LCA of GPC supply chains: scope 3 hotspots

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GPC LCA Background and Objectives

Geopolymer Concrete (GPC) has emerged as a promising alternative to Ordinary Portland Cement (OPC) concrete, with the potential to significantly reduce carbon emissions in the construction industry. The development of GPC technology dates back to the 1970s when Joseph Davidovits first coined the term "geopolymer," but recent environmental concerns have accelerated research and implementation efforts. The evolution of GPC technology has been marked by continuous improvements in mix design, curing methods, and industrial by-product utilization as precursors.

The primary objective of conducting Life Cycle Assessment (LCA) on GPC supply chains is to comprehensively quantify and evaluate the environmental impacts associated with geopolymer concrete production, with particular emphasis on scope 3 emission hotspots. Scope 3 emissions, which encompass indirect emissions occurring in a company's value chain, represent a significant yet often overlooked component of the total carbon footprint in construction materials.

This technical research aims to establish a standardized methodology for assessing the complete environmental profile of GPC, from raw material extraction to end-of-life scenarios. By focusing on scope 3 emissions, we intend to identify critical intervention points within the supply chain where emissions reduction strategies would yield maximum benefits. The research will also facilitate meaningful comparisons between GPC and conventional concrete systems across various environmental impact categories.

Current technological trends in GPC development include the optimization of alkali activators, exploration of novel precursors beyond fly ash and slag, and enhancement of mechanical properties for specialized applications. These advancements necessitate updated and more granular LCA studies that can accurately reflect the environmental implications of these innovations.

The expected outcomes of this research include the development of a robust LCA framework specifically tailored for GPC systems, identification of key environmental hotspots within the supply chain, and formulation of evidence-based recommendations for reducing the carbon footprint of GPC production. Additionally, this research aims to contribute to the standardization of LCA methodologies for alternative cementitious materials, addressing current inconsistencies in system boundaries and impact assessment methods.

By establishing clear environmental benchmarks for GPC, this research will support informed decision-making among stakeholders in the construction industry and potentially accelerate the adoption of low-carbon concrete alternatives. The findings will also guide future research directions in geopolymer technology, focusing efforts on addressing the most environmentally impactful aspects of the production process.

The primary objective of conducting Life Cycle Assessment (LCA) on GPC supply chains is to comprehensively quantify and evaluate the environmental impacts associated with geopolymer concrete production, with particular emphasis on scope 3 emission hotspots. Scope 3 emissions, which encompass indirect emissions occurring in a company's value chain, represent a significant yet often overlooked component of the total carbon footprint in construction materials.

This technical research aims to establish a standardized methodology for assessing the complete environmental profile of GPC, from raw material extraction to end-of-life scenarios. By focusing on scope 3 emissions, we intend to identify critical intervention points within the supply chain where emissions reduction strategies would yield maximum benefits. The research will also facilitate meaningful comparisons between GPC and conventional concrete systems across various environmental impact categories.

Current technological trends in GPC development include the optimization of alkali activators, exploration of novel precursors beyond fly ash and slag, and enhancement of mechanical properties for specialized applications. These advancements necessitate updated and more granular LCA studies that can accurately reflect the environmental implications of these innovations.

The expected outcomes of this research include the development of a robust LCA framework specifically tailored for GPC systems, identification of key environmental hotspots within the supply chain, and formulation of evidence-based recommendations for reducing the carbon footprint of GPC production. Additionally, this research aims to contribute to the standardization of LCA methodologies for alternative cementitious materials, addressing current inconsistencies in system boundaries and impact assessment methods.

By establishing clear environmental benchmarks for GPC, this research will support informed decision-making among stakeholders in the construction industry and potentially accelerate the adoption of low-carbon concrete alternatives. The findings will also guide future research directions in geopolymer technology, focusing efforts on addressing the most environmentally impactful aspects of the production process.

Market Demand Analysis for Low-Carbon Concrete

The global concrete industry is experiencing a significant shift towards sustainable alternatives, with low-carbon concrete solutions gaining substantial market traction. Current market analysis indicates that the traditional Portland cement concrete industry, valued at approximately $395 billion in 2022, faces increasing pressure to reduce its environmental footprint, as it accounts for nearly 8% of global CO2 emissions. This creates a substantial market opportunity for Geopolymer Concrete (GPC) and other low-carbon alternatives.

