Ambient-cure geopolymer concretes: how to achieve high early strength

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geopolymer Concrete Development and Strength Objectives

Geopolymer concrete represents a revolutionary alternative to traditional Portland cement concrete, offering significant environmental benefits through reduced CO2 emissions. The development of geopolymer technology has evolved considerably since its conceptualization by Joseph Davidovits in the 1970s, with research intensifying over the past two decades as sustainability concerns have grown in the construction industry. The fundamental chemistry involves the activation of aluminosilicate materials through alkaline solutions, creating three-dimensional polymeric networks with excellent binding properties.

Current technological trajectories indicate a shift toward ambient-curing systems that eliminate the need for heat curing, which has been a significant barrier to widespread adoption. This evolution aims to make geopolymer concrete more practical for in-situ applications while maintaining performance advantages. The primary technical objective is to achieve high early strength development under ambient curing conditions, comparable to or exceeding that of ordinary Portland cement concrete.

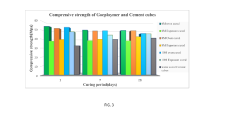

Specifically, the strength targets for ambient-cure geopolymer concrete include reaching compressive strengths of 20 MPa within 24 hours and 40 MPa at 28 days without thermal activation. These benchmarks are essential for making the technology viable for commercial construction applications, particularly in precast elements and structural components where early formwork removal and rapid construction sequences are economically advantageous.

The technical evolution has progressed through several distinct phases: initial laboratory proof-of-concept, optimization of mix designs, development of activator systems, and now the refinement of ambient-curing methodologies. Each phase has contributed critical knowledge toward understanding the complex reaction mechanisms and performance parameters that influence strength development.

Key technical challenges being addressed include the slow polymerization rates at ambient temperatures, variability in raw material characteristics, and the need for consistent quality control protocols. Research is increasingly focused on chemical accelerators, alternative activator formulations, and hybrid binder systems that can catalyze reaction kinetics without external heat input.

The ultimate goal extends beyond merely achieving high early strength to developing a comprehensive technology package that addresses workability, durability, and long-term performance while maintaining the sustainability advantages inherent to geopolymer systems. This includes standardization efforts to facilitate industry adoption and regulatory acceptance, as well as life-cycle assessments to quantify environmental benefits compared to conventional concrete technologies.

Current technological trajectories indicate a shift toward ambient-curing systems that eliminate the need for heat curing, which has been a significant barrier to widespread adoption. This evolution aims to make geopolymer concrete more practical for in-situ applications while maintaining performance advantages. The primary technical objective is to achieve high early strength development under ambient curing conditions, comparable to or exceeding that of ordinary Portland cement concrete.

Specifically, the strength targets for ambient-cure geopolymer concrete include reaching compressive strengths of 20 MPa within 24 hours and 40 MPa at 28 days without thermal activation. These benchmarks are essential for making the technology viable for commercial construction applications, particularly in precast elements and structural components where early formwork removal and rapid construction sequences are economically advantageous.

The technical evolution has progressed through several distinct phases: initial laboratory proof-of-concept, optimization of mix designs, development of activator systems, and now the refinement of ambient-curing methodologies. Each phase has contributed critical knowledge toward understanding the complex reaction mechanisms and performance parameters that influence strength development.

Key technical challenges being addressed include the slow polymerization rates at ambient temperatures, variability in raw material characteristics, and the need for consistent quality control protocols. Research is increasingly focused on chemical accelerators, alternative activator formulations, and hybrid binder systems that can catalyze reaction kinetics without external heat input.

The ultimate goal extends beyond merely achieving high early strength to developing a comprehensive technology package that addresses workability, durability, and long-term performance while maintaining the sustainability advantages inherent to geopolymer systems. This includes standardization efforts to facilitate industry adoption and regulatory acceptance, as well as life-cycle assessments to quantify environmental benefits compared to conventional concrete technologies.

Market Analysis for Rapid-Setting Sustainable Concrete

The rapid-setting sustainable concrete market is experiencing significant growth driven by increasing infrastructure development and the construction industry's shift towards environmentally friendly materials. The global market for sustainable concrete solutions was valued at approximately $26.2 billion in 2022 and is projected to reach $41.8 billion by 2028, growing at a CAGR of 8.1%. Within this segment, rapid-setting sustainable concrete products are emerging as a particularly dynamic sector due to their dual benefits of environmental sustainability and construction efficiency.

