Activated Carbon Adsorption: Pore Size Distribution, Micropore/Mesopore Balance And Kinetics

SEP 17, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Activated Carbon Adsorption Background and Objectives

Activated carbon adsorption technology has evolved significantly since its initial applications in water purification during the early 20th century. The journey began with rudimentary charcoal filters and has progressed to highly engineered adsorbent materials with precisely controlled pore structures. This evolution has been driven by increasing demands for more efficient contaminant removal across various industries including water treatment, air purification, food processing, and pharmaceutical manufacturing.

The fundamental principle underlying activated carbon's effectiveness lies in its unique porous structure, which provides an extensive internal surface area—typically ranging from 500 to 3000 m²/g—capable of capturing and retaining a wide spectrum of organic and inorganic compounds through physical adsorption mechanisms. Recent decades have witnessed substantial advancements in understanding the critical relationship between carbon's pore architecture and its adsorption performance.

Research has increasingly focused on the strategic engineering of pore size distributions to optimize adsorption capacity and kinetics for specific target compounds. The scientific community now recognizes that micropores (<2 nm) primarily contribute to adsorption capacity through strong binding energies, while mesopores (2-50 nm) facilitate rapid mass transfer and accessibility to the internal pore network. This balance between micropores and mesopores has emerged as a central consideration in activated carbon design.

The technological trajectory has shifted from merely maximizing surface area to precisely tailoring pore architectures for specific applications. Modern activation techniques—including physical activation with steam or CO₂ and chemical activation using agents like phosphoric acid, zinc chloride, or potassium hydroxide—now enable unprecedented control over the resulting pore structure characteristics.

Current research objectives in this field center on developing a comprehensive understanding of the complex relationships between pore size distribution, adsorption kinetics, and removal efficiency for various contaminants. Particular emphasis is being placed on elucidating the optimal micropore/mesopore balance for different target molecules based on their size, polarity, and concentration levels.

The ultimate goal is to establish predictive models that can guide the rational design of next-generation activated carbons with application-specific pore architectures. These models aim to correlate molecular properties of adsorbates with optimal pore size distributions, enabling the development of highly selective adsorbents that maximize both adsorption capacity and kinetics while minimizing energy consumption during regeneration processes.

Additionally, researchers are exploring novel precursor materials and activation methods to enhance sustainability and cost-effectiveness, with particular interest in biomass-derived activated carbons that offer renewable alternatives to traditional coal-based products while potentially providing unique pore characteristics beneficial for specific applications.

The fundamental principle underlying activated carbon's effectiveness lies in its unique porous structure, which provides an extensive internal surface area—typically ranging from 500 to 3000 m²/g—capable of capturing and retaining a wide spectrum of organic and inorganic compounds through physical adsorption mechanisms. Recent decades have witnessed substantial advancements in understanding the critical relationship between carbon's pore architecture and its adsorption performance.

Research has increasingly focused on the strategic engineering of pore size distributions to optimize adsorption capacity and kinetics for specific target compounds. The scientific community now recognizes that micropores (<2 nm) primarily contribute to adsorption capacity through strong binding energies, while mesopores (2-50 nm) facilitate rapid mass transfer and accessibility to the internal pore network. This balance between micropores and mesopores has emerged as a central consideration in activated carbon design.

The technological trajectory has shifted from merely maximizing surface area to precisely tailoring pore architectures for specific applications. Modern activation techniques—including physical activation with steam or CO₂ and chemical activation using agents like phosphoric acid, zinc chloride, or potassium hydroxide—now enable unprecedented control over the resulting pore structure characteristics.

Current research objectives in this field center on developing a comprehensive understanding of the complex relationships between pore size distribution, adsorption kinetics, and removal efficiency for various contaminants. Particular emphasis is being placed on elucidating the optimal micropore/mesopore balance for different target molecules based on their size, polarity, and concentration levels.

The ultimate goal is to establish predictive models that can guide the rational design of next-generation activated carbons with application-specific pore architectures. These models aim to correlate molecular properties of adsorbates with optimal pore size distributions, enabling the development of highly selective adsorbents that maximize both adsorption capacity and kinetics while minimizing energy consumption during regeneration processes.

Additionally, researchers are exploring novel precursor materials and activation methods to enhance sustainability and cost-effectiveness, with particular interest in biomass-derived activated carbons that offer renewable alternatives to traditional coal-based products while potentially providing unique pore characteristics beneficial for specific applications.

