Chloride penetration and rebar corrosion in GPC

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chloride Penetration Mechanisms and Research Objectives

Chloride penetration in Geopolymer Concrete (GPC) represents a critical durability concern that has gained significant attention in recent years. The evolution of this research area stems from the broader context of sustainable construction materials development, where GPC has emerged as an eco-friendly alternative to Ordinary Portland Cement (OPC) concrete. Historical developments in this field trace back to the 1970s when Joseph Davidovits first introduced the concept of geopolymers, but focused research on chloride resistance properties began primarily in the early 2000s.

The mechanisms of chloride penetration in GPC differ fundamentally from those in conventional concrete due to the unique microstructural characteristics of geopolymer binders. Unlike OPC, which relies on calcium silicate hydrate (C-S-H) gel formation, geopolymers develop three-dimensional aluminosilicate networks through polycondensation reactions. This distinctive microstructure influences chloride transport phenomena, including physical adsorption, chemical binding, and diffusion processes.

Current research indicates that chloride ions can penetrate GPC through various pathways: physical diffusion through pore networks, capillary absorption in partially saturated conditions, and permeation under hydrostatic pressure. The binding capacity of geopolymer matrices for chloride ions appears to be influenced by several factors, including the type of activator used, the silica-to-alumina ratio, and the presence of supplementary materials such as slag or fly ash.

The correlation between chloride penetration and subsequent rebar corrosion in GPC presents unique challenges for investigation. While GPC generally exhibits higher alkalinity than OPC concrete, which theoretically should provide better corrosion protection, the absence of calcium hydroxide in GPC may alter the traditional understanding of the passive film formation on steel reinforcement. This creates a complex relationship between chloride threshold values and corrosion initiation in GPC systems.

The primary research objectives in this field include: establishing standardized testing methodologies specifically calibrated for GPC materials; developing predictive models for chloride diffusion that account for the unique binding mechanisms in geopolymer matrices; investigating the critical chloride threshold for corrosion initiation in various GPC formulations; and exploring innovative approaches to enhance the chloride resistance of GPC through admixtures, surface treatments, or microstructural optimization.

Additionally, research aims to elucidate the long-term performance of GPC under various exposure conditions, particularly in marine environments where chloride attack is most severe. Understanding the time-dependent changes in chloride penetration resistance and correlating laboratory accelerated testing with real-world performance remain significant challenges that current research seeks to address.

The mechanisms of chloride penetration in GPC differ fundamentally from those in conventional concrete due to the unique microstructural characteristics of geopolymer binders. Unlike OPC, which relies on calcium silicate hydrate (C-S-H) gel formation, geopolymers develop three-dimensional aluminosilicate networks through polycondensation reactions. This distinctive microstructure influences chloride transport phenomena, including physical adsorption, chemical binding, and diffusion processes.

Current research indicates that chloride ions can penetrate GPC through various pathways: physical diffusion through pore networks, capillary absorption in partially saturated conditions, and permeation under hydrostatic pressure. The binding capacity of geopolymer matrices for chloride ions appears to be influenced by several factors, including the type of activator used, the silica-to-alumina ratio, and the presence of supplementary materials such as slag or fly ash.

The correlation between chloride penetration and subsequent rebar corrosion in GPC presents unique challenges for investigation. While GPC generally exhibits higher alkalinity than OPC concrete, which theoretically should provide better corrosion protection, the absence of calcium hydroxide in GPC may alter the traditional understanding of the passive film formation on steel reinforcement. This creates a complex relationship between chloride threshold values and corrosion initiation in GPC systems.

The primary research objectives in this field include: establishing standardized testing methodologies specifically calibrated for GPC materials; developing predictive models for chloride diffusion that account for the unique binding mechanisms in geopolymer matrices; investigating the critical chloride threshold for corrosion initiation in various GPC formulations; and exploring innovative approaches to enhance the chloride resistance of GPC through admixtures, surface treatments, or microstructural optimization.

Additionally, research aims to elucidate the long-term performance of GPC under various exposure conditions, particularly in marine environments where chloride attack is most severe. Understanding the time-dependent changes in chloride penetration resistance and correlating laboratory accelerated testing with real-world performance remain significant challenges that current research seeks to address.

