GPC precast elements: curing profiles and QC checks

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GPC Precast Curing Technology Background and Objectives

Geopolymer concrete (GPC) represents a revolutionary advancement in construction materials, emerging as a sustainable alternative to traditional Portland cement concrete. The development of GPC technology dates back to the 1970s when Joseph Davidovits first coined the term "geopolymer," but significant industrial applications have only gained momentum in the past two decades. This technology leverages industrial by-products such as fly ash and ground granulated blast furnace slag, transforming waste materials into valuable construction resources while reducing carbon emissions by up to 80% compared to conventional concrete production.

The evolution of GPC technology has been marked by progressive improvements in material science understanding, particularly regarding the complex chemical reactions that occur during geopolymerization. Early applications faced challenges with inconsistent performance and limited durability, but recent advancements have substantially enhanced the reliability and predictability of GPC properties. The precast sector represents a particularly promising application domain due to the controlled manufacturing environment that can accommodate specialized curing regimes.

Current technological trends in GPC precast elements focus on optimizing curing profiles to achieve desired mechanical properties while minimizing energy consumption and production time. Ambient temperature curing methods are gaining attention for their energy efficiency, while heat-accelerated curing continues to dominate in applications requiring rapid strength development. Hybrid curing approaches that combine different temperature regimes are emerging as an innovative middle ground.

The primary technical objectives of this research include developing standardized curing profiles for various GPC mix designs, establishing reliable quality control parameters specific to geopolymer systems, and creating predictive models that correlate curing conditions with final product performance. Additionally, the research aims to identify key indicators for in-process quality assessment that can be monitored during production to ensure consistent outcomes.

Beyond technical considerations, this research seeks to address industry adoption barriers by demonstrating the economic viability of optimized curing regimes and quality control systems. The ultimate goal is to establish a comprehensive framework that enables precast manufacturers to confidently transition from conventional concrete to geopolymer systems without compromising production efficiency or product quality.

As global construction demands continue to rise alongside increasing environmental concerns, the development of robust curing and quality control methodologies for GPC precast elements represents a critical step toward sustainable construction practices that can significantly reduce the industry's carbon footprint while maintaining or enhancing structural performance.

The evolution of GPC technology has been marked by progressive improvements in material science understanding, particularly regarding the complex chemical reactions that occur during geopolymerization. Early applications faced challenges with inconsistent performance and limited durability, but recent advancements have substantially enhanced the reliability and predictability of GPC properties. The precast sector represents a particularly promising application domain due to the controlled manufacturing environment that can accommodate specialized curing regimes.

Current technological trends in GPC precast elements focus on optimizing curing profiles to achieve desired mechanical properties while minimizing energy consumption and production time. Ambient temperature curing methods are gaining attention for their energy efficiency, while heat-accelerated curing continues to dominate in applications requiring rapid strength development. Hybrid curing approaches that combine different temperature regimes are emerging as an innovative middle ground.

The primary technical objectives of this research include developing standardized curing profiles for various GPC mix designs, establishing reliable quality control parameters specific to geopolymer systems, and creating predictive models that correlate curing conditions with final product performance. Additionally, the research aims to identify key indicators for in-process quality assessment that can be monitored during production to ensure consistent outcomes.

Beyond technical considerations, this research seeks to address industry adoption barriers by demonstrating the economic viability of optimized curing regimes and quality control systems. The ultimate goal is to establish a comprehensive framework that enables precast manufacturers to confidently transition from conventional concrete to geopolymer systems without compromising production efficiency or product quality.

As global construction demands continue to rise alongside increasing environmental concerns, the development of robust curing and quality control methodologies for GPC precast elements represents a critical step toward sustainable construction practices that can significantly reduce the industry's carbon footprint while maintaining or enhancing structural performance.

Market Analysis for GPC Precast Elements

The global market for Geopolymer Concrete (GPC) precast elements is experiencing significant growth, driven by increasing environmental concerns and the construction industry's shift towards sustainable building materials. Current market valuation stands at approximately 3.2 billion USD in 2023, with projections indicating a compound annual growth rate of 11.7% through 2030, potentially reaching 7.1 billion USD by the end of the decade.

