Geopolymer concrete explained: chemistry, mix design, and cure

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Geopolymer Concrete Evolution and Research Objectives

Geopolymer concrete represents a revolutionary alternative to traditional Portland cement concrete, emerging from decades of research into sustainable construction materials. The evolution of geopolymer technology can be traced back to the 1970s when Joseph Davidovits first coined the term "geopolymer" to describe inorganic polymeric materials formed through geosynthesis. This technology draws inspiration from ancient construction practices, notably those used in Roman structures and Egyptian pyramids, where durable cementitious materials were created without modern Portland cement.

The fundamental chemistry behind geopolymers involves the alkaline activation of aluminosilicate materials, typically industrial by-products such as fly ash, ground granulated blast furnace slag (GGBFS), or metakaolin. This activation process creates three-dimensional polymeric networks of silicon, aluminum, and oxygen atoms, resulting in a material with comparable or superior properties to conventional concrete while significantly reducing carbon emissions.

Recent technological advancements have focused on optimizing mix designs to enhance workability, strength development, and durability. The evolution of geopolymer concrete has been marked by progressive improvements in understanding the complex reaction mechanisms, the role of various precursors, and the influence of alkaline activators on final properties. Research has expanded from laboratory-scale experiments to field applications, demonstrating the practical viability of geopolymer concrete in real-world construction scenarios.

Current research objectives in geopolymer concrete technology are multifaceted, addressing both fundamental scientific understanding and practical implementation challenges. Primary goals include developing standardized mix design methodologies that can accommodate varying raw material compositions, as industrial by-products often exhibit inconsistent chemical properties. Researchers aim to establish reliable curing protocols that can function effectively across diverse environmental conditions, moving beyond the current reliance on elevated temperature curing in many applications.

Another critical research direction involves enhancing the long-term durability of geopolymer concrete, particularly its resistance to carbonation, chloride penetration, and alkali-silica reaction. Scientists are investigating the microstructural evolution of geopolymers over time to better predict service life performance. Additionally, there is significant interest in expanding the range of suitable precursor materials to include more locally available resources, thereby reducing transportation costs and further improving the environmental footprint.

The ultimate objective of geopolymer concrete research is to facilitate widespread commercial adoption by addressing technical barriers while simultaneously developing appropriate standards and specifications. This includes creating user-friendly design tools for engineers, establishing quality control protocols for production, and providing comprehensive performance data to build confidence among stakeholders in the construction industry.

The fundamental chemistry behind geopolymers involves the alkaline activation of aluminosilicate materials, typically industrial by-products such as fly ash, ground granulated blast furnace slag (GGBFS), or metakaolin. This activation process creates three-dimensional polymeric networks of silicon, aluminum, and oxygen atoms, resulting in a material with comparable or superior properties to conventional concrete while significantly reducing carbon emissions.

Recent technological advancements have focused on optimizing mix designs to enhance workability, strength development, and durability. The evolution of geopolymer concrete has been marked by progressive improvements in understanding the complex reaction mechanisms, the role of various precursors, and the influence of alkaline activators on final properties. Research has expanded from laboratory-scale experiments to field applications, demonstrating the practical viability of geopolymer concrete in real-world construction scenarios.

Current research objectives in geopolymer concrete technology are multifaceted, addressing both fundamental scientific understanding and practical implementation challenges. Primary goals include developing standardized mix design methodologies that can accommodate varying raw material compositions, as industrial by-products often exhibit inconsistent chemical properties. Researchers aim to establish reliable curing protocols that can function effectively across diverse environmental conditions, moving beyond the current reliance on elevated temperature curing in many applications.

Another critical research direction involves enhancing the long-term durability of geopolymer concrete, particularly its resistance to carbonation, chloride penetration, and alkali-silica reaction. Scientists are investigating the microstructural evolution of geopolymers over time to better predict service life performance. Additionally, there is significant interest in expanding the range of suitable precursor materials to include more locally available resources, thereby reducing transportation costs and further improving the environmental footprint.