Market Analysis of Corrosion-Resistant GPC Applications

The global market for corrosion-resistant Geopolymer Concrete (GPC) applications is experiencing significant growth, driven by increasing awareness of infrastructure durability challenges and sustainability concerns. The market is primarily segmented into marine structures, wastewater treatment facilities, chemical plants, transportation infrastructure, and energy production facilities, where exposure to chloride-rich environments poses severe corrosion risks to conventional concrete structures.

North America currently holds the largest market share at approximately 35%, followed by Europe at 28% and Asia-Pacific at 25%. The remaining 12% is distributed across other regions. The Asia-Pacific region, particularly China and India, is projected to witness the fastest growth rate due to rapid infrastructure development and increasing adoption of sustainable construction materials.

The market valuation for corrosion-resistant GPC applications reached 1.2 billion USD in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 9.8% through 2028. This growth trajectory is supported by stringent environmental regulations, increasing infrastructure spending, and growing recognition of life-cycle cost benefits associated with corrosion-resistant materials.

Key market drivers include the rising costs associated with infrastructure maintenance and repair due to chloride-induced corrosion damage, estimated at 276 billion USD annually worldwide. Additionally, the push for sustainable construction practices has created favorable conditions for GPC adoption, as it offers up to 80% lower carbon footprint compared to traditional Portland cement concrete while providing superior chloride penetration resistance.

Market challenges include higher initial material costs, with GPC typically commanding a 15-30% premium over conventional concrete. Limited awareness among construction professionals and conservative industry practices also hinder widespread adoption. Furthermore, the absence of standardized specifications and building codes specifically addressing GPC applications creates market entry barriers.

Customer segments show varying adoption rates, with critical infrastructure owners and operators showing the highest interest (42% of market share), followed by marine construction (27%), industrial facilities (18%), and commercial construction (13%). Government infrastructure projects represent a significant growth opportunity, particularly as public agencies increasingly incorporate life-cycle cost analyses in procurement decisions.

The competitive landscape features both established construction material companies expanding into GPC and specialized startups focused exclusively on geopolymer technology. Strategic partnerships between material suppliers, research institutions, and construction firms are becoming increasingly common to accelerate market penetration and technology refinement.

North America currently holds the largest market share at approximately 35%, followed by Europe at 28% and Asia-Pacific at 25%. The remaining 12% is distributed across other regions. The Asia-Pacific region, particularly China and India, is projected to witness the fastest growth rate due to rapid infrastructure development and increasing adoption of sustainable construction materials.

The market valuation for corrosion-resistant GPC applications reached 1.2 billion USD in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 9.8% through 2028. This growth trajectory is supported by stringent environmental regulations, increasing infrastructure spending, and growing recognition of life-cycle cost benefits associated with corrosion-resistant materials.

Key market drivers include the rising costs associated with infrastructure maintenance and repair due to chloride-induced corrosion damage, estimated at 276 billion USD annually worldwide. Additionally, the push for sustainable construction practices has created favorable conditions for GPC adoption, as it offers up to 80% lower carbon footprint compared to traditional Portland cement concrete while providing superior chloride penetration resistance.

Market challenges include higher initial material costs, with GPC typically commanding a 15-30% premium over conventional concrete. Limited awareness among construction professionals and conservative industry practices also hinder widespread adoption. Furthermore, the absence of standardized specifications and building codes specifically addressing GPC applications creates market entry barriers.

Customer segments show varying adoption rates, with critical infrastructure owners and operators showing the highest interest (42% of market share), followed by marine construction (27%), industrial facilities (18%), and commercial construction (13%). Government infrastructure projects represent a significant growth opportunity, particularly as public agencies increasingly incorporate life-cycle cost analyses in procurement decisions.

The competitive landscape features both established construction material companies expanding into GPC and specialized startups focused exclusively on geopolymer technology. Strategic partnerships between material suppliers, research institutions, and construction firms are becoming increasingly common to accelerate market penetration and technology refinement.