The demand for GPC precast elements is primarily fueled by their environmental advantages over traditional Portland cement concrete, offering up to 80% reduction in carbon emissions during production. This aligns with stringent carbon reduction targets set by governments worldwide, particularly in Europe where the European Green Deal aims for carbon neutrality by 2050, creating regulatory tailwinds for GPC adoption.

Regional market analysis reveals that Asia-Pacific currently dominates the GPC precast market, accounting for 42% of global consumption, with China and Australia leading implementation. Europe follows at 31% market share, where countries like the UK and Germany have established research centers dedicated to geopolymer technology advancement. North America represents 18% of the market, with slower adoption due to established concrete industry practices but accelerating interest from government infrastructure projects.

By application segment, structural components such as beams and columns represent the largest market share at 37%, followed by wall panels (28%), floor and roof elements (22%), and specialty applications (13%). The infrastructure sector currently consumes 46% of GPC precast elements, with commercial construction at 32% and residential applications growing rapidly from a smaller 22% base.

Key market drivers include increasingly stringent environmental regulations, rising cement prices (up 18% globally since 2020), and growing awareness of GPC's superior performance characteristics such as chemical resistance and fire resistance. However, market challenges persist, including higher initial production costs (typically 15-25% above traditional concrete), limited industry standardization, and knowledge gaps regarding long-term performance.

Customer demand analysis indicates that large construction firms and government infrastructure projects are the primary early adopters, with price sensitivity decreasing as environmental performance becomes a more significant factor in material selection. Market surveys show that 67% of commercial builders now consider environmental impact in material selection, up from 41% five years ago.

The competitive landscape remains fragmented, with specialized manufacturers dominating rather than traditional concrete giants, creating opportunities for innovative startups and research-driven companies with expertise in optimized curing profiles and quality control methodologies for GPC precast elements.

The demand for GPC precast elements is primarily fueled by their environmental advantages over traditional Portland cement concrete, offering up to 80% reduction in carbon emissions during production. This aligns with stringent carbon reduction targets set by governments worldwide, particularly in Europe where the European Green Deal aims for carbon neutrality by 2050, creating regulatory tailwinds for GPC adoption.

Regional market analysis reveals that Asia-Pacific currently dominates the GPC precast market, accounting for 42% of global consumption, with China and Australia leading implementation. Europe follows at 31% market share, where countries like the UK and Germany have established research centers dedicated to geopolymer technology advancement. North America represents 18% of the market, with slower adoption due to established concrete industry practices but accelerating interest from government infrastructure projects.

By application segment, structural components such as beams and columns represent the largest market share at 37%, followed by wall panels (28%), floor and roof elements (22%), and specialty applications (13%). The infrastructure sector currently consumes 46% of GPC precast elements, with commercial construction at 32% and residential applications growing rapidly from a smaller 22% base.

Key market drivers include increasingly stringent environmental regulations, rising cement prices (up 18% globally since 2020), and growing awareness of GPC's superior performance characteristics such as chemical resistance and fire resistance. However, market challenges persist, including higher initial production costs (typically 15-25% above traditional concrete), limited industry standardization, and knowledge gaps regarding long-term performance.

Customer demand analysis indicates that large construction firms and government infrastructure projects are the primary early adopters, with price sensitivity decreasing as environmental performance becomes a more significant factor in material selection. Market surveys show that 67% of commercial builders now consider environmental impact in material selection, up from 41% five years ago.

The competitive landscape remains fragmented, with specialized manufacturers dominating rather than traditional concrete giants, creating opportunities for innovative startups and research-driven companies with expertise in optimized curing profiles and quality control methodologies for GPC precast elements.

Current Curing Challenges and Technical Limitations

The current state of curing technology for Geopolymer Concrete (GPC) precast elements faces significant challenges that limit widespread industrial adoption. Traditional ambient curing methods often result in inconsistent mechanical properties and extended setting times, making production scheduling difficult for manufacturers. When examining heat curing approaches, maintaining precise temperature control throughout large precast elements presents substantial technical difficulties, with temperature gradients causing internal stresses and potential microcracking.

Energy consumption during the curing process remains a critical limitation, particularly for heat curing which requires substantial energy input to maintain elevated temperatures (typically 60-80°C) for extended periods (8-24 hours). This energy requirement directly impacts production costs and carbon footprint, partially undermining the environmental benefits of GPC over traditional concrete.

