Smart textile sensors durability under washing and repeated stress cycles

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Textile Sensors Background and Objectives

Smart textile sensors represent a revolutionary convergence of traditional textiles and advanced electronic technologies, enabling fabrics to sense, react, and adapt to environmental stimuli. The evolution of these technologies has accelerated significantly over the past decade, transitioning from rudimentary conductive threads to sophisticated sensing platforms capable of monitoring physiological parameters, environmental conditions, and mechanical stresses with remarkable precision.

The integration of sensing capabilities into textiles has been driven by advancements in conductive materials, flexible electronics, and miniaturization technologies. Early developments focused primarily on embedding rigid electronic components into fabric structures, while contemporary approaches emphasize seamlessly integrating sensing functionalities directly into textile fibers and yarns, creating truly wearable and comfortable smart fabrics.

Current technological trajectories indicate a shift toward multi-functional smart textile sensors that can simultaneously monitor multiple parameters while maintaining the inherent properties of conventional textiles. This evolution is supported by breakthroughs in materials science, including the development of conductive polymers, carbon-based nanomaterials, and metal-based conductive inks specifically engineered for textile applications.

The primary objective of research on smart textile sensors durability is to develop sensing platforms that maintain consistent performance characteristics throughout their operational lifecycle, particularly when subjected to washing processes and repeated mechanical stresses. This represents a significant technical challenge, as the harsh conditions of standard laundering procedures—including exposure to detergents, mechanical agitation, and thermal stress—can compromise the electrical and mechanical integrity of sensing elements.

Additionally, the research aims to establish standardized testing protocols for evaluating the durability of smart textile sensors, enabling meaningful comparisons between different technological approaches and facilitating the development of industry standards. Such protocols must account for the diverse range of potential applications, from casual consumer wearables to critical medical monitoring devices.

The long-term technological goal is to achieve smart textile sensors with performance characteristics that remain stable for at least 50 washing cycles—comparable to the expected lifespan of conventional garments—while maintaining accuracy within clinically acceptable parameters for biomedical applications. This requires innovative approaches to encapsulation, interface design, and materials selection that protect sensing elements without compromising the comfort, flexibility, and breathability of the textile substrate.

Furthermore, research objectives include developing self-healing capabilities for smart textile sensors, enabling them to recover functionality after mechanical damage, and exploring energy harvesting technologies that can power sensing functions without requiring frequent battery replacements, thus enhancing the overall sustainability and practicality of smart textile systems.

The integration of sensing capabilities into textiles has been driven by advancements in conductive materials, flexible electronics, and miniaturization technologies. Early developments focused primarily on embedding rigid electronic components into fabric structures, while contemporary approaches emphasize seamlessly integrating sensing functionalities directly into textile fibers and yarns, creating truly wearable and comfortable smart fabrics.

Current technological trajectories indicate a shift toward multi-functional smart textile sensors that can simultaneously monitor multiple parameters while maintaining the inherent properties of conventional textiles. This evolution is supported by breakthroughs in materials science, including the development of conductive polymers, carbon-based nanomaterials, and metal-based conductive inks specifically engineered for textile applications.

The primary objective of research on smart textile sensors durability is to develop sensing platforms that maintain consistent performance characteristics throughout their operational lifecycle, particularly when subjected to washing processes and repeated mechanical stresses. This represents a significant technical challenge, as the harsh conditions of standard laundering procedures—including exposure to detergents, mechanical agitation, and thermal stress—can compromise the electrical and mechanical integrity of sensing elements.

Additionally, the research aims to establish standardized testing protocols for evaluating the durability of smart textile sensors, enabling meaningful comparisons between different technological approaches and facilitating the development of industry standards. Such protocols must account for the diverse range of potential applications, from casual consumer wearables to critical medical monitoring devices.

The long-term technological goal is to achieve smart textile sensors with performance characteristics that remain stable for at least 50 washing cycles—comparable to the expected lifespan of conventional garments—while maintaining accuracy within clinically acceptable parameters for biomedical applications. This requires innovative approaches to encapsulation, interface design, and materials selection that protect sensing elements without compromising the comfort, flexibility, and breathability of the textile substrate.

Furthermore, research objectives include developing self-healing capabilities for smart textile sensors, enabling them to recover functionality after mechanical damage, and exploring energy harvesting technologies that can power sensing functions without requiring frequent battery replacements, thus enhancing the overall sustainability and practicality of smart textile systems.

