Activated Carbon Adsorption: PFAS/Trace Organics Removal, Selectivity And Regeneration

SEP 17, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PFAS Removal Technology Background and Objectives

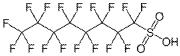

Per- and polyfluoroalkyl substances (PFAS) have emerged as significant environmental contaminants of concern due to their persistence, bioaccumulation potential, and associated health risks. These synthetic chemicals have been widely used since the 1940s in various industrial applications and consumer products, including non-stick cookware, water-repellent fabrics, fire-fighting foams, and food packaging. The extraordinary stability of carbon-fluorine bonds in PFAS molecules contributes to their environmental persistence, earning them the designation as "forever chemicals."

The evolution of PFAS removal technologies has accelerated in recent years as regulatory scrutiny has intensified. Initially, conventional water treatment processes proved largely ineffective against these compounds. However, activated carbon adsorption emerged as one of the earliest viable treatment approaches, demonstrating promising results for removing certain PFAS compounds from water. The technology has evolved from simple granular activated carbon (GAC) systems to more sophisticated powdered activated carbon (PAC) applications and specialized formulations designed specifically for PFAS capture.

Current technological trends in activated carbon adsorption for PFAS removal focus on enhancing selectivity, improving adsorption capacity, and developing sustainable regeneration methods. Research is increasingly directed toward understanding the mechanisms of PFAS adsorption onto carbon surfaces, the impact of carbon pore size distribution, and the influence of water chemistry on removal efficiency. Additionally, there is growing interest in developing hybrid systems that combine activated carbon with other treatment technologies to achieve more comprehensive PFAS removal.

The primary technical objectives in this field include developing activated carbon materials with higher selectivity for PFAS compounds, particularly short-chain varieties that have traditionally been more challenging to remove. Researchers aim to increase adsorption capacity while minimizing competition from natural organic matter and other contaminants. Another critical goal is establishing economically viable regeneration methods that can extend the useful life of activated carbon media, reducing operational costs and environmental impacts associated with frequent media replacement.

Furthermore, there is an urgent need to address the fate of adsorbed PFAS compounds, ensuring that they are not simply transferred from one environmental compartment to another. This includes developing destruction technologies that can be applied to spent activated carbon or exploring methods to permanently sequester these compounds in environmentally secure forms.

As regulatory standards for PFAS continue to become more stringent globally, the development of efficient, cost-effective, and sustainable activated carbon-based technologies for PFAS removal represents a critical research priority with significant implications for public health and environmental protection.

The evolution of PFAS removal technologies has accelerated in recent years as regulatory scrutiny has intensified. Initially, conventional water treatment processes proved largely ineffective against these compounds. However, activated carbon adsorption emerged as one of the earliest viable treatment approaches, demonstrating promising results for removing certain PFAS compounds from water. The technology has evolved from simple granular activated carbon (GAC) systems to more sophisticated powdered activated carbon (PAC) applications and specialized formulations designed specifically for PFAS capture.

Current technological trends in activated carbon adsorption for PFAS removal focus on enhancing selectivity, improving adsorption capacity, and developing sustainable regeneration methods. Research is increasingly directed toward understanding the mechanisms of PFAS adsorption onto carbon surfaces, the impact of carbon pore size distribution, and the influence of water chemistry on removal efficiency. Additionally, there is growing interest in developing hybrid systems that combine activated carbon with other treatment technologies to achieve more comprehensive PFAS removal.

The primary technical objectives in this field include developing activated carbon materials with higher selectivity for PFAS compounds, particularly short-chain varieties that have traditionally been more challenging to remove. Researchers aim to increase adsorption capacity while minimizing competition from natural organic matter and other contaminants. Another critical goal is establishing economically viable regeneration methods that can extend the useful life of activated carbon media, reducing operational costs and environmental impacts associated with frequent media replacement.

Furthermore, there is an urgent need to address the fate of adsorbed PFAS compounds, ensuring that they are not simply transferred from one environmental compartment to another. This includes developing destruction technologies that can be applied to spent activated carbon or exploring methods to permanently sequester these compounds in environmentally secure forms.

As regulatory standards for PFAS continue to become more stringent globally, the development of efficient, cost-effective, and sustainable activated carbon-based technologies for PFAS removal represents a critical research priority with significant implications for public health and environmental protection.