Market Demand Analysis for Optimized Activated Carbon

The global activated carbon market has witnessed substantial growth, valued at approximately 3.4 billion USD in 2022 and projected to reach 5.8 billion USD by 2030, with a compound annual growth rate of 6.9%. This growth is primarily driven by increasing environmental regulations across industries and rising awareness about water and air purification needs.

Water treatment represents the largest application segment, accounting for nearly 40% of the market share. Municipal water treatment facilities are increasingly adopting activated carbon systems with optimized pore distributions to meet stringent regulatory standards for contaminant removal. The demand for micropore-dominant activated carbon is particularly strong in this sector due to its effectiveness in removing low molecular weight organic compounds and disinfection byproducts.

Air purification applications have shown the fastest growth rate at 8.2% annually, fueled by deteriorating air quality in urban areas and stricter emission control regulations in industrial settings. This segment specifically requires activated carbons with balanced micropore-mesopore distributions to effectively capture both small gas molecules and larger particulate contaminants.

The pharmaceutical and food & beverage industries are emerging as significant consumers of specialized activated carbon products. These sectors demand precisely engineered pore size distributions to achieve selective adsorption of specific molecules while maintaining production efficiency. The premium price these industries are willing to pay for customized solutions has attracted numerous manufacturers to develop tailored products.

Regional analysis indicates that Asia-Pacific dominates the market with a 45% share, led by China and India's rapid industrialization and environmental remediation efforts. North America and Europe follow with 25% and 20% market shares respectively, where the focus is increasingly on advanced activated carbon products with optimized kinetics for specialized applications.

Consumer preferences are shifting toward activated carbon products with faster adsorption kinetics and higher capacity, even at premium pricing. This trend is particularly evident in point-of-use water treatment systems and air purifiers for residential applications, where performance metrics like breakthrough time and total adsorption capacity directly influence purchasing decisions.

Market research indicates that products featuring balanced micropore-mesopore distributions command price premiums of 15-30% over conventional activated carbons, reflecting their superior performance characteristics and the technical complexity involved in their production. This price differential has motivated significant R&D investments from major industry players seeking to optimize pore architecture for specific target contaminants.

Water treatment represents the largest application segment, accounting for nearly 40% of the market share. Municipal water treatment facilities are increasingly adopting activated carbon systems with optimized pore distributions to meet stringent regulatory standards for contaminant removal. The demand for micropore-dominant activated carbon is particularly strong in this sector due to its effectiveness in removing low molecular weight organic compounds and disinfection byproducts.

Air purification applications have shown the fastest growth rate at 8.2% annually, fueled by deteriorating air quality in urban areas and stricter emission control regulations in industrial settings. This segment specifically requires activated carbons with balanced micropore-mesopore distributions to effectively capture both small gas molecules and larger particulate contaminants.

The pharmaceutical and food & beverage industries are emerging as significant consumers of specialized activated carbon products. These sectors demand precisely engineered pore size distributions to achieve selective adsorption of specific molecules while maintaining production efficiency. The premium price these industries are willing to pay for customized solutions has attracted numerous manufacturers to develop tailored products.

Regional analysis indicates that Asia-Pacific dominates the market with a 45% share, led by China and India's rapid industrialization and environmental remediation efforts. North America and Europe follow with 25% and 20% market shares respectively, where the focus is increasingly on advanced activated carbon products with optimized kinetics for specialized applications.

Consumer preferences are shifting toward activated carbon products with faster adsorption kinetics and higher capacity, even at premium pricing. This trend is particularly evident in point-of-use water treatment systems and air purifiers for residential applications, where performance metrics like breakthrough time and total adsorption capacity directly influence purchasing decisions.

Market research indicates that products featuring balanced micropore-mesopore distributions command price premiums of 15-30% over conventional activated carbons, reflecting their superior performance characteristics and the technical complexity involved in their production. This price differential has motivated significant R&D investments from major industry players seeking to optimize pore architecture for specific target contaminants.

Current Challenges in Pore Size Distribution Engineering

Despite significant advancements in activated carbon technology, engineering precise pore size distributions remains one of the most challenging aspects in the field. The fundamental challenge stems from the inherent complexity of controlling carbon structure formation during activation processes. Traditional activation methods, whether physical or chemical, often produce heterogeneous pore structures with limited control over specific pore size ranges, particularly in achieving optimal micropore/mesopore balance.

