Carbon footprint analysis: GPC vs portland cement

AUG 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

GPC vs Portland Cement: Carbon Footprint Background & Objectives

The cement industry has been a significant contributor to global carbon emissions, accounting for approximately 8% of worldwide CO2 emissions. This environmental impact has driven research into alternative binding materials with lower carbon footprints. Geopolymer Cement (GPC) has emerged as a promising alternative to traditional Ordinary Portland Cement (OPC), which has dominated construction for over 200 years. The evolution of cement technology reflects a growing awareness of sustainability challenges in construction materials.

Portland cement production dates back to 1824 when Joseph Aspdin patented the process in England. Its manufacturing involves limestone calcination at high temperatures (1400-1500°C), releasing substantial CO2 through both the chemical decomposition of limestone and the energy-intensive heating process. In contrast, GPC technology has developed more recently, utilizing industrial by-products like fly ash and ground granulated blast furnace slag, which require significantly lower processing temperatures (around 600-800°C).

The technical trajectory of cement development has shifted from performance-focused improvements to environmentally conscious innovations. This shift represents a fundamental change in industry priorities, driven by global climate agreements and increasing regulatory pressure on carbon-intensive industries. The cement sector faces mounting pressure to reduce its environmental impact while maintaining the mechanical properties and durability that make cement essential to modern infrastructure.

This technical pre-research report aims to comprehensively analyze the carbon footprint differential between GPC and Portland cement across their entire life cycles. The primary objective is to quantify the environmental benefits of GPC adoption and identify potential barriers to its widespread implementation. Additionally, we seek to evaluate the technical performance characteristics of GPC compared to traditional Portland cement to determine if environmental benefits come at the cost of structural integrity or longevity.

Secondary objectives include mapping the geographical distribution of raw materials necessary for GPC production, assessing the economic viability of transitioning to GPC technology at scale, and identifying potential policy mechanisms that could accelerate adoption. The analysis will incorporate both direct emissions from manufacturing processes and indirect emissions from transportation, resource extraction, and end-of-life considerations.

By establishing a clear understanding of the carbon footprint differential between these cement technologies, this report will provide valuable insights for construction industry stakeholders, policymakers, and researchers working toward more sustainable building practices. The findings will contribute to the broader goal of decarbonizing the construction sector while maintaining the structural integrity and safety standards that modern infrastructure demands.

Portland cement production dates back to 1824 when Joseph Aspdin patented the process in England. Its manufacturing involves limestone calcination at high temperatures (1400-1500°C), releasing substantial CO2 through both the chemical decomposition of limestone and the energy-intensive heating process. In contrast, GPC technology has developed more recently, utilizing industrial by-products like fly ash and ground granulated blast furnace slag, which require significantly lower processing temperatures (around 600-800°C).

The technical trajectory of cement development has shifted from performance-focused improvements to environmentally conscious innovations. This shift represents a fundamental change in industry priorities, driven by global climate agreements and increasing regulatory pressure on carbon-intensive industries. The cement sector faces mounting pressure to reduce its environmental impact while maintaining the mechanical properties and durability that make cement essential to modern infrastructure.

This technical pre-research report aims to comprehensively analyze the carbon footprint differential between GPC and Portland cement across their entire life cycles. The primary objective is to quantify the environmental benefits of GPC adoption and identify potential barriers to its widespread implementation. Additionally, we seek to evaluate the technical performance characteristics of GPC compared to traditional Portland cement to determine if environmental benefits come at the cost of structural integrity or longevity.

Secondary objectives include mapping the geographical distribution of raw materials necessary for GPC production, assessing the economic viability of transitioning to GPC technology at scale, and identifying potential policy mechanisms that could accelerate adoption. The analysis will incorporate both direct emissions from manufacturing processes and indirect emissions from transportation, resource extraction, and end-of-life considerations.

By establishing a clear understanding of the carbon footprint differential between these cement technologies, this report will provide valuable insights for construction industry stakeholders, policymakers, and researchers working toward more sustainable building practices. The findings will contribute to the broader goal of decarbonizing the construction sector while maintaining the structural integrity and safety standards that modern infrastructure demands.