Market Analysis for PFAS Treatment Solutions

The global PFAS treatment solutions market is experiencing rapid growth, driven by increasing regulatory pressure and public awareness of the health risks associated with these "forever chemicals." Current market valuation stands at approximately $2.1 billion in 2023, with projections indicating a compound annual growth rate of 8.7% through 2030, potentially reaching $3.5 billion by the end of the decade.

Activated carbon adsorption technology currently holds the largest market share among PFAS treatment solutions, accounting for roughly 35% of the total market. This dominance is attributed to its established efficacy, relatively lower implementation costs compared to emerging technologies, and widespread availability. Municipal water treatment represents the largest end-user segment, followed by industrial wastewater treatment and remediation projects.

Geographically, North America leads the market with approximately 40% share, driven by stringent EPA regulations and numerous PFAS contamination sites. Europe follows at 30%, with the European Union's recent initiatives to regulate PFAS as a chemical class accelerating adoption. The Asia-Pacific region, though currently representing only 20% of the market, is expected to witness the fastest growth rate as countries like Japan, South Korea, and China begin implementing stricter environmental regulations.

Customer demand is increasingly focused on treatment solutions that offer both effectiveness and cost efficiency. While activated carbon demonstrates high removal efficiency for long-chain PFAS compounds, its performance limitations with short-chain PFAS compounds are creating market opportunities for complementary or alternative technologies. This has led to a segmentation of the market between standard solutions for general applications and premium solutions for challenging scenarios requiring higher removal rates.

The competitive landscape features both established water treatment companies expanding their PFAS-specific offerings and specialized startups focusing exclusively on innovative PFAS remediation technologies. Major players include Evoqua Water Technologies, Calgon Carbon Corporation (Kuraray), Xylem, and AquaMetals, collectively controlling approximately 65% of the market.

Key market drivers include increasingly stringent regulatory standards, growing litigation concerning PFAS contamination, and heightened public awareness. The most significant market restraint remains the high cost of treatment, particularly for complete destruction or removal of short-chain PFAS compounds. Additionally, the challenge of spent media disposal represents both a market constraint and an opportunity for companies developing regeneration technologies.

Customer willingness to pay premium prices for PFAS treatment solutions varies significantly by sector, with drinking water utilities demonstrating the highest price sensitivity due to public funding constraints, while industrial clients with regulatory compliance mandates show greater flexibility in budget allocation for effective solutions.

Activated carbon adsorption technology currently holds the largest market share among PFAS treatment solutions, accounting for roughly 35% of the total market. This dominance is attributed to its established efficacy, relatively lower implementation costs compared to emerging technologies, and widespread availability. Municipal water treatment represents the largest end-user segment, followed by industrial wastewater treatment and remediation projects.

Geographically, North America leads the market with approximately 40% share, driven by stringent EPA regulations and numerous PFAS contamination sites. Europe follows at 30%, with the European Union's recent initiatives to regulate PFAS as a chemical class accelerating adoption. The Asia-Pacific region, though currently representing only 20% of the market, is expected to witness the fastest growth rate as countries like Japan, South Korea, and China begin implementing stricter environmental regulations.

Customer demand is increasingly focused on treatment solutions that offer both effectiveness and cost efficiency. While activated carbon demonstrates high removal efficiency for long-chain PFAS compounds, its performance limitations with short-chain PFAS compounds are creating market opportunities for complementary or alternative technologies. This has led to a segmentation of the market between standard solutions for general applications and premium solutions for challenging scenarios requiring higher removal rates.

The competitive landscape features both established water treatment companies expanding their PFAS-specific offerings and specialized startups focusing exclusively on innovative PFAS remediation technologies. Major players include Evoqua Water Technologies, Calgon Carbon Corporation (Kuraray), Xylem, and AquaMetals, collectively controlling approximately 65% of the market.

Key market drivers include increasingly stringent regulatory standards, growing litigation concerning PFAS contamination, and heightened public awareness. The most significant market restraint remains the high cost of treatment, particularly for complete destruction or removal of short-chain PFAS compounds. Additionally, the challenge of spent media disposal represents both a market constraint and an opportunity for companies developing regeneration technologies.

Customer willingness to pay premium prices for PFAS treatment solutions varies significantly by sector, with drinking water utilities demonstrating the highest price sensitivity due to public funding constraints, while industrial clients with regulatory compliance mandates show greater flexibility in budget allocation for effective solutions.