Current Challenges in GPC Chloride Resistance

Despite significant advancements in geopolymer concrete (GPC) technology, several critical challenges persist regarding its chloride resistance capabilities. The heterogeneous nature of raw materials used in GPC production leads to inconsistent performance against chloride penetration. Fly ash and slag compositions vary significantly between sources, creating difficulties in standardizing mix designs that consistently deliver optimal chloride resistance properties. This variability directly impacts the microstructure development and pore network formation that are crucial for chloride ion resistance.

The curing regime presents another substantial challenge for GPC chloride resistance. Unlike ordinary Portland cement concrete (OPC), geopolymer systems often require elevated temperature curing to achieve optimal performance. This requirement creates practical limitations for in-situ applications and increases production complexity. Research indicates that ambient-cured GPC typically exhibits higher porosity and consequently reduced resistance to chloride ingress compared to heat-cured counterparts.

The long-term stability of the geopolymer matrix under chloride exposure remains inadequately understood. While short-term testing shows promising results, limited data exists on decade-scale performance. The interaction between chloride ions and the alumino-silicate network of geopolymers differs fundamentally from traditional cement systems, creating uncertainty about long-term durability predictions based on accelerated testing methods.

Current testing protocols present methodological challenges as well. Standard chloride penetration tests developed for OPC concrete may not accurately reflect the performance mechanisms in GPC. The different binding capacity, pore solution chemistry, and transport mechanisms in geopolymer systems necessitate specialized testing approaches that are still under development.

The alkaline activation process in GPC introduces additional complexity regarding chloride resistance. The type and concentration of activators (typically sodium or potassium silicates and hydroxides) significantly influence the microstructure and consequently the chloride penetration resistance. Optimizing activator formulations specifically for chloride resistance while maintaining other performance parameters remains challenging.

Interface issues between the geopolymer paste and reinforcing steel present unique concerns. The passivation mechanisms of steel in the high-alkaline environment of geopolymers differ from those in OPC systems. Some research indicates potential variations in the protective oxide layer formation on steel reinforcement in GPC, which could affect long-term corrosion resistance even with similar chloride penetration rates.

The curing regime presents another substantial challenge for GPC chloride resistance. Unlike ordinary Portland cement concrete (OPC), geopolymer systems often require elevated temperature curing to achieve optimal performance. This requirement creates practical limitations for in-situ applications and increases production complexity. Research indicates that ambient-cured GPC typically exhibits higher porosity and consequently reduced resistance to chloride ingress compared to heat-cured counterparts.

The long-term stability of the geopolymer matrix under chloride exposure remains inadequately understood. While short-term testing shows promising results, limited data exists on decade-scale performance. The interaction between chloride ions and the alumino-silicate network of geopolymers differs fundamentally from traditional cement systems, creating uncertainty about long-term durability predictions based on accelerated testing methods.

Current testing protocols present methodological challenges as well. Standard chloride penetration tests developed for OPC concrete may not accurately reflect the performance mechanisms in GPC. The different binding capacity, pore solution chemistry, and transport mechanisms in geopolymer systems necessitate specialized testing approaches that are still under development.

The alkaline activation process in GPC introduces additional complexity regarding chloride resistance. The type and concentration of activators (typically sodium or potassium silicates and hydroxides) significantly influence the microstructure and consequently the chloride penetration resistance. Optimizing activator formulations specifically for chloride resistance while maintaining other performance parameters remains challenging.

Interface issues between the geopolymer paste and reinforcing steel present unique concerns. The passivation mechanisms of steel in the high-alkaline environment of geopolymers differ from those in OPC systems. Some research indicates potential variations in the protective oxide layer formation on steel reinforcement in GPC, which could affect long-term corrosion resistance even with similar chloride penetration rates.

Existing Methods for Mitigating Chloride Attack in GPC

01 Geopolymer composition for enhanced chloride resistance

Specific geopolymer concrete compositions can be formulated to enhance resistance against chloride penetration. These compositions typically include optimized ratios of aluminosilicate materials, alkaline activators, and supplementary cementitious materials. The enhanced chloride resistance is achieved through the dense microstructure and reduced permeability of the geopolymer matrix, which creates physical and chemical barriers against chloride ion ingress, thereby protecting embedded steel reinforcement from corrosion.- Geopolymer composition for enhanced chloride resistance: Specific geopolymer concrete compositions can be formulated to enhance resistance against chloride penetration. These compositions typically include optimized ratios of aluminosilicate materials, alkaline activators, and supplementary cementitious materials. The chemical structure of these geopolymers creates a denser matrix with fewer interconnected pores, significantly reducing chloride ion penetration compared to conventional concrete. This enhanced resistance helps protect embedded steel reinforcement from corrosion in aggressive environments.