Market Demand Analysis for Low-Carbon Cement Alternatives

The global cement industry is experiencing a significant shift towards sustainable alternatives, driven by increasing environmental concerns and regulatory pressures. Portland cement production accounts for approximately 8% of global CO2 emissions, making it one of the most carbon-intensive manufacturing processes. This environmental impact has created a substantial market demand for low-carbon alternatives such as Geopolymer Cement (GPC).

Market research indicates that the global green cement market was valued at $26.2 billion in 2021 and is projected to reach $72.4 billion by 2030, growing at a CAGR of 11.8%. This growth is primarily fueled by stringent government regulations aimed at reducing carbon emissions in construction activities and increasing awareness about sustainable building materials.

Regional analysis reveals varying levels of market readiness. Europe leads in adoption of low-carbon cement alternatives, with countries like Germany, France, and the Netherlands implementing carbon taxes and incentives for green building materials. The Asia-Pacific region represents the fastest-growing market, particularly in China and India, where rapid urbanization and infrastructure development coincide with increasing environmental concerns.

Consumer sentiment studies show that 67% of construction companies are willing to pay a premium of 5-15% for cement products with significantly lower carbon footprints, provided they meet performance standards. This willingness has increased by 22% over the past five years, indicating a growing market acceptance of sustainable alternatives.

Key market drivers include government regulations such as carbon pricing mechanisms, green building certification programs like LEED and BREEAM, and corporate sustainability commitments. The European Union's Carbon Border Adjustment Mechanism and various national net-zero targets are creating regulatory environments that favor low-carbon cement alternatives.

Market barriers remain significant, including higher production costs for GPC compared to Portland cement, limited awareness among end-users, and concerns about long-term performance. The price premium for GPC currently ranges from 15-40% above traditional Portland cement, though this gap is narrowing as production scales up and carbon pricing mechanisms become more widespread.

Industry forecasts suggest that by 2030, low-carbon cement alternatives could capture 25-30% of the global cement market, with GPC potentially representing 10-15% of this segment. This transition is expected to accelerate as carbon pricing becomes more prevalent and technological improvements reduce production costs of alternative cements.

Market research indicates that the global green cement market was valued at $26.2 billion in 2021 and is projected to reach $72.4 billion by 2030, growing at a CAGR of 11.8%. This growth is primarily fueled by stringent government regulations aimed at reducing carbon emissions in construction activities and increasing awareness about sustainable building materials.

Regional analysis reveals varying levels of market readiness. Europe leads in adoption of low-carbon cement alternatives, with countries like Germany, France, and the Netherlands implementing carbon taxes and incentives for green building materials. The Asia-Pacific region represents the fastest-growing market, particularly in China and India, where rapid urbanization and infrastructure development coincide with increasing environmental concerns.

Consumer sentiment studies show that 67% of construction companies are willing to pay a premium of 5-15% for cement products with significantly lower carbon footprints, provided they meet performance standards. This willingness has increased by 22% over the past five years, indicating a growing market acceptance of sustainable alternatives.

Key market drivers include government regulations such as carbon pricing mechanisms, green building certification programs like LEED and BREEAM, and corporate sustainability commitments. The European Union's Carbon Border Adjustment Mechanism and various national net-zero targets are creating regulatory environments that favor low-carbon cement alternatives.

Market barriers remain significant, including higher production costs for GPC compared to Portland cement, limited awareness among end-users, and concerns about long-term performance. The price premium for GPC currently ranges from 15-40% above traditional Portland cement, though this gap is narrowing as production scales up and carbon pricing mechanisms become more widespread.

Industry forecasts suggest that by 2030, low-carbon cement alternatives could capture 25-30% of the global cement market, with GPC potentially representing 10-15% of this segment. This transition is expected to accelerate as carbon pricing becomes more prevalent and technological improvements reduce production costs of alternative cements.

Current State and Challenges in Cement Carbon Footprint Reduction

The global cement industry currently faces significant challenges in reducing its carbon footprint, with Portland cement production alone accounting for approximately 8% of worldwide CO2 emissions. This substantial environmental impact stems primarily from two sources: the calcination process that releases CO2 from limestone, and the high-temperature kilns powered predominantly by fossil fuels. Despite growing awareness and regulatory pressure, progress in decarbonizing cement production remains incremental rather than transformative.