Current Challenges in Activated Carbon PFAS Adsorption

Activated carbon adsorption for PFAS removal faces significant technical challenges despite its widespread application. The primary obstacle lies in the complex molecular structure of PFAS compounds, which contain both hydrophobic fluorinated carbon chains and hydrophilic functional groups. This dual nature complicates the adsorption mechanism, as traditional activated carbon primarily targets hydrophobic interactions, leading to variable removal efficiencies across different PFAS compounds.

Competition from natural organic matter (NOM) and other contaminants in water matrices severely impacts PFAS adsorption performance. These competing substances can occupy adsorption sites, reducing the effective capacity for PFAS removal. Studies indicate that NOM can decrease PFAS adsorption by 30-70% depending on water characteristics, significantly diminishing treatment efficiency in real-world applications.

The adsorption kinetics present another substantial challenge. While activated carbon shows promising equilibrium capacities for many PFAS compounds, the rate of adsorption is often slow, particularly for short-chain PFAS. This necessitates longer contact times in treatment systems, reducing throughput and increasing operational costs. The mass transfer limitations within carbon pores create diffusion barriers that further slow the process.

Selectivity issues compound these challenges, as activated carbon exhibits preferential adsorption for long-chain PFAS over emerging short-chain alternatives. As regulatory focus shifts toward comprehensive PFAS management, this selectivity gap becomes increasingly problematic. Current data shows removal efficiencies dropping from >95% for long-chain compounds to <50% for many short-chain variants.

Regeneration difficulties represent perhaps the most significant economic and environmental barrier. Conventional thermal regeneration methods (700-900°C) are energy-intensive and can lead to incomplete PFAS destruction, potentially creating harmful byproducts. Chemical regeneration approaches using solvents or surfactants generate secondary waste streams requiring additional treatment. The incomplete recovery of adsorption capacity after regeneration (typically 70-85% of original capacity) necessitates periodic carbon replacement.

Scale-up challenges further complicate implementation, as laboratory performance often fails to translate directly to full-scale operations. Factors such as flow distribution, channeling, and fouling become more pronounced at larger scales, reducing treatment efficiency and increasing maintenance requirements. The variability in influent water quality across different sites demands customized design approaches, complicating standardization efforts.

These technical limitations collectively impact the economic viability and sustainability of activated carbon for PFAS treatment, driving research toward enhanced carbon formulations and hybrid treatment approaches to overcome these persistent challenges.

Competition from natural organic matter (NOM) and other contaminants in water matrices severely impacts PFAS adsorption performance. These competing substances can occupy adsorption sites, reducing the effective capacity for PFAS removal. Studies indicate that NOM can decrease PFAS adsorption by 30-70% depending on water characteristics, significantly diminishing treatment efficiency in real-world applications.

The adsorption kinetics present another substantial challenge. While activated carbon shows promising equilibrium capacities for many PFAS compounds, the rate of adsorption is often slow, particularly for short-chain PFAS. This necessitates longer contact times in treatment systems, reducing throughput and increasing operational costs. The mass transfer limitations within carbon pores create diffusion barriers that further slow the process.

Selectivity issues compound these challenges, as activated carbon exhibits preferential adsorption for long-chain PFAS over emerging short-chain alternatives. As regulatory focus shifts toward comprehensive PFAS management, this selectivity gap becomes increasingly problematic. Current data shows removal efficiencies dropping from >95% for long-chain compounds to <50% for many short-chain variants.

Regeneration difficulties represent perhaps the most significant economic and environmental barrier. Conventional thermal regeneration methods (700-900°C) are energy-intensive and can lead to incomplete PFAS destruction, potentially creating harmful byproducts. Chemical regeneration approaches using solvents or surfactants generate secondary waste streams requiring additional treatment. The incomplete recovery of adsorption capacity after regeneration (typically 70-85% of original capacity) necessitates periodic carbon replacement.

Scale-up challenges further complicate implementation, as laboratory performance often fails to translate directly to full-scale operations. Factors such as flow distribution, channeling, and fouling become more pronounced at larger scales, reducing treatment efficiency and increasing maintenance requirements. The variability in influent water quality across different sites demands customized design approaches, complicating standardization efforts.

These technical limitations collectively impact the economic viability and sustainability of activated carbon for PFAS treatment, driving research toward enhanced carbon formulations and hybrid treatment approaches to overcome these persistent challenges.

