Activated Carbon Adsorption: Gas-Phase VOC Control, Humidity Effects And Desorption

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

VOC Control Technology Background and Objectives

Volatile Organic Compounds (VOCs) have emerged as significant environmental pollutants since the mid-20th century, with increasing industrial activities and urbanization contributing to their prevalence in ambient air. These compounds, characterized by their high vapor pressure at ordinary room temperature, encompass a diverse range of chemicals including benzene, toluene, formaldehyde, and numerous industrial solvents. The recognition of VOCs as major contributors to photochemical smog, ground-level ozone formation, and various adverse health effects has driven the development of control technologies over the past several decades.

The evolution of VOC control technologies has progressed through several distinct phases. Initial approaches in the 1970s focused primarily on thermal oxidation and catalytic oxidation, which effectively destroyed VOCs but required significant energy input. The 1980s and 1990s saw the emergence of adsorption technologies, particularly activated carbon systems, as energy-efficient alternatives for VOC capture and potential recovery.

Activated carbon adsorption has since established itself as a cornerstone technology in VOC control strategies due to its versatility, relatively low operational costs, and high removal efficiencies for a wide spectrum of VOC compounds. The technology leverages the extensive internal surface area of activated carbon—typically ranging from 500 to 1500 m²/g—to physically bind VOC molecules through van der Waals forces.

The primary objective of current research and development in activated carbon adsorption for VOC control is to address several persistent challenges that limit its effectiveness in real-world applications. Chief among these is understanding and mitigating the impact of humidity on adsorption performance, as water vapor competes with VOCs for adsorption sites, significantly reducing removal efficiency in high-humidity environments common in industrial settings.

Additionally, the desorption process—critical for regenerating saturated carbon and potentially recovering valuable VOCs—presents technical challenges related to energy efficiency, complete contaminant removal, and maintaining the structural integrity of the carbon over multiple adsorption-desorption cycles.

Recent technological goals focus on developing advanced carbon materials with enhanced selectivity for VOCs over water vapor, optimizing regeneration protocols to minimize energy consumption while maximizing desorption efficiency, and integrating activated carbon systems with complementary technologies to create hybrid solutions capable of addressing complex VOC mixtures across varying operational conditions.

The pursuit of these objectives is driven by increasingly stringent environmental regulations worldwide, growing awareness of indoor air quality concerns, and industrial demands for more cost-effective and sustainable pollution control technologies that align with broader carbon reduction initiatives.

The evolution of VOC control technologies has progressed through several distinct phases. Initial approaches in the 1970s focused primarily on thermal oxidation and catalytic oxidation, which effectively destroyed VOCs but required significant energy input. The 1980s and 1990s saw the emergence of adsorption technologies, particularly activated carbon systems, as energy-efficient alternatives for VOC capture and potential recovery.

Activated carbon adsorption has since established itself as a cornerstone technology in VOC control strategies due to its versatility, relatively low operational costs, and high removal efficiencies for a wide spectrum of VOC compounds. The technology leverages the extensive internal surface area of activated carbon—typically ranging from 500 to 1500 m²/g—to physically bind VOC molecules through van der Waals forces.

The primary objective of current research and development in activated carbon adsorption for VOC control is to address several persistent challenges that limit its effectiveness in real-world applications. Chief among these is understanding and mitigating the impact of humidity on adsorption performance, as water vapor competes with VOCs for adsorption sites, significantly reducing removal efficiency in high-humidity environments common in industrial settings.

Additionally, the desorption process—critical for regenerating saturated carbon and potentially recovering valuable VOCs—presents technical challenges related to energy efficiency, complete contaminant removal, and maintaining the structural integrity of the carbon over multiple adsorption-desorption cycles.

Recent technological goals focus on developing advanced carbon materials with enhanced selectivity for VOCs over water vapor, optimizing regeneration protocols to minimize energy consumption while maximizing desorption efficiency, and integrating activated carbon systems with complementary technologies to create hybrid solutions capable of addressing complex VOC mixtures across varying operational conditions.

