How Activated Carbon Adsorption Maximizes PFAS Removal Under High TOC?

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PFAS Removal Background and Objectives

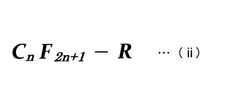

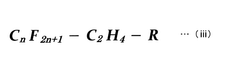

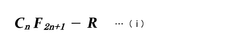

Per- and polyfluoroalkyl substances (PFAS) have emerged as significant environmental contaminants of global concern due to their persistence, bioaccumulation potential, and adverse health effects. These synthetic chemicals, characterized by carbon-fluorine bonds that are among the strongest in organic chemistry, have been widely used since the 1940s in various industrial applications and consumer products, including firefighting foams, non-stick cookware, water-repellent fabrics, and food packaging materials.

The historical development of PFAS technology has progressed through several generations, beginning with long-chain compounds such as perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS), which were later recognized as particularly problematic due to their extreme environmental persistence and bioaccumulative properties. This recognition led to voluntary phase-outs and regulatory restrictions in many countries, prompting a shift toward shorter-chain PFAS alternatives that were initially presumed to be less harmful.

Recent scientific evidence, however, indicates that these replacement compounds may pose similar environmental and health concerns, leading to the concept of PFAS as a class of chemicals requiring comprehensive management approaches. The ubiquitous presence of these "forever chemicals" in water resources has created an urgent need for effective remediation technologies.

Activated carbon adsorption has emerged as one of the most promising treatment technologies for PFAS removal from water. This technology leverages the strong hydrophobic interactions between PFAS molecules and the carbon surface to achieve separation from aqueous environments. However, the efficiency of this process is significantly challenged in real-world applications where high levels of Total Organic Carbon (TOC) are present, as these organic compounds compete with PFAS for adsorption sites.

The primary objective of this technical research is to investigate and optimize activated carbon adsorption processes specifically for maximizing PFAS removal under high TOC conditions. This includes understanding the fundamental mechanisms of competitive adsorption, identifying the key parameters affecting removal efficiency, and developing innovative approaches to overcome the limitations imposed by competing organic matter.

Additionally, this research aims to establish practical guidelines for water treatment facilities dealing with PFAS contamination in high-organic-content waters, including source waters affected by natural organic matter and industrial wastewaters with complex organic matrices. By addressing these challenges, we seek to enhance the applicability and cost-effectiveness of activated carbon technologies in diverse water treatment scenarios, ultimately contributing to more comprehensive protection of public health and environmental quality from PFAS contamination.

The historical development of PFAS technology has progressed through several generations, beginning with long-chain compounds such as perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS), which were later recognized as particularly problematic due to their extreme environmental persistence and bioaccumulative properties. This recognition led to voluntary phase-outs and regulatory restrictions in many countries, prompting a shift toward shorter-chain PFAS alternatives that were initially presumed to be less harmful.

Recent scientific evidence, however, indicates that these replacement compounds may pose similar environmental and health concerns, leading to the concept of PFAS as a class of chemicals requiring comprehensive management approaches. The ubiquitous presence of these "forever chemicals" in water resources has created an urgent need for effective remediation technologies.

Activated carbon adsorption has emerged as one of the most promising treatment technologies for PFAS removal from water. This technology leverages the strong hydrophobic interactions between PFAS molecules and the carbon surface to achieve separation from aqueous environments. However, the efficiency of this process is significantly challenged in real-world applications where high levels of Total Organic Carbon (TOC) are present, as these organic compounds compete with PFAS for adsorption sites.

The primary objective of this technical research is to investigate and optimize activated carbon adsorption processes specifically for maximizing PFAS removal under high TOC conditions. This includes understanding the fundamental mechanisms of competitive adsorption, identifying the key parameters affecting removal efficiency, and developing innovative approaches to overcome the limitations imposed by competing organic matter.

Additionally, this research aims to establish practical guidelines for water treatment facilities dealing with PFAS contamination in high-organic-content waters, including source waters affected by natural organic matter and industrial wastewaters with complex organic matrices. By addressing these challenges, we seek to enhance the applicability and cost-effectiveness of activated carbon technologies in diverse water treatment scenarios, ultimately contributing to more comprehensive protection of public health and environmental quality from PFAS contamination.