Current Activated Carbon Adsorption Methodologies

01 Selective adsorption mechanisms of activated carbon

Activated carbon exhibits selective adsorption properties based on pore size distribution, surface chemistry, and target contaminant characteristics. The selectivity can be enhanced through modification of surface functional groups or by controlling the activation process to create specific pore structures. This allows for preferential adsorption of certain compounds over others, making it effective for targeted pollutant removal in complex mixtures.- Selective adsorption mechanisms of activated carbon: Activated carbon exhibits selective adsorption properties based on pore size distribution, surface chemistry, and target contaminant characteristics. The selectivity can be enhanced through modification of surface functional groups or by controlling the activation process to create specific pore structures. These mechanisms allow activated carbon to preferentially adsorb certain compounds over others, making it effective for targeted removal of contaminants from gas or liquid streams.

- Thermal regeneration techniques for activated carbon: Thermal regeneration involves heating spent activated carbon to high temperatures (typically 600-900°C) to desorb and decompose adsorbed contaminants. This process can be conducted in rotary kilns, multiple hearth furnaces, or fluidized bed systems, often with controlled atmospheres to prevent carbon oxidation. Thermal methods effectively restore 90-95% of the original adsorption capacity while minimizing carbon loss, though they require significant energy input.

- Chemical and solvent-based regeneration methods: Chemical regeneration utilizes solvents, acids, bases, or oxidizing agents to extract or decompose adsorbed contaminants without removing the carbon from the treatment system. These methods operate at lower temperatures than thermal regeneration, reducing energy requirements and carbon attrition. Solvent extraction is particularly effective for recovering valuable adsorbed compounds, while chemical oxidation can decompose persistent organic contaminants. The choice of regenerant depends on the nature of the adsorbate and desired recovery objectives.

- Innovative regeneration systems and equipment: Advanced regeneration systems incorporate automated controls, energy recovery mechanisms, and continuous operation capabilities to improve efficiency and reduce operational costs. These systems may include in-situ regeneration capabilities that minimize handling of spent carbon, integrated heat recovery units that capture and reuse thermal energy, or combined approaches that sequence different regeneration methods. Novel equipment designs focus on optimizing contact between regenerants and carbon while minimizing carbon loss and environmental impacts.

- Factors affecting regeneration efficiency and carbon lifespan: Regeneration efficiency is influenced by multiple factors including the nature and concentration of adsorbates, regeneration conditions (temperature, time, chemical concentrations), carbon properties, and cumulative regeneration cycles. Each regeneration cycle typically results in some loss of adsorption capacity due to pore blockage, carbon attrition, or structural changes. Optimizing regeneration parameters based on specific applications can extend carbon lifespan and maintain selectivity across multiple use cycles, improving the economic and environmental sustainability of activated carbon systems.

02 Thermal regeneration techniques for activated carbon

Thermal regeneration involves heating spent activated carbon to high temperatures (typically 600-900°C) to desorb and decompose adsorbed contaminants. This process can be conducted in rotary kilns, multiple hearth furnaces, or fluidized bed systems, often under controlled atmospheres to prevent carbon oxidation. Thermal methods effectively restore 70-90% of the original adsorption capacity while minimizing carbon loss during regeneration.Expand Specific Solutions03 Chemical regeneration methods for activated carbon

Chemical regeneration utilizes solvents, acids, bases, or oxidizing agents to extract or decompose adsorbed contaminants without requiring high temperatures. Common reagents include sodium hydroxide, potassium hydroxide, acids, and organic solvents. This approach is particularly effective for recovering activated carbon used in water treatment applications and offers advantages in energy efficiency compared to thermal methods, though it may introduce secondary contamination concerns.Expand Specific Solutions04 Innovative activated carbon regeneration systems

Advanced regeneration systems incorporate novel technologies such as microwave heating, ultrasonic treatment, supercritical fluid extraction, and electrochemical processes. These innovations aim to improve regeneration efficiency, reduce energy consumption, and minimize carbon loss during the regeneration cycle. Some systems integrate multiple regeneration methods or employ continuous regeneration processes for industrial applications requiring sustained adsorption performance.Expand Specific Solutions05 Modified activated carbon for enhanced selectivity

