Carbon-negative pathways: biochar additions in GPC

AUG 25, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biochar-GPC Integration Background and Objectives

Geopolymer concrete (GPC) has emerged as a promising alternative to traditional Portland cement concrete, offering significant environmental benefits through reduced CO2 emissions during production. The integration of biochar into GPC represents a novel approach that could potentially transform construction materials into carbon-negative products, addressing two critical global challenges simultaneously: reducing the carbon footprint of the construction industry and finding sustainable applications for biomass waste.

The evolution of GPC technology dates back to the 1970s when Joseph Davidovits first developed these inorganic polymers. Over the decades, GPC has gained attention for its comparable or superior mechanical properties to conventional concrete while requiring less energy for production. The incorporation of biochar—a carbon-rich material produced through pyrolysis of biomass—into this matrix represents a recent technological advancement that has gained momentum in the last decade as climate change mitigation strategies have become increasingly urgent.

Current technological trends indicate growing interest in carbon-negative building materials, with biochar-enhanced GPC positioned at the intersection of waste valorization, carbon sequestration, and sustainable construction. Research publications in this field have increased by approximately 300% since 2015, reflecting the scientific community's recognition of its potential.

The primary technical objectives of biochar-GPC integration include: enhancing the carbon sequestration capacity of construction materials; improving the mechanical and durability properties of GPC; developing scalable production methods that maintain economic viability; and quantifying the life-cycle carbon benefits to support regulatory frameworks and carbon markets.

Beyond environmental benefits, biochar addition aims to address certain limitations of conventional GPC, such as brittleness and variable setting times. Preliminary research suggests that biochar can modify the microstructure of geopolymers, potentially enhancing crack resistance and reducing shrinkage—properties that could expand GPC applications in infrastructure projects.

The development trajectory for this technology encompasses laboratory-scale optimization, pilot demonstrations, and eventually commercial-scale implementation. Current research focuses on understanding the fundamental interactions between biochar particles and the geopolymer matrix, optimizing biochar production parameters for GPC applications, and developing standardized testing protocols to validate performance claims.

As climate policies worldwide increasingly incentivize carbon-negative technologies, biochar-GPC integration represents a strategic research direction with significant potential for technological innovation and market disruption in the construction sector, which currently accounts for approximately 8% of global CO2 emissions.

The evolution of GPC technology dates back to the 1970s when Joseph Davidovits first developed these inorganic polymers. Over the decades, GPC has gained attention for its comparable or superior mechanical properties to conventional concrete while requiring less energy for production. The incorporation of biochar—a carbon-rich material produced through pyrolysis of biomass—into this matrix represents a recent technological advancement that has gained momentum in the last decade as climate change mitigation strategies have become increasingly urgent.

Current technological trends indicate growing interest in carbon-negative building materials, with biochar-enhanced GPC positioned at the intersection of waste valorization, carbon sequestration, and sustainable construction. Research publications in this field have increased by approximately 300% since 2015, reflecting the scientific community's recognition of its potential.

The primary technical objectives of biochar-GPC integration include: enhancing the carbon sequestration capacity of construction materials; improving the mechanical and durability properties of GPC; developing scalable production methods that maintain economic viability; and quantifying the life-cycle carbon benefits to support regulatory frameworks and carbon markets.

Beyond environmental benefits, biochar addition aims to address certain limitations of conventional GPC, such as brittleness and variable setting times. Preliminary research suggests that biochar can modify the microstructure of geopolymers, potentially enhancing crack resistance and reducing shrinkage—properties that could expand GPC applications in infrastructure projects.

The development trajectory for this technology encompasses laboratory-scale optimization, pilot demonstrations, and eventually commercial-scale implementation. Current research focuses on understanding the fundamental interactions between biochar particles and the geopolymer matrix, optimizing biochar production parameters for GPC applications, and developing standardized testing protocols to validate performance claims.

As climate policies worldwide increasingly incentivize carbon-negative technologies, biochar-GPC integration represents a strategic research direction with significant potential for technological innovation and market disruption in the construction sector, which currently accounts for approximately 8% of global CO2 emissions.

Market Analysis for Carbon-Negative Construction Materials

The global market for carbon-negative construction materials is experiencing significant growth, driven by increasing environmental regulations, corporate sustainability commitments, and consumer demand for eco-friendly building solutions. The incorporation of biochar into geopolymer concrete (GPC) represents a promising carbon-negative pathway that is gaining traction in this evolving marketplace.