Manufacturing consistency presents a major hurdle, as slight variations in precursor materials, activation temperature, or residence time can dramatically alter the resulting pore architecture. Even with standardized protocols, batch-to-batch variations in pore size distributions can reach 10-15%, significantly affecting adsorption performance in critical applications like water purification or gas separation.

The micropore/mesopore balance optimization represents another significant challenge. While micropores (<2 nm) provide high surface area for adsorption capacity, mesopores (2-50 nm) facilitate mass transport kinetics. Current technologies struggle to simultaneously maximize both features without compromising either aspect. This trade-off becomes particularly problematic in applications requiring both high capacity and rapid kinetics, such as in emergency response filtration systems or industrial-scale gas purification.

Characterization limitations further complicate development efforts. Current analytical techniques like nitrogen adsorption and mercury porosimetry provide incomplete pictures of the actual pore network structure. These methods often fail to accurately represent interconnected pore networks or detect closed pores, leading to discrepancies between predicted and actual adsorption performance.

Computational modeling of pore size engineering remains underdeveloped compared to experimental approaches. While molecular dynamics and Monte Carlo simulations offer insights into adsorption mechanisms, they typically simplify pore geometries and cannot fully account for the complex, heterogeneous nature of activated carbon structures. This gap between theoretical models and practical outcomes hinders predictive capabilities for rational design.

Cost-effective scaling presents additional challenges. Laboratory-scale methods that achieve precise pore size distributions often employ expensive templates or multi-step activation procedures that become economically prohibitive at industrial scales. The industry continues to seek economically viable approaches that can maintain precise pore engineering at commercial production volumes.

Environmental considerations add another layer of complexity, as traditional activation processes can generate significant waste streams and consume substantial energy. Developing greener approaches to pore engineering that minimize environmental impact while maintaining performance specifications represents an ongoing challenge for researchers and manufacturers alike.

Manufacturing consistency presents a major hurdle, as slight variations in precursor materials, activation temperature, or residence time can dramatically alter the resulting pore architecture. Even with standardized protocols, batch-to-batch variations in pore size distributions can reach 10-15%, significantly affecting adsorption performance in critical applications like water purification or gas separation.

The micropore/mesopore balance optimization represents another significant challenge. While micropores (<2 nm) provide high surface area for adsorption capacity, mesopores (2-50 nm) facilitate mass transport kinetics. Current technologies struggle to simultaneously maximize both features without compromising either aspect. This trade-off becomes particularly problematic in applications requiring both high capacity and rapid kinetics, such as in emergency response filtration systems or industrial-scale gas purification.

Characterization limitations further complicate development efforts. Current analytical techniques like nitrogen adsorption and mercury porosimetry provide incomplete pictures of the actual pore network structure. These methods often fail to accurately represent interconnected pore networks or detect closed pores, leading to discrepancies between predicted and actual adsorption performance.

Computational modeling of pore size engineering remains underdeveloped compared to experimental approaches. While molecular dynamics and Monte Carlo simulations offer insights into adsorption mechanisms, they typically simplify pore geometries and cannot fully account for the complex, heterogeneous nature of activated carbon structures. This gap between theoretical models and practical outcomes hinders predictive capabilities for rational design.

Cost-effective scaling presents additional challenges. Laboratory-scale methods that achieve precise pore size distributions often employ expensive templates or multi-step activation procedures that become economically prohibitive at industrial scales. The industry continues to seek economically viable approaches that can maintain precise pore engineering at commercial production volumes.

Environmental considerations add another layer of complexity, as traditional activation processes can generate significant waste streams and consume substantial energy. Developing greener approaches to pore engineering that minimize environmental impact while maintaining performance specifications represents an ongoing challenge for researchers and manufacturers alike.

Current Methodologies for Micropore/Mesopore Balance Optimization

01 Micropore and mesopore distribution optimization for specific applications

The balance between micropores and mesopores in activated carbon can be optimized for specific applications. Different applications require different pore size distributions. For example, some applications benefit from a higher proportion of micropores for molecular sieving, while others require more mesopores for adsorption of larger molecules. The distribution can be controlled during the manufacturing process through selection of raw materials and activation conditions.- Optimal micropore/mesopore ratio for specific applications: The balance between micropores (<2 nm) and mesopores (2-50 nm) in activated carbon significantly affects its performance in various applications. Different applications require specific micropore/mesopore ratios to achieve optimal results. For gas storage and small molecule adsorption, a higher micropore volume is preferred, while for larger molecule adsorption and liquid phase applications, a balanced distribution with sufficient mesopores improves diffusion kinetics and overall performance.