The ultimate objective of geopolymer concrete research is to facilitate widespread commercial adoption by addressing technical barriers while simultaneously developing appropriate standards and specifications. This includes creating user-friendly design tools for engineers, establishing quality control protocols for production, and providing comprehensive performance data to build confidence among stakeholders in the construction industry.

Market Analysis for Sustainable Construction Materials

The sustainable construction materials market is experiencing significant growth driven by increasing environmental concerns and regulatory pressures to reduce carbon emissions in the construction industry. The global market for sustainable construction materials was valued at approximately $230 billion in 2022 and is projected to reach $425 billion by 2030, growing at a CAGR of around 8.5% during the forecast period. Geopolymer concrete represents one of the fastest-growing segments within this market, with an estimated growth rate of 12-15% annually.

Demand for geopolymer concrete is primarily driven by its substantially lower carbon footprint compared to Ordinary Portland Cement (OPC) concrete. While traditional concrete production accounts for approximately 8% of global CO2 emissions, geopolymer alternatives can reduce this environmental impact by 60-80%, depending on the specific formulation and raw materials used.

Regional analysis indicates that Asia-Pacific currently dominates the geopolymer concrete market, with Australia leading in commercial applications and research. Europe follows closely, with significant adoption in countries like Germany, France, and the UK, where stringent environmental regulations are accelerating market growth. North America is showing increasing interest, particularly in infrastructure applications where durability and chemical resistance are paramount.

By application segment, the market for geopolymer concrete is diversifying rapidly. Infrastructure projects represent the largest market share (approximately 40%), followed by commercial buildings (30%), residential construction (15%), and specialized applications such as marine structures and high-temperature environments (15%). The infrastructure segment's dominance is attributed to geopolymer concrete's superior durability and resistance to chemical attack.

End-user analysis reveals that government and public sector projects currently constitute the largest customer base for geopolymer concrete, driven by green procurement policies and sustainability targets. However, private sector adoption is accelerating, particularly among companies with strong ESG commitments.

Price sensitivity remains a significant market factor, with geopolymer concrete typically commanding a 15-25% premium over traditional concrete. However, this gap is narrowing as production scales up and as carbon pricing mechanisms in various regions begin to internalize the environmental costs of traditional cement production.

Market challenges include limited awareness among construction professionals, inconsistent regulatory frameworks across regions, and supply chain constraints for key raw materials such as fly ash and slag. These challenges are gradually being addressed through industry education initiatives, standardization efforts, and the development of alternative precursor materials.

Demand for geopolymer concrete is primarily driven by its substantially lower carbon footprint compared to Ordinary Portland Cement (OPC) concrete. While traditional concrete production accounts for approximately 8% of global CO2 emissions, geopolymer alternatives can reduce this environmental impact by 60-80%, depending on the specific formulation and raw materials used.

Regional analysis indicates that Asia-Pacific currently dominates the geopolymer concrete market, with Australia leading in commercial applications and research. Europe follows closely, with significant adoption in countries like Germany, France, and the UK, where stringent environmental regulations are accelerating market growth. North America is showing increasing interest, particularly in infrastructure applications where durability and chemical resistance are paramount.

By application segment, the market for geopolymer concrete is diversifying rapidly. Infrastructure projects represent the largest market share (approximately 40%), followed by commercial buildings (30%), residential construction (15%), and specialized applications such as marine structures and high-temperature environments (15%). The infrastructure segment's dominance is attributed to geopolymer concrete's superior durability and resistance to chemical attack.

End-user analysis reveals that government and public sector projects currently constitute the largest customer base for geopolymer concrete, driven by green procurement policies and sustainability targets. However, private sector adoption is accelerating, particularly among companies with strong ESG commitments.

Price sensitivity remains a significant market factor, with geopolymer concrete typically commanding a 15-25% premium over traditional concrete. However, this gap is narrowing as production scales up and as carbon pricing mechanisms in various regions begin to internalize the environmental costs of traditional cement production.

Market challenges include limited awareness among construction professionals, inconsistent regulatory frameworks across regions, and supply chain constraints for key raw materials such as fly ash and slag. These challenges are gradually being addressed through industry education initiatives, standardization efforts, and the development of alternative precursor materials.

