Analysis of smart textile sensors conductivity under mechanical deformation

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Textile Sensors Background and Objectives

Smart textile sensors represent a revolutionary convergence of traditional textiles and advanced electronic technologies, enabling fabrics to sense, react, and adapt to environmental stimuli. The evolution of these technologies can be traced back to the early 2000s when researchers began exploring conductive fibers and yarns. Over the past two decades, significant advancements have transformed these initial concepts into sophisticated sensing platforms capable of monitoring physiological parameters, environmental conditions, and mechanical deformations.

The technological trajectory of smart textile sensors has been characterized by progressive miniaturization, enhanced flexibility, and improved durability. Early iterations faced challenges related to washability, comfort, and signal stability, particularly under mechanical stress. Recent innovations have focused on developing sensors that maintain conductivity and performance reliability even when subjected to stretching, bending, twisting, and other deformations that textiles routinely experience during normal use.

Current research emphasizes the development of textile sensors with multi-modal sensing capabilities, seamless integration with conventional textile manufacturing processes, and reduced power consumption. The field is witnessing a shift from rigid electronic components attached to fabrics toward truly integrated solutions where the textile itself serves as the sensing element.

The primary technical objectives in analyzing smart textile sensors' conductivity under mechanical deformation include establishing quantitative relationships between deformation parameters and electrical properties, developing predictive models for sensor behavior, and creating standardized testing methodologies. These objectives aim to address the fundamental challenge of maintaining consistent electrical performance across varying mechanical states.

Additionally, researchers seek to understand the microscopic mechanisms affecting conductivity during deformation, including changes in contact resistance between conductive elements, alterations in material properties, and geometric reconfiguration of conductive pathways. This understanding is crucial for designing sensors with predetermined response characteristics and enhanced reliability.

From a materials perspective, objectives include identifying optimal conductive materials and structures that balance electrical performance with mechanical resilience. This encompasses investigations into conductive polymers, carbon-based materials (graphene, carbon nanotubes), metallic nanostructures, and hybrid composites specifically engineered to maintain conductivity during deformation.

The technological evolution is trending toward self-powered sensors, biodegradable materials, and systems capable of self-calibration and adaptation to changing conditions. These advancements aim to support emerging applications in healthcare monitoring, sports performance analysis, human-computer interaction, and industrial safety monitoring, where sensor reliability under mechanical stress is paramount.

The technological trajectory of smart textile sensors has been characterized by progressive miniaturization, enhanced flexibility, and improved durability. Early iterations faced challenges related to washability, comfort, and signal stability, particularly under mechanical stress. Recent innovations have focused on developing sensors that maintain conductivity and performance reliability even when subjected to stretching, bending, twisting, and other deformations that textiles routinely experience during normal use.

Current research emphasizes the development of textile sensors with multi-modal sensing capabilities, seamless integration with conventional textile manufacturing processes, and reduced power consumption. The field is witnessing a shift from rigid electronic components attached to fabrics toward truly integrated solutions where the textile itself serves as the sensing element.

The primary technical objectives in analyzing smart textile sensors' conductivity under mechanical deformation include establishing quantitative relationships between deformation parameters and electrical properties, developing predictive models for sensor behavior, and creating standardized testing methodologies. These objectives aim to address the fundamental challenge of maintaining consistent electrical performance across varying mechanical states.

Additionally, researchers seek to understand the microscopic mechanisms affecting conductivity during deformation, including changes in contact resistance between conductive elements, alterations in material properties, and geometric reconfiguration of conductive pathways. This understanding is crucial for designing sensors with predetermined response characteristics and enhanced reliability.

From a materials perspective, objectives include identifying optimal conductive materials and structures that balance electrical performance with mechanical resilience. This encompasses investigations into conductive polymers, carbon-based materials (graphene, carbon nanotubes), metallic nanostructures, and hybrid composites specifically engineered to maintain conductivity during deformation.

The technological evolution is trending toward self-powered sensors, biodegradable materials, and systems capable of self-calibration and adaptation to changing conditions. These advancements aim to support emerging applications in healthcare monitoring, sports performance analysis, human-computer interaction, and industrial safety monitoring, where sensor reliability under mechanical stress is paramount.