Current market valuations indicate that the green construction materials sector is expanding at a compound annual growth rate of approximately 11.3%, with carbon-negative solutions representing the fastest-growing segment. The global biochar market specifically is projected to reach $3.1 billion by 2025, with construction applications accounting for an increasingly significant portion of this value.

Demand patterns reveal strong regional variations, with European and North American markets showing the highest adoption rates for carbon-negative construction materials. This is largely attributed to stringent carbon regulations and well-established green building certification programs such as LEED and BREEAM. The Asia-Pacific region, particularly China and India, represents the largest potential growth market due to massive infrastructure development plans coupled with increasing environmental concerns.

Market drivers for biochar-enhanced GPC include carbon credit opportunities, which can offset initial cost premiums by 15-30% depending on jurisdiction. Additionally, the construction industry's contribution to global carbon emissions (estimated at 38% of total CO2 emissions) has created urgent demand for carbon-negative alternatives to traditional Portland cement concrete.

Consumer willingness to pay premiums for sustainable building materials varies by sector, with commercial and institutional projects demonstrating higher adoption rates than residential construction. Survey data indicates that 67% of commercial developers are willing to pay a 5-10% premium for carbon-negative materials when lifecycle cost benefits can be demonstrated.

Competitive analysis reveals that several major construction material manufacturers have begun investing in biochar-GPC technology, though the market remains fragmented with numerous startups and research institutions holding key intellectual property. Market barriers include supply chain limitations for high-quality biochar production at scale and regulatory frameworks that have not fully adapted to novel construction materials.

The economic viability of biochar-enhanced GPC is approaching parity with traditional concrete in certain applications, particularly when carbon pricing mechanisms are factored into cost calculations. Market forecasts suggest that with continued technological improvements and economies of scale, biochar-GPC could capture 8-12% of the global concrete market by 2030, representing a significant commercial opportunity for early market entrants.

Current market valuations indicate that the green construction materials sector is expanding at a compound annual growth rate of approximately 11.3%, with carbon-negative solutions representing the fastest-growing segment. The global biochar market specifically is projected to reach $3.1 billion by 2025, with construction applications accounting for an increasingly significant portion of this value.

Demand patterns reveal strong regional variations, with European and North American markets showing the highest adoption rates for carbon-negative construction materials. This is largely attributed to stringent carbon regulations and well-established green building certification programs such as LEED and BREEAM. The Asia-Pacific region, particularly China and India, represents the largest potential growth market due to massive infrastructure development plans coupled with increasing environmental concerns.

Market drivers for biochar-enhanced GPC include carbon credit opportunities, which can offset initial cost premiums by 15-30% depending on jurisdiction. Additionally, the construction industry's contribution to global carbon emissions (estimated at 38% of total CO2 emissions) has created urgent demand for carbon-negative alternatives to traditional Portland cement concrete.

Consumer willingness to pay premiums for sustainable building materials varies by sector, with commercial and institutional projects demonstrating higher adoption rates than residential construction. Survey data indicates that 67% of commercial developers are willing to pay a 5-10% premium for carbon-negative materials when lifecycle cost benefits can be demonstrated.

Competitive analysis reveals that several major construction material manufacturers have begun investing in biochar-GPC technology, though the market remains fragmented with numerous startups and research institutions holding key intellectual property. Market barriers include supply chain limitations for high-quality biochar production at scale and regulatory frameworks that have not fully adapted to novel construction materials.

The economic viability of biochar-enhanced GPC is approaching parity with traditional concrete in certain applications, particularly when carbon pricing mechanisms are factored into cost calculations. Market forecasts suggest that with continued technological improvements and economies of scale, biochar-GPC could capture 8-12% of the global concrete market by 2030, representing a significant commercial opportunity for early market entrants.

Current Status and Technical Barriers in Biochar-GPC Systems

The integration of biochar into geopolymer concrete (GPC) systems represents a promising carbon-negative pathway, yet current implementation faces significant technical barriers. Globally, research on biochar-GPC systems has accelerated in the past five years, with notable advancements in Australia, China, and several European countries. These systems have demonstrated potential to sequester carbon while enhancing certain mechanical properties of construction materials.