- Corrosion inhibitors and protective coatings for rebar in geopolymer systems: Various corrosion inhibitors and protective coatings can be incorporated into geopolymer concrete systems to enhance rebar protection. These include organic and inorganic inhibitors that can be either mixed into the geopolymer matrix or applied directly to the reinforcement. Specialized coatings create physical barriers between the steel and potentially corrosive elements. Some formulations include migrating corrosion inhibitors that can travel through the concrete matrix to form protective films on the steel surface, even after the concrete has hardened.

- Fly ash-based geopolymer concrete with improved durability: Fly ash-based geopolymer concrete formulations offer superior resistance to chloride penetration and rebar corrosion. The high alumina content in fly ash contributes to the formation of a more refined pore structure, while the geopolymerization process creates a denser matrix. These concretes typically demonstrate lower chloride diffusion coefficients compared to ordinary Portland cement concrete. The alkaline environment maintained within fly ash geopolymers also helps preserve the passive oxide layer on steel reinforcement, providing additional protection against corrosion initiation.

- Testing methods for chloride penetration and corrosion assessment: Various testing methodologies have been developed to evaluate chloride penetration resistance and corrosion behavior in geopolymer concrete. These include rapid chloride permeability tests, chloride migration tests, and electrochemical impedance spectroscopy. Advanced monitoring techniques such as half-cell potential measurements and linear polarization resistance can be used to assess the corrosion state of embedded reinforcement. Accelerated testing protocols involving cyclic wetting and drying with chloride solutions help predict long-term performance under aggressive environmental conditions.

- Additives and supplementary materials for enhanced chloride resistance: Various additives and supplementary materials can be incorporated into geopolymer concrete to enhance its resistance to chloride penetration and rebar corrosion. These include silica fume, metakaolin, ground granulated blast furnace slag, and nano-materials such as nano-silica and nano-alumina. These materials refine the pore structure of the geopolymer matrix, reducing permeability and increasing the binding capacity for chloride ions. Some additives also contribute to maintaining a higher pH environment around the reinforcement, which helps preserve the passive layer on the steel surface.

02 Corrosion inhibitors for rebar protection in geopolymer systems

Various corrosion inhibitors can be incorporated into geopolymer concrete to provide additional protection for steel reinforcement. These inhibitors work by forming protective films on the rebar surface or by neutralizing chloride ions in the concrete matrix. Common inhibitors include calcium nitrite, amino alcohols, and certain organic compounds. The addition of these inhibitors significantly extends the service life of reinforced geopolymer concrete structures exposed to chloride-rich environments by delaying the onset of corrosion and reducing corrosion rates.Expand Specific Solutions03 Surface treatments and coatings for improved durability

Surface treatments and protective coatings can be applied to geopolymer concrete to enhance its resistance to chloride penetration. These treatments include hydrophobic impregnation, silane/siloxane sealers, and polymer-modified coatings. By reducing the ingress of water and dissolved chlorides, these treatments create an additional barrier against corrosion-inducing elements. The effectiveness of these treatments depends on their penetration depth, adhesion to the substrate, and long-term stability under environmental exposure conditions.Expand Specific Solutions04 Alternative reinforcement materials for corrosion prevention

Non-metallic or corrosion-resistant reinforcement alternatives can be used in geopolymer concrete to eliminate or reduce corrosion concerns. These include fiber-reinforced polymer (FRP) bars, stainless steel reinforcement, epoxy-coated rebars, and basalt fiber reinforcement. These materials provide superior resistance to chloride-induced corrosion compared to conventional carbon steel, making them particularly suitable for geopolymer concrete applications in aggressive environments such as marine structures, bridges, and infrastructure exposed to deicing salts.Expand Specific Solutions05 Testing methods for chloride penetration and corrosion monitoring