Market Demand for Advanced PFAS Treatment Solutions

The global market for PFAS (per- and polyfluoroalkyl substances) treatment solutions is experiencing unprecedented growth, driven by increasing regulatory pressure and public awareness of these "forever chemicals." With PFAS contamination affecting drinking water supplies worldwide, the demand for effective removal technologies has surged dramatically across municipal water treatment, industrial wastewater management, and remediation sectors.

Municipal water utilities represent the largest market segment, as they face stringent regulatory compliance requirements for PFAS in drinking water. The EPA's proposed Maximum Contaminant Levels (MCLs) for six PFAS compounds, including PFOA and PFOS at near-zero levels of 4 parts per trillion, has created immediate demand for treatment solutions capable of achieving these ultra-low concentrations even in challenging high-TOC water conditions.

Industrial sectors, particularly chemical manufacturing, textiles, paper production, and firefighting training facilities, constitute another rapidly expanding market segment. These industries face mounting pressure to treat PFAS-contaminated wastewater before discharge, especially when organic carbon levels are elevated from manufacturing processes. The liability concerns and potential for regulatory enforcement actions are driving proactive investment in advanced treatment technologies.

The remediation market for contaminated sites represents a third significant growth area. Military bases, airports, and industrial facilities with historical PFAS contamination require specialized treatment approaches that can handle complex water matrices with varying levels of total organic carbon (TOC) that typically interfere with PFAS removal efficiency.

Market analysis indicates that technologies demonstrating consistent PFAS removal performance under challenging conditions, particularly high TOC environments, command premium pricing and market preference. Activated carbon solutions that can overcome the competitive adsorption challenges posed by high organic carbon content are especially valued for their operational reliability and cost-effectiveness compared to alternatives like ion exchange or membrane filtration.

Regional market variations are notable, with North America and Europe leading in adoption due to more advanced regulatory frameworks. However, the Asia-Pacific region is projected to show the fastest growth rate as awareness increases and regulatory structures mature. Australia has emerged as a particularly active market following widespread PFAS contamination discoveries.

Customer willingness to pay has increased substantially as the health and liability risks of PFAS become more widely understood. Treatment solutions that can demonstrate consistent performance in removing PFAS below regulatory limits, even in high-TOC conditions, are commanding significant price premiums over conventional water treatment technologies.

Municipal water utilities represent the largest market segment, as they face stringent regulatory compliance requirements for PFAS in drinking water. The EPA's proposed Maximum Contaminant Levels (MCLs) for six PFAS compounds, including PFOA and PFOS at near-zero levels of 4 parts per trillion, has created immediate demand for treatment solutions capable of achieving these ultra-low concentrations even in challenging high-TOC water conditions.

Industrial sectors, particularly chemical manufacturing, textiles, paper production, and firefighting training facilities, constitute another rapidly expanding market segment. These industries face mounting pressure to treat PFAS-contaminated wastewater before discharge, especially when organic carbon levels are elevated from manufacturing processes. The liability concerns and potential for regulatory enforcement actions are driving proactive investment in advanced treatment technologies.

The remediation market for contaminated sites represents a third significant growth area. Military bases, airports, and industrial facilities with historical PFAS contamination require specialized treatment approaches that can handle complex water matrices with varying levels of total organic carbon (TOC) that typically interfere with PFAS removal efficiency.

Market analysis indicates that technologies demonstrating consistent PFAS removal performance under challenging conditions, particularly high TOC environments, command premium pricing and market preference. Activated carbon solutions that can overcome the competitive adsorption challenges posed by high organic carbon content are especially valued for their operational reliability and cost-effectiveness compared to alternatives like ion exchange or membrane filtration.

Regional market variations are notable, with North America and Europe leading in adoption due to more advanced regulatory frameworks. However, the Asia-Pacific region is projected to show the fastest growth rate as awareness increases and regulatory structures mature. Australia has emerged as a particularly active market following widespread PFAS contamination discoveries.

Customer willingness to pay has increased substantially as the health and liability risks of PFAS become more widely understood. Treatment solutions that can demonstrate consistent performance in removing PFAS below regulatory limits, even in high-TOC conditions, are commanding significant price premiums over conventional water treatment technologies.