Activated carbon can be modified through impregnation with metal ions, functional groups, or nanoparticles to enhance selectivity toward specific contaminants. Surface modifications can alter the hydrophobic/hydrophilic balance, introduce specific binding sites, or create catalytic properties. These modifications enable the development of specialized adsorbents for applications such as heavy metal removal, pharmaceutical compound adsorption, or selective gas separation, significantly improving performance over conventional activated carbon.Expand Specific Solutions

Leading Companies in PFAS Treatment Industry

The activated carbon adsorption market for PFAS/trace organics removal is in a growth phase, driven by increasing regulatory pressure and environmental concerns. The global market is expanding rapidly, with projections indicating significant growth as water treatment standards become more stringent worldwide. Technologically, the field is moderately mature but evolving, with companies like MeadWestvaco, Evoqua Water Technologies, and Desotec leading commercial applications. Research institutions such as Texas A&M University and Battelle Memorial Institute are advancing regeneration techniques and selectivity improvements. Emerging players like Puraffinity and Onvector are developing innovative approaches to address limitations in traditional activated carbon technologies. The competitive landscape features established industrial players alongside specialized environmental technology firms, with increasing focus on sustainable regeneration methods and enhanced selectivity for specific contaminants.

Evoqua Water Technologies LLC

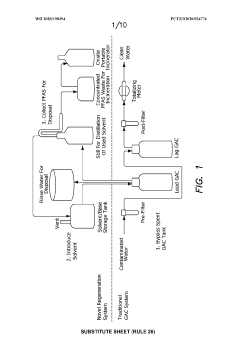

Technical Solution: Evoqua has developed advanced activated carbon solutions specifically engineered for PFAS removal, including their proprietary PFAS-optimized GAC (granular activated carbon) systems. Their technology employs specialized carbon materials with enhanced micropore structures that target the molecular size range of PFAS compounds. Evoqua's systems incorporate multi-stage treatment trains that combine different carbon types to address varying chain-length PFAS molecules. Their approach includes real-time monitoring systems that track breakthrough patterns to optimize carbon usage and replacement schedules. Evoqua has also pioneered mobile activated carbon systems that can be rapidly deployed for emergency PFAS contamination scenarios, with treatment capacities ranging from 10-1,000 gallons per minute depending on configuration.

Strengths: Industry-leading removal efficiency for short and long-chain PFAS compounds; extensive field implementation experience across municipal and industrial applications; comprehensive service network for carbon exchange and regeneration. Weaknesses: Higher initial capital costs compared to standard GAC systems; potential for competitive adsorption issues in complex water matrices; regeneration process can be energy-intensive.

Desotec NV

Technical Solution: Desotec has developed a mobile activated carbon filtration technology called MOBICON® specifically designed for PFAS/trace organics removal. Their system utilizes specially engineered activated carbon with optimized pore size distribution to target PFAS molecules effectively. The technology employs a series of mobile filter units that can be configured in lead-lag arrangements to ensure complete breakthrough protection. Desotec's approach incorporates real-time remote monitoring capabilities that track contaminant levels and predict carbon saturation points with proprietary algorithms. Their closed-loop system manages the entire carbon lifecycle, from initial installation through spent carbon removal and regeneration, achieving removal efficiencies exceeding 99% for most PFAS compounds. The company has also developed specialized pre-treatment protocols to address competing organic compounds that might reduce PFAS adsorption efficiency.

Strengths: Highly mobile and flexible deployment options; closed-loop carbon management system minimizes handling risks; advanced monitoring provides predictive maintenance capabilities. Weaknesses: May require more frequent carbon changeouts for waters with high organic loading; regeneration process has limitations for completely destroying adsorbed PFAS; higher operational costs for remote locations.

Key Patents in Selective PFAS Adsorption Technology

Systems and methods of regenerating activated carbon

PatentWO2020198394A1

Innovation

- A method and system for regenerating activated carbon contaminated with PFAS and PFOS using a solution comprising at least 50% alcohol and 0.2-0.5% base, allowing for on-site regeneration and reuse of the activated carbon, which maintains or improves its adsorption and desorption capabilities.