The pursuit of these objectives is driven by increasingly stringent environmental regulations worldwide, growing awareness of indoor air quality concerns, and industrial demands for more cost-effective and sustainable pollution control technologies that align with broader carbon reduction initiatives.

Market Analysis for Gas-Phase VOC Control Solutions

The global market for Gas-Phase Volatile Organic Compound (VOC) control solutions has experienced significant growth in recent years, driven primarily by increasingly stringent environmental regulations and growing awareness of indoor air quality concerns. The market was valued at approximately USD 7.2 billion in 2022 and is projected to reach USD 9.8 billion by 2027, representing a compound annual growth rate of 6.3%.

Activated carbon adsorption technology holds a dominant position in this market, accounting for roughly 35% of the total market share. This prominence can be attributed to its versatility, cost-effectiveness, and relatively simple implementation compared to alternative technologies such as thermal oxidation, catalytic oxidation, and biofiltration.

Geographically, North America and Europe currently lead the market due to their stringent regulatory frameworks regarding industrial emissions and air quality standards. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected growth rates exceeding 8% annually through 2027, primarily driven by rapid industrialization and increasing regulatory pressure.

By industry vertical, chemical processing, petrochemical, and automotive manufacturing sectors collectively account for over 60% of the total market demand. However, emerging applications in semiconductor manufacturing, pharmaceutical production, and commercial building HVAC systems are showing the highest growth rates, expanding at 9-11% annually.

A notable market trend is the increasing demand for integrated VOC control systems that address multiple challenges simultaneously, including humidity management and energy-efficient desorption capabilities. This trend is reflected in recent product innovations from leading market players, who are developing next-generation activated carbon solutions with enhanced moisture resistance and regeneration properties.

Customer preferences are increasingly shifting toward solutions offering lower total cost of ownership rather than merely lower initial capital expenditure. This shift has created market opportunities for service-based business models, including leasing arrangements and performance-based contracts for VOC control systems.

Market challenges include price sensitivity in emerging economies, technical limitations of activated carbon in high-humidity environments, and competition from alternative technologies. Despite these challenges, the market outlook remains positive, supported by ongoing regulatory tightening globally and growing corporate sustainability initiatives that prioritize air quality management.

Activated carbon adsorption technology holds a dominant position in this market, accounting for roughly 35% of the total market share. This prominence can be attributed to its versatility, cost-effectiveness, and relatively simple implementation compared to alternative technologies such as thermal oxidation, catalytic oxidation, and biofiltration.

Geographically, North America and Europe currently lead the market due to their stringent regulatory frameworks regarding industrial emissions and air quality standards. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with projected growth rates exceeding 8% annually through 2027, primarily driven by rapid industrialization and increasing regulatory pressure.

By industry vertical, chemical processing, petrochemical, and automotive manufacturing sectors collectively account for over 60% of the total market demand. However, emerging applications in semiconductor manufacturing, pharmaceutical production, and commercial building HVAC systems are showing the highest growth rates, expanding at 9-11% annually.

A notable market trend is the increasing demand for integrated VOC control systems that address multiple challenges simultaneously, including humidity management and energy-efficient desorption capabilities. This trend is reflected in recent product innovations from leading market players, who are developing next-generation activated carbon solutions with enhanced moisture resistance and regeneration properties.

Customer preferences are increasingly shifting toward solutions offering lower total cost of ownership rather than merely lower initial capital expenditure. This shift has created market opportunities for service-based business models, including leasing arrangements and performance-based contracts for VOC control systems.

Market challenges include price sensitivity in emerging economies, technical limitations of activated carbon in high-humidity environments, and competition from alternative technologies. Despite these challenges, the market outlook remains positive, supported by ongoing regulatory tightening globally and growing corporate sustainability initiatives that prioritize air quality management.