- Manufacturing methods to control pore size distribution: Various manufacturing techniques can be employed to control the pore size distribution in activated carbon. These include selection of raw materials, activation methods (physical or chemical), activation temperature, activation time, and post-treatment processes. Chemical activation using agents like KOH, ZnCl2, or H3PO4 can create different pore structures, while physical activation with steam or CO2 can be controlled to develop specific pore size distributions. The activation temperature and duration significantly influence the micropore/mesopore balance.

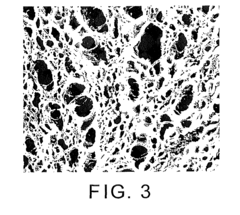

- Hierarchical pore structure development: Developing hierarchical pore structures in activated carbon involves creating an interconnected network of micropores, mesopores, and macropores. This hierarchical structure enhances mass transfer efficiency and accessibility to the internal surface area. Techniques such as templating, dual activation processes, and controlled carbonization can be used to create these hierarchical structures. The synergistic effect of different pore sizes improves the overall performance of activated carbon in applications requiring both high capacity and fast kinetics.

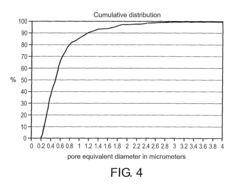

- Characterization techniques for pore size distribution: Various analytical methods are used to characterize the pore size distribution in activated carbon. Nitrogen adsorption at 77K with BET analysis is commonly used to determine surface area and pore volume. The t-plot method helps distinguish between micropores and mesopores, while BJH analysis provides information about mesopore distribution. Mercury porosimetry is useful for larger pores, and small-angle X-ray scattering (SAXS) can provide complementary information. Advanced techniques like density functional theory (DFT) offer more accurate pore size distribution analysis.

- Application-specific pore size optimization: Optimizing the micropore/mesopore balance for specific applications is crucial for maximizing activated carbon performance. For supercapacitors, a balance favoring mesopores improves electrolyte accessibility while maintaining high surface area. In water treatment, a combination of micropores for small contaminant removal and mesopores for larger organic compounds is ideal. For gas separation and storage, tailored micropore distributions enhance selectivity and capacity. Medical and pharmaceutical applications often require specific pore size distributions to control drug loading and release kinetics.

02 Manufacturing methods to control pore size distribution

Various manufacturing methods can be employed to control the pore size distribution in activated carbon. These include chemical activation using agents like phosphoric acid, zinc chloride, or potassium hydroxide, physical activation with steam or carbon dioxide, and combinations of both. The activation temperature, time, and agent concentration significantly influence the resulting micropore/mesopore balance. Post-treatment methods such as acid washing or heat treatment can further modify the pore structure.Expand Specific Solutions03 Characterization techniques for pore size distribution analysis

Several analytical techniques are used to characterize the pore size distribution in activated carbon. Nitrogen adsorption at 77K with BET (Brunauer-Emmett-Teller) analysis is commonly used to determine surface area and pore volume. The t-plot method helps distinguish between micropores and mesopores. Mercury porosimetry is useful for larger pores, while small-angle X-ray scattering (SAXS) provides information about pore shapes. Gas adsorption isotherms analyzed by methods such as DFT (Density Functional Theory) offer detailed pore size distribution data.Expand Specific Solutions04 Hierarchical pore structures with controlled micropore/mesopore ratios

Hierarchical pore structures in activated carbon feature an optimized combination of micropores, mesopores, and sometimes macropores. These structures provide both high adsorption capacity from micropores and efficient mass transport through larger pores. Creating such hierarchical structures often involves templating methods, dual activation processes, or the use of specific precursors. The synergistic effect of different pore sizes enhances overall performance in applications like supercapacitors, catalysis, and environmental remediation.Expand Specific Solutions05 Impact of raw materials on micropore/mesopore balance