Current Challenges in PFAS Adsorption with High TOC

The adsorption of Per- and Polyfluoroalkyl Substances (PFAS) using activated carbon faces significant challenges when operating in environments with high Total Organic Carbon (TOC) concentrations. High TOC levels, typically found in landfill leachates, industrial wastewaters, and contaminated groundwater, create direct competition for adsorption sites on activated carbon surfaces. Organic matter molecules occupy binding sites that would otherwise be available for PFAS compounds, substantially reducing removal efficiency.

Competition mechanisms occur through several pathways. Larger organic molecules can physically block access to micropores where PFAS adsorption predominantly takes place. This pore blockage phenomenon is particularly problematic for smaller PFAS compounds that rely on micropore adsorption. Additionally, dissolved organic matter often carries negative charges that can repel the negatively charged functional groups of many PFAS compounds, creating electrostatic interference that further inhibits adsorption.

Kinetic limitations present another critical challenge. The presence of high TOC slows down PFAS adsorption rates by increasing the mass transfer resistance at the liquid-solid interface. This delayed equilibrium achievement significantly extends the required contact time for effective treatment, reducing the operational efficiency of adsorption systems in real-world applications.

The chemical complexity of TOC compounds further complicates the adsorption process. Natural organic matter consists of diverse compounds with varying molecular weights, functional groups, and hydrophobicity. These characteristics influence competitive adsorption behaviors in ways that are difficult to predict or model accurately. Certain organic fractions show particularly strong competitive effects against specific PFAS compounds, creating variable treatment outcomes depending on the specific composition of the water matrix.

Operational challenges also emerge in high-TOC environments. Activated carbon media experiences accelerated fouling and requires more frequent regeneration or replacement, substantially increasing operational costs. The reduced adsorption capacity necessitates larger treatment systems and higher carbon dosages to achieve regulatory compliance, further escalating capital expenditures.

Analytical difficulties compound these technical challenges. High TOC levels interfere with accurate PFAS detection and quantification, complicating performance monitoring and optimization efforts. This analytical uncertainty makes it difficult to precisely determine treatment effectiveness and establish reliable design parameters for full-scale implementation.

Recent research has identified that the impact of TOC varies significantly across different PFAS compounds. Short-chain PFAS appear more susceptible to competitive effects than their long-chain counterparts, creating selective removal patterns that may not align with regulatory priorities or risk-based treatment goals.

Competition mechanisms occur through several pathways. Larger organic molecules can physically block access to micropores where PFAS adsorption predominantly takes place. This pore blockage phenomenon is particularly problematic for smaller PFAS compounds that rely on micropore adsorption. Additionally, dissolved organic matter often carries negative charges that can repel the negatively charged functional groups of many PFAS compounds, creating electrostatic interference that further inhibits adsorption.

Kinetic limitations present another critical challenge. The presence of high TOC slows down PFAS adsorption rates by increasing the mass transfer resistance at the liquid-solid interface. This delayed equilibrium achievement significantly extends the required contact time for effective treatment, reducing the operational efficiency of adsorption systems in real-world applications.

The chemical complexity of TOC compounds further complicates the adsorption process. Natural organic matter consists of diverse compounds with varying molecular weights, functional groups, and hydrophobicity. These characteristics influence competitive adsorption behaviors in ways that are difficult to predict or model accurately. Certain organic fractions show particularly strong competitive effects against specific PFAS compounds, creating variable treatment outcomes depending on the specific composition of the water matrix.

Operational challenges also emerge in high-TOC environments. Activated carbon media experiences accelerated fouling and requires more frequent regeneration or replacement, substantially increasing operational costs. The reduced adsorption capacity necessitates larger treatment systems and higher carbon dosages to achieve regulatory compliance, further escalating capital expenditures.

Analytical difficulties compound these technical challenges. High TOC levels interfere with accurate PFAS detection and quantification, complicating performance monitoring and optimization efforts. This analytical uncertainty makes it difficult to precisely determine treatment effectiveness and establish reliable design parameters for full-scale implementation.

Recent research has identified that the impact of TOC varies significantly across different PFAS compounds. Short-chain PFAS appear more susceptible to competitive effects than their long-chain counterparts, creating selective removal patterns that may not align with regulatory priorities or risk-based treatment goals.