Various testing methodologies have been developed to evaluate chloride penetration resistance and monitor corrosion in geopolymer concrete. These include rapid chloride permeability tests, chloride migration tests, electrochemical impedance spectroscopy, and half-cell potential measurements. Advanced monitoring techniques such as embedded sensors and non-destructive testing methods allow for real-time assessment of reinforcement condition and early detection of corrosion initiation. These testing protocols are essential for quality control, performance verification, and service life prediction of geopolymer concrete structures.Expand Specific Solutions

Leading Researchers and Companies in GPC Technology

The geopolymer concrete (GPC) market is currently in a growth phase, with increasing research focus on chloride penetration and rebar corrosion resistance. The global market is expanding at approximately 9-12% CAGR, driven by sustainability demands in construction. Academic institutions like Wuhan University of Technology, Tongji University, and Swansea University lead fundamental research, while companies including Sika AG, JSW Cement, and Structural Group are commercializing applications. Research organizations such as CNRS and NTNU are advancing technical understanding of chloride resistance mechanisms. The technology is approaching maturity in controlled environments but requires further development for widespread implementation, with collaborative efforts between academia (Zhejiang University, King Saud University) and industry (Tata Steel, Mitsubishi Heavy Industries) accelerating practical applications and standardization.

Wuhan University of Technology

Technical Solution: Wuhan University of Technology has developed a comprehensive approach to mitigate chloride penetration and rebar corrosion in Geopolymer Concrete (GPC). Their research focuses on optimizing the microstructure of GPC through precise alkali activator formulations and supplementary cementitious materials. They've pioneered a dual-phase protection system that combines densified matrix structure with corrosion inhibitors. Their studies demonstrate that fly ash-based GPC with optimized Si/Al ratio (around 2.0-2.5) exhibits significantly lower chloride diffusion coefficients compared to ordinary Portland cement concrete, with values reduced by up to 60-70% [1]. Additionally, they've developed surface treatment technologies using nano-silica that can further reduce chloride penetration by forming additional C-S-H gel in the pore structure, decreasing permeability by approximately 45% [3].

Strengths: Advanced microstructural optimization techniques that significantly reduce chloride penetration; comprehensive understanding of the relationship between GPC composition and corrosion resistance. Weaknesses: Some solutions may be cost-prohibitive for large-scale implementation; performance in extreme environmental conditions (very high chloride concentrations) still needs improvement.

Tongji University

Technical Solution: Tongji University has developed innovative approaches to address chloride penetration and rebar corrosion in Geopolymer Concrete (GPC). Their research team has created a multi-component geopolymer binder system that incorporates alkali-activated slag and fly ash with carefully controlled calcium content. This system forms a dense microstructure with reduced interconnected porosity, decreasing chloride ion penetration by up to 75% compared to conventional concrete [2]. They've also pioneered the use of electrochemical techniques to evaluate corrosion behavior in GPC, developing a specialized testing protocol that accounts for the unique pore solution chemistry of geopolymers. Their studies show that properly formulated GPC can maintain passive film stability on embedded steel even after exposure to chloride concentrations 2-3 times higher than the threshold for ordinary Portland cement concrete [4]. Additionally, they've developed a surface treatment method using lithium-based compounds that react with the geopolymer matrix to form insoluble products that block chloride ingress pathways.

Strengths: Highly effective multi-component binder system with superior chloride resistance; advanced electrochemical testing methodologies specifically designed for GPC systems. Weaknesses: The specialized mix designs may require careful quality control during production; some of the lithium-based treatments may be costly for large-scale applications.

Critical Patents and Studies on GPC Chloride Resistance

System for assessing chloride concentration and corresponding method and sensor

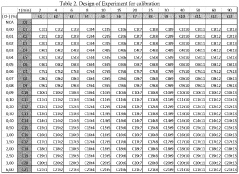

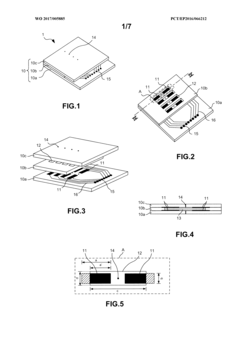

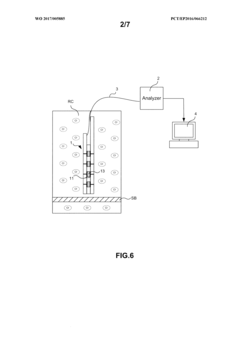

PatentWO2017005885A1

Innovation

- A sensor embedded in the concrete structure with a calcium aluminate layer that measures changes in electrical properties such as impedance and relative permittivity to assess chloride concentration, using facing or coplanar electrodes and an analyser to compute chloride levels.