Market research demonstrates growing demand across multiple sectors, with the construction industry leading adoption rates. Commercial building projects represent the largest market segment, followed by infrastructure development and residential construction. This demand is primarily driven by increasingly stringent environmental regulations, corporate sustainability commitments, and government procurement policies that favor low-carbon building materials.

Regional market assessment reveals varying adoption rates, with Europe and North America showing the strongest market growth for low-carbon concrete solutions. The European market is particularly robust due to the EU's ambitious carbon reduction targets and carbon pricing mechanisms. The Asia-Pacific region, despite being the largest concrete consumer globally, shows uneven adoption but represents the highest growth potential, especially in China and India where urbanization continues at rapid rates.

Consumer sentiment analysis indicates that while price sensitivity remains a concern, there is increasing willingness among project developers and contractors to pay premium prices for materials that help meet sustainability goals. The price premium tolerance typically ranges between 10-15% for commercial projects with strong environmental commitments.

Market forecasts project the global low-carbon concrete market to grow at a compound annual growth rate of 13.2% between 2023 and 2030, significantly outpacing traditional concrete. Geopolymer concrete specifically is expected to capture an increasing market share, with projections suggesting it could represent up to 6% of the global concrete market by 2030, compared to less than 1% currently.

Supply chain analysis reveals growing interest from material suppliers and ready-mix concrete producers in developing GPC capabilities, though production capacity remains limited compared to traditional concrete. This supply constraint represents both a challenge and opportunity for market entrants focused on scope 3 emission reductions.

Customer interviews with construction firms, developers, and public infrastructure agencies confirm increasing interest in life cycle assessment data for concrete products, with particular emphasis on understanding and reducing scope 3 emissions throughout the supply chain. This represents a key market differentiator for GPC producers who can demonstrate comprehensive carbon footprint reductions across their entire value chain.

Market research demonstrates growing demand across multiple sectors, with the construction industry leading adoption rates. Commercial building projects represent the largest market segment, followed by infrastructure development and residential construction. This demand is primarily driven by increasingly stringent environmental regulations, corporate sustainability commitments, and government procurement policies that favor low-carbon building materials.

Regional market assessment reveals varying adoption rates, with Europe and North America showing the strongest market growth for low-carbon concrete solutions. The European market is particularly robust due to the EU's ambitious carbon reduction targets and carbon pricing mechanisms. The Asia-Pacific region, despite being the largest concrete consumer globally, shows uneven adoption but represents the highest growth potential, especially in China and India where urbanization continues at rapid rates.

Consumer sentiment analysis indicates that while price sensitivity remains a concern, there is increasing willingness among project developers and contractors to pay premium prices for materials that help meet sustainability goals. The price premium tolerance typically ranges between 10-15% for commercial projects with strong environmental commitments.

Market forecasts project the global low-carbon concrete market to grow at a compound annual growth rate of 13.2% between 2023 and 2030, significantly outpacing traditional concrete. Geopolymer concrete specifically is expected to capture an increasing market share, with projections suggesting it could represent up to 6% of the global concrete market by 2030, compared to less than 1% currently.

Supply chain analysis reveals growing interest from material suppliers and ready-mix concrete producers in developing GPC capabilities, though production capacity remains limited compared to traditional concrete. This supply constraint represents both a challenge and opportunity for market entrants focused on scope 3 emission reductions.

Customer interviews with construction firms, developers, and public infrastructure agencies confirm increasing interest in life cycle assessment data for concrete products, with particular emphasis on understanding and reducing scope 3 emissions throughout the supply chain. This represents a key market differentiator for GPC producers who can demonstrate comprehensive carbon footprint reductions across their entire value chain.