Demand for ambient-cure geopolymer concretes with high early strength capabilities is especially pronounced in urban infrastructure projects where minimizing traffic disruption is critical. Transportation departments and municipal authorities represent the largest customer segment, accounting for nearly 38% of market demand. These entities prioritize materials that enable rapid road repairs, bridge rehabilitation, and runway maintenance with minimal closure times.

Commercial construction represents the second-largest market segment at 27%, where time-sensitive projects benefit from reduced formwork striking times and accelerated construction schedules. The residential construction sector, while smaller at 18% of market share, is showing the fastest growth rate at 9.7% annually as developers increasingly recognize the economic benefits of faster project completion.

Regionally, North America and Europe currently dominate the market with combined 58% market share, primarily due to stringent environmental regulations and well-established green building certification systems. However, the Asia-Pacific region is projected to witness the highest growth rate of 11.3% through 2028, driven by massive infrastructure investments in China, India, and Southeast Asian countries.

Market analysis reveals several key demand drivers: increasing carbon taxation and environmental regulations are pushing construction firms toward lower-carbon alternatives to Portland cement; rising labor costs are incentivizing materials that reduce construction time; and growing emphasis on infrastructure resilience is creating demand for concrete with superior durability characteristics.

Customer willingness to pay premium prices for rapid-setting sustainable concrete varies significantly by application. For critical infrastructure repairs, customers demonstrate price tolerance up to 30-40% above conventional concrete costs, while commercial applications typically accept 15-25% premiums if demonstrable schedule benefits exist. The residential sector remains more price-sensitive, with acceptance thresholds around 10-15% above conventional materials.

Market penetration remains relatively low at 7% of the total concrete market, indicating substantial growth potential as technical challenges around early strength development are overcome and production scales to reduce costs.

Demand for ambient-cure geopolymer concretes with high early strength capabilities is especially pronounced in urban infrastructure projects where minimizing traffic disruption is critical. Transportation departments and municipal authorities represent the largest customer segment, accounting for nearly 38% of market demand. These entities prioritize materials that enable rapid road repairs, bridge rehabilitation, and runway maintenance with minimal closure times.

Commercial construction represents the second-largest market segment at 27%, where time-sensitive projects benefit from reduced formwork striking times and accelerated construction schedules. The residential construction sector, while smaller at 18% of market share, is showing the fastest growth rate at 9.7% annually as developers increasingly recognize the economic benefits of faster project completion.

Regionally, North America and Europe currently dominate the market with combined 58% market share, primarily due to stringent environmental regulations and well-established green building certification systems. However, the Asia-Pacific region is projected to witness the highest growth rate of 11.3% through 2028, driven by massive infrastructure investments in China, India, and Southeast Asian countries.

Market analysis reveals several key demand drivers: increasing carbon taxation and environmental regulations are pushing construction firms toward lower-carbon alternatives to Portland cement; rising labor costs are incentivizing materials that reduce construction time; and growing emphasis on infrastructure resilience is creating demand for concrete with superior durability characteristics.

Customer willingness to pay premium prices for rapid-setting sustainable concrete varies significantly by application. For critical infrastructure repairs, customers demonstrate price tolerance up to 30-40% above conventional concrete costs, while commercial applications typically accept 15-25% premiums if demonstrable schedule benefits exist. The residential sector remains more price-sensitive, with acceptance thresholds around 10-15% above conventional materials.

Market penetration remains relatively low at 7% of the total concrete market, indicating substantial growth potential as technical challenges around early strength development are overcome and production scales to reduce costs.

Current Challenges in Ambient-Cure Geopolymer Technology

Despite significant advancements in geopolymer technology, ambient-cure geopolymer concretes face several critical challenges that hinder their widespread adoption, particularly regarding early strength development. The absence of thermal curing creates a fundamental obstacle, as the polymerization reaction that forms the binding matrix proceeds significantly slower at ambient temperatures compared to elevated temperatures typically used in controlled curing environments.