Current Activated Carbon Adsorption Methodologies

01 Activated carbon modification for enhanced PFAS adsorption

Various modifications to activated carbon can significantly improve its PFAS adsorption capacity. These modifications include surface functionalization, pore structure optimization, and incorporation of specific chemical groups that increase affinity for PFAS compounds. Modified activated carbons demonstrate higher removal efficiency compared to conventional activated carbon, especially for short-chain PFAS that are typically more difficult to remove.- Activated carbon adsorption mechanisms for PFAS removal: Activated carbon effectively removes per- and polyfluoroalkyl substances (PFAS) from water through adsorption mechanisms. The high surface area and porous structure of activated carbon provide numerous binding sites for PFAS molecules. The hydrophobic interactions between the fluorinated chains of PFAS and the carbon surface are particularly effective for longer-chain PFAS compounds. Various types of activated carbon with different physical and chemical properties can be optimized for specific PFAS compounds.

- Modified activated carbon for enhanced PFAS adsorption: Chemical modifications of activated carbon can significantly improve its PFAS adsorption capacity. Surface treatments with specific functional groups can create stronger binding sites for PFAS molecules. Modifications may include nitrogen doping, metal impregnation, or oxidative treatments that alter the surface charge and chemistry of the carbon. These modifications can target specific PFAS compounds, particularly short-chain PFAS that are typically more difficult to remove with conventional activated carbon.

- Granular activated carbon filtration systems for PFAS treatment: Granular activated carbon (GAC) filtration systems are widely implemented for PFAS removal in water treatment facilities. These systems typically consist of fixed-bed columns where contaminated water passes through beds of GAC. System design parameters including contact time, flow rate, and bed depth significantly impact removal efficiency. Regular monitoring and carbon replacement schedules are necessary as adsorption capacity becomes exhausted over time. GAC systems can be integrated with existing water treatment infrastructure for cost-effective PFAS remediation.

- Powdered activated carbon for PFAS removal applications: Powdered activated carbon (PAC) offers advantages for PFAS removal in certain applications due to its higher surface area and faster adsorption kinetics compared to granular forms. PAC can be directly added to water treatment processes as a slurry, allowing for flexible dosing based on contamination levels. After adsorption, PAC with bound PFAS can be removed through conventional solid-liquid separation processes such as sedimentation, filtration, or membrane filtration. This approach is particularly useful for addressing temporary PFAS contamination events or as a supplementary treatment method.

- Regeneration and disposal of PFAS-loaded activated carbon: The regeneration and proper disposal of PFAS-loaded activated carbon presents significant challenges in treatment systems. Thermal regeneration methods must reach temperatures sufficient to destroy PFAS compounds without releasing harmful byproducts. Alternative regeneration approaches include solvent washing, steam treatment, and electrochemical methods. For spent carbon that cannot be regenerated, specialized disposal methods such as high-temperature incineration or stabilization before landfilling are required to prevent PFAS from re-entering the environment. Developing cost-effective regeneration technologies is crucial for the sustainability of activated carbon-based PFAS treatment systems.

02 Granular activated carbon (GAC) filtration systems

Granular activated carbon filtration systems represent a primary technology for PFAS removal from water. These systems typically consist of fixed-bed columns or filters containing GAC media through which contaminated water passes. The design parameters, including contact time, flow rate, and bed depth, significantly impact removal efficiency. GAC systems can be implemented at various scales, from point-of-use filters to large municipal treatment facilities.Expand Specific Solutions03 Powdered activated carbon (PAC) treatment processes

Powdered activated carbon offers advantages for PFAS removal due to its high surface area and rapid adsorption kinetics. PAC can be applied in batch treatment processes or as part of a continuous flow system. The smaller particle size of PAC compared to GAC provides more accessible adsorption sites, though it requires subsequent separation from treated water. PAC dosage, mixing conditions, and contact time are critical parameters affecting treatment efficiency.Expand Specific Solutions04 Regeneration and disposal of PFAS-loaded activated carbon

The management of spent activated carbon containing adsorbed PFAS presents significant challenges. Various regeneration methods have been developed, including thermal treatment, solvent washing, and advanced oxidation processes. These techniques aim to restore adsorption capacity while safely destroying or containing the removed PFAS compounds. Proper disposal methods for non-regenerable carbon must address the potential for PFAS leaching into the environment from landfills or during incineration.Expand Specific Solutions05 Hybrid treatment systems combining activated carbon with other technologies

Combining activated carbon adsorption with complementary treatment technologies can enhance overall PFAS removal efficiency. These hybrid systems may incorporate ion exchange resins, membrane filtration, advanced oxidation processes, or biological treatment. The synergistic effects of multiple treatment barriers can address a broader range of PFAS compounds with varying physicochemical properties, providing more complete removal than activated carbon alone.Expand Specific Solutions