Activated Carbon Adsorption: Current Status and Challenges

Activated carbon adsorption technology has evolved significantly over the past decades, establishing itself as one of the most widely implemented methods for volatile organic compound (VOC) control in industrial settings. Currently, the global market for activated carbon in gas-phase applications exceeds $1.2 billion, with an annual growth rate of approximately 8-10%. This growth is primarily driven by increasingly stringent environmental regulations across major economies, particularly in North America, Europe, and parts of Asia.

The current state of activated carbon adsorption technology demonstrates varying levels of maturity across different applications. For VOC removal in industrial exhaust streams, the technology has reached commercial maturity with removal efficiencies typically ranging from 90-99% under optimal conditions. However, significant challenges persist in maintaining these efficiency levels under fluctuating operational parameters, particularly in the presence of variable humidity conditions.

Humidity effects represent one of the most critical challenges facing activated carbon adsorption systems today. Research indicates that relative humidity above 50% can reduce VOC adsorption capacity by 20-40%, depending on the specific compounds involved. This reduction occurs because water molecules compete with VOC molecules for adsorption sites, particularly on hydrophilic activated carbon surfaces. The phenomenon is especially problematic for polar VOCs, where adsorption efficiency can decrease by up to 60% in high-humidity environments.

Desorption processes, essential for activated carbon regeneration, face technical limitations that impact the overall cost-effectiveness of the technology. Thermal desorption remains the predominant method, but energy requirements are substantial, typically consuming 3-5 kWh per kilogram of regenerated carbon. Alternative desorption methods such as pressure swing and microwave-assisted desorption show promise in laboratory settings but have yet to achieve widespread commercial implementation.

Material science innovations represent both progress and challenges in the field. Advanced activated carbons with tailored pore structures and surface chemistries have emerged, offering improved selectivity for specific VOCs. However, manufacturing costs for these specialized materials remain 30-50% higher than conventional activated carbons, limiting their widespread adoption.

Geographic distribution of activated carbon technology development shows concentration in specific regions. North America and Europe lead in research and implementation of advanced systems, while China dominates in production capacity, accounting for approximately 40% of global activated carbon manufacturing. This geographic disparity creates challenges in technology transfer and standardization across different markets.

Regulatory frameworks continue to evolve, with increasingly stringent VOC emission standards driving innovation but also creating compliance challenges. The technical gap between laboratory performance and real-world industrial applications remains significant, particularly in addressing the combined effects of humidity, temperature fluctuations, and mixed VOC streams.

The current state of activated carbon adsorption technology demonstrates varying levels of maturity across different applications. For VOC removal in industrial exhaust streams, the technology has reached commercial maturity with removal efficiencies typically ranging from 90-99% under optimal conditions. However, significant challenges persist in maintaining these efficiency levels under fluctuating operational parameters, particularly in the presence of variable humidity conditions.

Humidity effects represent one of the most critical challenges facing activated carbon adsorption systems today. Research indicates that relative humidity above 50% can reduce VOC adsorption capacity by 20-40%, depending on the specific compounds involved. This reduction occurs because water molecules compete with VOC molecules for adsorption sites, particularly on hydrophilic activated carbon surfaces. The phenomenon is especially problematic for polar VOCs, where adsorption efficiency can decrease by up to 60% in high-humidity environments.

Desorption processes, essential for activated carbon regeneration, face technical limitations that impact the overall cost-effectiveness of the technology. Thermal desorption remains the predominant method, but energy requirements are substantial, typically consuming 3-5 kWh per kilogram of regenerated carbon. Alternative desorption methods such as pressure swing and microwave-assisted desorption show promise in laboratory settings but have yet to achieve widespread commercial implementation.

Material science innovations represent both progress and challenges in the field. Advanced activated carbons with tailored pore structures and surface chemistries have emerged, offering improved selectivity for specific VOCs. However, manufacturing costs for these specialized materials remain 30-50% higher than conventional activated carbons, limiting their widespread adoption.