One major technical barrier is the slow reaction kinetics at room temperature. Without external heat input, the dissolution of aluminosilicate precursors and subsequent polycondensation reactions occur at reduced rates, resulting in delayed strength development during the critical first 24-72 hours after casting. This limitation severely restricts applications where early formwork removal or rapid loading is required.

The chemical composition optimization presents another significant challenge. Current formulations struggle to balance reactivity with workability at ambient conditions. Highly reactive mixes that might achieve better early strength often suffer from reduced workability and shorter setting times, creating practical difficulties in field applications. Conversely, more workable mixes typically demonstrate inadequate early strength properties.

Activator efficiency represents a persistent technical hurdle. Conventional alkaline activators (sodium or potassium hydroxide and silicate solutions) demonstrate reduced effectiveness at ambient temperatures, necessitating higher concentrations that introduce additional issues including efflorescence, increased shrinkage, and potential handling hazards during construction.

The variability of raw materials compounds these challenges. Fly ash, ground granulated blast furnace slag, and other industrial by-products used as precursors exhibit significant compositional variations depending on their source, making standardization difficult and resulting in inconsistent performance across different batches of ambient-cured geopolymer concrete.

Water content management presents a particular difficulty in ambient curing conditions. Unlike thermal curing where excess water evaporates rapidly, ambient curing retains moisture longer, potentially disrupting the geopolymerization process and creating microstructural weaknesses that compromise early strength development.

Admixture compatibility issues further complicate the technology. Many conventional concrete admixtures designed for ordinary Portland cement systems perform unpredictably in geopolymer matrices, with some retarding the already slow ambient polymerization process or interfering with the chemical reactions necessary for proper strength development.

The lack of standardized testing protocols specifically designed for ambient-cure geopolymers creates additional barriers to implementation. Current testing methods developed for traditional concrete may not accurately reflect the unique setting and hardening mechanisms of geopolymer systems, making performance evaluation and quality control problematic.

One major technical barrier is the slow reaction kinetics at room temperature. Without external heat input, the dissolution of aluminosilicate precursors and subsequent polycondensation reactions occur at reduced rates, resulting in delayed strength development during the critical first 24-72 hours after casting. This limitation severely restricts applications where early formwork removal or rapid loading is required.

The chemical composition optimization presents another significant challenge. Current formulations struggle to balance reactivity with workability at ambient conditions. Highly reactive mixes that might achieve better early strength often suffer from reduced workability and shorter setting times, creating practical difficulties in field applications. Conversely, more workable mixes typically demonstrate inadequate early strength properties.

Activator efficiency represents a persistent technical hurdle. Conventional alkaline activators (sodium or potassium hydroxide and silicate solutions) demonstrate reduced effectiveness at ambient temperatures, necessitating higher concentrations that introduce additional issues including efflorescence, increased shrinkage, and potential handling hazards during construction.

The variability of raw materials compounds these challenges. Fly ash, ground granulated blast furnace slag, and other industrial by-products used as precursors exhibit significant compositional variations depending on their source, making standardization difficult and resulting in inconsistent performance across different batches of ambient-cured geopolymer concrete.

Water content management presents a particular difficulty in ambient curing conditions. Unlike thermal curing where excess water evaporates rapidly, ambient curing retains moisture longer, potentially disrupting the geopolymerization process and creating microstructural weaknesses that compromise early strength development.

Admixture compatibility issues further complicate the technology. Many conventional concrete admixtures designed for ordinary Portland cement systems perform unpredictably in geopolymer matrices, with some retarding the already slow ambient polymerization process or interfering with the chemical reactions necessary for proper strength development.

The lack of standardized testing protocols specifically designed for ambient-cure geopolymers creates additional barriers to implementation. Current testing methods developed for traditional concrete may not accurately reflect the unique setting and hardening mechanisms of geopolymer systems, making performance evaluation and quality control problematic.