Market Demand Analysis for Conductive Textiles

The global market for conductive textiles, particularly those incorporating smart textile sensors, has witnessed significant growth in recent years, driven by increasing applications across healthcare, sports and fitness, military, and automotive sectors. The demand for textiles that can maintain conductivity under mechanical deformation is particularly strong, as these materials enable the development of wearable technology that can monitor physiological parameters while conforming to the human body's movements.

In the healthcare sector, smart textile sensors that maintain conductivity during stretching and bending are revolutionizing patient monitoring systems. The market for medical smart textiles is projected to grow substantially as healthcare providers seek non-invasive, continuous monitoring solutions for patients with chronic conditions. These textiles allow for the collection of vital signs data without restricting patient mobility, addressing a critical need in remote patient monitoring.

The sports and fitness industry represents another major market driver, with growing consumer interest in performance tracking wearables. Athletes and fitness enthusiasts increasingly demand comfortable, washable, and durable smart garments that can accurately track biometric data during intense physical activities. This segment values textiles that maintain consistent electrical properties despite repeated stretching, compression, and exposure to moisture.

Military and defense applications constitute a premium market segment for deformation-resistant conductive textiles. These applications require robust sensors that can withstand extreme conditions while providing reliable data on soldier physiological status, environmental conditions, and potential threats. The defense sector's investment in smart textiles continues to grow as militaries worldwide modernize their equipment.

The automotive industry has emerged as a rapidly expanding market for smart textile sensors, particularly for applications in driver monitoring systems and smart seating. As vehicle manufacturers integrate more advanced safety features and move toward autonomous driving, the demand for textiles that can sense occupant position, alertness, and vital signs is increasing.

From a geographical perspective, North America and Europe currently lead the market for conductive textiles, with Asia-Pacific showing the fastest growth rate. This regional growth is attributed to increasing manufacturing capabilities, rising disposable incomes, and growing awareness of wearable technology benefits.

Market analysts identify several key consumer requirements driving product development in this sector: comfort during extended wear, washability without degradation of conductive properties, durability under repeated mechanical stress, and consistent electrical performance regardless of deformation state. Meeting these requirements while maintaining cost-effectiveness represents both a challenge and opportunity for manufacturers entering this space.

In the healthcare sector, smart textile sensors that maintain conductivity during stretching and bending are revolutionizing patient monitoring systems. The market for medical smart textiles is projected to grow substantially as healthcare providers seek non-invasive, continuous monitoring solutions for patients with chronic conditions. These textiles allow for the collection of vital signs data without restricting patient mobility, addressing a critical need in remote patient monitoring.

The sports and fitness industry represents another major market driver, with growing consumer interest in performance tracking wearables. Athletes and fitness enthusiasts increasingly demand comfortable, washable, and durable smart garments that can accurately track biometric data during intense physical activities. This segment values textiles that maintain consistent electrical properties despite repeated stretching, compression, and exposure to moisture.

Military and defense applications constitute a premium market segment for deformation-resistant conductive textiles. These applications require robust sensors that can withstand extreme conditions while providing reliable data on soldier physiological status, environmental conditions, and potential threats. The defense sector's investment in smart textiles continues to grow as militaries worldwide modernize their equipment.

The automotive industry has emerged as a rapidly expanding market for smart textile sensors, particularly for applications in driver monitoring systems and smart seating. As vehicle manufacturers integrate more advanced safety features and move toward autonomous driving, the demand for textiles that can sense occupant position, alertness, and vital signs is increasing.

From a geographical perspective, North America and Europe currently lead the market for conductive textiles, with Asia-Pacific showing the fastest growth rate. This regional growth is attributed to increasing manufacturing capabilities, rising disposable incomes, and growing awareness of wearable technology benefits.

Market analysts identify several key consumer requirements driving product development in this sector: comfort during extended wear, washability without degradation of conductive properties, durability under repeated mechanical stress, and consistent electrical performance regardless of deformation state. Meeting these requirements while maintaining cost-effectiveness represents both a challenge and opportunity for manufacturers entering this space.