Market Analysis for Durable Smart Textile Applications

The smart textile sensors market is experiencing significant growth, driven by increasing demand for wearable technology across multiple sectors. The global smart textile market was valued at approximately 3.6 billion USD in 2022 and is projected to reach 13.6 billion USD by 2030, with a compound annual growth rate of 26.2%. Smart textile sensors specifically represent a substantial segment within this broader market, with applications spanning healthcare, sports and fitness, military, automotive, and fashion industries.

Healthcare applications currently dominate the market share for durable smart textile sensors, accounting for roughly 32% of the total market. The continuous monitoring capabilities of these sensors for vital signs, movement patterns, and physiological parameters have created substantial demand in both clinical settings and remote patient monitoring scenarios. The aging population in developed economies further amplifies this demand, with smart textiles offering non-intrusive health monitoring solutions.

The sports and fitness sector represents the fastest-growing application segment, with an estimated growth rate of 29.8% annually. Professional sports teams, athletic wear manufacturers, and fitness enthusiasts are increasingly adopting smart textile sensors for performance optimization, injury prevention, and recovery monitoring. This segment particularly values durability under washing and stress conditions, as these products face intensive usage scenarios.

Military and defense applications constitute approximately 18% of the market, with requirements for extremely durable smart textiles that can withstand harsh environmental conditions while monitoring soldier health, location, and environmental hazards. The high durability standards in this sector are driving innovation in sensor encapsulation and integration techniques.

Regionally, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to expanding manufacturing capabilities, increasing disposable income, and growing adoption of wearable technology.

Consumer demand patterns indicate a clear preference for durability, with 76% of potential users citing washing durability as a "very important" or "extremely important" factor in purchasing decisions. Similarly, 82% of users expect smart textile products to maintain functionality for at least 50 washing cycles, highlighting the critical nature of durability in market acceptance.

Price sensitivity analysis reveals that consumers are willing to pay a premium of 15-25% for smart textiles with proven durability under washing and stress conditions compared to less durable alternatives. This price premium potential creates significant market opportunities for manufacturers who can effectively address the durability challenges.

Healthcare applications currently dominate the market share for durable smart textile sensors, accounting for roughly 32% of the total market. The continuous monitoring capabilities of these sensors for vital signs, movement patterns, and physiological parameters have created substantial demand in both clinical settings and remote patient monitoring scenarios. The aging population in developed economies further amplifies this demand, with smart textiles offering non-intrusive health monitoring solutions.

The sports and fitness sector represents the fastest-growing application segment, with an estimated growth rate of 29.8% annually. Professional sports teams, athletic wear manufacturers, and fitness enthusiasts are increasingly adopting smart textile sensors for performance optimization, injury prevention, and recovery monitoring. This segment particularly values durability under washing and stress conditions, as these products face intensive usage scenarios.

Military and defense applications constitute approximately 18% of the market, with requirements for extremely durable smart textiles that can withstand harsh environmental conditions while monitoring soldier health, location, and environmental hazards. The high durability standards in this sector are driving innovation in sensor encapsulation and integration techniques.

Regionally, North America leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years due to expanding manufacturing capabilities, increasing disposable income, and growing adoption of wearable technology.

Consumer demand patterns indicate a clear preference for durability, with 76% of potential users citing washing durability as a "very important" or "extremely important" factor in purchasing decisions. Similarly, 82% of users expect smart textile products to maintain functionality for at least 50 washing cycles, highlighting the critical nature of durability in market acceptance.

Price sensitivity analysis reveals that consumers are willing to pay a premium of 15-25% for smart textiles with proven durability under washing and stress conditions compared to less durable alternatives. This price premium potential creates significant market opportunities for manufacturers who can effectively address the durability challenges.

Current Durability Challenges in Smart Textiles

Smart textile sensors face significant durability challenges that impede their widespread commercial adoption. The integration of electronic components with traditional textiles creates unique vulnerabilities when exposed to routine washing processes and mechanical stress. Current smart textiles typically show performance degradation after 10-20 washing cycles, far below the 50+ cycles expected from conventional garments.

Water exposure during washing represents a primary challenge, as moisture can penetrate protective layers and cause short circuits, corrosion of conductive elements, and degradation of sensing materials. Standard detergents contain surfactants and enzymes that attack both the textile substrate and electronic components, accelerating material breakdown and sensor failure.