Geographic distribution of activated carbon technology development shows concentration in specific regions. North America and Europe lead in research and implementation of advanced systems, while China dominates in production capacity, accounting for approximately 40% of global activated carbon manufacturing. This geographic disparity creates challenges in technology transfer and standardization across different markets.

Regulatory frameworks continue to evolve, with increasingly stringent VOC emission standards driving innovation but also creating compliance challenges. The technical gap between laboratory performance and real-world industrial applications remains significant, particularly in addressing the combined effects of humidity, temperature fluctuations, and mixed VOC streams.

Current Humidity Management Solutions in Adsorption Systems

01 Humidity effects on activated carbon adsorption

Humidity significantly impacts the efficiency of activated carbon in VOC adsorption. High humidity levels can reduce adsorption capacity as water molecules compete with VOCs for adsorption sites on the carbon surface. This competitive adsorption effect is particularly pronounced for hydrophilic VOCs. Various technologies have been developed to mitigate humidity effects, including pre-treatment systems to reduce moisture content in gas streams before they reach the activated carbon bed.- Humidity effects on activated carbon adsorption: Humidity significantly impacts the efficiency of activated carbon in VOC adsorption. High humidity levels can reduce adsorption capacity as water molecules compete with VOCs for adsorption sites on the carbon surface. This competitive adsorption is particularly pronounced at relative humidity levels above 50%. Some systems incorporate humidity control mechanisms such as dehumidifiers or pre-treatment steps to maintain optimal adsorption conditions and extend the service life of activated carbon filters.

- Desorption techniques for activated carbon regeneration: Various desorption methods are employed to regenerate saturated activated carbon and extend its operational life. These include thermal desorption (using hot air or steam), pressure swing desorption, and vacuum desorption. The choice of desorption technique depends on the specific VOCs being treated, energy considerations, and system requirements. Effective desorption not only restores adsorption capacity but can also allow for the recovery of valuable VOCs in some industrial applications.

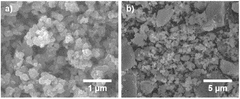

- Activated carbon structural modifications for enhanced VOC control: Structural modifications to activated carbon can significantly improve its VOC adsorption performance. These modifications include surface treatment to alter pore size distribution, impregnation with specific chemicals to enhance selectivity, and development of composite materials combining activated carbon with other adsorbents. Modified activated carbons can be tailored to target specific VOC compounds and maintain performance under challenging conditions such as high humidity or fluctuating VOC concentrations.

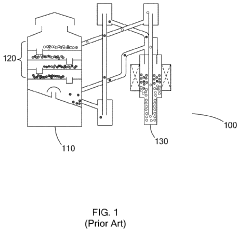

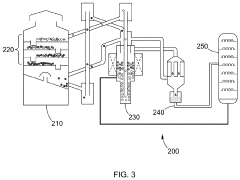

- Integrated VOC control systems using activated carbon: Integrated systems combine activated carbon adsorption with other treatment technologies to enhance overall VOC control efficiency. These systems may incorporate pre-treatment stages (such as particulate filters or condensers), multi-stage adsorption beds, and post-treatment processes. The integration allows for handling of complex VOC mixtures, accommodating varying concentration levels, and addressing humidity challenges. Such systems often include automated monitoring and control mechanisms to optimize performance and energy efficiency.

- Continuous monitoring and optimization of activated carbon systems: Advanced monitoring and control systems are essential for optimizing activated carbon VOC adsorption processes. These systems track parameters such as breakthrough curves, pressure drop, humidity levels, and VOC concentrations to determine optimal replacement or regeneration timing. Real-time monitoring enables dynamic adjustment of operating conditions to maintain efficiency despite varying inlet conditions. Predictive maintenance approaches based on monitoring data help prevent unexpected breakthrough and ensure consistent VOC removal performance.