Current Methodologies for Ambient-Cure Strength Acceleration

01 Alkali activators for ambient-cure geopolymer concrete

Various alkali activators can be used to enhance the early strength development of ambient-cure geopolymer concretes. These activators, such as sodium hydroxide, sodium silicate, and potassium hydroxide, play a crucial role in the dissolution of aluminosilicate precursors and subsequent geopolymerization process. The concentration and type of alkali activator significantly influence the early strength properties of the resulting geopolymer concrete, allowing for rapid strength gain without the need for heat curing.- Activator compositions for ambient-cure geopolymers: Specific activator compositions can significantly enhance the early strength development of ambient-cure geopolymer concretes. These activators typically include alkali metal silicates, hydroxides, or combinations thereof at optimized concentrations. The proper selection and ratio of activators can accelerate the geopolymerization reaction at ambient temperatures, leading to improved mechanical properties and faster strength gain without requiring heat curing.

- Supplementary cementitious materials for strength enhancement: Incorporating supplementary cementitious materials (SCMs) such as fly ash, slag, silica fume, or metakaolin into geopolymer mixtures can significantly improve early strength development at ambient temperatures. These materials provide additional reactive silica and alumina sources that participate in the geopolymerization process, resulting in denser microstructure and enhanced mechanical properties without the need for elevated temperature curing.

- Chemical admixtures for accelerated strength gain: Various chemical admixtures can be incorporated into ambient-cure geopolymer concrete formulations to accelerate strength development. These include calcium-based accelerators, set modifiers, and proprietary compounds that catalyze the geopolymerization reaction at room temperature. The admixtures modify the reaction kinetics, allowing for rapid hardening and strength gain within the first 24-72 hours after casting.

- Optimized mix design parameters for ambient curing: Careful optimization of mix design parameters is crucial for achieving high early strength in ambient-cured geopolymer concretes. Key factors include water-to-binder ratio, aggregate gradation, alkali content, and silica-to-alumina molar ratio. By balancing these parameters, the geopolymerization reaction can proceed efficiently at ambient temperatures, resulting in accelerated strength development without compromising long-term durability or workability.

- Hybrid binder systems for enhanced early strength: Hybrid binder systems that combine geopolymer precursors with small amounts of ordinary Portland cement or calcium-rich additives can significantly improve early strength development at ambient temperatures. These hybrid systems benefit from both the hydraulic reaction of calcium-based materials and the geopolymerization process, resulting in accelerated setting and hardening. The synergistic effect leads to superior early-age mechanical properties while maintaining the sustainability benefits of geopolymer technology.

02 Supplementary cementitious materials for strength enhancement

Incorporating supplementary cementitious materials (SCMs) such as fly ash, ground granulated blast furnace slag (GGBFS), and silica fume can significantly improve the early strength development of ambient-cure geopolymer concretes. These materials provide additional reactive silica and alumina sources that participate in the geopolymerization reaction, leading to enhanced mechanical properties. The proper selection and proportioning of these SCMs can optimize the early strength development while maintaining workability and durability of the geopolymer concrete.Expand Specific Solutions03 Chemical additives for accelerated strength development

Various chemical additives can be incorporated into ambient-cure geopolymer concrete mixtures to accelerate early strength development. These include calcium-based accelerators, lithium compounds, and certain organic polymers that modify the reaction kinetics of geopolymerization. These additives work by enhancing the dissolution rate of aluminosilicate precursors, promoting faster gel formation, and accelerating the hardening process, resulting in significantly improved early-age strength properties without requiring elevated temperature curing.Expand Specific Solutions04 Optimized mix design for enhanced early strength

Careful optimization of the mix design parameters can significantly enhance the early strength development of ambient-cure geopolymer concretes. Key factors include the water-to-binder ratio, activator concentration, silica-to-alumina ratio, and particle size distribution of the precursor materials. By systematically adjusting these parameters, the reaction kinetics can be optimized to achieve rapid strength gain at ambient temperatures, making these geopolymer concretes suitable for applications requiring high early strength without thermal curing.Expand Specific Solutions05 Nano-material incorporation for strength enhancement

The addition of nano-materials such as nano-silica, nano-alumina, carbon nanotubes, and graphene oxide can significantly improve the early strength development of ambient-cure geopolymer concretes. These nano-materials provide nucleation sites for geopolymer gel formation, enhance the microstructural density, and improve the interfacial transition zone between the geopolymer matrix and aggregates. Even at low dosages, these nano-materials can lead to substantial improvements in early-age mechanical properties without requiring heat curing.Expand Specific Solutions