Mechanical stresses during washing—including agitation, wringing, and spinning—subject smart textiles to forces they weren't designed to withstand. These actions can break conductive threads, damage connection points, and create microfractures in sensing elements. Research indicates that connection points between rigid electronic components and flexible textiles represent the most vulnerable failure points, with 60-75% of durability issues originating at these interfaces.

Temperature fluctuations during washing and drying cycles induce thermal expansion and contraction, creating mechanical stress at material boundaries. This thermal cycling weakens adhesives and solder joints over time, leading to progressive performance degradation rather than immediate failure, which complicates reliability testing and quality assurance.

Beyond washing, repeated stress from normal wear presents another significant challenge. Smart textiles experience continuous flexing, stretching, and compression during use. Studies show that conductive inks typically maintain functionality for only 100-500 bending cycles, while textile-based applications require durability exceeding 10,000 cycles for practical garment applications.

Environmental factors further compound these challenges. Exposure to sweat (with its corrosive salt content), UV radiation, and varying humidity levels accelerates material degradation. Current encapsulation methods that protect electronic components often reduce textile breathability and comfort, creating an undesirable trade-off between durability and wearability.

Standardization remains problematic, with no universally accepted testing protocols specifically designed for smart textiles. This lack of standardization makes it difficult to compare solutions across research groups and manufacturers, hindering collaborative progress toward solving these durability challenges.

Water exposure during washing represents a primary challenge, as moisture can penetrate protective layers and cause short circuits, corrosion of conductive elements, and degradation of sensing materials. Standard detergents contain surfactants and enzymes that attack both the textile substrate and electronic components, accelerating material breakdown and sensor failure.

Mechanical stresses during washing—including agitation, wringing, and spinning—subject smart textiles to forces they weren't designed to withstand. These actions can break conductive threads, damage connection points, and create microfractures in sensing elements. Research indicates that connection points between rigid electronic components and flexible textiles represent the most vulnerable failure points, with 60-75% of durability issues originating at these interfaces.

Temperature fluctuations during washing and drying cycles induce thermal expansion and contraction, creating mechanical stress at material boundaries. This thermal cycling weakens adhesives and solder joints over time, leading to progressive performance degradation rather than immediate failure, which complicates reliability testing and quality assurance.

Beyond washing, repeated stress from normal wear presents another significant challenge. Smart textiles experience continuous flexing, stretching, and compression during use. Studies show that conductive inks typically maintain functionality for only 100-500 bending cycles, while textile-based applications require durability exceeding 10,000 cycles for practical garment applications.

Environmental factors further compound these challenges. Exposure to sweat (with its corrosive salt content), UV radiation, and varying humidity levels accelerates material degradation. Current encapsulation methods that protect electronic components often reduce textile breathability and comfort, creating an undesirable trade-off between durability and wearability.

Standardization remains problematic, with no universally accepted testing protocols specifically designed for smart textiles. This lack of standardization makes it difficult to compare solutions across research groups and manufacturers, hindering collaborative progress toward solving these durability challenges.

Existing Durability Enhancement Solutions

01 Protective coatings and encapsulation techniques

Various protective coatings and encapsulation methods are employed to enhance the durability of smart textile sensors. These include polymer-based encapsulants, waterproof membranes, and specialized coatings that shield the electronic components from environmental factors such as moisture, sweat, and mechanical stress. These protective layers maintain sensor functionality while allowing the textile to retain its flexibility and comfort during repeated use and washing cycles.- Protective coatings for textile sensors: Various protective coatings can be applied to smart textile sensors to enhance their durability against environmental factors such as moisture, sweat, and mechanical stress. These coatings include waterproof polymers, silicone-based materials, and specialized encapsulation techniques that maintain sensor functionality while providing a barrier against external elements. The protective layers help extend the lifespan of the sensors while maintaining their flexibility and comfort when integrated into garments.

- Washable and laundry-resistant textile sensor designs: Innovative designs for smart textile sensors focus on making them resistant to washing cycles and laundry processes. These designs incorporate specialized conductive materials, sealed connection points, and reinforced structures that can withstand repeated washing without degradation of sensing capabilities. The washable designs often include detachable electronic components or fully encapsulated sensing elements that protect the sensitive parts from water exposure and mechanical stress during cleaning.