GPC Technology Status and Scope 3 Emission Challenges

Geopolymer Concrete (GPC) has emerged as a promising alternative to Ordinary Portland Cement (OPC) concrete, with global research and implementation efforts accelerating over the past decade. Currently, GPC technology has advanced from laboratory-scale experiments to commercial applications in several countries, including Australia, India, and parts of Europe. The primary attraction of GPC lies in its potential to reduce carbon emissions by up to 80% compared to conventional concrete, primarily through the utilization of industrial by-products like fly ash and ground granulated blast furnace slag.

Despite these advancements, GPC faces significant challenges in achieving widespread commercial adoption. The technology remains constrained by geographical limitations in raw material availability, with inconsistent quality of precursor materials affecting performance predictability. Additionally, the lack of standardized production protocols and long-term performance data creates barriers to regulatory approval and industry acceptance in many regions.

When examining Scope 3 emission hotspots within the GPC supply chain, several critical challenges emerge. Transportation of raw materials represents a substantial emission source, particularly when precursors must be transported over long distances due to localized availability. Studies indicate that transportation can contribute between 10-30% of total GPC emissions, depending on geographical contexts and logistics arrangements.

The processing of aluminosilicate precursors constitutes another significant emission hotspot. Energy-intensive grinding and thermal activation processes required for certain precursors like metakaolin can offset some of the inherent carbon benefits of GPC. Current research indicates that optimizing these processing parameters could reduce associated emissions by 15-25%.

Alkaline activator production, particularly sodium silicate and sodium hydroxide, represents perhaps the most critical Scope 3 emission challenge. These chemicals typically account for 40-70% of GPC's carbon footprint, with conventional production methods being highly energy-intensive. Recent technological innovations in low-carbon activator synthesis show promise but remain at early development stages.

End-of-life considerations present additional challenges, as current recycling infrastructure is primarily designed for conventional concrete. Limited data exists on the long-term leaching behavior and recyclability of GPC structures, creating uncertainty in lifecycle emission calculations.

Geographically, GPC technology development shows distinct patterns, with Australia, China, and parts of Europe leading in research output and commercial applications. However, implementation in developing economies, where concrete demand is highest, remains limited due to technical knowledge gaps and supply chain constraints. This geographical disparity represents a significant barrier to maximizing GPC's global emission reduction potential.

Despite these advancements, GPC faces significant challenges in achieving widespread commercial adoption. The technology remains constrained by geographical limitations in raw material availability, with inconsistent quality of precursor materials affecting performance predictability. Additionally, the lack of standardized production protocols and long-term performance data creates barriers to regulatory approval and industry acceptance in many regions.

When examining Scope 3 emission hotspots within the GPC supply chain, several critical challenges emerge. Transportation of raw materials represents a substantial emission source, particularly when precursors must be transported over long distances due to localized availability. Studies indicate that transportation can contribute between 10-30% of total GPC emissions, depending on geographical contexts and logistics arrangements.

The processing of aluminosilicate precursors constitutes another significant emission hotspot. Energy-intensive grinding and thermal activation processes required for certain precursors like metakaolin can offset some of the inherent carbon benefits of GPC. Current research indicates that optimizing these processing parameters could reduce associated emissions by 15-25%.

Alkaline activator production, particularly sodium silicate and sodium hydroxide, represents perhaps the most critical Scope 3 emission challenge. These chemicals typically account for 40-70% of GPC's carbon footprint, with conventional production methods being highly energy-intensive. Recent technological innovations in low-carbon activator synthesis show promise but remain at early development stages.

End-of-life considerations present additional challenges, as current recycling infrastructure is primarily designed for conventional concrete. Limited data exists on the long-term leaching behavior and recyclability of GPC structures, creating uncertainty in lifecycle emission calculations.

Geographically, GPC technology development shows distinct patterns, with Australia, China, and parts of Europe leading in research output and commercial applications. However, implementation in developing economies, where concrete demand is highest, remains limited due to technical knowledge gaps and supply chain constraints. This geographical disparity represents a significant barrier to maximizing GPC's global emission reduction potential.