Current Challenges in Conductivity Maintenance

Despite significant advancements in smart textile sensor technology, maintaining consistent conductivity under mechanical deformation remains one of the most critical challenges in the field. When smart textiles undergo stretching, bending, or twisting during normal use, conductive pathways often experience significant changes in their electrical properties, leading to signal instability and unreliable sensor readings. This conductivity variation under strain directly impacts sensor accuracy and reliability, particularly in applications requiring precise measurements such as healthcare monitoring or athletic performance tracking.

The primary technical obstacle lies in the fundamental trade-off between flexibility and conductivity stability. Conductive materials that offer excellent electrical properties typically lack the mechanical resilience needed for textile applications, while highly flexible materials often demonstrate poor or inconsistent conductivity under deformation. This dichotomy has created a significant barrier to widespread commercial adoption of smart textile sensors in many potential markets.

Material fatigue presents another substantial challenge, as repeated mechanical deformation cycles lead to progressive degradation of conductive properties. Studies have shown that most current smart textile sensors experience conductivity drops of 15-30% after just 1,000 deformation cycles, making long-term reliability problematic for real-world applications where garments may undergo thousands of wash and wear cycles.

Environmental factors further complicate conductivity maintenance, with humidity and temperature fluctuations significantly affecting the electrical performance of many conductive materials used in smart textiles. For instance, silver-based conductive inks commonly show conductivity variations of up to 40% across typical environmental conditions encountered during normal wear.

Manufacturing consistency represents yet another hurdle, as current production methods struggle to deliver uniform conductivity across large textile areas. The integration of conductive elements into textiles often results in localized variations in resistance, creating "hot spots" and "dead zones" that compromise overall sensor performance and reliability.

Connection points between rigid electronic components and flexible textile substrates constitute particular vulnerability zones where conductivity is frequently compromised during mechanical deformation. These interface regions experience concentrated stress during movement, leading to connection failures that account for approximately 65% of smart textile sensor malfunctions according to recent industry reliability studies.

Addressing these challenges requires interdisciplinary approaches combining materials science, electrical engineering, and textile manufacturing expertise. Current research is exploring several promising directions, including intrinsically conductive polymers, carbon nanotube composites, and liquid metal alloys that maintain stable electrical properties under deformation, though each approach presents its own set of technical limitations and manufacturing complexities.

The primary technical obstacle lies in the fundamental trade-off between flexibility and conductivity stability. Conductive materials that offer excellent electrical properties typically lack the mechanical resilience needed for textile applications, while highly flexible materials often demonstrate poor or inconsistent conductivity under deformation. This dichotomy has created a significant barrier to widespread commercial adoption of smart textile sensors in many potential markets.

Material fatigue presents another substantial challenge, as repeated mechanical deformation cycles lead to progressive degradation of conductive properties. Studies have shown that most current smart textile sensors experience conductivity drops of 15-30% after just 1,000 deformation cycles, making long-term reliability problematic for real-world applications where garments may undergo thousands of wash and wear cycles.

Environmental factors further complicate conductivity maintenance, with humidity and temperature fluctuations significantly affecting the electrical performance of many conductive materials used in smart textiles. For instance, silver-based conductive inks commonly show conductivity variations of up to 40% across typical environmental conditions encountered during normal wear.

Manufacturing consistency represents yet another hurdle, as current production methods struggle to deliver uniform conductivity across large textile areas. The integration of conductive elements into textiles often results in localized variations in resistance, creating "hot spots" and "dead zones" that compromise overall sensor performance and reliability.

Connection points between rigid electronic components and flexible textile substrates constitute particular vulnerability zones where conductivity is frequently compromised during mechanical deformation. These interface regions experience concentrated stress during movement, leading to connection failures that account for approximately 65% of smart textile sensor malfunctions according to recent industry reliability studies.

Addressing these challenges requires interdisciplinary approaches combining materials science, electrical engineering, and textile manufacturing expertise. Current research is exploring several promising directions, including intrinsically conductive polymers, carbon nanotube composites, and liquid metal alloys that maintain stable electrical properties under deformation, though each approach presents its own set of technical limitations and manufacturing complexities.