Leading Companies and Research Institutions in Geopolymer Industry

The ambient-cure geopolymer concrete market is in its growth phase, characterized by increasing demand for sustainable construction materials with reduced carbon footprint. The global market size is expanding rapidly, projected to reach significant value as construction industries seek alternatives to traditional Portland cement. Technologically, the field is advancing but still maturing, with key players like Sobute New Materials, Wuhan University of Technology, and Korea Institute of Construction Technology leading research on early strength development. Companies including Banah UK, IHI Construction Materials, and China Resources Cement Technology are investing in proprietary formulations to overcome ambient-curing challenges. Academic-industry collaborations between institutions like Central South University and corporations such as Sinopec Petroleum Engineering are accelerating innovation in this space, focusing on activator chemistry and mix design optimization for commercial viability.

Sobute New Materials Co., Ltd.

Technical Solution: Sobute New Materials has developed an advanced ambient-cure geopolymer system called "RapidGeo" that achieves high early strength through precise chemical engineering of the activation solution. Their technology utilizes a proprietary blend of sodium silicate with modified phosphate-based accelerators that catalyze the geopolymerization reaction at ambient temperatures. The company has optimized the modulus (SiO2/Na2O ratio) of their activator solution to between 1.2-1.5, which they found critical for balancing workability and early strength development. Their system incorporates highly reactive calcined clay (metakaolin) blended with ground granulated blast furnace slag in specific proportions to enhance early-age reaction kinetics. RapidGeo achieves compressive strengths exceeding 15 MPa within 12 hours and 30 MPa within 24 hours at ambient temperatures (20°C), making it suitable for precast applications without heat curing.

Strengths: The system offers exceptional early strength development while maintaining sufficient working time (30-45 minutes), making it practical for field applications. Their formulation has demonstrated excellent durability in aggressive environments, particularly resistance to chloride penetration and acid attack. Weaknesses: The specialized activator chemicals increase production costs compared to conventional concrete, and the system shows higher sensitivity to water content variations, requiring more precise mix control during production.

Denka Corp.

Technical Solution: Denka Corporation has developed "DenkaGeo-Rapid" technology, an ambient-cure geopolymer system designed specifically for high early strength applications. Their approach utilizes a calcium-enriched aluminosilicate precursor blend combined with a highly alkaline dual-activator system. The technology incorporates their proprietary calcium sulfoaluminate (CSA) accelerator that works synergistically with the geopolymer reaction to form ettringite phases in the early stages, contributing to rapid strength development. Denka's system employs a carefully controlled particle size distribution of precursors (primarily fly ash and slag) with specific surface areas exceeding 500 m²/kg to maximize dissolution rates at ambient temperatures. Their activator solution features a precisely calibrated alkali concentration and silicate modulus that promotes rapid gel formation while maintaining adequate workability. The DenkaGeo-Rapid system achieves compressive strengths of 15-20 MPa within 6 hours and 30-35 MPa within 24 hours at ambient temperatures (20°C).

Strengths: Exceptional early strength development makes it ideal for applications requiring rapid turnaround, such as precast elements, repairs, and fast-track construction. The system demonstrates excellent bond strength to existing concrete substrates, making it particularly suitable for repair applications. Weaknesses: The inclusion of specialized CSA components increases the material cost compared to conventional systems. The rapid setting characteristics can present challenges for large-scale placements without appropriate retarding admixtures.

Key Patents and Research on Rapid-Strength Geopolymer Formulations

A process of preparing high early strength geopolymer concrete

PatentActiveIN202341057914A

Innovation

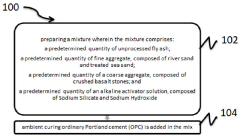

- A geopolymer concrete production method using ceramic tile waste, industrial slag, and recycled aggregates, with a binary blend of pozzolanic materials, mechanical activation, and alkaline solutions to enhance strength and durability, replacing 100% of conventional concrete ingredients with industrial by-products and recycled materials.