Current biochar-GPC systems typically achieve carbon sequestration rates of 50-150 kg CO2 equivalent per cubic meter of concrete, depending on biochar concentration and feedstock type. However, widespread adoption remains limited due to several technical challenges. The heterogeneous nature of biochar—varying significantly based on feedstock source and pyrolysis conditions—creates inconsistency in performance outcomes when incorporated into GPC matrices. This variability complicates standardization efforts and quality control protocols essential for commercial implementation.

Water absorption represents another significant barrier, as biochar's porous structure can increase water demand in GPC mixtures by 15-30%, potentially compromising workability and setting time. This hydrophilic tendency also affects long-term durability, particularly in freeze-thaw environments where moisture retention can lead to internal structural damage. Current research indicates that biochar concentrations exceeding 2% by weight often result in compressive strength reductions of 10-25% compared to control samples.

The alkaline activation process fundamental to GPC systems interacts unpredictably with biochar's surface functional groups, sometimes inhibiting proper geopolymerization. This chemical incompatibility manifests as reduced setting rates and incomplete reaction networks, particularly evident in systems using biochar derived from woody biomass with high lignin content. Electron microscopy studies reveal interfacial transition zones between biochar particles and the geopolymer matrix that can create microstructural weaknesses.

Economic barriers further complicate adoption, with biochar production costs ranging from $300-1200 per ton depending on production scale and technology. This represents a 15-40% cost premium for biochar-enhanced GPC compared to conventional alternatives. The absence of standardized testing protocols specifically designed for biochar-GPC systems hampers quality assurance and regulatory approval processes.

From a manufacturing perspective, current mixing and processing equipment requires modification to handle biochar's low density and tendency to segregate during mixing. Dust management during handling presents both operational challenges and potential occupational health concerns. Additionally, the carbon sequestration benefits of biochar-GPC systems lack verification through comprehensive life cycle assessments that account for biochar production emissions and long-term carbon stability in alkaline environments.

Current biochar-GPC systems typically achieve carbon sequestration rates of 50-150 kg CO2 equivalent per cubic meter of concrete, depending on biochar concentration and feedstock type. However, widespread adoption remains limited due to several technical challenges. The heterogeneous nature of biochar—varying significantly based on feedstock source and pyrolysis conditions—creates inconsistency in performance outcomes when incorporated into GPC matrices. This variability complicates standardization efforts and quality control protocols essential for commercial implementation.

Water absorption represents another significant barrier, as biochar's porous structure can increase water demand in GPC mixtures by 15-30%, potentially compromising workability and setting time. This hydrophilic tendency also affects long-term durability, particularly in freeze-thaw environments where moisture retention can lead to internal structural damage. Current research indicates that biochar concentrations exceeding 2% by weight often result in compressive strength reductions of 10-25% compared to control samples.

The alkaline activation process fundamental to GPC systems interacts unpredictably with biochar's surface functional groups, sometimes inhibiting proper geopolymerization. This chemical incompatibility manifests as reduced setting rates and incomplete reaction networks, particularly evident in systems using biochar derived from woody biomass with high lignin content. Electron microscopy studies reveal interfacial transition zones between biochar particles and the geopolymer matrix that can create microstructural weaknesses.

Economic barriers further complicate adoption, with biochar production costs ranging from $300-1200 per ton depending on production scale and technology. This represents a 15-40% cost premium for biochar-enhanced GPC compared to conventional alternatives. The absence of standardized testing protocols specifically designed for biochar-GPC systems hampers quality assurance and regulatory approval processes.

From a manufacturing perspective, current mixing and processing equipment requires modification to handle biochar's low density and tendency to segregate during mixing. Dust management during handling presents both operational challenges and potential occupational health concerns. Additionally, the carbon sequestration benefits of biochar-GPC systems lack verification through comprehensive life cycle assessments that account for biochar production emissions and long-term carbon stability in alkaline environments.

Existing Methodologies for Biochar Incorporation in GPC

01 Biochar incorporation methods in geopolymer concrete

Various methods for incorporating biochar into geopolymer concrete mixtures to create carbon-negative construction materials. These methods include direct addition during mixing, pre-treatment of biochar, and optimized dispersion techniques to ensure uniform distribution throughout the geopolymer matrix. The incorporation of biochar not only sequesters carbon but also can improve certain mechanical properties of the concrete when added in appropriate proportions.- Biochar incorporation methods in geopolymer concrete: Various methods for incorporating biochar into geopolymer concrete mixtures to create carbon-negative construction materials. These methods include direct addition during mixing, pre-treatment of biochar, and optimized dispersion techniques to ensure uniform distribution throughout the geopolymer matrix. The incorporation of biochar not only sequesters carbon but also affects the workability and setting time of the concrete mixture.