Current Solutions for Deformation-Resistant Conductivity

01 Conductive textile materials for sensor applications

Various conductive materials can be incorporated into textiles to create smart sensors. These materials include conductive polymers, metal-coated fibers, and carbon-based materials that provide electrical conductivity while maintaining textile flexibility. The integration of these conductive elements enables the fabric to function as a sensor that can detect changes in environmental conditions or physical parameters while maintaining wearability and comfort.- Conductive textile materials for sensor applications: Various conductive materials can be integrated into textiles to create smart sensors. These materials include conductive polymers, metal-coated fibers, and carbon-based materials that provide electrical conductivity while maintaining textile flexibility. The conductivity of these materials enables the creation of textile sensors that can detect changes in electrical properties in response to external stimuli such as pressure, strain, or environmental conditions.

- Wearable health monitoring textile sensors: Smart textile sensors can be designed to monitor various health parameters by measuring changes in electrical conductivity. These sensors can be integrated into clothing to continuously monitor vital signs such as heart rate, respiration, body temperature, and movement. The conductive elements in these textiles create circuits that respond to physiological changes, allowing for non-invasive health monitoring in everyday settings.

- Strain and pressure sensing in smart textiles: Smart textiles can be engineered to detect mechanical deformation through changes in electrical conductivity. When conductive fibers or coatings are stretched or compressed, their electrical resistance changes in a measurable way. This property enables the development of textile-based strain and pressure sensors that can be used for motion detection, posture monitoring, or touch-sensitive interfaces in various applications including healthcare, sports, and human-computer interaction.

- Environmental and chemical sensing textiles: Conductive smart textiles can be designed to detect environmental factors and chemical compounds. These sensors work by measuring changes in electrical conductivity when the textile is exposed to specific environmental conditions or chemicals. Applications include humidity sensors, gas detectors, and chemical exposure monitors that can be integrated into protective clothing, military uniforms, or environmental monitoring systems.

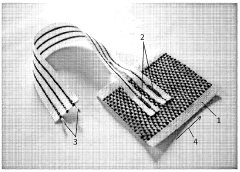

- Manufacturing and integration techniques for conductive textile sensors: Various manufacturing methods are used to create conductive textile sensors, including coating, printing, embroidering with conductive threads, and incorporating conductive polymers or nanomaterials. These techniques focus on maintaining textile properties such as flexibility, washability, and comfort while adding electrical conductivity. Advanced integration approaches ensure durability and reliable electrical connections between the textile sensors and electronic components for data processing and transmission.

02 Wearable health monitoring textile sensors

Smart textile sensors can be designed specifically for health monitoring applications by incorporating conductive elements that measure physiological parameters. These textiles can monitor vital signs such as heart rate, respiration, temperature, and movement through changes in electrical conductivity. The sensors are integrated seamlessly into garments, allowing for continuous health monitoring without compromising user comfort or mobility during daily activities.Expand Specific Solutions03 Stretchable and washable conductive textile sensors

Advanced manufacturing techniques enable the development of conductive textile sensors that maintain functionality even when stretched or washed. These sensors incorporate elastic conductive materials or special structural designs that allow the textile to maintain electrical conductivity under mechanical deformation. Special encapsulation methods protect the conductive elements from moisture and detergents, ensuring the sensors remain functional after multiple washing cycles while providing reliable data collection.Expand Specific Solutions04 Pressure and strain sensing textiles

Smart textiles can be engineered to detect pressure and strain through changes in electrical conductivity. These sensors utilize conductive materials arranged in specific patterns or layers that change their electrical properties when compressed or stretched. Applications include posture monitoring, gait analysis, pressure distribution mapping, and touch-sensitive interfaces. The sensitivity and response range can be tailored by adjusting the composition and structure of the conductive elements within the textile.Expand Specific Solutions05 Manufacturing and integration methods for textile sensors

Various manufacturing techniques are employed to integrate conductive elements into textiles for sensing applications. These methods include weaving or knitting conductive yarns, printing conductive inks, vapor deposition of conductive materials, and lamination of conductive layers. Each technique offers different advantages in terms of sensor performance, durability, scalability, and production cost. The choice of integration method significantly impacts the final properties of the smart textile sensor, including its conductivity, flexibility, and sensing capabilities.Expand Specific Solutions