Current LCA Approaches for GPC Scope 3 Emissions

01 Raw material sourcing and transportation emissions

The extraction, processing, and transportation of raw materials for geopolymer concrete production contribute significantly to Scope 3 emissions. These materials include fly ash, slag, metakaolin, and alkaline activators. Long-distance transportation of these materials, especially when sourced from different geographical locations, creates emission hotspots in the supply chain. Optimizing sourcing strategies and using locally available materials can help reduce these emissions.- Raw material sourcing and transportation emissions: The extraction, processing, and transportation of raw materials for geopolymer concrete production contribute significantly to Scope 3 emissions. These materials include fly ash, slag, metakaolin, and alkaline activators. The long-distance transportation of these materials, especially when sourced from different geographical locations, creates emission hotspots in the supply chain. Optimizing sourcing strategies and using locally available materials can help reduce these emissions.

- Alkaline activator production emissions: The production of alkaline activators such as sodium hydroxide and sodium silicate is energy-intensive and generates substantial Scope 3 emissions in the geopolymer concrete supply chain. These chemicals require high-temperature processing and energy-intensive manufacturing methods. Innovations in low-carbon activator production and alternative activator formulations can significantly reduce the carbon footprint of geopolymer concrete.

- End-of-life management and circular economy approaches: The end-of-life phase of geopolymer concrete contributes to Scope 3 emissions through demolition, waste processing, and disposal activities. Implementing circular economy principles by recycling and reusing geopolymer concrete waste as aggregates or raw materials for new concrete production can reduce these emissions. Advanced crushing and separation technologies enable better recovery of materials from demolished structures, closing the loop in the supply chain.

- Manufacturing process optimization and energy efficiency: The manufacturing processes for geopolymer concrete components involve significant energy consumption, contributing to Scope 3 emissions. This includes mixing, curing, and forming operations. Optimizing these processes through improved equipment efficiency, renewable energy integration, and innovative curing techniques can reduce emissions. Low-temperature curing methods and energy recovery systems are particularly effective in minimizing the carbon footprint of geopolymer concrete production.

- Carbon capture and utilization in geopolymer production: Incorporating carbon capture, utilization, and storage (CCUS) technologies in the geopolymer concrete supply chain can address Scope 3 emission hotspots. These technologies can capture CO2 from various production processes and either store it or utilize it in the concrete curing process. Mineralization techniques that permanently sequester CO2 in geopolymer concrete offer promising pathways for reducing the overall carbon footprint of construction materials.

02 Alkaline activator production emissions

The production of alkaline activators such as sodium hydroxide and sodium silicate is energy-intensive and represents a major emission hotspot in geopolymer concrete supply chains. These chemicals require high-temperature processing and energy-intensive manufacturing methods, contributing significantly to the carbon footprint. Developing alternative, lower-emission activators or optimizing production processes can help mitigate these Scope 3 emissions.Expand Specific Solutions03 Waste utilization and circular economy approaches

Incorporating industrial by-products and waste materials into geopolymer concrete formulations can significantly reduce Scope 3 emissions. Utilizing materials like fly ash from coal power plants, blast furnace slag from steel production, and other industrial wastes diverts these materials from landfills and reduces the need for virgin material extraction. This circular economy approach creates emission reduction opportunities throughout the supply chain.Expand Specific Solutions04 Curing and processing energy requirements

The curing process for geopolymer concrete can be energy-intensive, particularly when heat curing is required. This creates emission hotspots in the manufacturing stage of the supply chain. Ambient temperature curing methods and optimization of curing conditions can reduce these emissions. Additionally, the processing equipment and methods used in mixing and placing geopolymer concrete can contribute to Scope 3 emissions through their energy consumption and operational requirements.Expand Specific Solutions05 End-of-life considerations and carbon sequestration

The end-of-life phase of geopolymer concrete, including demolition, recycling, and disposal, represents a significant Scope 3 emission consideration. Geopolymer concrete has potential advantages in terms of recyclability and carbon sequestration capabilities compared to traditional concrete. Designing geopolymer concrete with enhanced durability and recyclability can reduce lifecycle emissions. Some formulations can also sequester carbon during their service life, potentially offsetting emissions from other parts of the supply chain.Expand Specific Solutions