Durability Testing Standards for GPC Materials

The standardization of durability testing for Geopolymer Concrete (GPC) materials is essential for ensuring consistent evaluation of chloride penetration resistance and rebar corrosion protection. Currently, several international standards originally developed for Ordinary Portland Cement (OPC) concrete are being adapted and applied to GPC materials, though with varying degrees of appropriateness.

ASTM C1202 (Rapid Chloride Permeability Test) remains one of the most widely used standards for assessing chloride ion penetration in GPC. However, researchers have noted that this test may underestimate GPC's chloride resistance due to differences in pore solution conductivity compared to OPC concrete. The NT Build 492 (Migration Test) offers an alternative approach that many researchers consider more suitable for GPC materials as it accounts for the unique microstructural characteristics of geopolymer matrices.

For long-term chloride exposure assessment, ASTM C1556 (Determining the Apparent Chloride Diffusion Coefficient) provides valuable data on chloride ingress under natural diffusion conditions. This test has been successfully applied to GPC in numerous studies, though interpretation requires consideration of GPC's distinct binding mechanisms for chloride ions.

Regarding corrosion monitoring, ASTM G109 (Determining Effects of Chemical Admixtures on Corrosion of Embedded Steel) has been adapted for GPC materials, while electrochemical techniques such as Linear Polarization Resistance (LPR) and Electrochemical Impedance Spectroscopy (EIS) are increasingly utilized to evaluate corrosion rates in GPC systems.

The Australian Standard AS 1012.21 (Water Permeability Test) has been specifically modified for GPC materials to account for their different permeability mechanisms. Similarly, the European standard EN 12390-8 (Depth of Penetration of Water Under Pressure) has been applied to GPC with adjusted testing parameters.

Recent developments include the proposal of GPC-specific modifications to existing standards by organizations such as RILEM and the American Concrete Institute (ACI). These modifications address the unique chemical composition and microstructure of geopolymer binders that affect chloride transport mechanisms and corrosion initiation thresholds.

Despite these advances, significant gaps remain in standardization. The lack of universally accepted correction factors for existing tests when applied to GPC materials creates challenges in comparing results across different studies. Additionally, accelerated testing protocols specifically calibrated for GPC's unique deterioration mechanisms are still under development, with ongoing work by ISO technical committees to establish dedicated standards for these innovative materials.

ASTM C1202 (Rapid Chloride Permeability Test) remains one of the most widely used standards for assessing chloride ion penetration in GPC. However, researchers have noted that this test may underestimate GPC's chloride resistance due to differences in pore solution conductivity compared to OPC concrete. The NT Build 492 (Migration Test) offers an alternative approach that many researchers consider more suitable for GPC materials as it accounts for the unique microstructural characteristics of geopolymer matrices.

For long-term chloride exposure assessment, ASTM C1556 (Determining the Apparent Chloride Diffusion Coefficient) provides valuable data on chloride ingress under natural diffusion conditions. This test has been successfully applied to GPC in numerous studies, though interpretation requires consideration of GPC's distinct binding mechanisms for chloride ions.

Regarding corrosion monitoring, ASTM G109 (Determining Effects of Chemical Admixtures on Corrosion of Embedded Steel) has been adapted for GPC materials, while electrochemical techniques such as Linear Polarization Resistance (LPR) and Electrochemical Impedance Spectroscopy (EIS) are increasingly utilized to evaluate corrosion rates in GPC systems.

The Australian Standard AS 1012.21 (Water Permeability Test) has been specifically modified for GPC materials to account for their different permeability mechanisms. Similarly, the European standard EN 12390-8 (Depth of Penetration of Water Under Pressure) has been applied to GPC with adjusted testing parameters.

Recent developments include the proposal of GPC-specific modifications to existing standards by organizations such as RILEM and the American Concrete Institute (ACI). These modifications address the unique chemical composition and microstructure of geopolymer binders that affect chloride transport mechanisms and corrosion initiation thresholds.