Current reduction strategies include improving energy efficiency in production facilities, which has yielded modest gains of 10-15% in carbon reduction. Alternative fuel substitution, particularly using waste-derived fuels, has been implemented in many modern plants but typically achieves only 20-30% emission reductions. Clinker substitution with supplementary cementitious materials (SCMs) like fly ash and blast furnace slag represents another widely adopted approach, though availability constraints limit its scalability.

Carbon capture technologies are being piloted at several cement plants globally, with post-combustion capture showing promise but facing economic viability challenges due to high implementation costs ranging from $50-100 per ton of CO2 captured. The technology readiness level (TRL) for most carbon capture solutions in cement production remains between 6-8, indicating they are not yet fully commercialized.

Geopolymer Cement (GPC) has emerged as a potentially disruptive alternative, demonstrating 60-80% lower carbon emissions compared to Portland cement in laboratory and small-scale commercial applications. However, its widespread adoption faces significant barriers including limited industrial-scale production experience, inconsistent raw material supply chains, and regulatory frameworks that favor conventional cement technologies.

The geographical distribution of carbon reduction initiatives shows concentration in Europe and parts of Asia, particularly China and Japan, while developing regions with rapidly growing cement demand lag in implementation. This creates a concerning scenario where global cement emissions could continue rising despite technological advances in certain regions.

Technical standardization represents another critical challenge, as existing building codes and standards were developed for Portland cement-based materials. The lengthy process of developing and validating new standards for alternative cements creates market entry barriers for innovative solutions like GPC.

Economic factors further complicate the transition, with conventional Portland cement benefiting from established economies of scale and infrastructure. Without carbon pricing mechanisms or significant policy interventions, the cost differential between conventional and low-carbon cement alternatives remains a substantial obstacle to market transformation.

Current reduction strategies include improving energy efficiency in production facilities, which has yielded modest gains of 10-15% in carbon reduction. Alternative fuel substitution, particularly using waste-derived fuels, has been implemented in many modern plants but typically achieves only 20-30% emission reductions. Clinker substitution with supplementary cementitious materials (SCMs) like fly ash and blast furnace slag represents another widely adopted approach, though availability constraints limit its scalability.

Carbon capture technologies are being piloted at several cement plants globally, with post-combustion capture showing promise but facing economic viability challenges due to high implementation costs ranging from $50-100 per ton of CO2 captured. The technology readiness level (TRL) for most carbon capture solutions in cement production remains between 6-8, indicating they are not yet fully commercialized.

Geopolymer Cement (GPC) has emerged as a potentially disruptive alternative, demonstrating 60-80% lower carbon emissions compared to Portland cement in laboratory and small-scale commercial applications. However, its widespread adoption faces significant barriers including limited industrial-scale production experience, inconsistent raw material supply chains, and regulatory frameworks that favor conventional cement technologies.

The geographical distribution of carbon reduction initiatives shows concentration in Europe and parts of Asia, particularly China and Japan, while developing regions with rapidly growing cement demand lag in implementation. This creates a concerning scenario where global cement emissions could continue rising despite technological advances in certain regions.

Technical standardization represents another critical challenge, as existing building codes and standards were developed for Portland cement-based materials. The lengthy process of developing and validating new standards for alternative cements creates market entry barriers for innovative solutions like GPC.

Economic factors further complicate the transition, with conventional Portland cement benefiting from established economies of scale and infrastructure. Without carbon pricing mechanisms or significant policy interventions, the cost differential between conventional and low-carbon cement alternatives remains a substantial obstacle to market transformation.

Existing Carbon Footprint Assessment Methodologies for Cement

01 Comparative carbon footprint analysis between GPC and Portland cement

Geopolymer cement (GPC) generally has a significantly lower carbon footprint compared to ordinary Portland cement (OPC). Studies show that GPC production can reduce CO2 emissions by up to 80% compared to traditional Portland cement. This reduction is primarily due to the elimination of the high-temperature calcination process required for Portland cement production, which is responsible for a large portion of its carbon emissions.- Comparative carbon footprint analysis of GPC vs Portland cement: Geopolymer cement (GPC) generally has a significantly lower carbon footprint compared to Ordinary Portland Cement (OPC). Studies show that GPC production can reduce CO2 emissions by 40-80% compared to traditional Portland cement. This reduction is primarily due to the elimination of the high-temperature calcination process required for Portland cement production, which is responsible for a large portion of its carbon emissions. The use of industrial by-products like fly ash and slag in GPC further contributes to its environmental advantages.