Key Industry Players in GPC Supply Chain

The Life Cycle Assessment (LCA) of Geopolymer Concrete (GPC) supply chains is currently in an emerging growth phase, with the global market expanding as sustainable construction alternatives gain traction. The market size is projected to increase significantly due to rising environmental regulations and carbon reduction targets. Technologically, GPC is advancing from experimental to commercial implementation, with varying degrees of maturity across different applications. Key players driving innovation include academic institutions like Southeast University and Dalian University of Technology conducting foundational research, while companies such as Interface, Inc. and State Grid Corp. of China are implementing practical applications. Research institutes like China Electric Power Research Institute and Railway Construction Research Institute are developing industry-specific applications, creating a competitive landscape that balances academic research with commercial implementation focused on reducing scope 3 emissions.

Dalian University of Technology

Technical Solution: Dalian University of Technology has developed comprehensive Life Cycle Assessment methodologies specifically for Geopolymer Concrete (GPC) supply chains. Their research focuses on quantifying scope 3 emission hotspots through detailed inventory analysis of raw materials, manufacturing processes, and end-of-life scenarios. The university has pioneered a multi-regional input-output model that tracks emissions across the entire GPC value chain, with particular attention to fly ash and slag sourcing variations. Their LCA framework incorporates sensitivity analysis to identify critical emission factors in different geographic contexts, revealing that transportation of raw materials contributes significantly to scope 3 emissions (15-30% of total carbon footprint). The research team has also developed specialized software tools that enable real-time carbon footprint monitoring throughout the GPC production process, allowing for optimization of supply chain configurations to minimize environmental impacts while maintaining structural performance requirements.

Strengths: Strong academic research capabilities with advanced modeling techniques that provide detailed emission breakdowns across the entire supply chain. Their multi-regional approach accounts for geographic variations in raw material sourcing. Weaknesses: As an academic institution, implementation of findings may require industry partnerships, and some models may need adaptation for commercial-scale production environments.

China Academy of Railway Sciences Group Co. Ltd.

Technical Solution: China Academy of Railway Sciences Group has developed a specialized Life Cycle Assessment framework for Geopolymer Concrete applications in railway infrastructure, with particular emphasis on scope 3 emission hotspots. Their technical approach integrates transportation-specific parameters into traditional LCA methodologies, accounting for the unique requirements of railway construction and maintenance. The Academy has created a comprehensive database of emission factors specifically for GPC applications in high-speed rail platforms, sleepers, and supporting structures. Their research has identified that the transportation of raw materials to construction sites represents a significant emission hotspot, accounting for approximately 25-35% of total scope 3 emissions in railway applications. To address this, they've developed a regional sourcing optimization model that reduces transportation distances while maintaining material quality standards. Additionally, their LCA framework incorporates durability and service life predictions, demonstrating that the extended lifespan of GPC in railway applications (estimated at 15-25% longer than conventional concrete) significantly reduces lifecycle emissions when maintenance and replacement cycles are considered.

Strengths: Highly specialized expertise in railway applications provides detailed insights into a specific high-impact sector. Their integration of durability factors into LCA calculations offers a more comprehensive view of true lifecycle impacts. Weaknesses: The narrow focus on railway applications may limit broader applicability to other construction sectors. Their assessment methodologies may be tailored to Chinese railway standards and practices, potentially requiring adaptation for international applications.

Critical Hotspot Analysis Techniques for GPC

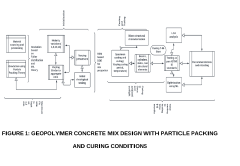

A method of optimizing geopolymer concrete performance through particle packing density and life cycle assessment

PatentPendingIN202441033642A

Innovation

- Applying the Particle Packing Density theory to optimize the gradation of aggregates and cementitious materials, combined with Life Cycle Assessment and machine learning to evaluate and enhance the mechanical and durability properties of geopolymer concrete, while varying precursor dosage, molarity, and curing conditions.

Analyse use geopolymer concrete in rigid pavements and verify its strength and durability characteristics with normal concrete pavements

PatentPendingIN202311022889A

Innovation

- The study demonstrates the feasibility of producing geopolymer concrete using carefully selected local materials, focusing on compressive strength, tensile strength, and flexibility by varying cement exchange rates and activator solution contents, which results in enhanced compressive strength and reduced water absorption compared to ordinary Portland cement (OPC) concrete.