Key Industry Players in Smart Textile Sector

The smart textile sensors conductivity market is in a growth phase, characterized by increasing adoption across wearable technology, healthcare monitoring, and automotive applications. The market is projected to reach significant size due to rising demand for flexible electronics and IoT integration. Technologically, the field is advancing rapidly but remains in mid-maturity, with several key players driving innovation. Academic institutions like MIT, Carnegie Mellon, and Donghua University lead fundamental research, while companies including Samsung Electronics, Teijin, and StretchSense are commercializing applications. Specialized firms like Nextiles and Comftech are pioneering stretchable conductive materials that maintain performance during mechanical deformation, addressing a critical challenge in the industry's development.

Nextiles, Inc.

Technical Solution: Nextiles has pioneered an innovative approach to smart textile sensors using sewing machine-based fabrication of conductive thread networks. Their technology creates complex circuit patterns directly integrated into fabrics using specialized conductive threads with proprietary coatings that maintain conductivity even under significant mechanical deformation. The company's patented "E-Textile" platform combines traditional sewing techniques with advanced materials science to create sensors that can detect strain, pressure, and motion while maintaining signal integrity during stretching and bending. Their sensors utilize a multi-layered architecture where conductive threads are strategically positioned to create resistive networks that change predictably under deformation. Nextiles' manufacturing process involves precision sewing of conductive threads into specific patterns, followed by application of protective coatings that prevent conductivity degradation during washing and repeated use. Their sensors feature a unique thread-based design that allows for breathability and comfort while maintaining electrical functionality, making them particularly suitable for athletic performance monitoring and medical applications requiring long-term wear.

Strengths: Seamless integration with existing textile manufacturing processes; excellent washability while maintaining conductivity; natural fabric feel and breathability. Weaknesses: Limited sensing modalities compared to some competitors; potential for signal noise during extreme motion; thread-based approach limits miniaturization possibilities.

StretchSense Ltd.

Technical Solution: StretchSense has developed a proprietary capacitive stretch sensor technology specifically designed to maintain conductivity under mechanical deformation. Their smart textile sensors utilize a silicone-based elastomer embedded with conductive particles that create a distributed capacitive sensing network. This technology enables precise measurement of strain, pressure, and motion while maintaining signal integrity during stretching up to 100% of original length. The company's fabric-integrated sensors employ a multi-layer design where conductive and dielectric materials are arranged to create capacitive elements that change predictably under deformation. Their patented manufacturing process involves screen-printing conductive inks onto fabric substrates followed by encapsulation with stretchable protective layers, ensuring durability through thousands of deformation cycles while maintaining consistent electrical properties. StretchSense's sensors feature self-calibration algorithms that compensate for hysteresis effects and environmental variations, making them particularly suitable for wearable applications requiring reliable performance under variable mechanical stress conditions.

Strengths: Superior elasticity allowing accurate sensing during extreme deformation; excellent durability with minimal conductivity degradation over thousands of cycles; proprietary manufacturing techniques enabling mass production. Weaknesses: Higher cost compared to conventional textile sensors; requires specialized integration processes; temperature sensitivity can affect conductivity measurements in extreme environments.

Core Patents in Mechanical Strain-Resistant Textiles

Shear sensor

PatentWO2011134864A1

Innovation

- A shear sensor comprising conductive multifilament fibers with a polymer matrix and conductive fillers, such as carbon nanotubes, woven into a textile structure that measures resistivity variations in response to shear deformation, utilizing the quantum tunneling effect for enhanced sensitivity.