A high strength geopolymer concrete composition and a method to produce the high strength geopolymer concrete

PatentInactiveIN202121028510A

Innovation

- The production of high-strength geopolymer concrete using unprocessed fly ash, treated sea sand as a supplementary fine aggregate, and an alkaline activator solution composed of Sodium Silicate and Sodium Hydroxide, with optimal ratios and curing conditions to enhance compressive strength and durability.

Environmental Impact and Carbon Footprint Assessment

The environmental impact of ambient-cure geopolymer concretes represents a significant advantage over traditional Portland cement concrete (PCC). Conventional concrete production accounts for approximately 8% of global CO2 emissions, with cement manufacturing being the primary contributor. Ambient-cure geopolymer concretes offer a promising alternative with substantially lower carbon footprints, reducing CO2 emissions by 40-80% compared to traditional concrete.

The carbon footprint reduction stems primarily from eliminating the high-temperature calcination process required for Portland cement production. While achieving high early strength in ambient-cure geopolymers presents technical challenges, the environmental benefits remain compelling. Life cycle assessment (LCA) studies indicate that even with additives to enhance early strength, these geopolymer systems maintain significant environmental advantages.

Raw material sourcing further enhances the sustainability profile of ambient-cure geopolymers. These systems typically utilize industrial by-products such as fly ash, ground granulated blast furnace slag (GGBFS), and other aluminosilicate materials that would otherwise be landfilled. This circular economy approach diverts waste from disposal sites while reducing the need for virgin material extraction.

Water consumption represents another environmental dimension where ambient-cure geopolymers demonstrate advantages. Research indicates that geopolymer concrete production requires approximately 20-30% less water than conventional concrete manufacturing. This water conservation benefit becomes increasingly important in regions facing water scarcity challenges.

The durability characteristics of high early strength ambient-cure geopolymers also contribute to their environmental profile. Enhanced durability translates to longer service life and reduced maintenance requirements, further decreasing the life-cycle environmental impact. Studies suggest properly formulated geopolymer concretes can resist chemical attack, freeze-thaw damage, and other deterioration mechanisms more effectively than traditional concrete.

Local emissions during production and application present another environmental consideration. Ambient-cure systems eliminate the need for heat curing, reducing energy consumption and associated emissions at construction sites. This aspect becomes particularly valuable in urban environments where air quality concerns are paramount.

Regulatory frameworks increasingly recognize these environmental benefits, with several countries implementing carbon taxation and green building certification systems that favor low-carbon construction materials. This regulatory landscape creates additional market incentives for developing high early strength ambient-cure geopolymer technologies that maintain optimal environmental performance.

The carbon footprint reduction stems primarily from eliminating the high-temperature calcination process required for Portland cement production. While achieving high early strength in ambient-cure geopolymers presents technical challenges, the environmental benefits remain compelling. Life cycle assessment (LCA) studies indicate that even with additives to enhance early strength, these geopolymer systems maintain significant environmental advantages.

Raw material sourcing further enhances the sustainability profile of ambient-cure geopolymers. These systems typically utilize industrial by-products such as fly ash, ground granulated blast furnace slag (GGBFS), and other aluminosilicate materials that would otherwise be landfilled. This circular economy approach diverts waste from disposal sites while reducing the need for virgin material extraction.

Water consumption represents another environmental dimension where ambient-cure geopolymers demonstrate advantages. Research indicates that geopolymer concrete production requires approximately 20-30% less water than conventional concrete manufacturing. This water conservation benefit becomes increasingly important in regions facing water scarcity challenges.

The durability characteristics of high early strength ambient-cure geopolymers also contribute to their environmental profile. Enhanced durability translates to longer service life and reduced maintenance requirements, further decreasing the life-cycle environmental impact. Studies suggest properly formulated geopolymer concretes can resist chemical attack, freeze-thaw damage, and other deterioration mechanisms more effectively than traditional concrete.

Local emissions during production and application present another environmental consideration. Ambient-cure systems eliminate the need for heat curing, reducing energy consumption and associated emissions at construction sites. This aspect becomes particularly valuable in urban environments where air quality concerns are paramount.

Regulatory frameworks increasingly recognize these environmental benefits, with several countries implementing carbon taxation and green building certification systems that favor low-carbon construction materials. This regulatory landscape creates additional market incentives for developing high early strength ambient-cure geopolymer technologies that maintain optimal environmental performance.