Quality control mechanisms for GPC curing are notably underdeveloped compared to those for Ordinary Portland Cement (OPC) concrete. Real-time monitoring systems capable of tracking the geopolymerization process are limited, with most manufacturers relying on post-production testing rather than in-process quality assurance. This reactive approach leads to higher rejection rates and material waste.

The variability of raw materials presents another significant challenge. Fly ash and slag compositions can vary considerably between sources and even batches, requiring constant adjustment of mix designs and curing profiles. Current technology lacks robust adaptive systems that can automatically modify curing parameters based on raw material characteristics.

Scaling issues further complicate the curing process, as laboratory-optimized curing profiles often perform differently when applied to industrial-scale precast elements. The thermal mass effect in larger elements creates uneven curing conditions, with core and surface regions experiencing different reaction rates and potentially different microstructural development.

Humidity control during curing represents another technical limitation, as moisture loss during heat curing can impair the geopolymerization process. Current enclosure systems and moisture retention technologies are often inadequate for maintaining optimal humidity levels throughout the entire curing cycle.

The lack of standardized curing protocols specifically designed for GPC precast elements hampers quality consistency across the industry. Unlike OPC concrete, which benefits from decades of standardization, GPC curing remains largely based on manufacturer-specific practices rather than universally accepted standards. This absence of standardization creates barriers to market entry and complicates quality assurance processes for end users.

Energy consumption during the curing process remains a critical limitation, particularly for heat curing which requires substantial energy input to maintain elevated temperatures (typically 60-80°C) for extended periods (8-24 hours). This energy requirement directly impacts production costs and carbon footprint, partially undermining the environmental benefits of GPC over traditional concrete.

Quality control mechanisms for GPC curing are notably underdeveloped compared to those for Ordinary Portland Cement (OPC) concrete. Real-time monitoring systems capable of tracking the geopolymerization process are limited, with most manufacturers relying on post-production testing rather than in-process quality assurance. This reactive approach leads to higher rejection rates and material waste.

The variability of raw materials presents another significant challenge. Fly ash and slag compositions can vary considerably between sources and even batches, requiring constant adjustment of mix designs and curing profiles. Current technology lacks robust adaptive systems that can automatically modify curing parameters based on raw material characteristics.

Scaling issues further complicate the curing process, as laboratory-optimized curing profiles often perform differently when applied to industrial-scale precast elements. The thermal mass effect in larger elements creates uneven curing conditions, with core and surface regions experiencing different reaction rates and potentially different microstructural development.

Humidity control during curing represents another technical limitation, as moisture loss during heat curing can impair the geopolymerization process. Current enclosure systems and moisture retention technologies are often inadequate for maintaining optimal humidity levels throughout the entire curing cycle.

The lack of standardized curing protocols specifically designed for GPC precast elements hampers quality consistency across the industry. Unlike OPC concrete, which benefits from decades of standardization, GPC curing remains largely based on manufacturer-specific practices rather than universally accepted standards. This absence of standardization creates barriers to market entry and complicates quality assurance processes for end users.

Established Curing Profiles and Quality Control Protocols

01 Temperature-controlled curing processes for GPC precast elements

Temperature control during the curing process of geopolymer cement (GPC) precast elements significantly affects the final strength and durability of the product. Various heating methods and temperature profiles can be applied to optimize the curing process, including gradual temperature increases, maintaining specific temperature ranges, and controlled cooling phases. These temperature-controlled curing processes can enhance the mechanical properties and reduce curing time for GPC precast elements.- Temperature-controlled curing processes for GPC precast elements: Temperature control during the curing process of geopolymer cement (GPC) precast elements significantly affects the final strength and durability of the product. Various heating methods and temperature profiles can be employed to optimize the curing process, including steam curing, electrical heating, and controlled ambient temperature environments. The optimal temperature range typically falls between 40-80°C, with specific profiles designed to gradually increase and maintain temperature for proper geopolymerization reactions.

- Time-dependent curing profiles for enhanced mechanical properties: The duration and timing of the curing process for GPC precast elements play crucial roles in developing optimal mechanical properties. Research indicates that specific time-dependent curing profiles can enhance compressive strength, reduce shrinkage, and improve overall durability. These profiles typically involve an initial setting period at ambient temperature followed by accelerated curing phases. The total curing time can range from 24 hours to several days depending on the specific formulation and desired properties of the final product.