02 Desorption techniques for activated carbon regeneration

Various desorption methods are employed to regenerate saturated activated carbon for continued VOC control. These include thermal desorption using steam or hot gas, pressure swing desorption, and vacuum desorption. The choice of desorption technique depends on the specific VOCs adsorbed, energy efficiency considerations, and the desired recovery of the adsorbed compounds. Some systems incorporate automated regeneration cycles to maintain continuous operation of VOC control systems.Expand Specific Solutions03 Advanced activated carbon materials for enhanced VOC control

Specialized activated carbon materials have been developed to improve VOC adsorption performance. These include modified activated carbons with enhanced surface properties, impregnated carbons with specific chemical additives to target certain VOC compounds, and composite materials combining activated carbon with other adsorbents. These advanced materials offer higher adsorption capacities, better selectivity for specific VOCs, and improved resistance to humidity effects compared to conventional activated carbons.Expand Specific Solutions04 Integrated VOC control systems using activated carbon

Comprehensive VOC control systems integrate activated carbon adsorption with complementary technologies for improved efficiency. These systems may combine pre-treatment stages for humidity control, multi-stage adsorption beds for different VOC types, and post-treatment processes for complete VOC removal. Some designs incorporate heat recovery from thermal desorption processes to improve energy efficiency, while others feature automated monitoring and control systems to optimize performance under varying operating conditions.Expand Specific Solutions05 Performance optimization for activated carbon VOC adsorption

Various strategies are employed to optimize the performance of activated carbon adsorption systems for VOC control. These include optimizing flow rates and residence times, designing efficient carbon bed configurations, implementing temperature control systems, and developing predictive maintenance protocols. Advanced monitoring techniques are used to detect breakthrough and determine optimal regeneration timing. Mathematical models and simulation tools help predict adsorption behavior under different operating conditions, enabling system design optimization.Expand Specific Solutions

Key Industry Players in VOC Control Technologies

The activated carbon adsorption market for VOC control is in a growth phase, driven by increasing environmental regulations and industrial emissions concerns. The market size is expanding globally, with significant investments in R&D to enhance adsorption efficiency under varying humidity conditions. Technologically, companies like LG Chem, Kuraray, and Purafil demonstrate advanced maturity in developing specialized activated carbon products with improved humidity resistance and desorption capabilities. Research institutions such as Shanghai Advanced Research Institute and CNRS are advancing fundamental understanding of adsorption mechanisms, while industrial players like Sinopec and Toyobo focus on commercial applications. The competitive landscape shows a mix of chemical conglomerates, specialized environmental technology firms, and research-driven organizations collaborating to address technical challenges in gas-phase VOC control systems.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced activated carbon adsorption systems for VOC control featuring multi-stage adsorption beds with specialized impregnation techniques. Their technology employs hydrophobic activated carbon materials specifically engineered to maintain performance under varying humidity conditions (30-90% RH). Sinopec's system incorporates temperature swing adsorption (TSA) with precise humidity control mechanisms that adjust the moisture content in the incoming gas stream. For desorption, they utilize a combination of thermal regeneration (180-250°C) and steam stripping methods, achieving VOC recovery rates exceeding 95%. Their process includes an innovative moisture-resistant coating on carbon surfaces that prevents competitive adsorption between water molecules and VOCs, maintaining removal efficiency above 90% even at high humidity levels. The system features automated monitoring of breakthrough curves and predictive maintenance algorithms to optimize replacement cycles.

Strengths: Superior humidity resistance through specialized carbon surface treatments; high VOC recovery rates; integrated monitoring systems for performance optimization. Weaknesses: Higher initial capital investment compared to conventional systems; requires significant energy input for thermal regeneration; performance may still degrade with extremely high moisture content (>95% RH).

Kuraray Co., Ltd.