Standardization and Testing Protocols for Early Strength Evaluation

Standardization of testing protocols for early strength evaluation in ambient-cure geopolymer concretes represents a critical challenge in the industry. Currently, there exists significant variability in how researchers and manufacturers assess early strength development, making cross-study comparisons difficult and hindering widespread adoption of these sustainable concrete alternatives.

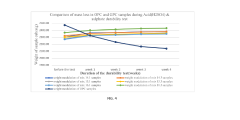

The most commonly employed test method is compressive strength testing according to ASTM C39/C39M or equivalent international standards. However, these protocols were originally designed for ordinary Portland cement concrete and may not adequately capture the unique strength development characteristics of geopolymer systems, particularly in ambient-cure conditions where reaction kinetics differ substantially.

Time intervals for early strength testing also lack standardization. While conventional concrete typically undergoes testing at 1, 3, 7, and 28 days, ambient-cure geopolymers may require more frequent early-age testing (e.g., 6, 12, 24, 48, and 72 hours) to properly characterize their rapid strength development patterns. This granularity is essential for applications requiring precise knowledge of strength evolution.

Non-destructive testing methods show particular promise for continuous monitoring of early strength development. Techniques such as ultrasonic pulse velocity (UPV), rebound hammer tests, and electrical resistivity measurements can provide valuable real-time data without specimen destruction. However, correlation factors between these indirect measurements and actual compressive strength must be established specifically for ambient-cure geopolymer systems.

Calorimetry testing protocols need standardization to correlate heat evolution with strength development in ambient-cure systems. Unlike conventional concrete where heat of hydration is well-understood, the exothermic reactions in geopolymers follow different patterns that vary with precursor materials and activator compositions.

Microstructural analysis techniques including X-ray diffraction (XRD), scanning electron microscopy (SEM), and nuclear magnetic resonance (NMR) spectroscopy require standardized sample preparation and analysis protocols specific to geopolymers. These methods are crucial for understanding the fundamental mechanisms driving early strength development but currently lack consistent application across research groups.

International efforts to develop geopolymer-specific testing standards are underway through organizations like RILEM, ASTM International, and various national standards bodies. These initiatives aim to establish consensus-based protocols that account for the unique characteristics of ambient-cure geopolymer systems while maintaining compatibility with existing concrete industry practices where possible.

The most commonly employed test method is compressive strength testing according to ASTM C39/C39M or equivalent international standards. However, these protocols were originally designed for ordinary Portland cement concrete and may not adequately capture the unique strength development characteristics of geopolymer systems, particularly in ambient-cure conditions where reaction kinetics differ substantially.

Time intervals for early strength testing also lack standardization. While conventional concrete typically undergoes testing at 1, 3, 7, and 28 days, ambient-cure geopolymers may require more frequent early-age testing (e.g., 6, 12, 24, 48, and 72 hours) to properly characterize their rapid strength development patterns. This granularity is essential for applications requiring precise knowledge of strength evolution.

Non-destructive testing methods show particular promise for continuous monitoring of early strength development. Techniques such as ultrasonic pulse velocity (UPV), rebound hammer tests, and electrical resistivity measurements can provide valuable real-time data without specimen destruction. However, correlation factors between these indirect measurements and actual compressive strength must be established specifically for ambient-cure geopolymer systems.

Calorimetry testing protocols need standardization to correlate heat evolution with strength development in ambient-cure systems. Unlike conventional concrete where heat of hydration is well-understood, the exothermic reactions in geopolymers follow different patterns that vary with precursor materials and activator compositions.

Microstructural analysis techniques including X-ray diffraction (XRD), scanning electron microscopy (SEM), and nuclear magnetic resonance (NMR) spectroscopy require standardized sample preparation and analysis protocols specific to geopolymers. These methods are crucial for understanding the fundamental mechanisms driving early strength development but currently lack consistent application across research groups.

International efforts to develop geopolymer-specific testing standards are underway through organizations like RILEM, ASTM International, and various national standards bodies. These initiatives aim to establish consensus-based protocols that account for the unique characteristics of ambient-cure geopolymer systems while maintaining compatibility with existing concrete industry practices where possible.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!