Current Geopolymer Technology Status and Barriers

Geopolymer concrete technology has advanced significantly over the past two decades, yet remains predominantly in the research and development phase with limited commercial applications. Current global production represents less than 1% of total concrete production, indicating substantial room for growth. The technology has reached TRL 6-7 (Technology Readiness Level), with successful demonstrations in non-critical applications but lacking widespread standardization.

The primary technical barriers hindering widespread adoption include inconsistent raw material quality, particularly fly ash and slag, which significantly impacts final product performance. The variability in precursor materials necessitates customized mix designs for each source, complicating quality control and scalability. Additionally, the curing process presents significant challenges, as geopolymer concrete typically requires elevated temperature curing (40-80°C) to achieve optimal strength development, limiting on-site applications.

Current manufacturing processes face efficiency constraints, with longer setting times compared to ordinary Portland cement (OPC) concrete. The specialized knowledge required for mix design optimization creates a steep learning curve for industry professionals accustomed to conventional concrete practices. Furthermore, the lack of long-term performance data (beyond 20 years) creates uncertainty regarding durability in critical infrastructure applications.

Regulatory barriers present another significant obstacle, as most building codes and standards worldwide are tailored to OPC concrete. The absence of standardized testing protocols specifically designed for geopolymer concrete complicates quality assurance and certification processes. This regulatory gap increases perceived risk among engineers, architects, and contractors, limiting specification in commercial projects.

Economic factors also constrain adoption, with current production costs approximately 10-30% higher than conventional concrete, depending on regional availability of precursor materials and activation chemicals. The specialized equipment required for precise alkali activator handling and mixing represents additional capital investment for concrete producers.

Geographically, Australia leads in commercial implementation, followed by parts of Europe and North America. Research centers in these regions, along with emerging work in China and India, are addressing key technical challenges through innovations in ambient temperature curing methods, standardized mix designs, and alternative precursor materials. Recent breakthroughs include hybrid systems combining geopolymer technology with minor Portland cement additions, which address some workability and curing challenges while maintaining most environmental benefits.

The primary technical barriers hindering widespread adoption include inconsistent raw material quality, particularly fly ash and slag, which significantly impacts final product performance. The variability in precursor materials necessitates customized mix designs for each source, complicating quality control and scalability. Additionally, the curing process presents significant challenges, as geopolymer concrete typically requires elevated temperature curing (40-80°C) to achieve optimal strength development, limiting on-site applications.

Current manufacturing processes face efficiency constraints, with longer setting times compared to ordinary Portland cement (OPC) concrete. The specialized knowledge required for mix design optimization creates a steep learning curve for industry professionals accustomed to conventional concrete practices. Furthermore, the lack of long-term performance data (beyond 20 years) creates uncertainty regarding durability in critical infrastructure applications.

Regulatory barriers present another significant obstacle, as most building codes and standards worldwide are tailored to OPC concrete. The absence of standardized testing protocols specifically designed for geopolymer concrete complicates quality assurance and certification processes. This regulatory gap increases perceived risk among engineers, architects, and contractors, limiting specification in commercial projects.

Economic factors also constrain adoption, with current production costs approximately 10-30% higher than conventional concrete, depending on regional availability of precursor materials and activation chemicals. The specialized equipment required for precise alkali activator handling and mixing represents additional capital investment for concrete producers.

Geographically, Australia leads in commercial implementation, followed by parts of Europe and North America. Research centers in these regions, along with emerging work in China and India, are addressing key technical challenges through innovations in ambient temperature curing methods, standardized mix designs, and alternative precursor materials. Recent breakthroughs include hybrid systems combining geopolymer technology with minor Portland cement additions, which address some workability and curing challenges while maintaining most environmental benefits.

Leading Organizations in Geopolymer Concrete Research

Geopolymer concrete technology is currently in a transitional phase from research to commercial application, with a growing market projected to reach significant scale by 2030. The technology demonstrates moderate maturity, with academic institutions like Zhengzhou University, Tongji University, and University of Melbourne leading fundamental research, while companies such as Sobute New Materials, Sekisui Chemical, and Cement Australia are advancing industrial applications. The competitive landscape shows a clear division between research-focused entities developing chemical formulations and curing methodologies, and commercial players working on scalable production techniques. Regional innovation hubs are emerging in China, Australia, and India, with increasing cross-sector collaboration between academia and industry driving standardization efforts and market adoption.