Technical Solution: Kuraray has pioneered a proprietary activated carbon technology called "KURARAYCOAL" specifically designed for gas-phase VOC control applications. Their solution features spherical activated carbon beads with controlled micropore and mesopore distributions, optimized for different VOC molecular weights and polarities. The technology incorporates a hydrophobic surface treatment that significantly reduces the negative impact of humidity on adsorption capacity, maintaining over 85% efficiency at relative humidity levels up to 80%. For humidity management, Kuraray implements a pre-conditioning system that moderates incoming gas moisture content through temperature control. Their desorption approach utilizes a low-temperature vacuum swing process (operating at 80-120°C) that reduces energy consumption by approximately 40% compared to conventional thermal desorption methods. The regeneration cycle is carefully controlled to prevent carbon degradation, extending media life by up to 30%. Additionally, Kuraray has developed a proprietary "moisture barrier zone" within their adsorption beds that acts as a protective buffer against humidity spikes.

Strengths: Energy-efficient desorption process; extended media life through optimized regeneration; excellent performance stability across varying humidity conditions; spherical carbon format provides low pressure drop. Weaknesses: Higher initial cost compared to conventional activated carbon; requires more complex system controls; performance can still be affected by extremely high humidity conditions (>90% RH).

Critical Patents in Activated Carbon Desorption Techniques

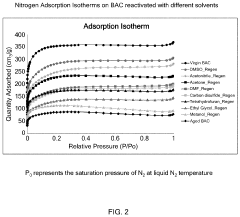

Recovery of adsorption capacity of beaded activated carbon using gas-phase organic solvents

PatentActiveUS11369946B2

Innovation

- A method involving the use of a vapor-phase stream of organic solvents such as dimethyl sulfoxide, acetonitrile, or tetrahydrofuran, passed over VOC-loaded BAC to extract VOCs, allowing for regeneration at lower temperatures and recovering the solvents for reuse, thereby maintaining the carbon's adsorption capacity and reducing mechanical stress.

Volatile organic compound adsorbent and adsorption filter renewable by light energy, and manufacturing method thereof

PatentActiveKR1020230061640A

Innovation

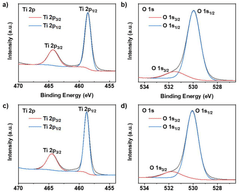

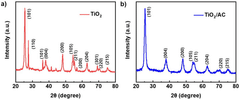

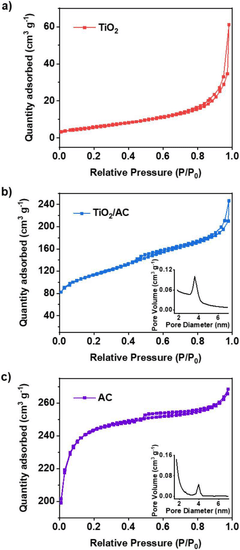

- A composite adsorbent composed of titanium dioxide (TiO2) supported on activated carbon, which regenerates adsorption capacity through light energy irradiation, such as UV rays, maintaining high efficiency and reusability.

Environmental Regulations Impacting VOC Control Technologies

The regulatory landscape governing Volatile Organic Compounds (VOCs) has evolved significantly over the past decades, creating a complex framework that directly impacts the implementation and development of control technologies such as activated carbon adsorption systems. At the international level, the United Nations Framework Convention on Climate Change (UNFCCC) and subsequent protocols have established broad guidelines for reducing greenhouse gas emissions, indirectly affecting VOC control strategies.

In the United States, the Clean Air Act and its amendments form the cornerstone of VOC regulation. The National Ambient Air Quality Standards (NAAQS) set by the Environmental Protection Agency (EPA) establish permissible concentration limits for ozone, a secondary pollutant formed through VOC reactions. Additionally, the EPA's Maximum Achievable Control Technology (MACT) standards specifically target hazardous air pollutants, many of which are VOCs, requiring industries to implement stringent control measures.

The European Union's regulatory framework includes the Industrial Emissions Directive (IED) and the VOC Solvents Emissions Directive, which impose strict emission limits and monitoring requirements. These regulations have driven significant technological advancements in activated carbon adsorption systems, particularly in addressing humidity effects and optimizing desorption processes.