The choice of raw materials significantly influences the micropore/mesopore balance in activated carbon. Biomass-derived carbons from materials like coconut shells typically yield high micropore volumes, while wood-based carbons tend to develop more mesopores. Coal-based activated carbons can be tailored to have various pore distributions depending on the coal type and activation process. Novel precursors such as polymers, resins, and metal-organic frameworks allow for precise control over the resulting pore architecture.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Carbon Adsorption

Activated carbon adsorption technology is currently in a mature growth phase, with the global market valued at approximately $3.5 billion and projected to expand at a CAGR of 8-10% through 2028. The competitive landscape features established players like Kuraray, BLÜCHER GmbH, and Osaka Gas Chemicals leading innovation in micropore/mesopore distribution optimization, while companies such as BASF and Sinopec leverage their scale for mass production. Academic-industrial collaborations are accelerating, with institutions like Dalian University of Technology and Southeast University partnering with Toyota and Sony to develop next-generation carbons with tailored pore architectures. The technology maturity varies by application, with water treatment applications being most advanced, while specialized applications in energy storage and carbon capture (as pursued by Climeworks) represent emerging growth segments.

BLÜCHER GmbH

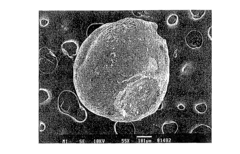

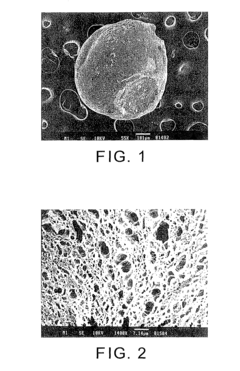

Technical Solution: BLÜCHER GmbH has developed a proprietary spherical activated carbon technology with precisely controlled pore size distribution. Their SARATECH® activated carbon products feature a bimodal pore structure with optimized micropore/mesopore balance, achieving up to 1400 m²/g surface area. The company employs a unique polymer-based manufacturing process that allows for tailored pore architecture, with micropores (<2 nm) for high adsorption capacity and mesopores (2-50 nm) for enhanced diffusion kinetics. Their spherical particles exhibit uniform size distribution (0.3-1.2 mm) and high mechanical stability, enabling rapid adsorption kinetics due to short diffusion pathways. BLÜCHER's technology incorporates post-activation treatments to modify surface chemistry for selective adsorption of specific contaminants, particularly excelling in removing organic micropollutants from water and air purification applications[1][3].

Strengths: Precise control over pore size distribution enables application-specific optimization; spherical shape provides superior kinetics and reduced pressure drop in fixed beds. Weaknesses: Higher production costs compared to conventional coal or coconut-based carbons; specialized manufacturing process may limit production scalability for mass-market applications.

Kuraray Co., Ltd.

Technical Solution: Kuraray has pioneered the development of activated carbon with controlled pore structure through their patented KURARAY COAL technology. Their approach utilizes phenolic resin precursors to create activated carbon with precisely engineered micropore/mesopore ratios. The company's manufacturing process involves a two-stage activation method that first creates a microporous structure (pores <2 nm) through controlled carbonization at 400-700°C, followed by selective mesopore (2-50 nm) development using steam or CO2 activation at 700-900°C. This results in activated carbon with surface areas exceeding 1500 m²/g and tailored pore volume distributions. Kuraray's products feature a unique "ink-bottle" pore structure that enhances adsorption capacity while maintaining favorable kinetics. Their GG series specifically targets applications requiring rapid adsorption kinetics with a mesopore volume of 0.3-0.5 cm³/g complementing micropore volumes of 0.6-0.8 cm³/g. The company has also developed proprietary surface modification techniques to enhance selectivity for specific adsorbates[2][5].

Strengths: Exceptional control over pore architecture allows customization for specific applications; synthetic precursor ensures consistent quality and reduced impurities compared to natural raw materials. Weaknesses: Higher production costs than conventional activated carbons; energy-intensive manufacturing process contributes to larger carbon footprint compared to some bio-based alternatives.

Key Adsorption Kinetics Mechanisms and Mathematical Models

Carbon beads with multimodal pore size distribution

PatentActiveUS8227376B2

Innovation

- A multi-modal pore distribution activated carbon is formed by combining multiple carbonizable precursors or carbon structures, such as nanotubes, to create a composite with varying pore sizes, allowing for enhanced adsorption kinetics and capacity through a tailored distribution of larger and smaller pores, which can be achieved through a process involving carbonization and activation of a composite precursor mixture.