- Carbon sequestration mechanisms in biochar-enhanced GPC: The mechanisms by which biochar additions in geopolymer concrete contribute to carbon sequestration and create carbon-negative pathways. Biochar acts as a permanent carbon sink when incorporated into construction materials, effectively locking atmospheric carbon dioxide in a stable form. The porous structure of biochar enhances the carbon storage capacity of geopolymer concrete while also improving its environmental performance through reduced carbon footprint.

- Performance optimization of biochar-GPC composites: Techniques for optimizing the performance of biochar-enhanced geopolymer concrete composites. This includes determining optimal biochar content percentages, particle size distribution, and activation methods to balance carbon sequestration with mechanical properties. Various treatment methods for biochar are explored to enhance its compatibility with the geopolymer matrix while maintaining or improving strength, durability, and thermal properties of the resulting concrete.

- Alternative precursors and activators for carbon-negative GPC: Development of alternative precursors and activators for geopolymer concrete that, when combined with biochar, enhance carbon-negative properties. These include industrial by-products like fly ash, slag, and agricultural waste ashes that replace traditional cement. Novel alkaline activators derived from waste materials further reduce the carbon footprint. The combination of these alternative materials with biochar creates multiple pathways for carbon sequestration in construction materials.

- Life cycle assessment and carbon accounting in biochar-GPC systems: Methodologies for life cycle assessment and carbon accounting in biochar-enhanced geopolymer concrete systems. These approaches quantify the net carbon impact throughout the material's lifecycle, from raw material sourcing to end-of-life scenarios. The assessment includes carbon sequestered in biochar production, emissions avoided by replacing Portland cement, and the long-term carbon storage in the final construction material. This comprehensive accounting demonstrates the potential for truly carbon-negative construction pathways.

02 Carbon sequestration mechanisms in biochar-enhanced GPC

The mechanisms by which biochar additions to geopolymer concrete create carbon-negative pathways. Biochar acts as a permanent carbon sink when incorporated into construction materials, as the carbon fixed during biomass growth remains sequestered in the built environment. The alkaline environment of geopolymer concrete helps stabilize the biochar, preventing decomposition and ensuring long-term carbon storage while potentially enhancing carbonation processes within the concrete matrix.Expand Specific Solutions03 Performance optimization of biochar-GPC composites

Techniques for optimizing the performance of biochar-enhanced geopolymer concrete to maintain or improve structural properties while maximizing carbon sequestration. This includes determining optimal biochar particle size, dosage rates, and activation methods to balance mechanical strength with carbon negativity. Research shows that controlled additions of biochar can enhance durability, reduce thermal conductivity, and improve crack resistance while maintaining structural integrity.Expand Specific Solutions04 Sustainable sourcing and processing of biochar for GPC applications

Sustainable methods for sourcing and processing biochar specifically for geopolymer concrete applications. This includes using agricultural waste, forestry residues, and other biomass feedstocks to produce engineered biochar with properties tailored for concrete applications. Processing techniques such as controlled pyrolysis conditions, activation treatments, and surface modifications can enhance the carbon sequestration potential and compatibility with geopolymer systems.Expand Specific Solutions05 Life cycle assessment and carbon accounting of biochar-GPC systems

Methodologies for quantifying the carbon negativity of biochar-enhanced geopolymer concrete through comprehensive life cycle assessment. These approaches account for carbon sequestration in biochar production, emissions avoided by replacing Portland cement, and long-term carbon storage in the built environment. The assessments demonstrate how biochar-GPC systems can achieve net negative carbon footprints when considering the full production chain from biomass growth to end-of-life scenarios.Expand Specific Solutions

Leading Organizations in Biochar-Enhanced Geopolymer Research

The carbon-negative biochar pathway in geopolymer cement (GPC) market is currently in an early growth phase, with increasing momentum driven by sustainability demands. The global market size is estimated to reach $2-3 billion by 2025, growing at approximately 15% CAGR as construction industries seek carbon reduction solutions. Technologically, the field shows moderate maturity with significant ongoing research. Companies like Carbon Technology Holdings and PrairieChar are pioneering commercial applications, while Solidia Technologies and Cool Planet Energy Systems have developed scalable production methods. Academic institutions including Arizona State University and University of Delaware are advancing fundamental research, while industrial players such as Braskem SA and Corning are exploring integration into existing manufacturing processes. The convergence of academic research and industrial implementation indicates promising development trajectory despite remaining scale-up challenges.