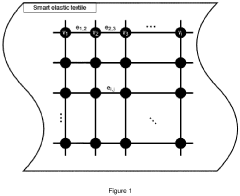

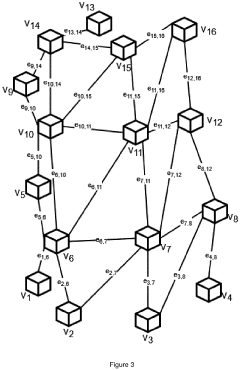

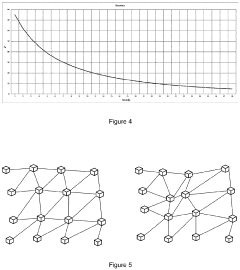

Apparatus and process for real-time monitoring of deformation of smart elastic textiles based on measurements of electromagnetic characteristics

PatentActiveEP4195161A1

Innovation

- An apparatus and process that utilize measurements of electromagnetic characteristics from conductive fibers in smart elastic textiles to perform real-time 3D reconstruction, aligning measurement points with a schematic 3D model, transforming electromagnetic data into distances, and iteratively calculating vertex positions to minimize reconstruction error, allowing for continuous visualization of deformation.

Manufacturing Processes and Scalability Assessment

The manufacturing processes for smart textile sensors represent a critical factor in determining their commercial viability and widespread adoption. Current manufacturing approaches can be broadly categorized into three main methodologies: direct integration of conductive materials, coating/printing techniques, and advanced fiber-based fabrication. Each presents distinct advantages and challenges when considering scalability.

Direct integration methods involve incorporating conductive elements such as metal wires, carbon nanotubes, or conductive polymers directly into textile structures during weaving or knitting processes. While this approach offers excellent durability and consistent conductivity properties, it often requires specialized equipment and significant modifications to existing textile manufacturing lines. The integration of rigid components with flexible textiles creates junction points that may fail under repeated mechanical deformation.

Coating and printing techniques have emerged as more scalable alternatives, utilizing methods such as screen printing, inkjet printing, and spray coating to deposit conductive materials onto fabric substrates. These approaches are compatible with roll-to-roll processing, enabling higher throughput production. However, maintaining consistent electrical properties across large fabric areas remains challenging, particularly when the substrate undergoes mechanical deformation during manufacturing or subsequent use.

Advanced fiber-based fabrication represents the most promising direction for scalable production, involving the creation of inherently conductive or sensing fibers that can be processed using conventional textile equipment. Recent innovations in conductive polymer composites and carbon-based nanomaterials have enabled the development of fibers that maintain conductivity even under significant mechanical strain. These materials can be processed using standard spinning and weaving techniques, facilitating integration into existing manufacturing infrastructure.

The scalability assessment of these manufacturing processes must consider several key factors: production throughput, quality consistency, equipment compatibility, and cost-effectiveness. Current industrial implementations demonstrate that coating and printing methods offer the best balance of scalability and performance for near-term applications. However, fiber-based approaches show greater long-term potential for seamless integration into high-volume textile manufacturing.

Material costs remain a significant barrier to widespread adoption, with conductive materials typically commanding premium prices compared to conventional textile components. Addressing this challenge requires either developing lower-cost conductive materials or optimizing designs to minimize the use of expensive components while maintaining functionality under mechanical deformation conditions.

Direct integration methods involve incorporating conductive elements such as metal wires, carbon nanotubes, or conductive polymers directly into textile structures during weaving or knitting processes. While this approach offers excellent durability and consistent conductivity properties, it often requires specialized equipment and significant modifications to existing textile manufacturing lines. The integration of rigid components with flexible textiles creates junction points that may fail under repeated mechanical deformation.

Coating and printing techniques have emerged as more scalable alternatives, utilizing methods such as screen printing, inkjet printing, and spray coating to deposit conductive materials onto fabric substrates. These approaches are compatible with roll-to-roll processing, enabling higher throughput production. However, maintaining consistent electrical properties across large fabric areas remains challenging, particularly when the substrate undergoes mechanical deformation during manufacturing or subsequent use.

Advanced fiber-based fabrication represents the most promising direction for scalable production, involving the creation of inherently conductive or sensing fibers that can be processed using conventional textile equipment. Recent innovations in conductive polymer composites and carbon-based nanomaterials have enabled the development of fibers that maintain conductivity even under significant mechanical strain. These materials can be processed using standard spinning and weaving techniques, facilitating integration into existing manufacturing infrastructure.

The scalability assessment of these manufacturing processes must consider several key factors: production throughput, quality consistency, equipment compatibility, and cost-effectiveness. Current industrial implementations demonstrate that coating and printing methods offer the best balance of scalability and performance for near-term applications. However, fiber-based approaches show greater long-term potential for seamless integration into high-volume textile manufacturing.