- Raw material substitution for carbon reduction: The use of alternative raw materials in cement production can significantly reduce the carbon footprint. Geopolymer cement utilizes industrial by-products such as fly ash from coal power plants, blast furnace slag from steel production, and other aluminosilicate materials that would otherwise be waste. These substitutions not only reduce the need for virgin raw materials but also decrease the embodied carbon in the final cement product. Additionally, the incorporation of these materials often requires less energy for processing compared to the raw materials used in Portland cement.

- Manufacturing process innovations for reduced emissions: Innovations in the manufacturing processes of both GPC and Portland cement are focused on reducing carbon emissions. For GPC, low-temperature alkali activation processes significantly reduce energy consumption compared to the high-temperature kiln operations required for Portland cement. Advanced curing techniques, optimized mix designs, and improved activation methods for geopolymers can further reduce the carbon footprint. For Portland cement, process improvements include alternative fuels, carbon capture technologies, and more efficient kiln designs to minimize the environmental impact of production.

- Performance and durability considerations in low-carbon cements: The performance and durability characteristics of low-carbon cement alternatives are crucial for their widespread adoption. Geopolymer cements have demonstrated comparable or superior performance to Portland cement in terms of compressive strength, chemical resistance, and durability in aggressive environments. However, factors such as setting time, workability, and long-term performance under various environmental conditions must be carefully considered. Balancing carbon footprint reduction with maintaining or improving performance properties is essential for the successful implementation of sustainable cement technologies.

- Life cycle assessment and standardization of low-carbon cements: Comprehensive life cycle assessment (LCA) methodologies are being developed to accurately quantify the environmental impact of different cement types. These assessments consider not only the production phase but also transportation, application, service life, and end-of-life scenarios. Standardization efforts are underway to establish consistent methods for measuring and reporting the carbon footprint of cement products, which is essential for fair comparisons and regulatory compliance. The development of international standards for geopolymer and other alternative cements is critical for their broader market acceptance and integration into building codes.

02 Raw materials and industrial by-products in GPC production

Geopolymer cement utilizes industrial by-products such as fly ash, blast furnace slag, and other aluminosilicate materials as primary raw materials, significantly reducing the carbon footprint compared to Portland cement. These materials would otherwise be disposed of as waste, making GPC production an environmentally beneficial process that contributes to circular economy principles while reducing the need for virgin material extraction.Expand Specific Solutions03 Manufacturing process innovations for reduced emissions

Innovations in the manufacturing processes of both geopolymer and Portland cement aim to reduce carbon emissions. These include using alternative fuels, optimizing kiln operations, implementing carbon capture technologies, and developing novel curing methods that require less energy. For geopolymer cement specifically, ambient temperature curing techniques have been developed that further reduce the energy requirements compared to conventional heat curing methods.Expand Specific Solutions04 Performance and durability comparisons affecting lifecycle carbon footprint

The durability and performance characteristics of geopolymer cement compared to Portland cement significantly impact the overall lifecycle carbon footprint. Geopolymer cements often demonstrate superior resistance to chemical attack, fire resistance, and reduced permeability, potentially leading to longer service life and reduced maintenance requirements. These factors contribute to a lower lifecycle carbon footprint beyond just the initial production emissions.Expand Specific Solutions05 Blended cement systems for carbon footprint reduction

Blended cement systems that combine Portland cement with geopolymer materials or other supplementary cementitious materials offer a transitional approach to reducing carbon footprint. These hybrid systems allow for gradual adoption of lower-carbon alternatives while maintaining compatibility with existing construction practices and standards. Research shows that even partial replacement of Portland cement with geopolymer materials can achieve significant carbon emission reductions while maintaining required performance characteristics.Expand Specific Solutions

Key Industry Players in Sustainable Cement Development

The carbon footprint analysis comparing Geopolymer Cement (GPC) versus Portland cement reveals an industry in transition, with growing market interest driven by sustainability demands. While the global market for low-carbon cements is expanding rapidly, the technology remains in early commercial adoption phases. Leading players like Terra CO2 Technology and Solidia Technologies are pioneering commercial GPC solutions, while established companies such as W.R. Grace and GCP Applied Technologies are integrating alternative cement technologies into their portfolios. Academic institutions including Zhengzhou University and University of British Columbia are advancing fundamental research, while government entities like CNRS and CSIR provide critical research infrastructure. The competitive landscape shows a blend of startups, established materials companies, and research institutions collaborating to overcome technical and market barriers to widespread GPC adoption.