Leading Companies in PFAS Treatment Industry

The PFAS removal market using activated carbon adsorption is transitioning from early adoption to growth phase, with increasing regulatory pressure driving a projected market expansion to $2.5 billion by 2025. Technical maturity varies significantly among key players. Industry leaders Evoqua Water Technologies and Battelle Memorial Institute have developed advanced carbon-based solutions optimized for high TOC conditions, while academic institutions like Clemson University and Tsinghua University contribute fundamental research on adsorption mechanisms. Emerging companies like Onvector and Gradiant are introducing hybrid technologies combining activated carbon with complementary treatment methods. The challenge of PFAS removal under high TOC conditions remains partially solved, with ongoing innovation focused on carbon surface modifications and regeneration techniques to overcome competitive adsorption limitations.

Evoqua Water Technologies LLC

Technical Solution: Evoqua has developed advanced activated carbon adsorption systems specifically designed for PFAS removal in high TOC environments. Their technology employs a multi-barrier approach combining specialized granular activated carbon (GAC) with proprietary pre-treatment processes to address organic competition. The system utilizes tailored carbon materials with optimized pore size distribution and surface chemistry that maintain high adsorption capacity even when organic matter is present. Evoqua's solution incorporates real-time monitoring and automated backwashing cycles that respond to changing influent conditions, preventing fouling and extending media life. Their PFAS removal systems achieve over 99% removal efficiency for long-chain PFAS and maintain effectiveness for short-chain compounds by employing sequential treatment trains with different carbon types optimized for specific PFAS groups. The technology also features regeneration capabilities that reduce waste and operational costs while maintaining treatment efficacy.

Strengths: Comprehensive solution with proven effectiveness in high-TOC conditions; proprietary carbon formulations specifically designed for PFAS; integrated monitoring systems for optimized performance. Weaknesses: Higher initial capital investment compared to standard GAC systems; requires more frequent maintenance in extremely high TOC environments; regeneration process creates secondary waste streams requiring management.

Battelle Memorial Institute

Technical Solution: Battelle has developed an advanced activated carbon system for PFAS removal that specifically addresses high TOC interference. Their technology combines specially formulated activated carbon with a proprietary pre-treatment process that selectively reduces competing organic matter before PFAS adsorption. The system utilizes a multi-barrier approach incorporating tailored carbon materials with optimized surface chemistry that maintains high PFAS affinity even in organically-loaded waters. Battelle's solution features a novel carbon modification technique that introduces specific functional groups enhancing PFAS selectivity through both hydrophobic and electrostatic interactions. Their technology employs a sequential treatment train with different carbon formulations optimized for specific PFAS chain lengths, achieving over 99% removal for long-chain PFAS and maintaining effectiveness for short-chain compounds even in waters with TOC exceeding 8 mg/L. The system includes real-time monitoring capabilities that adjust operational parameters based on influent water quality, optimizing performance and extending media life in variable conditions.

Strengths: Research-driven approach with highly specialized carbon formulations; excellent performance across wide range of PFAS compounds; adaptive control systems for optimized operation. Weaknesses: Higher implementation costs than standard treatment systems; requires more technical expertise for operation; regeneration process more complex than conventional GAC systems.

Key Technical Innovations in PFAS-TOC Competitive Adsorption

Per- and polyfluoroalkyl compound-adsorbing activated carbon

PatentWO2021033595A1

Innovation

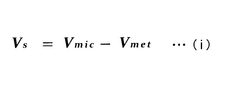

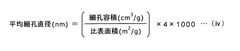

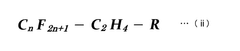

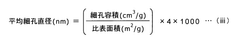

- Development of a per- and polyfluoroalkyl compound-adsorbing activated carbon with a specific surface area of 900 m^2/g, featuring a combination of micropore and mesopore volumes that enhance adsorption and desorption capabilities, along with increased surface oxide amounts for improved chemical adsorption, utilizing fibrous or granular activated carbon with specific pore distributions and surface functional groups.