Environmental Applications and Sustainability Considerations

Activated carbon adsorption technology has emerged as a cornerstone in environmental remediation efforts, with applications spanning water purification, air quality management, and industrial waste treatment. The unique pore structure characteristics of activated carbon—particularly the distribution between micropores and mesopores—directly influence its effectiveness in removing various environmental contaminants.

In water treatment applications, activated carbon with optimized micropore/mesopore balance demonstrates exceptional capacity for removing organic pollutants, pharmaceutical residues, and disinfection byproducts. Municipal water treatment facilities increasingly rely on granular activated carbon (GAC) systems, where the kinetics of adsorption determine contact time requirements and overall system efficiency. Recent implementations in developing regions have shown that locally-produced activated carbons with tailored pore distributions can provide cost-effective solutions for addressing region-specific water contamination issues.

Air quality management represents another critical environmental application, where activated carbon filters with balanced pore structures effectively capture volatile organic compounds (VOCs), odorous gases, and airborne particulates. The kinetics of gas-phase adsorption are particularly sensitive to pore size distribution, with micropores providing high adsorption capacity for small molecules while mesopores facilitate rapid diffusion and accessibility to adsorption sites.

From a sustainability perspective, the production and regeneration of activated carbon present both challenges and opportunities. Traditional activation processes are energy-intensive, with significant carbon footprints. However, recent innovations in low-temperature activation techniques and the utilization of renewable precursors (agricultural wastes, biomass residues) have substantially improved the environmental profile of activated carbon production. Life cycle assessments indicate that optimizing pore structure during manufacturing can reduce energy requirements by 15-30%, while simultaneously enhancing adsorption performance.

The regeneration and reuse of spent activated carbon represent critical sustainability considerations. Thermal regeneration processes, while effective at restoring adsorption capacity, consume significant energy and may result in partial pore structure collapse. Advanced regeneration techniques utilizing supercritical fluids and microwave-assisted processes show promise in preserving the delicate micropore/mesopore balance while reducing energy consumption by up to 40% compared to conventional methods.

Circular economy principles are increasingly being applied to activated carbon applications, with spent materials finding secondary uses in soil amendment, construction materials, and energy storage applications. This cascade utilization approach maximizes the environmental benefits of the initial carbon investment and reduces overall waste generation, making activated carbon adsorption technology increasingly aligned with sustainable development goals.

In water treatment applications, activated carbon with optimized micropore/mesopore balance demonstrates exceptional capacity for removing organic pollutants, pharmaceutical residues, and disinfection byproducts. Municipal water treatment facilities increasingly rely on granular activated carbon (GAC) systems, where the kinetics of adsorption determine contact time requirements and overall system efficiency. Recent implementations in developing regions have shown that locally-produced activated carbons with tailored pore distributions can provide cost-effective solutions for addressing region-specific water contamination issues.

Air quality management represents another critical environmental application, where activated carbon filters with balanced pore structures effectively capture volatile organic compounds (VOCs), odorous gases, and airborne particulates. The kinetics of gas-phase adsorption are particularly sensitive to pore size distribution, with micropores providing high adsorption capacity for small molecules while mesopores facilitate rapid diffusion and accessibility to adsorption sites.

From a sustainability perspective, the production and regeneration of activated carbon present both challenges and opportunities. Traditional activation processes are energy-intensive, with significant carbon footprints. However, recent innovations in low-temperature activation techniques and the utilization of renewable precursors (agricultural wastes, biomass residues) have substantially improved the environmental profile of activated carbon production. Life cycle assessments indicate that optimizing pore structure during manufacturing can reduce energy requirements by 15-30%, while simultaneously enhancing adsorption performance.

The regeneration and reuse of spent activated carbon represent critical sustainability considerations. Thermal regeneration processes, while effective at restoring adsorption capacity, consume significant energy and may result in partial pore structure collapse. Advanced regeneration techniques utilizing supercritical fluids and microwave-assisted processes show promise in preserving the delicate micropore/mesopore balance while reducing energy consumption by up to 40% compared to conventional methods.

Circular economy principles are increasingly being applied to activated carbon applications, with spent materials finding secondary uses in soil amendment, construction materials, and energy storage applications. This cascade utilization approach maximizes the environmental benefits of the initial carbon investment and reduces overall waste generation, making activated carbon adsorption technology increasingly aligned with sustainable development goals.