The University of Stavanger

Technical Solution: The University of Stavanger has developed innovative geopolymer cement formulations specifically optimized for the oil and gas industry, with applications in well cementing that demonstrate carbon footprint reductions of 50-60% compared to Portland cement. Their research focuses on alkali-activated materials using industrial by-products such as fly ash and blast furnace slag, combined with novel activators that enhance performance under high-pressure, high-temperature downhole conditions. The university's technology includes specialized retarders and accelerators that provide unprecedented control over setting times in geopolymer systems, addressing a key challenge for field applications. Their geopolymer formulations demonstrate superior resistance to acid attack and CO2 exposure, critical for carbon capture and storage applications. The research team has conducted extensive testing under simulated wellbore conditions, demonstrating mechanical integrity and zonal isolation capabilities comparable or superior to Portland cement-based systems. They have also developed innovative testing methodologies specifically designed to evaluate geopolymer performance under the unique conditions found in oil and gas wells, providing crucial data for industry adoption.

Strengths: Excellent durability in aggressive environments (acid, CO2, high temperature), significant carbon reduction (50-60%), superior thermal stability for high-temperature wells, and compatibility with existing well cementing equipment. Weaknesses: Higher material costs compared to Portland cement, limited field history compared to conventional systems, logistical challenges with material supply chains in remote locations, and sensitivity to water content requiring precise quality control during mixing.

Solidia Technologies, Inc.

Technical Solution: Solidia Technologies has developed a revolutionary low-carbon cement and concrete manufacturing process that reduces the carbon footprint by up to 70% compared to Portland cement. Their technology uses a non-hydraulic calcium silicate cement that cures by carbonation rather than hydration, actively sequestering CO2 during the curing process. The production requires lower kiln temperatures (around 1200°C versus 1450°C for Portland cement), significantly reducing energy consumption and associated emissions. Solidia's process also reduces water usage by up to 80% and recycles 100% of water used in production. Their cement can be produced in existing cement kilns with minimal modifications, allowing for seamless industry adoption. The technology has been validated through partnerships with major industry players like LafargeHolcim and has been commercially deployed in precast concrete applications across multiple markets.

Strengths: Dramatic carbon reduction (up to 70%), lower energy requirements, significant water conservation, compatibility with existing manufacturing infrastructure, and carbon sequestration during curing. Weaknesses: Limited to certain applications initially (primarily precast), requires CO2 for curing which may present logistical challenges in some regions, and different material properties may require adjustments to construction practices.

Technical Analysis of GPC vs Portland Cement Emissions Profiles

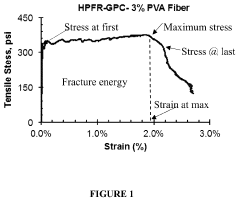

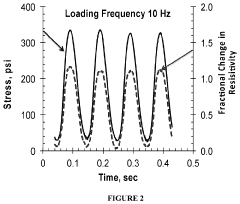

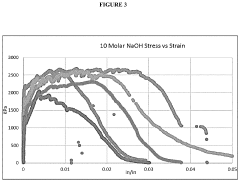

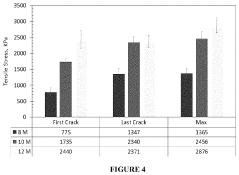

Self-sensing high performance fiber reinforced geopolymer composites

PatentActiveUS11802083B2

Innovation

- Development of self-sensing high-performance fiber-reinforced Geopolymer composites using carbon nanofibers (CNF) and Polyvinyl Alcohol (PVA) fibers, which are uniformly dispersed to improve stiffness, flexural strength, and conductivity, enabling non-destructive monitoring and damage detection.

