and optimize system design for energy efficiency. These approaches include computational fluid dynamics (CFD), empirical correlations, and machine learning algorithms that can forecast pressure drop under various operating conditions. By accurately predicting pressure drop behavior, adsorption systems can be designed with optimal bed dimensions, flow rates, and carbon particle sizes to minimize energy consumption while maintaining treatment objectives.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Adsorption Technology

The activated carbon adsorption market for multi-bed swing operations is currently in a growth phase, with increasing focus on energy efficiency and pressure drop optimization. The market is estimated to reach $3.5-4 billion by 2025, driven by stringent environmental regulations and industrial decarbonization efforts. Leading players include established industrial gas companies like Air Liquide, Air Products & Chemicals, and Praxair Technology, who possess mature technology portfolios. UOP LLC and ExxonMobil Technology & Engineering demonstrate strong technical capabilities in adsorption system design. Emerging players such as Climeworks and CarbonPoint Solutions are introducing innovative approaches to carbon capture using advanced adsorption techniques. Research institutions including Arizona State University and Jiangsu University are contributing to technological advancement, while Saudi Arabian Oil Co. and TotalEnergies are investing in carbon capture applications for the energy sector.

Praxair Technology, Inc.

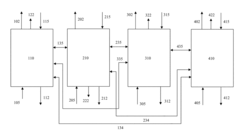

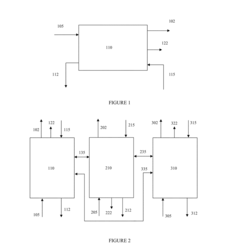

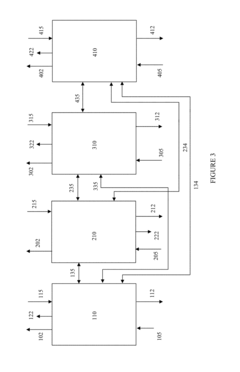

Technical Solution: Praxair has developed advanced multi-bed pressure swing adsorption (PSA) systems utilizing activated carbon for gas separation and purification. Their technology employs a coordinated swing operation with multiple adsorption beds working in sequence to ensure continuous processing while individual beds undergo regeneration. The system incorporates sophisticated valve sequencing and automated controls to optimize the pressure equalization between beds, significantly reducing energy consumption during depressurization and repressurization cycles. Praxair's proprietary bed design features optimized flow distributors that minimize pressure drop across the activated carbon beds while maintaining uniform gas flow, addressing one of the key challenges in adsorption technology. Their systems typically operate at pressures between 4-30 bar with cycle times engineered to maximize working capacity of the activated carbon while minimizing energy requirements. The company has also developed specialized activated carbon formulations with tailored pore size distributions to enhance selectivity for specific gas separations.

Strengths: Superior pressure equalization technology reduces energy consumption by up to 25% compared to conventional systems. Advanced flow distribution design minimizes pressure drop while maintaining separation efficiency. Weaknesses: Higher initial capital investment required compared to simpler adsorption systems. System complexity necessitates more sophisticated control systems and maintenance protocols.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has pioneered innovative multi-bed activated carbon adsorption systems with advanced swing operation protocols. Their technology utilizes a proprietary bed design that optimizes gas flow patterns to minimize pressure drop while maximizing contact with the activated carbon surface area. The company's PRISM® adsorption systems incorporate sophisticated pressure management algorithms that continuously adjust operating parameters based on feed composition and product demand, achieving energy savings of up to 30% compared to conventional fixed-parameter systems. Air Products has developed specialized activated carbon materials with engineered pore structures that provide enhanced selectivity for target molecules while reducing overall pressure drop. Their multi-bed configurations typically employ 4-12 adsorption vessels operating in a coordinated sequence with precise timing control to optimize pressure equalization between beds during transition phases. The company's systems feature advanced heat management techniques that recover and redistribute thermal energy generated during adsorption, further improving overall energy efficiency.

Strengths: Adaptive control systems optimize performance across varying operating conditions, providing exceptional flexibility. Proprietary activated carbon formulations deliver superior selectivity and capacity for specific applications. Weaknesses: Complex control systems require specialized technical expertise for operation and maintenance. Higher-grade activated carbon materials increase replacement costs during system lifecycle.

Key Patents and Innovations in Pressure Drop Reduction

High temperature pressure swing adsorption for advanced sorption enhanced water gas shift

PatentActiveUS20180036674A1

Innovation

- A pressure swing adsorption (PSA) process is employed to separate CO2 and H2 from syngas at high temperatures, using adsorbent materials like alkali metal carbonates and transition metal oxides, which allows for the recovery of high-purity CO2 and H2 streams with reduced energy consumption by minimizing the use of steam and avoiding the need for high-temperature steam rinses.