- Humidity control systems for GPC precast element curing: Maintaining appropriate humidity levels during the curing process of geopolymer cement precast elements is essential for preventing premature drying and ensuring complete geopolymerization. Various humidity control systems have been developed, including sealed curing chambers, water spraying mechanisms, and humidity-controlled environments. Optimal relative humidity levels typically range between 80-95% during the critical initial curing phase, gradually reducing as the curing process progresses to allow for controlled moisture release from the elements.

- Accelerated curing techniques for GPC precast production: Accelerated curing techniques have been developed to reduce production time and increase manufacturing efficiency for geopolymer cement precast elements. These techniques include microwave curing, infrared heating, and high-pressure steam curing. By carefully controlling the acceleration parameters, manufacturers can achieve comparable or superior mechanical properties compared to conventional curing methods while significantly reducing the overall production cycle time. These methods are particularly valuable for high-volume production facilities where turnover rate directly impacts profitability.

- Multi-stage curing profiles for complex GPC precast elements: Complex geopolymer cement precast elements often require multi-stage curing profiles to account for varying thickness, reinforcement configurations, and geometric complexities. These profiles typically involve different temperature, humidity, and pressure conditions applied in sequence to ensure uniform curing throughout the element. Advanced monitoring systems using embedded sensors can track the curing progress in real-time, allowing for dynamic adjustments to the curing parameters based on the actual geopolymerization reaction progress within different sections of the element.

02 Steam curing techniques for GPC precast elements

Steam curing is widely used for geopolymer cement precast elements to accelerate the curing process and improve strength development. This technique involves exposing the precast elements to steam at controlled temperature and pressure conditions for specific durations. Steam curing creates a humid environment that facilitates the geopolymerization reaction, resulting in enhanced mechanical properties and reduced curing time compared to ambient curing methods.Expand Specific Solutions03 Multi-stage curing profiles for optimized GPC performance

Multi-stage curing profiles involve a sequence of different curing conditions applied at specific intervals to optimize the performance of geopolymer cement precast elements. These profiles typically include an initial pre-curing phase at ambient temperature, followed by accelerated curing at elevated temperatures, and finally a controlled cooling phase. This approach allows for better control of the geopolymerization reaction, resulting in improved mechanical properties, reduced shrinkage, and enhanced durability of the final product.Expand Specific Solutions04 Ambient temperature curing methods for GPC precast elements

Ambient temperature curing methods for geopolymer cement precast elements involve curing at room temperature without additional heat application. These methods often utilize specific activators or admixtures to facilitate the geopolymerization reaction at lower temperatures. While ambient curing typically requires longer curing times compared to heat-accelerated methods, it offers advantages such as reduced energy consumption, simpler production processes, and lower carbon footprint. Various techniques can be employed to enhance the effectiveness of ambient curing, including humidity control and the use of specialized curing compounds.Expand Specific Solutions05 Specialized equipment and systems for controlled curing of GPC elements

Specialized equipment and systems are designed specifically for the controlled curing of geopolymer cement precast elements. These include automated curing chambers with precise temperature and humidity control, heat circulation systems, steam generators, and monitoring devices that track curing parameters in real-time. Advanced systems may incorporate programmable curing profiles that can be customized based on the specific composition of the geopolymer mix and the desired properties of the final product. These specialized curing systems ensure consistency in the quality of precast elements and optimize the curing process for improved efficiency and performance.Expand Specific Solutions

Key Patents and Research in GPC Curing Technology

Advanced quality control tools for manufacturing bimodal and multimodal polyethylene resins

PatentWO2019168729A1

Innovation

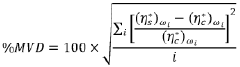

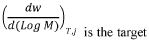

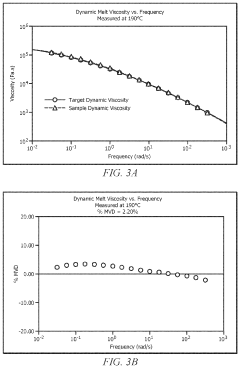

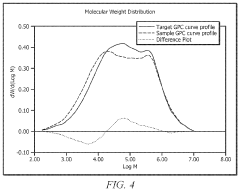

- A method involving polymerization in multiple reaction zones with independent control of ethylene concentration, comonomer concentration, hydrogen to ethylene ratio, temperature, catalyst concentration, cocatalyst concentration, pressure, and residence time, followed by dynamic viscosity and gel permeation chromatography (GPC) analysis to characterize resin quality, with adjustments to parameters to achieve target dynamic viscosity and GPC curve profile deviations.