In Asia, rapidly industrializing nations like China and India have implemented increasingly stringent VOC regulations. China's Air Pollution Prevention and Control Action Plan and India's National Clean Air Programme both emphasize VOC reduction as a key component of their air quality improvement strategies, creating substantial markets for advanced adsorption technologies.

Industry-specific regulations further shape the technological landscape. For instance, the petroleum refining sector faces the Refinery MACT standards, while the chemical manufacturing industry must comply with the Hazardous Organic NESHAP (HON) regulations. These sector-specific requirements often necessitate customized activated carbon solutions that account for unique process conditions, including varying humidity levels and desorption requirements.

Recent regulatory trends indicate a movement toward more comprehensive VOC monitoring and control. The EPA's Next Generation Compliance initiative emphasizes continuous emissions monitoring, which has spurred innovation in real-time performance tracking for activated carbon systems. Similarly, the EU's evolving Best Available Techniques Reference Documents (BREFs) continue to raise performance standards for VOC control technologies.

These regulatory frameworks not only drive compliance-focused technology adoption but also stimulate research and development in addressing key technical challenges, such as humidity interference with adsorption efficiency and energy-efficient desorption methods. As regulations continue to tighten globally, the market for advanced activated carbon adsorption systems is expected to expand, particularly for solutions that offer improved performance under varying operational conditions.

In the United States, the Clean Air Act and its amendments form the cornerstone of VOC regulation. The National Ambient Air Quality Standards (NAAQS) set by the Environmental Protection Agency (EPA) establish permissible concentration limits for ozone, a secondary pollutant formed through VOC reactions. Additionally, the EPA's Maximum Achievable Control Technology (MACT) standards specifically target hazardous air pollutants, many of which are VOCs, requiring industries to implement stringent control measures.

The European Union's regulatory framework includes the Industrial Emissions Directive (IED) and the VOC Solvents Emissions Directive, which impose strict emission limits and monitoring requirements. These regulations have driven significant technological advancements in activated carbon adsorption systems, particularly in addressing humidity effects and optimizing desorption processes.

In Asia, rapidly industrializing nations like China and India have implemented increasingly stringent VOC regulations. China's Air Pollution Prevention and Control Action Plan and India's National Clean Air Programme both emphasize VOC reduction as a key component of their air quality improvement strategies, creating substantial markets for advanced adsorption technologies.

Industry-specific regulations further shape the technological landscape. For instance, the petroleum refining sector faces the Refinery MACT standards, while the chemical manufacturing industry must comply with the Hazardous Organic NESHAP (HON) regulations. These sector-specific requirements often necessitate customized activated carbon solutions that account for unique process conditions, including varying humidity levels and desorption requirements.

Recent regulatory trends indicate a movement toward more comprehensive VOC monitoring and control. The EPA's Next Generation Compliance initiative emphasizes continuous emissions monitoring, which has spurred innovation in real-time performance tracking for activated carbon systems. Similarly, the EU's evolving Best Available Techniques Reference Documents (BREFs) continue to raise performance standards for VOC control technologies.

These regulatory frameworks not only drive compliance-focused technology adoption but also stimulate research and development in addressing key technical challenges, such as humidity interference with adsorption efficiency and energy-efficient desorption methods. As regulations continue to tighten globally, the market for advanced activated carbon adsorption systems is expected to expand, particularly for solutions that offer improved performance under varying operational conditions.

Lifecycle Assessment of Activated Carbon Adsorption Systems

The lifecycle assessment of activated carbon adsorption systems provides a comprehensive evaluation of environmental impacts throughout the entire lifespan of these systems, from raw material extraction to end-of-life disposal. This assessment is crucial for understanding the true sustainability of activated carbon technologies used in VOC control applications.

The production phase of activated carbon involves energy-intensive processes including carbonization and activation, typically requiring temperatures between 600-1200°C. These processes contribute significantly to the carbon footprint of the material, with estimates suggesting that producing one kilogram of activated carbon generates approximately 3-5 kg of CO2 equivalent emissions. The raw material source—whether coal, coconut shells, or wood—substantially influences this environmental impact profile.