Regulatory Framework and Carbon Pricing Impact on Cement Industry

The global cement industry faces increasingly stringent regulatory frameworks aimed at reducing carbon emissions, with significant implications for both traditional Portland cement and emerging alternatives like Geopolymer Cement (GPC). The Paris Agreement has established ambitious targets for greenhouse gas reduction, prompting many nations to implement specific regulations targeting the cement sector, which accounts for approximately 8% of global CO2 emissions.

Carbon pricing mechanisms have emerged as a primary regulatory tool, with over 40 jurisdictions worldwide implementing either carbon taxes or cap-and-trade systems. The European Union's Emissions Trading System (EU ETS) represents the most developed framework, where cement producers must purchase allowances for their emissions, creating direct financial incentives for carbon reduction. Recent carbon prices in the EU have reached €80-90 per tonne, significantly impacting production economics.

In North America, regulatory approaches vary by region. California's cap-and-trade program and Canada's federal carbon pricing backstop impose costs on cement manufacturers, while other regions maintain less stringent requirements. This regulatory patchwork creates competitive challenges for producers operating across multiple jurisdictions.

The Asia-Pacific region, responsible for approximately 75% of global cement production, shows varied regulatory maturity. China's national emissions trading scheme, launched in 2021, is gradually incorporating cement production, while India has implemented performance standards rather than direct carbon pricing. These divergent approaches reflect different economic priorities and development stages.

For GPC manufacturers, these regulatory frameworks present both challenges and opportunities. While GPC's lower carbon footprint (typically 40-80% less than Portland cement) provides a significant advantage under carbon pricing regimes, regulatory recognition of alternative cements remains inconsistent. Building codes and standards in many jurisdictions still favor traditional Portland cement, creating market access barriers despite environmental benefits.

Forward-looking policies are beginning to address this imbalance. The EU's sustainable product initiatives and green procurement policies increasingly recognize embodied carbon in construction materials. Similarly, several jurisdictions are implementing carbon border adjustment mechanisms to prevent "carbon leakage" through imports from regions with less stringent regulations, potentially benefiting domestic low-carbon cement production.

The financial impact of these regulatory frameworks is substantial. Analysis indicates that at carbon prices of €50-100 per tonne, the cost advantage of GPC over Portland cement increases by 15-30%, potentially accelerating market adoption despite higher base production costs in some regions.

Carbon pricing mechanisms have emerged as a primary regulatory tool, with over 40 jurisdictions worldwide implementing either carbon taxes or cap-and-trade systems. The European Union's Emissions Trading System (EU ETS) represents the most developed framework, where cement producers must purchase allowances for their emissions, creating direct financial incentives for carbon reduction. Recent carbon prices in the EU have reached €80-90 per tonne, significantly impacting production economics.

In North America, regulatory approaches vary by region. California's cap-and-trade program and Canada's federal carbon pricing backstop impose costs on cement manufacturers, while other regions maintain less stringent requirements. This regulatory patchwork creates competitive challenges for producers operating across multiple jurisdictions.

The Asia-Pacific region, responsible for approximately 75% of global cement production, shows varied regulatory maturity. China's national emissions trading scheme, launched in 2021, is gradually incorporating cement production, while India has implemented performance standards rather than direct carbon pricing. These divergent approaches reflect different economic priorities and development stages.

For GPC manufacturers, these regulatory frameworks present both challenges and opportunities. While GPC's lower carbon footprint (typically 40-80% less than Portland cement) provides a significant advantage under carbon pricing regimes, regulatory recognition of alternative cements remains inconsistent. Building codes and standards in many jurisdictions still favor traditional Portland cement, creating market access barriers despite environmental benefits.

Forward-looking policies are beginning to address this imbalance. The EU's sustainable product initiatives and green procurement policies increasingly recognize embodied carbon in construction materials. Similarly, several jurisdictions are implementing carbon border adjustment mechanisms to prevent "carbon leakage" through imports from regions with less stringent regulations, potentially benefiting domestic low-carbon cement production.

The financial impact of these regulatory frameworks is substantial. Analysis indicates that at carbon prices of €50-100 per tonne, the cost advantage of GPC over Portland cement increases by 15-30%, potentially accelerating market adoption despite higher base production costs in some regions.