Advanced Quality Control Tools for Manufacturing Bimodal and Multimodal Polyethylene Resins

PatentPendingUS20230322973A1

Innovation

- A method involving polymerization in multiple reaction zones with independent control of parameters like ethylene concentration, comonomer concentration, and catalyst levels, followed by dynamic viscosity and gel permeation chromatography (GPC) analysis to assess and adjust resin properties to meet target deviations, ensuring high-quality resin production.

Environmental Impact and Sustainability Considerations

Geopolymer concrete (GPC) precast elements represent a significant advancement in sustainable construction materials, offering substantial environmental benefits compared to traditional Portland cement concrete. The production of GPC generates approximately 80% less carbon dioxide emissions than conventional concrete, primarily due to the elimination of the energy-intensive clinker production process. This reduction in greenhouse gas emissions positions GPC as a critical technology for meeting global carbon reduction targets in the construction industry, which currently accounts for nearly 8% of global CO2 emissions.

The sustainability profile of GPC extends beyond carbon footprint considerations. The curing process for GPC precast elements typically requires less energy than traditional concrete when optimized properly. Lower-temperature curing profiles, ranging from ambient to moderate heat (60-80°C), can be developed to minimize energy consumption while maintaining structural integrity. Additionally, GPC formulations can incorporate various industrial by-products such as fly ash, ground granulated blast furnace slag, and other aluminosilicate waste materials, effectively transforming industrial waste into valuable construction resources.

Water conservation represents another significant environmental advantage of GPC technology. The curing profiles for GPC can be designed to minimize water usage compared to conventional concrete curing methods. Closed-loop water systems in precast facilities can further reduce the environmental impact, with potential water savings of 30-50% compared to traditional concrete manufacturing processes. Quality control checks should include monitoring of water consumption metrics to ensure sustainability targets are consistently met.

Life cycle assessment (LCA) studies indicate that GPC precast elements, when properly manufactured with optimized curing profiles, can achieve a 40-70% reduction in environmental impact across multiple indicators including global warming potential, acidification, and resource depletion. However, these benefits are highly dependent on local material availability, transportation distances of raw materials, and the specific energy mix used in production facilities. Quality control protocols should therefore include verification of supply chain sustainability metrics to maintain the environmental advantages of GPC products.

The durability characteristics of properly cured GPC precast elements further enhance their sustainability profile. Research indicates that well-cured GPC can demonstrate superior resistance to chemical attack, freeze-thaw cycles, and chloride penetration compared to conventional concrete. This enhanced durability translates to longer service life and reduced maintenance requirements, factors that significantly improve the life-cycle environmental performance of structures. Quality control checks should therefore include accelerated durability testing to ensure that the environmental benefits are maintained throughout the intended service life of the precast elements.

The sustainability profile of GPC extends beyond carbon footprint considerations. The curing process for GPC precast elements typically requires less energy than traditional concrete when optimized properly. Lower-temperature curing profiles, ranging from ambient to moderate heat (60-80°C), can be developed to minimize energy consumption while maintaining structural integrity. Additionally, GPC formulations can incorporate various industrial by-products such as fly ash, ground granulated blast furnace slag, and other aluminosilicate waste materials, effectively transforming industrial waste into valuable construction resources.

Water conservation represents another significant environmental advantage of GPC technology. The curing profiles for GPC can be designed to minimize water usage compared to conventional concrete curing methods. Closed-loop water systems in precast facilities can further reduce the environmental impact, with potential water savings of 30-50% compared to traditional concrete manufacturing processes. Quality control checks should include monitoring of water consumption metrics to ensure sustainability targets are consistently met.