Tongji University

Technical Solution: Tongji University has developed advanced geopolymer concrete technology focusing on high-performance applications in aggressive environments. Their chemistry approach centers on a binary activation system using sodium hydroxide and sodium silicate with precisely controlled modulus (SiO2/Na2O ratio typically maintained between 1.8-2.2). Their research has pioneered the use of nano-silica and nano-alumina additives (0.5-2% by weight of binder) to enhance the geopolymerization process and refine the microstructure of the resulting concrete. Their mix design methodology incorporates a multi-stage mixing protocol that optimizes the dissolution of aluminosilicate precursors before introducing the alkaline activator, resulting in more complete geopolymerization and enhanced mechanical properties. Tongji's curing protocol involves a two-stage approach with initial ambient temperature pre-curing (20-25°C for 24 hours) followed by moderate temperature curing (60-70°C for 6-12 hours) with controlled humidity (RH>90%). Their research demonstrates that this approach produces geopolymer concrete with compressive strengths exceeding 70 MPa and exceptional durability in freeze-thaw conditions, with durability factors 15-20% higher than comparable strength Portland cement concrete.

Strengths: Their nano-modified geopolymer systems achieve exceptional mechanical properties and durability characteristics, particularly in freeze-thaw environments. Their multi-stage mixing protocol optimizes the geopolymerization reaction and improves material homogeneity. Weaknesses: The incorporation of nanomaterials increases production costs and requires specialized mixing equipment to ensure proper dispersion, potentially limiting widespread commercial adoption.

Liverpool John Moores University

Technical Solution: Liverpool John Moores University has developed innovative geopolymer concrete formulations focusing on ambient-temperature curing systems. Their chemistry approach centers on the use of modified sodium silicate solutions with carefully controlled SiO2/Na2O molar ratios (typically 1.6-2.0) combined with supplementary activators including calcium hydroxide to promote reaction kinetics at ambient temperatures. Their mix design methodology incorporates a multi-component binder system utilizing fly ash, GGBFS, and small quantities of calcined clay to optimize reactivity and mechanical property development. A distinctive aspect of their research is the development of internal curing techniques using pre-soaked lightweight aggregates or superabsorbent polymers to maintain optimal moisture conditions during the geopolymerization process. Their curing protocol eliminates the need for external heat application by utilizing the internal chemistry of their activator system to generate sufficient reaction heat. Research from the university demonstrates that their ambient-cured geopolymer concrete achieves compressive strengths of 35-45 MPa at 28 days and exhibits excellent durability characteristics, particularly in terms of chloride penetration resistance and carbonation resistance.

Strengths: Their ambient temperature curing system eliminates energy requirements associated with heat curing, making field implementation more practical. Their internal curing approach solves moisture-related challenges in geopolymer curing. Weaknesses: Their multi-component binder system increases complexity in quality control and may require more sophisticated batching systems compared to simpler formulations.

Critical Patents in Geopolymer Chemistry and Curing

A mix of geopolymer concrete and method for appropriate mix proportion of constituent and desired compressive strength

PatentActiveIN202111013559A

Innovation

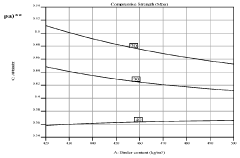

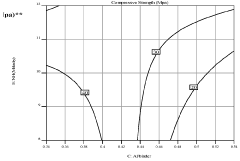

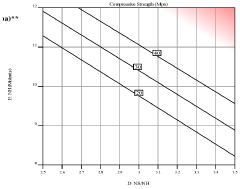

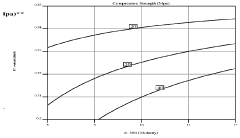

- The proposed method uses Response Surface Methodology (RSM) to create 2D contour plots of various factors, categorizing mixes by curing regime (ambient, 60°C, and 90°C), incorporating fly ash and blast furnace slag as main binders, and optimizing alkali activator content, water/solid ratio, and curing temperature to achieve target compressive strengths efficiently.