Active carbon for adsorbing perfluoroalkyl and polyfluoroalkyl compounds in water sample

PatentWO2021033596A1

Innovation

- Activated carbon with a specific surface area of 800 m^2/g and controlled surface oxide content, used in the form of fibrous or granular activated carbon, effectively adsorbs and desorbs per- and polyfluoroalkyl compounds, enabling accurate quantitative measurements by improving adsorption and handling efficiency.

Environmental Regulations Impacting PFAS Treatment

The regulatory landscape for PFAS (Per- and Polyfluoroalkyl Substances) treatment has evolved significantly in recent years, directly influencing the development and implementation of activated carbon adsorption technologies. The United States Environmental Protection Agency (EPA) has established health advisory levels for PFOA and PFOS at 70 parts per trillion (ppt), with some states implementing even stricter standards. These regulations have created an urgent need for effective treatment solutions, particularly in high TOC (Total Organic Carbon) environments where treatment efficacy is often compromised.

In 2021, the EPA announced its PFAS Strategic Roadmap, outlining a comprehensive approach to addressing PFAS contamination, including the development of enforceable drinking water standards. This regulatory framework has accelerated research into optimizing activated carbon adsorption systems specifically designed to maintain performance even when competing organic matter is present in high concentrations.

The European Union has taken a similar regulatory approach through its Water Framework Directive, establishing environmental quality standards for PFAS compounds. These international regulations have created a global market for advanced treatment technologies that can effectively remove PFAS while managing the interference from high TOC levels.

Regulatory compliance costs have become a significant driver for innovation in activated carbon technologies. Treatment facilities facing stringent PFAS removal requirements must balance regulatory compliance with operational efficiency, particularly when dealing with source waters containing elevated organic carbon. This economic pressure has spurred research into specialized activated carbon formulations and regeneration techniques that maintain adsorption capacity despite organic competition.

Recent amendments to the Safe Drinking Water Act in the United States have specifically targeted PFAS monitoring and removal requirements, with activated carbon being recognized as a Best Available Technology (BAT). However, these regulations also acknowledge the limitations of conventional treatment approaches in challenging water matrices, creating regulatory pathways for innovative solutions that address the specific challenges of PFAS removal under high TOC conditions.

Industry-specific discharge regulations have further complicated the regulatory landscape, with different standards applying to various sectors including textile manufacturing, firefighting training facilities, and chemical production plants. These sector-specific requirements have led to customized activated carbon solutions designed to address the unique characteristics of industrial wastewaters, including those with elevated organic content that would typically interfere with PFAS adsorption.

The regulatory trend is clearly moving toward more comprehensive PFAS management strategies, with increasing focus on treatment technologies that remain effective across diverse water quality conditions. This regulatory pressure continues to drive innovation in activated carbon technologies specifically engineered to overcome the competitive adsorption challenges presented by high TOC environments.

In 2021, the EPA announced its PFAS Strategic Roadmap, outlining a comprehensive approach to addressing PFAS contamination, including the development of enforceable drinking water standards. This regulatory framework has accelerated research into optimizing activated carbon adsorption systems specifically designed to maintain performance even when competing organic matter is present in high concentrations.

The European Union has taken a similar regulatory approach through its Water Framework Directive, establishing environmental quality standards for PFAS compounds. These international regulations have created a global market for advanced treatment technologies that can effectively remove PFAS while managing the interference from high TOC levels.

Regulatory compliance costs have become a significant driver for innovation in activated carbon technologies. Treatment facilities facing stringent PFAS removal requirements must balance regulatory compliance with operational efficiency, particularly when dealing with source waters containing elevated organic carbon. This economic pressure has spurred research into specialized activated carbon formulations and regeneration techniques that maintain adsorption capacity despite organic competition.

Recent amendments to the Safe Drinking Water Act in the United States have specifically targeted PFAS monitoring and removal requirements, with activated carbon being recognized as a Best Available Technology (BAT). However, these regulations also acknowledge the limitations of conventional treatment approaches in challenging water matrices, creating regulatory pathways for innovative solutions that address the specific challenges of PFAS removal under high TOC conditions.

Industry-specific discharge regulations have further complicated the regulatory landscape, with different standards applying to various sectors including textile manufacturing, firefighting training facilities, and chemical production plants. These sector-specific requirements have led to customized activated carbon solutions designed to address the unique characteristics of industrial wastewaters, including those with elevated organic content that would typically interfere with PFAS adsorption.