A sorbent granulate for separation of carbon dioxide from a fluid mixture, and a method of producing thereof

PatentPendingCA3239485A1

Innovation

- The method involves producing sorbent granulates using amine functionalized sorbent material with a bimodal pore distribution, achieved by grinding and granulating the material with a binder to create granulates with a diameter range of 0.1-25 millimeters, enhancing accessibility and adsorption kinetics while minimizing pressure drop.

Environmental Impact and Sustainability Considerations

Activated carbon adsorption systems, particularly those employing multi-bed swing operations, present significant environmental implications that must be carefully considered in their implementation and operation. The environmental footprint of these systems extends beyond their primary function of contaminant removal, encompassing resource consumption, waste generation, and broader ecological impacts.

The carbon footprint associated with activated carbon production represents a substantial environmental consideration. Manufacturing processes typically involve energy-intensive thermal activation procedures that contribute to greenhouse gas emissions. Additionally, raw material sourcing—whether from coal, coconut shells, or wood—raises concerns regarding sustainable harvesting practices and potential deforestation impacts when biomass sources are utilized.

Energy consumption during operation constitutes another critical environmental factor. Multi-bed swing operations require energy for pressure modulation, temperature control, and regeneration cycles. The environmental impact varies significantly based on the energy source powering these systems, with renewable energy integration offering potential for substantial emissions reduction compared to fossil fuel dependence.

Waste management challenges emerge throughout the lifecycle of activated carbon adsorption systems. Spent carbon requires proper disposal or regeneration, with the latter often involving additional energy expenditure and potential emissions. The adsorbed contaminants themselves may represent hazardous waste requiring specialized handling protocols to prevent secondary environmental contamination.

Water usage represents an often-overlooked environmental consideration, particularly in systems employing steam regeneration techniques or those requiring cooling water. In water-stressed regions, this consumption may contribute to resource scarcity and ecosystem stress.

From a sustainability perspective, optimized multi-bed swing operations offer promising advantages. Properly designed systems minimize pressure drop, reducing unnecessary energy expenditure while maintaining effective contaminant removal. Advanced regeneration techniques can extend carbon lifespan, decreasing replacement frequency and associated environmental impacts.

Life cycle assessment methodologies reveal opportunities for environmental performance enhancement through system optimization. Reducing pressure drop not only improves energy efficiency but diminishes associated emissions. Similarly, heat recovery systems during regeneration cycles can significantly improve overall sustainability metrics by recapturing thermal energy that would otherwise be wasted.

The environmental benefits of activated carbon adsorption must be weighed against these impacts, considering the potential harm from untreated emissions or discharges. This balanced assessment should inform technology selection, system design, and operational parameters to maximize environmental protection while minimizing ecological footprint.

The carbon footprint associated with activated carbon production represents a substantial environmental consideration. Manufacturing processes typically involve energy-intensive thermal activation procedures that contribute to greenhouse gas emissions. Additionally, raw material sourcing—whether from coal, coconut shells, or wood—raises concerns regarding sustainable harvesting practices and potential deforestation impacts when biomass sources are utilized.

Energy consumption during operation constitutes another critical environmental factor. Multi-bed swing operations require energy for pressure modulation, temperature control, and regeneration cycles. The environmental impact varies significantly based on the energy source powering these systems, with renewable energy integration offering potential for substantial emissions reduction compared to fossil fuel dependence.

Waste management challenges emerge throughout the lifecycle of activated carbon adsorption systems. Spent carbon requires proper disposal or regeneration, with the latter often involving additional energy expenditure and potential emissions. The adsorbed contaminants themselves may represent hazardous waste requiring specialized handling protocols to prevent secondary environmental contamination.

Water usage represents an often-overlooked environmental consideration, particularly in systems employing steam regeneration techniques or those requiring cooling water. In water-stressed regions, this consumption may contribute to resource scarcity and ecosystem stress.

From a sustainability perspective, optimized multi-bed swing operations offer promising advantages. Properly designed systems minimize pressure drop, reducing unnecessary energy expenditure while maintaining effective contaminant removal. Advanced regeneration techniques can extend carbon lifespan, decreasing replacement frequency and associated environmental impacts.

Life cycle assessment methodologies reveal opportunities for environmental performance enhancement through system optimization. Reducing pressure drop not only improves energy efficiency but diminishes associated emissions. Similarly, heat recovery systems during regeneration cycles can significantly improve overall sustainability metrics by recapturing thermal energy that would otherwise be wasted.