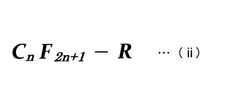

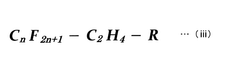

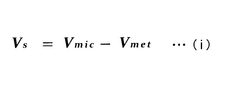

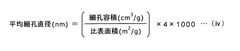

Per- and polyfluoroalkyl compound-adsorbing activated carbon

PatentWO2021033595A1

Innovation

- Development of a per- and polyfluoroalkyl compound-adsorbing activated carbon with a specific surface area of 900 m^2/g, featuring a combination of micropore and mesopore volumes that enhance adsorption and desorption capabilities, along with increased surface oxide amounts for improved chemical adsorption, utilizing fibrous or granular activated carbon with specific pore distributions and surface functional groups.

Environmental Regulations Impacting PFAS Treatment

The regulatory landscape governing PFAS (Per- and Polyfluoroalkyl Substances) treatment has evolved significantly in recent years, driving innovation in activated carbon adsorption technologies. At the federal level in the United States, the Environmental Protection Agency (EPA) has established health advisory levels for PFOA and PFOS at 70 parts per trillion (ppt), though these are non-enforceable guidelines rather than legally binding standards.

In 2022, the EPA proposed designating PFOA and PFOS as hazardous substances under CERCLA (Comprehensive Environmental Response, Compensation, and Liability Act), which would significantly impact remediation requirements and liability frameworks for contaminated sites. This regulatory shift has accelerated research into more efficient activated carbon formulations specifically designed for PFAS capture.

The Safe Drinking Water Act (SDWA) provides another regulatory mechanism through which the EPA is developing Maximum Contaminant Levels (MCLs) for certain PFAS compounds. Draft regulations proposed in 2023 would establish enforceable standards for six PFAS compounds, creating immediate compliance challenges for water utilities and driving demand for activated carbon treatment systems.

At the state level, regulatory frameworks vary considerably, with some states implementing much stricter standards than federal guidelines. For example, Michigan has established drinking water MCLs for seven PFAS compounds ranging from 6 ppt to 400,000 ppt, while California has notification levels as low as 5.1 ppt for PFOA. These stringent state-level regulations often serve as catalysts for technological advancement in activated carbon adsorption systems.

Internationally, the European Union's approach to PFAS regulation through REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) has focused on restricting the production and use of PFAS compounds. The EU's drinking water directive established a limit of 100 ng/L for the sum of 20 PFAS compounds, creating a different regulatory framework than the compound-by-compound approach common in the United States.

The Stockholm Convention on Persistent Organic Pollutants has also added several PFAS compounds to its list of restricted substances, creating global pressure for effective treatment technologies. This international regulatory pressure has spurred research into regeneration techniques for spent activated carbon, as sustainable treatment approaches become increasingly important for long-term compliance.

These evolving regulations have significant implications for activated carbon technology development, particularly regarding required removal efficiencies, monitoring protocols, and waste management practices. As regulatory thresholds continue to decrease, the selectivity of activated carbon for PFAS compounds in complex water matrices becomes increasingly critical for compliance.

In 2022, the EPA proposed designating PFOA and PFOS as hazardous substances under CERCLA (Comprehensive Environmental Response, Compensation, and Liability Act), which would significantly impact remediation requirements and liability frameworks for contaminated sites. This regulatory shift has accelerated research into more efficient activated carbon formulations specifically designed for PFAS capture.

The Safe Drinking Water Act (SDWA) provides another regulatory mechanism through which the EPA is developing Maximum Contaminant Levels (MCLs) for certain PFAS compounds. Draft regulations proposed in 2023 would establish enforceable standards for six PFAS compounds, creating immediate compliance challenges for water utilities and driving demand for activated carbon treatment systems.

At the state level, regulatory frameworks vary considerably, with some states implementing much stricter standards than federal guidelines. For example, Michigan has established drinking water MCLs for seven PFAS compounds ranging from 6 ppt to 400,000 ppt, while California has notification levels as low as 5.1 ppt for PFOA. These stringent state-level regulations often serve as catalysts for technological advancement in activated carbon adsorption systems.

Internationally, the European Union's approach to PFAS regulation through REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) has focused on restricting the production and use of PFAS compounds. The EU's drinking water directive established a limit of 100 ng/L for the sum of 20 PFAS compounds, creating a different regulatory framework than the compound-by-compound approach common in the United States.

The Stockholm Convention on Persistent Organic Pollutants has also added several PFAS compounds to its list of restricted substances, creating global pressure for effective treatment technologies. This international regulatory pressure has spurred research into regeneration techniques for spent activated carbon, as sustainable treatment approaches become increasingly important for long-term compliance.