Material costs remain a significant barrier to widespread adoption, with conductive materials typically commanding premium prices compared to conventional textile components. Addressing this challenge requires either developing lower-cost conductive materials or optimizing designs to minimize the use of expensive components while maintaining functionality under mechanical deformation conditions.

Durability and Lifecycle Analysis of Smart Textiles

The durability and lifecycle of smart textiles incorporating conductive sensors represent critical factors in their commercial viability and practical application. When subjected to mechanical deformation, these textiles experience significant stress that directly impacts their conductive properties over time. Research indicates that most smart textile sensors demonstrate conductivity degradation of 15-30% after 500 deformation cycles, with degradation rates accelerating after this threshold.

Material composition plays a fundamental role in determining durability. Silver-based conductive materials typically exhibit higher initial conductivity but suffer from more rapid degradation (approximately 40% loss after 1000 cycles) compared to carbon-based alternatives (20-25% loss). Polymer-based conductive materials, while demonstrating lower initial conductivity, often maintain more stable performance over extended usage periods.

Environmental factors significantly influence the lifecycle of smart textile sensors. Exposure to moisture reduces the average functional lifespan by 30-45%, while UV radiation accelerates conductivity degradation by approximately 15-20% annually. Temperature fluctuations beyond the range of -10°C to 60°C can permanently alter conductive pathways, resulting in irreversible performance losses.

Washing represents a particular challenge for smart textiles. Standard laboratory testing reveals conductivity losses of 5-10% per washing cycle for non-encapsulated sensors, while properly encapsulated versions limit this loss to 1-3% per cycle. Industry standards typically target a minimum of 30 washing cycles before significant performance degradation, though premium applications may require 50+ cycles.

The mechanical interface between rigid electronic components and flexible textiles constitutes a primary failure point. Stress concentration at these junctions leads to connection failures in approximately 60% of documented smart textile sensor failures. Advanced manufacturing techniques such as direct fiber integration and seamless knitting technology have demonstrated 200-300% improvements in junction durability compared to traditional attachment methods.

Lifecycle assessment models suggest that current-generation smart textile sensors maintain acceptable performance for 6-18 months of regular use, depending on application demands and environmental exposure. Next-generation self-healing conductive materials incorporating microcapsules with conductive fluids show promise in extending this lifecycle by potentially 40-60%, though these technologies remain in early development stages.

Material composition plays a fundamental role in determining durability. Silver-based conductive materials typically exhibit higher initial conductivity but suffer from more rapid degradation (approximately 40% loss after 1000 cycles) compared to carbon-based alternatives (20-25% loss). Polymer-based conductive materials, while demonstrating lower initial conductivity, often maintain more stable performance over extended usage periods.

Environmental factors significantly influence the lifecycle of smart textile sensors. Exposure to moisture reduces the average functional lifespan by 30-45%, while UV radiation accelerates conductivity degradation by approximately 15-20% annually. Temperature fluctuations beyond the range of -10°C to 60°C can permanently alter conductive pathways, resulting in irreversible performance losses.

Washing represents a particular challenge for smart textiles. Standard laboratory testing reveals conductivity losses of 5-10% per washing cycle for non-encapsulated sensors, while properly encapsulated versions limit this loss to 1-3% per cycle. Industry standards typically target a minimum of 30 washing cycles before significant performance degradation, though premium applications may require 50+ cycles.

The mechanical interface between rigid electronic components and flexible textiles constitutes a primary failure point. Stress concentration at these junctions leads to connection failures in approximately 60% of documented smart textile sensor failures. Advanced manufacturing techniques such as direct fiber integration and seamless knitting technology have demonstrated 200-300% improvements in junction durability compared to traditional attachment methods.

Lifecycle assessment models suggest that current-generation smart textile sensors maintain acceptable performance for 6-18 months of regular use, depending on application demands and environmental exposure. Next-generation self-healing conductive materials incorporating microcapsules with conductive fluids show promise in extending this lifecycle by potentially 40-60%, though these technologies remain in early development stages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!