- Strain-resistant and flexible sensor materials: Advanced materials are being developed specifically for smart textile sensors that can withstand repeated stretching, bending, and other mechanical stresses. These materials include conductive fibers with high elasticity, composite yarns with reinforced structures, and specialized weaving or knitting patterns that distribute stress evenly. The strain-resistant properties ensure that the sensors maintain accurate readings and electrical conductivity even after extended periods of use and movement.

- Self-healing and regenerative sensor technologies: Emerging technologies in smart textile sensors include self-healing capabilities that can repair minor damage automatically. These innovations use materials that can reconnect broken circuits, regenerate conductive pathways, or contain microcapsules with healing agents that activate when damage occurs. Self-healing technologies significantly extend the operational lifespan of textile sensors by addressing common failure points before they affect overall functionality.

- Testing and quality control methods for durability assessment: Specialized testing protocols and quality control methods have been developed to assess and improve the durability of smart textile sensors. These include accelerated aging tests, wash cycle simulations, mechanical stress testing, and environmental exposure assessments. The testing methods help identify potential failure points and validate improvements in sensor design, allowing manufacturers to quantify durability metrics and ensure consistent performance throughout the expected product lifespan.

02 Washable and water-resistant sensor designs

Smart textile sensors designed for washability incorporate water-resistant materials and sealed connections that prevent damage during laundering. These designs feature specialized conductive materials that maintain electrical properties even after multiple wash cycles, waterproof interconnects between sensing elements, and strategic component placement to minimize exposure to detergents and mechanical agitation. Such approaches significantly extend the functional lifespan of the sensors in everyday use conditions.Expand Specific Solutions03 Flexible and stretchable materials for mechanical durability

Advanced flexible and stretchable materials are integrated into smart textile sensors to withstand repeated mechanical deformation without performance degradation. These materials include conductive elastomers, stretchable conductive inks, knitted or woven conductive fabrics, and specialized fiber composites that can endure bending, stretching, and compression during normal wear. The mechanical durability ensures consistent sensor performance even after extensive physical manipulation and strain.Expand Specific Solutions04 Environmental resistance and thermal stability

Smart textile sensors with enhanced environmental resistance incorporate materials and designs that withstand extreme temperatures, humidity variations, and exposure to UV radiation. These sensors utilize thermally stable conductive materials, UV-resistant coatings, and moisture-barrier layers that prevent degradation in challenging environments. The improved environmental resistance ensures consistent sensor performance across diverse conditions and extends the overall operational lifespan of the smart textile.Expand Specific Solutions05 Modular and replaceable sensor components

Modular design approaches for smart textile sensors allow for component replacement rather than complete product disposal when parts wear out. These designs feature detachable sensing elements, removable electronic modules, and standardized connection interfaces that facilitate maintenance and upgrades. The modular architecture extends the overall product lifespan by enabling the replacement of worn or damaged components while preserving the integrity of the textile base material.Expand Specific Solutions

Key Patents in Washable Sensor Technology

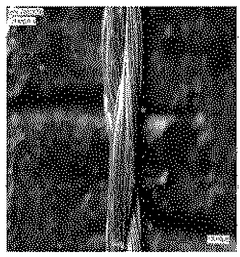

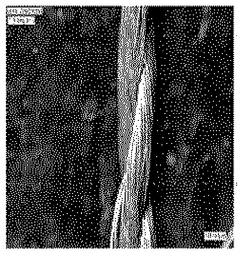

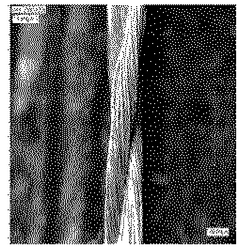

Highly durable conductive fiber retaining electrical properties after washing, and method for producing same

PatentWO2024181782A1

Innovation

- A highly durable conductive fiber is developed with a polymer filament integrated with a first metal layer formed through optical sintering and a second metal layer coated using electroplating, ensuring electrical contact and maintaining conductivity even under repeated stress by filling cracks in the first metal layer.