Characterization Techniques for Pore Structure Analysis

The comprehensive analysis of activated carbon's pore structure requires sophisticated characterization techniques that can accurately measure pore size distribution and differentiate between micropores (<2 nm), mesopores (2-50 nm), and macropores (>50 nm). These measurements are fundamental to understanding adsorption kinetics and capacity.

Gas adsorption techniques represent the gold standard for pore structure characterization. Nitrogen adsorption at 77K is widely employed for determining surface area and pore size distribution using models such as BET (Brunauer-Emmett-Teller) for surface area and BJH (Barrett-Joyner-Halenda) for mesopore analysis. For micropore characterization, CO2 adsorption at 273K offers superior resolution due to enhanced diffusion kinetics in narrow pores.

Mercury intrusion porosimetry (MIP) complements gas adsorption by measuring larger mesopores and macropores. This technique applies increasing pressure to force mercury into progressively smaller pores, providing valuable data on pore volume distribution in the range of 3 nm to 300 μm.

Small-angle X-ray scattering (SAXS) and small-angle neutron scattering (SANS) offer non-destructive alternatives that can probe pore structures across multiple length scales. These techniques analyze scattering patterns from porous materials to derive information about pore size, shape, and spatial distribution without requiring assumptions about pore geometry.

Advanced microscopy techniques have revolutionized direct visualization of pore structures. Scanning electron microscopy (SEM) provides surface morphology information, while transmission electron microscopy (TEM) can visualize internal pore networks at nanometer resolution. The emerging technique of 3D tomography combines multiple 2D images to reconstruct complete three-dimensional pore networks.

Nuclear magnetic resonance (NMR) cryoporometry utilizes the melting point depression of confined liquids to determine pore size distributions. This technique is particularly valuable for studying the connectivity and tortuosity of pore networks, which significantly influence adsorption kinetics.

Recent advances include the development of hybrid characterization approaches that combine multiple techniques to overcome individual limitations. For instance, combining gas adsorption with in-situ spectroscopic methods allows researchers to simultaneously monitor both structural and chemical aspects of the adsorption process, providing deeper insights into the relationship between pore structure and adsorption performance.

The selection of appropriate characterization techniques must consider the specific properties of the activated carbon being studied and the intended application. For kinetics studies, techniques that can provide information about pore connectivity and diffusion pathways are particularly valuable.

Gas adsorption techniques represent the gold standard for pore structure characterization. Nitrogen adsorption at 77K is widely employed for determining surface area and pore size distribution using models such as BET (Brunauer-Emmett-Teller) for surface area and BJH (Barrett-Joyner-Halenda) for mesopore analysis. For micropore characterization, CO2 adsorption at 273K offers superior resolution due to enhanced diffusion kinetics in narrow pores.

Mercury intrusion porosimetry (MIP) complements gas adsorption by measuring larger mesopores and macropores. This technique applies increasing pressure to force mercury into progressively smaller pores, providing valuable data on pore volume distribution in the range of 3 nm to 300 μm.

Small-angle X-ray scattering (SAXS) and small-angle neutron scattering (SANS) offer non-destructive alternatives that can probe pore structures across multiple length scales. These techniques analyze scattering patterns from porous materials to derive information about pore size, shape, and spatial distribution without requiring assumptions about pore geometry.

Advanced microscopy techniques have revolutionized direct visualization of pore structures. Scanning electron microscopy (SEM) provides surface morphology information, while transmission electron microscopy (TEM) can visualize internal pore networks at nanometer resolution. The emerging technique of 3D tomography combines multiple 2D images to reconstruct complete three-dimensional pore networks.

Nuclear magnetic resonance (NMR) cryoporometry utilizes the melting point depression of confined liquids to determine pore size distributions. This technique is particularly valuable for studying the connectivity and tortuosity of pore networks, which significantly influence adsorption kinetics.

Recent advances include the development of hybrid characterization approaches that combine multiple techniques to overcome individual limitations. For instance, combining gas adsorption with in-situ spectroscopic methods allows researchers to simultaneously monitor both structural and chemical aspects of the adsorption process, providing deeper insights into the relationship between pore structure and adsorption performance.

The selection of appropriate characterization techniques must consider the specific properties of the activated carbon being studied and the intended application. For kinetics studies, techniques that can provide information about pore connectivity and diffusion pathways are particularly valuable.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!