A process for geopolymer concrete making with curing at ambient temperature and without using sodium hydroxide

PatentInactiveIN201747006052A

Innovation

- A method of forming geopolymer concrete at room temperature using a composition comprising sodium silicate, Aluminum oxide, fly ash, granulated blast furnace slag, and aggregates, with Aluminum oxide replacing metal hydroxide, and sodium silicate with a SiO2/Na2O mass ratio of 1.8 to 2.4, allowing for room temperature curing without heating.

Environmental Impact Assessment of Geopolymer Concrete

The environmental impact assessment of geopolymer concrete reveals significant advantages over traditional Portland cement concrete (PCC). Geopolymer concrete production generates approximately 80% less carbon dioxide emissions compared to conventional concrete, addressing one of the construction industry's most pressing environmental challenges. This reduction stems primarily from eliminating the calcination process required in Portland cement manufacturing, which accounts for about 60% of cement's carbon footprint.

Beyond carbon emissions, geopolymer concrete offers additional environmental benefits through its ability to incorporate industrial by-products. Fly ash from coal power plants and slag from steel manufacturing—materials that would otherwise require disposal in landfills—serve as primary precursors in geopolymer synthesis. This waste utilization creates a circular economy approach that simultaneously reduces landfill burden and conserves natural resources that would be extracted for traditional cement production.

Water consumption represents another critical environmental factor where geopolymer concrete demonstrates advantages. The production process typically requires 60-70% less water than conventional concrete manufacturing. This water efficiency becomes increasingly important in regions facing water scarcity and contributes to the overall sustainability profile of geopolymer concrete systems.

Life cycle assessment (LCA) studies indicate that geopolymer concrete's environmental benefits extend throughout its service life. The material exhibits superior durability in aggressive environments, potentially doubling the service life compared to Portland cement concrete in certain applications. This longevity translates to reduced maintenance requirements and less frequent replacement, further decreasing the environmental impact over the structure's lifetime.

Energy consumption analysis reveals a more complex picture. While geopolymer concrete curing often requires elevated temperatures (60-90°C), innovations in ambient-temperature curing formulations are narrowing this gap. When renewable energy sources power the curing process, the overall energy footprint can be significantly reduced compared to the energy-intensive clinker production for Portland cement.

Local environmental impacts must also be considered. The alkaline activators used in geopolymer production, typically sodium hydroxide and sodium silicate, present handling challenges and potential environmental hazards if improperly managed. However, research into less caustic alternatives and closed-loop manufacturing systems is addressing these concerns, with promising developments in using recycled glass and other silica-rich waste materials as alternative activators.

Beyond carbon emissions, geopolymer concrete offers additional environmental benefits through its ability to incorporate industrial by-products. Fly ash from coal power plants and slag from steel manufacturing—materials that would otherwise require disposal in landfills—serve as primary precursors in geopolymer synthesis. This waste utilization creates a circular economy approach that simultaneously reduces landfill burden and conserves natural resources that would be extracted for traditional cement production.

Water consumption represents another critical environmental factor where geopolymer concrete demonstrates advantages. The production process typically requires 60-70% less water than conventional concrete manufacturing. This water efficiency becomes increasingly important in regions facing water scarcity and contributes to the overall sustainability profile of geopolymer concrete systems.

Life cycle assessment (LCA) studies indicate that geopolymer concrete's environmental benefits extend throughout its service life. The material exhibits superior durability in aggressive environments, potentially doubling the service life compared to Portland cement concrete in certain applications. This longevity translates to reduced maintenance requirements and less frequent replacement, further decreasing the environmental impact over the structure's lifetime.

Energy consumption analysis reveals a more complex picture. While geopolymer concrete curing often requires elevated temperatures (60-90°C), innovations in ambient-temperature curing formulations are narrowing this gap. When renewable energy sources power the curing process, the overall energy footprint can be significantly reduced compared to the energy-intensive clinker production for Portland cement.