During the operational phase, activated carbon systems demonstrate environmental benefits through VOC removal efficiency, typically achieving 90-99% removal rates under optimal conditions. However, performance degradation due to humidity effects represents a significant operational challenge. Research indicates that relative humidity above 50% can reduce adsorption capacity by 20-40%, necessitating more frequent regeneration cycles and consequently increasing energy consumption.

The regeneration process, whether thermal, pressure swing, or steam-based, constitutes a substantial portion of the system's lifecycle energy demand. Thermal regeneration, the most common method, requires temperatures of 700-900°C, consuming 3-6 MJ of energy per kilogram of carbon regenerated. This energy requirement translates to additional greenhouse gas emissions that must be factored into the overall environmental assessment.

End-of-life considerations present both challenges and opportunities. Spent activated carbon often contains concentrated hazardous compounds that require special disposal procedures. However, innovative recycling approaches are emerging, with some technologies achieving up to 80% recovery rates for the carbon material, significantly extending its useful life and improving overall sustainability metrics.

When comparing activated carbon systems to alternative VOC control technologies such as catalytic oxidation or biofilters, lifecycle assessments reveal complex trade-offs. While activated carbon systems typically have higher material production impacts, they often demonstrate lower operational energy requirements compared to thermal oxidation systems, particularly for low-concentration VOC streams. The break-even point where activated carbon becomes environmentally preferable typically occurs at VOC concentrations below 1000 ppm.

Recent advances in sustainable activated carbon production, including the use of agricultural waste materials and low-energy activation methods, show promise for reducing lifecycle impacts by up to 40% compared to conventional production methods. These innovations represent important pathways toward improving the overall environmental profile of activated carbon adsorption systems for gas-phase VOC control applications.

The production phase of activated carbon involves energy-intensive processes including carbonization and activation, typically requiring temperatures between 600-1200°C. These processes contribute significantly to the carbon footprint of the material, with estimates suggesting that producing one kilogram of activated carbon generates approximately 3-5 kg of CO2 equivalent emissions. The raw material source—whether coal, coconut shells, or wood—substantially influences this environmental impact profile.

During the operational phase, activated carbon systems demonstrate environmental benefits through VOC removal efficiency, typically achieving 90-99% removal rates under optimal conditions. However, performance degradation due to humidity effects represents a significant operational challenge. Research indicates that relative humidity above 50% can reduce adsorption capacity by 20-40%, necessitating more frequent regeneration cycles and consequently increasing energy consumption.

The regeneration process, whether thermal, pressure swing, or steam-based, constitutes a substantial portion of the system's lifecycle energy demand. Thermal regeneration, the most common method, requires temperatures of 700-900°C, consuming 3-6 MJ of energy per kilogram of carbon regenerated. This energy requirement translates to additional greenhouse gas emissions that must be factored into the overall environmental assessment.

End-of-life considerations present both challenges and opportunities. Spent activated carbon often contains concentrated hazardous compounds that require special disposal procedures. However, innovative recycling approaches are emerging, with some technologies achieving up to 80% recovery rates for the carbon material, significantly extending its useful life and improving overall sustainability metrics.

When comparing activated carbon systems to alternative VOC control technologies such as catalytic oxidation or biofilters, lifecycle assessments reveal complex trade-offs. While activated carbon systems typically have higher material production impacts, they often demonstrate lower operational energy requirements compared to thermal oxidation systems, particularly for low-concentration VOC streams. The break-even point where activated carbon becomes environmentally preferable typically occurs at VOC concentrations below 1000 ppm.

Recent advances in sustainable activated carbon production, including the use of agricultural waste materials and low-energy activation methods, show promise for reducing lifecycle impacts by up to 40% compared to conventional production methods. These innovations represent important pathways toward improving the overall environmental profile of activated carbon adsorption systems for gas-phase VOC control applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!