Regulatory Framework for Construction Materials Emissions

The regulatory landscape governing construction materials emissions is rapidly evolving in response to global climate commitments. The Paris Agreement has catalyzed national policies targeting embodied carbon in building materials, with several jurisdictions implementing mandatory reporting requirements. The European Union leads with its Construction Products Regulation (CPR) and Environmental Product Declaration (EPD) frameworks, requiring manufacturers to disclose lifecycle environmental impacts of construction materials.

In North America, regulations vary by jurisdiction, with California's Buy Clean California Act establishing maximum Global Warming Potential thresholds for certain construction materials used in state-funded projects. Canada has implemented the Greening Government Strategy, which includes requirements for low-carbon concrete in federal projects.

The regulatory framework specifically addressing geopolymer concrete (GPC) remains fragmented. While conventional concrete is governed by established standards like ASTM C150 and EN 197, geopolymer binders often fall outside these traditional specifications. This regulatory gap creates market barriers despite GPC's environmental advantages. Several countries, including Australia with its Cement Concrete and Aggregates Australia (CCAA) guidelines, have developed interim standards to facilitate GPC adoption.

Scope 3 emissions reporting requirements are increasingly prominent in construction materials regulations. The Greenhouse Gas Protocol provides the foundation for categorizing these indirect emissions, while the Science Based Targets initiative (SBTi) has established specific guidance for the cement and concrete sector. These frameworks require companies to account for upstream and downstream emissions, including those from raw material extraction, transportation, and end-of-life processing.

Financial regulations are also influencing the construction materials sector through sustainable finance taxonomies. The EU Taxonomy for Sustainable Activities establishes technical screening criteria for activities substantially contributing to climate change mitigation, including cement and concrete production. This creates financial incentives for low-carbon alternatives like GPC.

Looking forward, regulatory trends indicate increasing stringency in emissions reporting and reduction requirements. Several jurisdictions are moving toward mandatory carbon disclosure and setting increasingly ambitious reduction targets. Carbon pricing mechanisms, including emissions trading schemes and carbon taxes, are expanding globally, creating economic drivers for low-carbon construction materials like GPC.

In North America, regulations vary by jurisdiction, with California's Buy Clean California Act establishing maximum Global Warming Potential thresholds for certain construction materials used in state-funded projects. Canada has implemented the Greening Government Strategy, which includes requirements for low-carbon concrete in federal projects.

The regulatory framework specifically addressing geopolymer concrete (GPC) remains fragmented. While conventional concrete is governed by established standards like ASTM C150 and EN 197, geopolymer binders often fall outside these traditional specifications. This regulatory gap creates market barriers despite GPC's environmental advantages. Several countries, including Australia with its Cement Concrete and Aggregates Australia (CCAA) guidelines, have developed interim standards to facilitate GPC adoption.

Scope 3 emissions reporting requirements are increasingly prominent in construction materials regulations. The Greenhouse Gas Protocol provides the foundation for categorizing these indirect emissions, while the Science Based Targets initiative (SBTi) has established specific guidance for the cement and concrete sector. These frameworks require companies to account for upstream and downstream emissions, including those from raw material extraction, transportation, and end-of-life processing.

Financial regulations are also influencing the construction materials sector through sustainable finance taxonomies. The EU Taxonomy for Sustainable Activities establishes technical screening criteria for activities substantially contributing to climate change mitigation, including cement and concrete production. This creates financial incentives for low-carbon alternatives like GPC.

Looking forward, regulatory trends indicate increasing stringency in emissions reporting and reduction requirements. Several jurisdictions are moving toward mandatory carbon disclosure and setting increasingly ambitious reduction targets. Carbon pricing mechanisms, including emissions trading schemes and carbon taxes, are expanding globally, creating economic drivers for low-carbon construction materials like GPC.

Supply Chain Optimization Strategies for GPC

Optimizing the supply chain for Geopolymer Concrete (GPC) requires strategic interventions across multiple operational dimensions to address scope 3 emission hotspots identified through Life Cycle Assessment. The primary optimization strategies focus on raw material sourcing, transportation logistics, manufacturing processes, and end-of-life management.