The environmental benefits of activated carbon adsorption must be weighed against these impacts, considering the potential harm from untreated emissions or discharges. This balanced assessment should inform technology selection, system design, and operational parameters to maximize environmental protection while minimizing ecological footprint.

Cost-Benefit Analysis of Advanced Adsorption Technologies

The implementation of advanced activated carbon adsorption technologies requires careful economic evaluation to determine their viability in industrial applications. When analyzing multi-bed swing operation systems, the cost-benefit ratio becomes a critical factor in decision-making processes for facility managers and engineers.

Initial capital expenditure for multi-bed swing adsorption systems is significantly higher than conventional single-bed systems, with investments ranging from $500,000 to $2.5 million depending on capacity and complexity. However, operational cost savings typically offset this premium within 3-5 years through improved energy efficiency and reduced carbon replacement frequency.

Energy consumption represents 40-60% of operational expenses in adsorption systems. Multi-bed configurations demonstrate 25-35% energy savings compared to traditional systems by optimizing pressure swing cycles and reducing regeneration energy requirements. The implementation of advanced control systems further enhances these savings by an additional 10-15% through real-time optimization of bed switching sequences.

Maintenance costs must be factored into the economic analysis, as multi-bed systems contain more valves, sensors, and control equipment. Annual maintenance typically accounts for 5-8% of the initial capital investment, though this is partially offset by the extended lifespan of the activated carbon media, which can last 30-50% longer in properly managed swing operations.

Pressure drop management technologies represent another significant economic consideration. Advanced flow distribution designs can reduce pressure drops by 15-20%, translating to annual energy savings of $20,000-$50,000 for medium-sized industrial applications. These savings must be weighed against the 10-15% higher initial equipment cost for such optimized designs.

Regulatory compliance benefits provide additional economic value through reduced environmental liabilities and potential carbon credit opportunities. Facilities implementing advanced adsorption technologies report 30-40% lower emissions-related compliance costs compared to those using conventional systems.

Return on investment calculations indicate that facilities processing high-value volatile organic compounds (VOCs) achieve payback periods of 18-30 months, while those handling lower-value contaminants may require 36-48 months to recoup initial investments. Sensitivity analysis reveals that energy prices significantly impact these calculations, with each 10% increase in energy costs improving ROI timelines by approximately 8%.

The total cost of ownership over a 10-year operational period demonstrates that advanced multi-bed swing adsorption systems typically provide 20-30% cost advantages over conventional technologies when accounting for all capital, operational, maintenance, and compliance factors.

Initial capital expenditure for multi-bed swing adsorption systems is significantly higher than conventional single-bed systems, with investments ranging from $500,000 to $2.5 million depending on capacity and complexity. However, operational cost savings typically offset this premium within 3-5 years through improved energy efficiency and reduced carbon replacement frequency.

Energy consumption represents 40-60% of operational expenses in adsorption systems. Multi-bed configurations demonstrate 25-35% energy savings compared to traditional systems by optimizing pressure swing cycles and reducing regeneration energy requirements. The implementation of advanced control systems further enhances these savings by an additional 10-15% through real-time optimization of bed switching sequences.

Maintenance costs must be factored into the economic analysis, as multi-bed systems contain more valves, sensors, and control equipment. Annual maintenance typically accounts for 5-8% of the initial capital investment, though this is partially offset by the extended lifespan of the activated carbon media, which can last 30-50% longer in properly managed swing operations.

Pressure drop management technologies represent another significant economic consideration. Advanced flow distribution designs can reduce pressure drops by 15-20%, translating to annual energy savings of $20,000-$50,000 for medium-sized industrial applications. These savings must be weighed against the 10-15% higher initial equipment cost for such optimized designs.

Regulatory compliance benefits provide additional economic value through reduced environmental liabilities and potential carbon credit opportunities. Facilities implementing advanced adsorption technologies report 30-40% lower emissions-related compliance costs compared to those using conventional systems.

Return on investment calculations indicate that facilities processing high-value volatile organic compounds (VOCs) achieve payback periods of 18-30 months, while those handling lower-value contaminants may require 36-48 months to recoup initial investments. Sensitivity analysis reveals that energy prices significantly impact these calculations, with each 10% increase in energy costs improving ROI timelines by approximately 8%.

The total cost of ownership over a 10-year operational period demonstrates that advanced multi-bed swing adsorption systems typically provide 20-30% cost advantages over conventional technologies when accounting for all capital, operational, maintenance, and compliance factors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!