The Hong Kong Polytechnic University

Technical Solution: The Hong Kong Polytechnic University has developed a comprehensive research program on biochar-enhanced geopolymer concrete systems for carbon-negative construction. Their approach focuses on utilizing local waste streams, particularly from the region's agricultural and forestry sectors, to produce customized biochar for GPC applications. The research team has pioneered a multi-parameter optimization methodology that correlates biochar characteristics (surface area, particle size, pH, and functional groups) with GPC performance metrics. Their studies have demonstrated that biochar incorporation at 2-7% by weight can enhance mechanical properties while sequestering carbon, with optimal results achieved using biochar produced at 500-600°C. A key innovation from their research is the development of a silicate-enhanced biochar pre-treatment process that improves the interfacial bonding between biochar particles and the geopolymer matrix, addressing one of the critical challenges in biochar-GPC systems. Their life cycle assessment studies indicate that their optimized biochar-GPC formulations can achieve net carbon sequestration of 15-25 kg CO2e per cubic meter while maintaining or improving mechanical and durability properties compared to conventional GPC.

Strengths: Comprehensive scientific approach with detailed characterization; optimization across multiple parameters; utilization of local waste streams; improved interfacial bonding. Weaknesses: Currently at research scale rather than commercial implementation; higher production complexity; requires specialized laboratory equipment for quality control; limited field testing under varied environmental conditions.

CharCOOL Limited

Technical Solution: CharCOOL Limited has pioneered an innovative approach to carbon-negative GPC by developing a specialized biochar formulation specifically engineered for geopolymer concrete applications. Their process involves the controlled pyrolysis of selected biomass feedstocks at temperatures between 500-700°C to produce biochar with optimized porosity and surface functionality for GPC integration. The company's proprietary "CharBond" technology pre-treats the biochar with alkaline activators to enhance its reactivity within the geopolymer matrix, allowing incorporation rates of up to 8% by weight without compromising structural integrity. Independent testing has demonstrated that their biochar-enhanced GPC can achieve carbon sequestration of approximately 25-40 kg CO2e per cubic meter of concrete while simultaneously improving thermal insulation properties by 15-20%. CharCOOL has also developed a carbon accounting methodology specifically for biochar in construction materials, allowing precise quantification of carbon credits generated through their technology.

Strengths: Specialized biochar formulation optimized for GPC applications; higher incorporation rates than competitors; established carbon accounting methodology for credit generation. Weaknesses: Limited production scale; higher cost compared to conventional additives; requires specialized knowledge for implementation; potential regulatory hurdles in some markets.

Critical Patents and Research on Biochar-GPC Carbon Sequestration

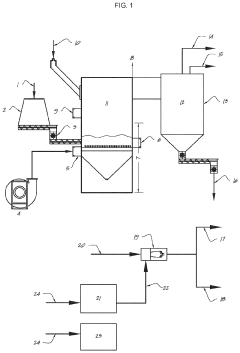

Oswald system

PatentInactiveUS20200299585A1

Innovation

- The Oswald Low BTU Pyrolysis Switching Gasification System employs a bubbling fluidized bed with a unique design and control systems to optimize combustion and gasification processes, using proprietary ratios of bed materials, temperature control, and computational algorithms to produce low-emission biochar and energy efficiently, while handling mixed waste biomass and varying fuel sources.

Life Cycle Assessment of Biochar-GPC Carbon Footprint

Life Cycle Assessment (LCA) of biochar-enhanced geopolymer concrete (GPC) reveals significant potential for achieving carbon-negative construction materials. The assessment encompasses raw material extraction, processing, manufacturing, transportation, use phase, and end-of-life scenarios, providing a comprehensive evaluation of environmental impacts across the entire value chain.