Local environmental impacts must also be considered. The alkaline activators used in geopolymer production, typically sodium hydroxide and sodium silicate, present handling challenges and potential environmental hazards if improperly managed. However, research into less caustic alternatives and closed-loop manufacturing systems is addressing these concerns, with promising developments in using recycled glass and other silica-rich waste materials as alternative activators.

Standardization and Regulatory Framework for Geopolymers

The standardization and regulatory framework for geopolymer concrete remains in a developmental stage compared to traditional Ordinary Portland Cement (OPC) concrete. This presents significant challenges for widespread commercial adoption despite the environmental and performance benefits of geopolymer technology. Currently, most building codes and construction standards worldwide are tailored specifically for OPC concrete, creating regulatory barriers for geopolymer implementation in structural applications.

Several international organizations are working to establish comprehensive standards for geopolymer concrete. The American Concrete Institute (ACI) has formed dedicated committees to develop guidelines for alternative cementitious materials, including geopolymers. Similarly, the European Committee for Standardization (CEN) has initiated working groups focused on standardizing testing methods and performance criteria for geopolymer-based construction materials.

Australia has emerged as a leader in geopolymer standardization, with the Standards Australia committee BD-090 developing specific provisions for geopolymer concrete within their concrete structures code. Their approach focuses on performance-based criteria rather than prescriptive requirements, allowing for innovation while maintaining safety standards.

Key challenges in developing regulatory frameworks include the variability in raw materials used for geopolymer production. Unlike OPC, which has relatively consistent composition globally, geopolymer precursors such as fly ash and slag can vary significantly depending on their source. This variability necessitates more complex quality control procedures and testing protocols to ensure consistent performance.

Testing methodologies present another regulatory challenge. Traditional concrete tests may not accurately reflect geopolymer performance characteristics, as the chemical reactions and curing mechanisms differ fundamentally from OPC. Specialized testing protocols are being developed to address these differences, particularly for assessing long-term durability and resistance to environmental factors.

For market acceptance, certification systems are being established in various regions. These include environmental product declarations (EPDs) that quantify the reduced carbon footprint of geopolymer concrete compared to traditional alternatives, providing regulatory incentives for their use in green building projects.

The path toward comprehensive standardization will likely require collaboration between academic institutions, industry stakeholders, and regulatory bodies to develop consensus-based standards that address both technical performance and sustainability metrics. As research continues to validate long-term performance data, regulatory frameworks are expected to evolve, potentially accelerating adoption of geopolymer concrete in mainstream construction applications.

Several international organizations are working to establish comprehensive standards for geopolymer concrete. The American Concrete Institute (ACI) has formed dedicated committees to develop guidelines for alternative cementitious materials, including geopolymers. Similarly, the European Committee for Standardization (CEN) has initiated working groups focused on standardizing testing methods and performance criteria for geopolymer-based construction materials.

Australia has emerged as a leader in geopolymer standardization, with the Standards Australia committee BD-090 developing specific provisions for geopolymer concrete within their concrete structures code. Their approach focuses on performance-based criteria rather than prescriptive requirements, allowing for innovation while maintaining safety standards.

Key challenges in developing regulatory frameworks include the variability in raw materials used for geopolymer production. Unlike OPC, which has relatively consistent composition globally, geopolymer precursors such as fly ash and slag can vary significantly depending on their source. This variability necessitates more complex quality control procedures and testing protocols to ensure consistent performance.

Testing methodologies present another regulatory challenge. Traditional concrete tests may not accurately reflect geopolymer performance characteristics, as the chemical reactions and curing mechanisms differ fundamentally from OPC. Specialized testing protocols are being developed to address these differences, particularly for assessing long-term durability and resistance to environmental factors.

For market acceptance, certification systems are being established in various regions. These include environmental product declarations (EPDs) that quantify the reduced carbon footprint of geopolymer concrete compared to traditional alternatives, providing regulatory incentives for their use in green building projects.

The path toward comprehensive standardization will likely require collaboration between academic institutions, industry stakeholders, and regulatory bodies to develop consensus-based standards that address both technical performance and sustainability metrics. As research continues to validate long-term performance data, regulatory frameworks are expected to evolve, potentially accelerating adoption of geopolymer concrete in mainstream construction applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!