Sourcing locally available precursor materials represents a critical optimization strategy. By establishing regional supply networks for fly ash, slag, and other aluminosilicate materials, companies can significantly reduce transportation-related emissions while supporting circular economy principles. Implementation of supplier certification programs that prioritize vendors with documented carbon reduction initiatives further strengthens this approach.

Transportation optimization presents substantial emission reduction opportunities within the GPC supply chain. Multi-modal transportation systems that leverage rail and water transport for bulk materials can achieve up to 70% lower emissions compared to conventional road transport. Additionally, route optimization algorithms and backhaul utilization strategies minimize empty vehicle movements, reducing the carbon footprint per ton-kilometer of material transported.

Manufacturing process optimization focuses on energy efficiency improvements and renewable energy integration. Ambient temperature curing techniques eliminate the need for heat curing, potentially reducing process-related emissions by 40-60% compared to traditional methods. Implementing energy management systems with real-time monitoring capabilities enables continuous optimization of production parameters.

Inventory management strategies utilizing just-in-time principles and demand forecasting algorithms help minimize overproduction and associated emissions. Digital supply chain solutions incorporating blockchain technology for material traceability and environmental impact verification create transparency across the value chain, enabling data-driven optimization decisions.

Collaborative approaches through industry partnerships and vertical integration strategies can consolidate transportation requirements and enable shared infrastructure development. These collaborative models facilitate knowledge transfer regarding best practices in emission reduction and create economies of scale for implementing carbon capture technologies at production facilities.

End-of-life considerations complete the optimization framework through design for deconstruction principles and closed-loop material recovery systems. Establishing regional recycling networks for GPC waste minimizes transportation distances for end-of-life materials while creating secondary raw material streams that further reduce virgin material requirements.

Implementation of these strategies requires a phased approach with continuous monitoring through standardized carbon accounting methodologies. Organizations should prioritize interventions based on emission reduction potential, implementation feasibility, and return on investment to develop a comprehensive roadmap for GPC supply chain optimization.

Sourcing locally available precursor materials represents a critical optimization strategy. By establishing regional supply networks for fly ash, slag, and other aluminosilicate materials, companies can significantly reduce transportation-related emissions while supporting circular economy principles. Implementation of supplier certification programs that prioritize vendors with documented carbon reduction initiatives further strengthens this approach.

Transportation optimization presents substantial emission reduction opportunities within the GPC supply chain. Multi-modal transportation systems that leverage rail and water transport for bulk materials can achieve up to 70% lower emissions compared to conventional road transport. Additionally, route optimization algorithms and backhaul utilization strategies minimize empty vehicle movements, reducing the carbon footprint per ton-kilometer of material transported.

Manufacturing process optimization focuses on energy efficiency improvements and renewable energy integration. Ambient temperature curing techniques eliminate the need for heat curing, potentially reducing process-related emissions by 40-60% compared to traditional methods. Implementing energy management systems with real-time monitoring capabilities enables continuous optimization of production parameters.

Inventory management strategies utilizing just-in-time principles and demand forecasting algorithms help minimize overproduction and associated emissions. Digital supply chain solutions incorporating blockchain technology for material traceability and environmental impact verification create transparency across the value chain, enabling data-driven optimization decisions.

Collaborative approaches through industry partnerships and vertical integration strategies can consolidate transportation requirements and enable shared infrastructure development. These collaborative models facilitate knowledge transfer regarding best practices in emission reduction and create economies of scale for implementing carbon capture technologies at production facilities.

End-of-life considerations complete the optimization framework through design for deconstruction principles and closed-loop material recovery systems. Establishing regional recycling networks for GPC waste minimizes transportation distances for end-of-life materials while creating secondary raw material streams that further reduce virgin material requirements.

Implementation of these strategies requires a phased approach with continuous monitoring through standardized carbon accounting methodologies. Organizations should prioritize interventions based on emission reduction potential, implementation feasibility, and return on investment to develop a comprehensive roadmap for GPC supply chain optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!