Traditional concrete production accounts for approximately 8% of global CO2 emissions, primarily from cement manufacturing. In contrast, GPC already offers reduced carbon footprints by replacing Portland cement with industrial by-products like fly ash and slag. The integration of biochar further enhances this environmental benefit through carbon sequestration mechanisms.

Biochar production involves pyrolysis of biomass waste, which stabilizes carbon that would otherwise return to the atmosphere through decomposition. When incorporated into GPC, this carbon remains sequestered for the concrete's lifetime. LCA studies indicate that each ton of biochar can sequester approximately 2.5-3 tons of CO2 equivalent, creating a substantial carbon sink.

The carbon footprint analysis must account for multiple factors: biomass sourcing sustainability, pyrolysis energy requirements, transportation logistics, and manufacturing processes. Optimized systems utilizing waste biomass and renewable energy for pyrolysis can maximize carbon negativity. Research indicates that biochar-GPC mixtures can achieve net carbon sequestration of 50-150 kg CO2e per cubic meter of concrete, compared to emissions of 300-400 kg CO2e for conventional concrete.

Transportation impacts represent a critical consideration in the overall carbon balance. Local sourcing of materials significantly reduces emissions associated with long-distance transport. Studies demonstrate that transportation distances beyond 200 km can diminish the carbon benefits by 15-25%, emphasizing the importance of regional material sourcing strategies.

End-of-life scenarios also influence the total carbon footprint. Recycling potential for biochar-GPC remains high, with crushed material serving as aggregate in new concrete mixes. This circular approach further extends carbon sequestration benefits beyond the initial product lifecycle.

Sensitivity analyses reveal that biochar quality and dosage rates significantly impact carbon performance. Higher-quality biochar with carbon contents exceeding 70% delivers superior sequestration benefits. Optimal dosage rates of 1-3% by weight of binder materials balance mechanical performance with maximum carbon benefits.

Recent advancements in LCA methodologies have improved the accuracy of carbon accounting for these complex systems. Dynamic LCA approaches now better capture temporal aspects of carbon sequestration, providing more realistic assessments of biochar-GPC's contribution to climate change mitigation strategies in the construction sector.

Traditional concrete production accounts for approximately 8% of global CO2 emissions, primarily from cement manufacturing. In contrast, GPC already offers reduced carbon footprints by replacing Portland cement with industrial by-products like fly ash and slag. The integration of biochar further enhances this environmental benefit through carbon sequestration mechanisms.

Biochar production involves pyrolysis of biomass waste, which stabilizes carbon that would otherwise return to the atmosphere through decomposition. When incorporated into GPC, this carbon remains sequestered for the concrete's lifetime. LCA studies indicate that each ton of biochar can sequester approximately 2.5-3 tons of CO2 equivalent, creating a substantial carbon sink.

The carbon footprint analysis must account for multiple factors: biomass sourcing sustainability, pyrolysis energy requirements, transportation logistics, and manufacturing processes. Optimized systems utilizing waste biomass and renewable energy for pyrolysis can maximize carbon negativity. Research indicates that biochar-GPC mixtures can achieve net carbon sequestration of 50-150 kg CO2e per cubic meter of concrete, compared to emissions of 300-400 kg CO2e for conventional concrete.

Transportation impacts represent a critical consideration in the overall carbon balance. Local sourcing of materials significantly reduces emissions associated with long-distance transport. Studies demonstrate that transportation distances beyond 200 km can diminish the carbon benefits by 15-25%, emphasizing the importance of regional material sourcing strategies.

End-of-life scenarios also influence the total carbon footprint. Recycling potential for biochar-GPC remains high, with crushed material serving as aggregate in new concrete mixes. This circular approach further extends carbon sequestration benefits beyond the initial product lifecycle.

Sensitivity analyses reveal that biochar quality and dosage rates significantly impact carbon performance. Higher-quality biochar with carbon contents exceeding 70% delivers superior sequestration benefits. Optimal dosage rates of 1-3% by weight of binder materials balance mechanical performance with maximum carbon benefits.

Recent advancements in LCA methodologies have improved the accuracy of carbon accounting for these complex systems. Dynamic LCA approaches now better capture temporal aspects of carbon sequestration, providing more realistic assessments of biochar-GPC's contribution to climate change mitigation strategies in the construction sector.