These evolving regulations have significant implications for activated carbon technology development, particularly regarding required removal efficiencies, monitoring protocols, and waste management practices. As regulatory thresholds continue to decrease, the selectivity of activated carbon for PFAS compounds in complex water matrices becomes increasingly critical for compliance.

Cost-Benefit Analysis of PFAS Removal Technologies

The economic evaluation of PFAS removal technologies reveals that activated carbon adsorption presents a competitive cost-benefit profile compared to alternative treatment methods. Initial capital investments for activated carbon systems range from $0.5-2 million for medium-scale municipal applications, with operational costs averaging $0.20-0.60 per thousand gallons treated, positioning it favorably against membrane filtration and advanced oxidation processes.

Lifecycle cost analysis demonstrates that while activated carbon requires periodic media replacement, its overall 20-year cost projection remains 15-30% lower than ion exchange systems when considering equivalent PFAS removal efficiency. The regeneration potential of activated carbon further enhances its economic profile, potentially reducing replacement media costs by 40-60% when thermal regeneration facilities are accessible.

Treatment efficiency metrics indicate that activated carbon systems achieve 90-99% PFAS removal at a cost of $1.50-3.00 per pound of PFAS removed, with higher efficiency for long-chain PFAS compounds. This translates to approximately $0.001-0.003 per gallon for water meeting the EPA's proposed 4 parts per trillion regulatory threshold.

Environmental impact assessments reveal additional economic benefits through reduced carbon footprint compared to energy-intensive alternatives. Activated carbon systems generate approximately 0.3-0.5 kg CO2 equivalent per thousand gallons treated, compared to 0.8-1.2 kg for advanced oxidation processes, representing potential carbon credit savings in regulated markets.

Scalability analysis demonstrates favorable economics across different implementation scales. Small community systems (serving <10,000 people) face higher per-capita costs ($150-250 annually) compared to large municipal implementations ($30-80 per capita), but remain more economical than point-of-use filtration alternatives ($300-500 per household annually).

Risk assessment calculations incorporating potential liability costs from PFAS contamination suggest that proactive implementation of activated carbon treatment systems represents a 3:1 return on investment when considering potential litigation expenses, property value impacts, and public health costs associated with untreated PFAS exposure.

Sensitivity analysis indicates that activated carbon economics are most vulnerable to fluctuations in raw material costs and disposal regulations. A 20% increase in virgin carbon pricing translates to approximately 8-12% increase in overall treatment costs, highlighting the importance of developing domestic carbon production capacity and regeneration infrastructure to maintain favorable economics.

Lifecycle cost analysis demonstrates that while activated carbon requires periodic media replacement, its overall 20-year cost projection remains 15-30% lower than ion exchange systems when considering equivalent PFAS removal efficiency. The regeneration potential of activated carbon further enhances its economic profile, potentially reducing replacement media costs by 40-60% when thermal regeneration facilities are accessible.

Treatment efficiency metrics indicate that activated carbon systems achieve 90-99% PFAS removal at a cost of $1.50-3.00 per pound of PFAS removed, with higher efficiency for long-chain PFAS compounds. This translates to approximately $0.001-0.003 per gallon for water meeting the EPA's proposed 4 parts per trillion regulatory threshold.

Environmental impact assessments reveal additional economic benefits through reduced carbon footprint compared to energy-intensive alternatives. Activated carbon systems generate approximately 0.3-0.5 kg CO2 equivalent per thousand gallons treated, compared to 0.8-1.2 kg for advanced oxidation processes, representing potential carbon credit savings in regulated markets.

Scalability analysis demonstrates favorable economics across different implementation scales. Small community systems (serving <10,000 people) face higher per-capita costs ($150-250 annually) compared to large municipal implementations ($30-80 per capita), but remain more economical than point-of-use filtration alternatives ($300-500 per household annually).

Risk assessment calculations incorporating potential liability costs from PFAS contamination suggest that proactive implementation of activated carbon treatment systems represents a 3:1 return on investment when considering potential litigation expenses, property value impacts, and public health costs associated with untreated PFAS exposure.

Sensitivity analysis indicates that activated carbon economics are most vulnerable to fluctuations in raw material costs and disposal regulations. A 20% increase in virgin carbon pricing translates to approximately 8-12% increase in overall treatment costs, highlighting the importance of developing domestic carbon production capacity and regeneration infrastructure to maintain favorable economics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!