Life cycle assessment (LCA) studies indicate that GPC precast elements, when properly manufactured with optimized curing profiles, can achieve a 40-70% reduction in environmental impact across multiple indicators including global warming potential, acidification, and resource depletion. However, these benefits are highly dependent on local material availability, transportation distances of raw materials, and the specific energy mix used in production facilities. Quality control protocols should therefore include verification of supply chain sustainability metrics to maintain the environmental advantages of GPC products.

The durability characteristics of properly cured GPC precast elements further enhance their sustainability profile. Research indicates that well-cured GPC can demonstrate superior resistance to chemical attack, freeze-thaw cycles, and chloride penetration compared to conventional concrete. This enhanced durability translates to longer service life and reduced maintenance requirements, factors that significantly improve the life-cycle environmental performance of structures. Quality control checks should therefore include accelerated durability testing to ensure that the environmental benefits are maintained throughout the intended service life of the precast elements.

Standardization and Certification Requirements

The standardization and certification landscape for Geopolymer Concrete (GPC) precast elements remains fragmented globally, presenting significant challenges for widespread industry adoption. Currently, most countries lack specific standards for GPC, forcing manufacturers to adapt existing Portland cement concrete (PCC) standards which may not adequately address GPC's unique properties and curing requirements. This regulatory gap creates uncertainty for stakeholders and impedes market penetration.

Key international standardization bodies including ASTM International, European Committee for Standardization (CEN), and International Organization for Standardization (ISO) have begun developing frameworks for alternative cementitious materials, though comprehensive GPC-specific standards remain limited. Australia leads with AS 3600 Supplement 1, which provides guidance on GPC applications, while other regions are still in developmental phases.

For GPC precast elements, certification requirements must address the specialized curing profiles that differ substantially from traditional concrete. Temperature-controlled curing regimes, typically ranging from 40°C to 80°C, require standardized monitoring protocols and documentation procedures. Quality control certification should mandate continuous temperature logging throughout the curing process with calibrated thermocouples at critical locations within elements.

Durability testing protocols represent another critical certification component, with accelerated testing methods needed to verify long-term performance. Standardized leaching tests, freeze-thaw resistance assessments, and alkali-silica reaction evaluations must be adapted specifically for GPC materials to ensure structural integrity over the designed service life.

Environmental certification frameworks are increasingly important, with Environmental Product Declarations (EPDs) becoming mandatory in many jurisdictions. GPC manufacturers must quantify and verify carbon footprint reductions compared to conventional concrete, requiring standardized life cycle assessment methodologies specific to geopolymer chemistry and raw material sourcing.

Performance-based certification approaches offer the most promising path forward, focusing on end-product requirements rather than prescriptive mix designs. This allows for innovation while maintaining quality assurance. Third-party certification bodies with expertise in alternative cementitious materials will be essential to validate compliance and build market confidence in GPC precast elements.

Key international standardization bodies including ASTM International, European Committee for Standardization (CEN), and International Organization for Standardization (ISO) have begun developing frameworks for alternative cementitious materials, though comprehensive GPC-specific standards remain limited. Australia leads with AS 3600 Supplement 1, which provides guidance on GPC applications, while other regions are still in developmental phases.

For GPC precast elements, certification requirements must address the specialized curing profiles that differ substantially from traditional concrete. Temperature-controlled curing regimes, typically ranging from 40°C to 80°C, require standardized monitoring protocols and documentation procedures. Quality control certification should mandate continuous temperature logging throughout the curing process with calibrated thermocouples at critical locations within elements.

Durability testing protocols represent another critical certification component, with accelerated testing methods needed to verify long-term performance. Standardized leaching tests, freeze-thaw resistance assessments, and alkali-silica reaction evaluations must be adapted specifically for GPC materials to ensure structural integrity over the designed service life.

Environmental certification frameworks are increasingly important, with Environmental Product Declarations (EPDs) becoming mandatory in many jurisdictions. GPC manufacturers must quantify and verify carbon footprint reductions compared to conventional concrete, requiring standardized life cycle assessment methodologies specific to geopolymer chemistry and raw material sourcing.

Performance-based certification approaches offer the most promising path forward, focusing on end-product requirements rather than prescriptive mix designs. This allows for innovation while maintaining quality assurance. Third-party certification bodies with expertise in alternative cementitious materials will be essential to validate compliance and build market confidence in GPC precast elements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!