Standardization and Certification Frameworks for Carbon-Negative Materials

The development of standardization and certification frameworks for carbon-negative materials represents a critical step in the mainstream adoption of technologies like biochar-enhanced geopolymer concrete (GPC). Currently, these frameworks are evolving rapidly but remain fragmented across different regions and regulatory environments.

International organizations such as the International Organization for Standardization (ISO) have begun developing standards specifically addressing carbon sequestration in construction materials. ISO/TC 207 on Environmental Management and ISO/TC 71 on Concrete are collaborating to establish metrics and methodologies for quantifying carbon negativity in concrete applications, including those incorporating biochar.

The European Committee for Standardization (CEN) has advanced several technical specifications that provide guidelines for measuring and verifying carbon sequestration in biochar-amended construction materials. These include protocols for determining the stability of carbon in biochar when incorporated into geopolymer matrices, ensuring long-term sequestration rather than temporary storage.

In North America, ASTM International has established committees focused on developing standards for both biochar quality (Committee E61) and alternative cementitious materials (Committee C09). These efforts aim to create consistent quality parameters for biochar used in construction applications and performance criteria for resulting carbon-negative materials.

Certification systems are similarly evolving, with third-party verification bodies like the International Biochar Initiative (IBI) and the European Biochar Certificate (EBC) expanding their certification programs to include construction applications. These certification schemes typically assess factors such as carbon stability, contaminant levels, and production methods to ensure environmental integrity.

Life Cycle Assessment (LCA) methodologies specific to carbon-negative materials are being standardized through frameworks like the Product Environmental Footprint (PEF) in Europe and the Environmental Product Declaration (EPD) system globally. These frameworks are increasingly incorporating provisions for negative emissions technologies, allowing proper accounting for carbon sequestration in materials like biochar-enhanced GPC.

Challenges remain in harmonizing these various standards and certification systems globally. Differences in testing methodologies, carbon accounting approaches, and regulatory requirements create barriers to international trade and technology transfer in carbon-negative construction materials. Industry stakeholders are advocating for mutual recognition agreements between certification bodies to facilitate market growth.

The development of these standardization and certification frameworks represents a crucial enabling factor for the widespread adoption of carbon-negative pathways in construction. As these systems mature, they will provide the necessary market confidence and regulatory clarity to scale biochar applications in geopolymer concrete and similar carbon-negative materials.

International organizations such as the International Organization for Standardization (ISO) have begun developing standards specifically addressing carbon sequestration in construction materials. ISO/TC 207 on Environmental Management and ISO/TC 71 on Concrete are collaborating to establish metrics and methodologies for quantifying carbon negativity in concrete applications, including those incorporating biochar.

The European Committee for Standardization (CEN) has advanced several technical specifications that provide guidelines for measuring and verifying carbon sequestration in biochar-amended construction materials. These include protocols for determining the stability of carbon in biochar when incorporated into geopolymer matrices, ensuring long-term sequestration rather than temporary storage.

In North America, ASTM International has established committees focused on developing standards for both biochar quality (Committee E61) and alternative cementitious materials (Committee C09). These efforts aim to create consistent quality parameters for biochar used in construction applications and performance criteria for resulting carbon-negative materials.

Certification systems are similarly evolving, with third-party verification bodies like the International Biochar Initiative (IBI) and the European Biochar Certificate (EBC) expanding their certification programs to include construction applications. These certification schemes typically assess factors such as carbon stability, contaminant levels, and production methods to ensure environmental integrity.

Life Cycle Assessment (LCA) methodologies specific to carbon-negative materials are being standardized through frameworks like the Product Environmental Footprint (PEF) in Europe and the Environmental Product Declaration (EPD) system globally. These frameworks are increasingly incorporating provisions for negative emissions technologies, allowing proper accounting for carbon sequestration in materials like biochar-enhanced GPC.

Challenges remain in harmonizing these various standards and certification systems globally. Differences in testing methodologies, carbon accounting approaches, and regulatory requirements create barriers to international trade and technology transfer in carbon-negative construction materials. Industry stakeholders are advocating for mutual recognition agreements between certification bodies to facilitate market growth.

The development of these standardization and certification frameworks represents a crucial enabling factor for the widespread adoption of carbon-negative pathways in construction. As these systems mature, they will provide the necessary market confidence and regulatory clarity to scale biochar applications in geopolymer concrete and similar carbon-negative materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!