Despite these advances, significant gaps remain in standardization. The lack of universally accepted correction factors for existing tests when applied to GPC materials creates challenges in comparing results across different studies. Additionally, accelerated testing protocols specifically calibrated for GPC's unique deterioration mechanisms are still under development, with ongoing work by ISO technical committees to establish dedicated standards for these innovative materials.

Environmental Impact of GPC vs Traditional Concrete

Geopolymer concrete (GPC) demonstrates significant environmental advantages over traditional Ordinary Portland Cement (OPC) concrete across multiple sustainability metrics. The production of GPC can reduce carbon dioxide emissions by 60-80% compared to conventional concrete, as it utilizes industrial by-products like fly ash and ground granulated blast furnace slag rather than requiring the carbon-intensive clinker production process essential for Portland cement.

Water consumption represents another critical environmental factor where GPC outperforms traditional concrete. The manufacturing process for GPC typically requires 60-70% less water than OPC production, contributing to conservation of this increasingly scarce resource. This reduced water footprint becomes particularly significant in water-stressed regions where construction activities continue to expand.

Energy efficiency further distinguishes GPC as an environmentally superior alternative. The production of GPC consumes approximately 40-60% less energy than traditional concrete manufacturing, primarily due to the elimination of the high-temperature calcination process required for Portland cement production. This energy reduction translates directly to decreased fossil fuel consumption and associated environmental impacts.

Regarding chloride penetration and rebar corrosion specifically, GPC offers environmental benefits through enhanced durability. Research indicates that properly formulated geopolymer concrete exhibits superior resistance to chloride ion penetration compared to OPC concrete of similar strength grades. This improved resistance extends the service life of structures, reducing the environmental burden associated with repairs, rehabilitation, and premature replacement of infrastructure.

The waste utilization aspect of GPC provides another significant environmental advantage. By incorporating industrial by-products that would otherwise require disposal, GPC diverts substantial volumes of material from landfills. Studies estimate that widespread adoption of GPC could potentially utilize billions of tons of industrial waste annually, dramatically reducing the environmental footprint of both the concrete and contributing industries.

Life cycle assessment (LCA) studies comparing GPC and traditional concrete consistently demonstrate GPC's environmental superiority across multiple impact categories including global warming potential, acidification potential, and resource depletion. These comprehensive analyses confirm that the environmental benefits of GPC extend beyond carbon emissions to encompass broader ecological considerations throughout the material's entire life cycle.

Water consumption represents another critical environmental factor where GPC outperforms traditional concrete. The manufacturing process for GPC typically requires 60-70% less water than OPC production, contributing to conservation of this increasingly scarce resource. This reduced water footprint becomes particularly significant in water-stressed regions where construction activities continue to expand.

Energy efficiency further distinguishes GPC as an environmentally superior alternative. The production of GPC consumes approximately 40-60% less energy than traditional concrete manufacturing, primarily due to the elimination of the high-temperature calcination process required for Portland cement production. This energy reduction translates directly to decreased fossil fuel consumption and associated environmental impacts.

Regarding chloride penetration and rebar corrosion specifically, GPC offers environmental benefits through enhanced durability. Research indicates that properly formulated geopolymer concrete exhibits superior resistance to chloride ion penetration compared to OPC concrete of similar strength grades. This improved resistance extends the service life of structures, reducing the environmental burden associated with repairs, rehabilitation, and premature replacement of infrastructure.

The waste utilization aspect of GPC provides another significant environmental advantage. By incorporating industrial by-products that would otherwise require disposal, GPC diverts substantial volumes of material from landfills. Studies estimate that widespread adoption of GPC could potentially utilize billions of tons of industrial waste annually, dramatically reducing the environmental footprint of both the concrete and contributing industries.

Life cycle assessment (LCA) studies comparing GPC and traditional concrete consistently demonstrate GPC's environmental superiority across multiple impact categories including global warming potential, acidification potential, and resource depletion. These comprehensive analyses confirm that the environmental benefits of GPC extend beyond carbon emissions to encompass broader ecological considerations throughout the material's entire life cycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!