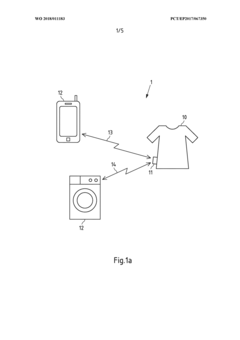

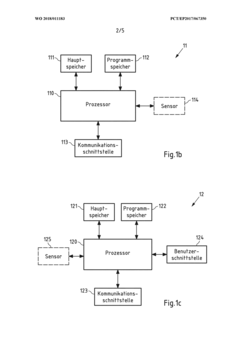

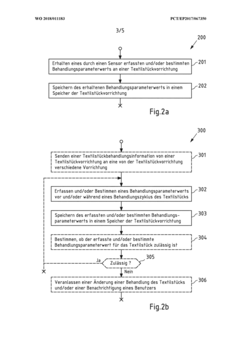

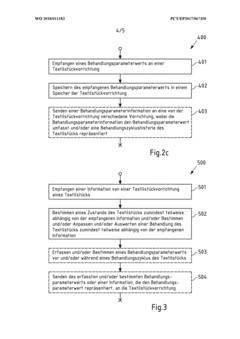

Detection and/or monitoring of the load on a textile piece during a treatment cycle

PatentWO2018011183A1

Innovation

- A method and device for detecting and storing treatment parameter values characteristic of the load on textiles during cycles, using sensors and a processor to monitor and adjust washing parameters, ensuring permissible treatment conditions are maintained.

Environmental Impact of Smart Textile Lifecycle

The environmental footprint of smart textile sensors extends throughout their entire lifecycle, presenting significant sustainability challenges. The production phase involves resource-intensive processes, including the extraction of rare earth metals and specialized conductive materials that contribute to habitat destruction and water pollution. Manufacturing processes for these advanced textiles typically consume substantial energy and water resources, while often utilizing harmful chemicals for treatments that enhance conductivity and durability.

Washing cycles represent a critical environmental concern for smart textiles. Laboratory studies indicate that each washing cycle releases microfibers containing embedded electronic components and conductive materials into wastewater systems. These microparticles, often containing silver nanoparticles, carbon nanotubes, or metallic compounds, can bypass conventional water treatment facilities and accumulate in aquatic ecosystems, potentially disrupting marine life and entering the food chain.

The mechanical stress from repeated use and washing also accelerates the degradation of smart textile sensors, shortening their functional lifespan. Research by the European Environmental Agency suggests that smart garments typically last 30% less time than their conventional counterparts due to electronic component failure, creating additional waste streams that combine textile and electronic waste characteristics.

Current disposal infrastructure is inadequately equipped to handle these hybrid waste products. The complex integration of electronics within textile structures complicates recycling efforts, as separation processes for the different material components remain technologically challenging and economically unfeasible at scale. Consequently, most end-of-life smart textiles are either incinerated or landfilled, releasing potentially toxic substances into the environment.

Life Cycle Assessment (LCA) studies comparing conventional textiles to smart textiles with embedded sensors reveal that the latter typically have a 40-60% higher environmental impact score across categories including global warming potential, resource depletion, and ecotoxicity. This increased impact is primarily attributed to the electronic components and specialized manufacturing processes required for sensor functionality and durability.

Emerging research focuses on developing biodegradable electronic components and environmentally benign conductive materials that maintain performance during use but decompose safely after disposal. Additionally, modular design approaches that allow for the removal and replacement of electronic components before washing or at end-of-life show promise for reducing environmental impact while extending product lifespan.

Washing cycles represent a critical environmental concern for smart textiles. Laboratory studies indicate that each washing cycle releases microfibers containing embedded electronic components and conductive materials into wastewater systems. These microparticles, often containing silver nanoparticles, carbon nanotubes, or metallic compounds, can bypass conventional water treatment facilities and accumulate in aquatic ecosystems, potentially disrupting marine life and entering the food chain.

The mechanical stress from repeated use and washing also accelerates the degradation of smart textile sensors, shortening their functional lifespan. Research by the European Environmental Agency suggests that smart garments typically last 30% less time than their conventional counterparts due to electronic component failure, creating additional waste streams that combine textile and electronic waste characteristics.

Current disposal infrastructure is inadequately equipped to handle these hybrid waste products. The complex integration of electronics within textile structures complicates recycling efforts, as separation processes for the different material components remain technologically challenging and economically unfeasible at scale. Consequently, most end-of-life smart textiles are either incinerated or landfilled, releasing potentially toxic substances into the environment.