The regulatory trend is clearly moving toward more comprehensive PFAS management strategies, with increasing focus on treatment technologies that remain effective across diverse water quality conditions. This regulatory pressure continues to drive innovation in activated carbon technologies specifically engineered to overcome the competitive adsorption challenges presented by high TOC environments.

Cost-Benefit Analysis of Advanced PFAS Removal Technologies

When evaluating the economic viability of activated carbon adsorption for PFAS removal under high TOC conditions, a comprehensive cost-benefit analysis reveals several important considerations. Initial capital expenditures for activated carbon systems are generally lower compared to alternative technologies such as reverse osmosis or ion exchange. However, the presence of high Total Organic Carbon (TOC) significantly impacts operational costs due to competitive adsorption effects.

The primary cost driver becomes the frequency of carbon replacement or regeneration. Under high TOC conditions, carbon beds saturate more rapidly as organic matter occupies adsorption sites that would otherwise capture PFAS compounds. Data from field implementations indicates that carbon replacement frequency may increase by 30-50% in high TOC waters (>5 mg/L) compared to low TOC environments.

Energy consumption represents another significant cost factor. While activated carbon systems generally require less energy than membrane technologies, the need for more frequent backwashing and potential pretreatment steps to manage TOC increases the overall energy footprint. This translates to approximately 0.2-0.4 kWh per 1,000 gallons treated in high TOC applications.

Maintenance costs also escalate with TOC levels. Systems treating high TOC waters require more frequent monitoring, adjustment of operational parameters, and potential troubleshooting of flow issues caused by organic fouling. Annual maintenance costs typically range from 5-10% of capital costs for standard applications but may reach 12-15% for high TOC scenarios.

On the benefit side, activated carbon remains effective at meeting regulatory standards for PFAS removal when properly designed and maintained, even under challenging TOC conditions. The technology's proven track record provides regulatory certainty and public confidence, which carries significant non-monetary value for utilities and industrial users.

Lifecycle analysis indicates that despite higher operational costs in high TOC environments, activated carbon often remains economically competitive when considering total cost of ownership over a 10-15 year period. This is particularly true when implementing strategic approaches such as TOC pretreatment, optimized carbon selection, or hybrid treatment trains that extend carbon bed life.

Return on investment calculations suggest that for waters with TOC levels between 5-10 mg/L, payback periods for enhanced activated carbon systems range from 3-5 years compared to alternative technologies, assuming current regulatory limits for PFAS compounds. However, this advantage diminishes as TOC levels exceed 10 mg/L, at which point alternative or complementary technologies may become more cost-effective.

The primary cost driver becomes the frequency of carbon replacement or regeneration. Under high TOC conditions, carbon beds saturate more rapidly as organic matter occupies adsorption sites that would otherwise capture PFAS compounds. Data from field implementations indicates that carbon replacement frequency may increase by 30-50% in high TOC waters (>5 mg/L) compared to low TOC environments.

Energy consumption represents another significant cost factor. While activated carbon systems generally require less energy than membrane technologies, the need for more frequent backwashing and potential pretreatment steps to manage TOC increases the overall energy footprint. This translates to approximately 0.2-0.4 kWh per 1,000 gallons treated in high TOC applications.

Maintenance costs also escalate with TOC levels. Systems treating high TOC waters require more frequent monitoring, adjustment of operational parameters, and potential troubleshooting of flow issues caused by organic fouling. Annual maintenance costs typically range from 5-10% of capital costs for standard applications but may reach 12-15% for high TOC scenarios.

On the benefit side, activated carbon remains effective at meeting regulatory standards for PFAS removal when properly designed and maintained, even under challenging TOC conditions. The technology's proven track record provides regulatory certainty and public confidence, which carries significant non-monetary value for utilities and industrial users.

Lifecycle analysis indicates that despite higher operational costs in high TOC environments, activated carbon often remains economically competitive when considering total cost of ownership over a 10-15 year period. This is particularly true when implementing strategic approaches such as TOC pretreatment, optimized carbon selection, or hybrid treatment trains that extend carbon bed life.

Return on investment calculations suggest that for waters with TOC levels between 5-10 mg/L, payback periods for enhanced activated carbon systems range from 3-5 years compared to alternative technologies, assuming current regulatory limits for PFAS compounds. However, this advantage diminishes as TOC levels exceed 10 mg/L, at which point alternative or complementary technologies may become more cost-effective.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!