Life Cycle Assessment (LCA) Methodologies for Cement Products

Life Cycle Assessment (LCA) methodologies provide a systematic framework for evaluating the environmental impacts of cement products throughout their entire life cycle. For comparing Geopolymer Cement (GPC) and Portland cement carbon footprints, several standardized LCA approaches are employed in the industry.

The ISO 14040 and 14044 standards form the foundation of cement product LCAs, establishing a four-phase methodology: goal and scope definition, inventory analysis, impact assessment, and interpretation. These standards ensure consistency and comparability across different cement type assessments, critical when evaluating novel alternatives like GPC against conventional Portland cement.

System boundary definition represents a crucial methodological consideration in cement LCAs. Cradle-to-gate assessments examine impacts from raw material extraction through manufacturing, while cradle-to-grave analyses extend to include use phase and end-of-life considerations. For cement carbon footprint comparisons, cradle-to-gate boundaries are most common, though expanding to cradle-to-grave provides more comprehensive insights into GPC's potential advantages over Portland cement.

Functional unit selection significantly influences comparative LCA outcomes. While traditional approaches use mass-based units (e.g., 1 ton of cement), performance-based functional units (e.g., volume of cement required to achieve specific strength characteristics) offer more meaningful comparisons between GPC and Portland cement, as they account for differences in material efficiency and service life.

Allocation procedures for multi-output processes present methodological challenges in cement LCAs. Economic allocation, mass allocation, and system expansion represent alternative approaches, each influencing carbon footprint calculations differently. The cement industry increasingly favors system expansion methods to account for by-products and waste utilization, particularly relevant for GPC which often incorporates industrial by-products.

Data quality and uncertainty management constitute critical methodological components. Primary data collection from manufacturing facilities provides the most accurate inputs, while secondary data from established databases (e.g., Ecoinvent, GaBi) fill gaps. Monte Carlo simulations and sensitivity analyses help quantify uncertainty in comparative assessments between cement types.

Impact assessment methods for carbon footprint analysis typically employ Global Warming Potential (GWP) metrics, with the IPCC's 100-year time horizon being standard practice. However, comprehensive assessments increasingly incorporate additional impact categories like acidification, eutrophication, and resource depletion to avoid burden-shifting between environmental impact categories when comparing GPC and Portland cement.

The ISO 14040 and 14044 standards form the foundation of cement product LCAs, establishing a four-phase methodology: goal and scope definition, inventory analysis, impact assessment, and interpretation. These standards ensure consistency and comparability across different cement type assessments, critical when evaluating novel alternatives like GPC against conventional Portland cement.

System boundary definition represents a crucial methodological consideration in cement LCAs. Cradle-to-gate assessments examine impacts from raw material extraction through manufacturing, while cradle-to-grave analyses extend to include use phase and end-of-life considerations. For cement carbon footprint comparisons, cradle-to-gate boundaries are most common, though expanding to cradle-to-grave provides more comprehensive insights into GPC's potential advantages over Portland cement.

Functional unit selection significantly influences comparative LCA outcomes. While traditional approaches use mass-based units (e.g., 1 ton of cement), performance-based functional units (e.g., volume of cement required to achieve specific strength characteristics) offer more meaningful comparisons between GPC and Portland cement, as they account for differences in material efficiency and service life.

Allocation procedures for multi-output processes present methodological challenges in cement LCAs. Economic allocation, mass allocation, and system expansion represent alternative approaches, each influencing carbon footprint calculations differently. The cement industry increasingly favors system expansion methods to account for by-products and waste utilization, particularly relevant for GPC which often incorporates industrial by-products.

Data quality and uncertainty management constitute critical methodological components. Primary data collection from manufacturing facilities provides the most accurate inputs, while secondary data from established databases (e.g., Ecoinvent, GaBi) fill gaps. Monte Carlo simulations and sensitivity analyses help quantify uncertainty in comparative assessments between cement types.

Impact assessment methods for carbon footprint analysis typically employ Global Warming Potential (GWP) metrics, with the IPCC's 100-year time horizon being standard practice. However, comprehensive assessments increasingly incorporate additional impact categories like acidification, eutrophication, and resource depletion to avoid burden-shifting between environmental impact categories when comparing GPC and Portland cement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!