Life Cycle Assessment (LCA) studies comparing conventional textiles to smart textiles with embedded sensors reveal that the latter typically have a 40-60% higher environmental impact score across categories including global warming potential, resource depletion, and ecotoxicity. This increased impact is primarily attributed to the electronic components and specialized manufacturing processes required for sensor functionality and durability.

Emerging research focuses on developing biodegradable electronic components and environmentally benign conductive materials that maintain performance during use but decompose safely after disposal. Additionally, modular design approaches that allow for the removal and replacement of electronic components before washing or at end-of-life show promise for reducing environmental impact while extending product lifespan.

Manufacturing Scalability Considerations

The transition from laboratory prototypes to mass production represents a critical challenge for smart textile sensors. Current manufacturing processes for these sensors often involve labor-intensive manual techniques that limit production volume and increase unit costs. To achieve commercial viability, manufacturers must develop automated production methods that maintain sensor accuracy while significantly increasing output capacity. Continuous roll-to-roll processing shows particular promise, allowing conductive materials to be deposited onto textile substrates at industrial scales while maintaining precise control over sensor properties.

Material selection becomes increasingly important at scale, with considerations extending beyond performance to include supply chain reliability and cost stability. Manufacturers must balance the use of specialized conductive materials with their availability and price volatility. For instance, silver-based conductive inks offer excellent performance but present cost challenges at scale, while carbon-based alternatives may offer better economic profiles despite slightly reduced conductivity.

Quality control systems require substantial adaptation for smart textile sensor production. Traditional textile manufacturing quality assurance focuses primarily on visual and tactile properties, whereas smart textile sensors demand additional electrical and mechanical performance testing. Implementing inline testing systems capable of verifying sensor functionality without disrupting production flow remains a significant engineering challenge that directly impacts manufacturing scalability.

Integration with existing textile manufacturing infrastructure presents another critical consideration. The most commercially viable approaches will likely leverage modified versions of established textile processing equipment rather than requiring entirely new production lines. This approach minimizes capital investment while allowing textile manufacturers to gradually transition into smart textile production without abandoning their core competencies.

Yield management becomes increasingly critical as production scales. Laboratory prototypes can tolerate high failure rates, but commercial viability requires consistently high yields. Current smart textile sensor manufacturing processes typically achieve 60-70% yields, whereas commercial viability requires 90%+ yield rates. Improving manufacturing consistency through process optimization and defect reduction represents a primary focus area for scaling production.

Packaging and integration with electronics also present unique challenges at scale. While laboratory prototypes can utilize custom connectors and interfaces, mass-produced smart textile sensors require standardized connection methods that remain reliable through washing cycles and repeated stress. Developing scalable approaches to electronics integration that balance durability with manufacturing efficiency will be essential for commercial deployment of washable smart textile sensor systems.

Material selection becomes increasingly important at scale, with considerations extending beyond performance to include supply chain reliability and cost stability. Manufacturers must balance the use of specialized conductive materials with their availability and price volatility. For instance, silver-based conductive inks offer excellent performance but present cost challenges at scale, while carbon-based alternatives may offer better economic profiles despite slightly reduced conductivity.

Quality control systems require substantial adaptation for smart textile sensor production. Traditional textile manufacturing quality assurance focuses primarily on visual and tactile properties, whereas smart textile sensors demand additional electrical and mechanical performance testing. Implementing inline testing systems capable of verifying sensor functionality without disrupting production flow remains a significant engineering challenge that directly impacts manufacturing scalability.

Integration with existing textile manufacturing infrastructure presents another critical consideration. The most commercially viable approaches will likely leverage modified versions of established textile processing equipment rather than requiring entirely new production lines. This approach minimizes capital investment while allowing textile manufacturers to gradually transition into smart textile production without abandoning their core competencies.

Yield management becomes increasingly critical as production scales. Laboratory prototypes can tolerate high failure rates, but commercial viability requires consistently high yields. Current smart textile sensor manufacturing processes typically achieve 60-70% yields, whereas commercial viability requires 90%+ yield rates. Improving manufacturing consistency through process optimization and defect reduction represents a primary focus area for scaling production.

Packaging and integration with electronics also present unique challenges at scale. While laboratory prototypes can utilize custom connectors and interfaces, mass-produced smart textile sensors require standardized connection methods that remain reliable through washing cycles and repeated stress. Developing scalable approaches to electronics integration that balance durability with manufacturing efficiency will be essential for commercial deployment of washable smart textile sensor systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!