Smart textile sensors qualification standards in occupational safety devices

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Textile Sensors Background and Objectives

Smart textile sensors represent a revolutionary convergence of traditional textiles and advanced electronic technologies, enabling fabrics to sense, react, and communicate with their environment. The evolution of these technologies began in the late 1990s with rudimentary conductive fabrics, progressing through significant advancements in miniaturization, flexibility, and integration capabilities over the past two decades. Today's smart textiles incorporate sophisticated sensing mechanisms including pressure, temperature, chemical, and biometric monitoring capabilities, fundamentally transforming how we interact with fabric-based products.

In the context of occupational safety, smart textile sensors have emerged as critical components in protecting workers across various high-risk industries including construction, manufacturing, mining, firefighting, and healthcare. These technologies enable real-time monitoring of environmental hazards, physiological parameters, and potential safety threats that traditional personal protective equipment (PPE) cannot address.

The technical trajectory of smart textile sensors shows accelerating development in several key areas: increased sensor sensitivity and accuracy, enhanced durability under harsh working conditions, improved power management systems, and more sophisticated data processing capabilities. Recent innovations have focused on creating seamless integration between the textile substrate and electronic components, resulting in more comfortable and practical safety devices that workers are more likely to adopt consistently.

Despite these advancements, the field faces significant challenges regarding standardization. Currently, there exists a fragmented landscape of qualification standards across different regions and industries, creating barriers to widespread implementation and interoperability. The absence of universally accepted testing methodologies and performance benchmarks has hindered both innovation and market adoption.

The primary technical objectives for smart textile sensors in occupational safety applications include developing comprehensive qualification standards that address durability, reliability, sensitivity, specificity, and biocompatibility. These standards must account for the unique challenges of textile-integrated electronics, including wash resistance, flexibility requirements, and long-term performance stability under varied environmental conditions.

Additionally, there is a pressing need to establish clear protocols for evaluating data accuracy, response time, and system integration capabilities across different occupational contexts. Future technical goals include creating adaptive sensing systems that can respond intelligently to changing risk conditions, developing self-powering capabilities through energy harvesting, and implementing advanced data analytics for predictive safety applications.

In the context of occupational safety, smart textile sensors have emerged as critical components in protecting workers across various high-risk industries including construction, manufacturing, mining, firefighting, and healthcare. These technologies enable real-time monitoring of environmental hazards, physiological parameters, and potential safety threats that traditional personal protective equipment (PPE) cannot address.

The technical trajectory of smart textile sensors shows accelerating development in several key areas: increased sensor sensitivity and accuracy, enhanced durability under harsh working conditions, improved power management systems, and more sophisticated data processing capabilities. Recent innovations have focused on creating seamless integration between the textile substrate and electronic components, resulting in more comfortable and practical safety devices that workers are more likely to adopt consistently.

Despite these advancements, the field faces significant challenges regarding standardization. Currently, there exists a fragmented landscape of qualification standards across different regions and industries, creating barriers to widespread implementation and interoperability. The absence of universally accepted testing methodologies and performance benchmarks has hindered both innovation and market adoption.

The primary technical objectives for smart textile sensors in occupational safety applications include developing comprehensive qualification standards that address durability, reliability, sensitivity, specificity, and biocompatibility. These standards must account for the unique challenges of textile-integrated electronics, including wash resistance, flexibility requirements, and long-term performance stability under varied environmental conditions.

Additionally, there is a pressing need to establish clear protocols for evaluating data accuracy, response time, and system integration capabilities across different occupational contexts. Future technical goals include creating adaptive sensing systems that can respond intelligently to changing risk conditions, developing self-powering capabilities through energy harvesting, and implementing advanced data analytics for predictive safety applications.

Market Analysis for Occupational Safety Wearables

The occupational safety wearables market has experienced significant growth in recent years, driven by increasing workplace safety regulations and growing awareness of employee health and well-being. The global market for smart wearable safety devices is currently valued at approximately 3.2 billion USD, with projections indicating a compound annual growth rate (CAGR) of 12.4% through 2028. This growth trajectory is particularly pronounced in industries with high occupational hazards, including construction, manufacturing, mining, and healthcare.

Smart textile sensors represent a rapidly expanding segment within this market, with an estimated market share of 18% that is expected to reach 25% by 2025. These advanced textiles integrate seamlessly into workwear and personal protective equipment (PPE), offering real-time monitoring capabilities without compromising comfort or mobility. The demand is especially strong in regions with stringent workplace safety regulations, with North America and Europe collectively accounting for over 60% of the global market.

Key market drivers include the rising costs associated with workplace injuries, which exceed 170 billion USD annually in direct and indirect expenses in the US alone. Insurance companies and employers are increasingly recognizing the return on investment from preventative safety technologies, creating a favorable environment for smart textile sensor adoption. Additionally, the COVID-19 pandemic has accelerated interest in wearable health monitoring solutions, with 78% of surveyed companies reporting increased consideration of such technologies since 2020.

Consumer preferences within this market demonstrate a clear trend toward non-intrusive, comfortable solutions that offer comprehensive data collection without hindering worker performance. Battery life remains a critical consideration, with 82% of potential enterprise customers citing extended operational duration as a "very important" or "extremely important" purchasing factor. Interoperability with existing safety systems and data platforms represents another significant market requirement.

Market barriers include concerns regarding data privacy, with 64% of workers expressing reservations about continuous monitoring. Initial implementation costs also present adoption challenges, particularly for small and medium enterprises. The absence of universally accepted qualification standards for smart textile sensors specifically designed for occupational safety applications creates market uncertainty and slows adoption rates in risk-averse industries.

Emerging market opportunities include the integration of artificial intelligence for predictive safety analytics, with 89% of industry experts identifying this as a high-potential growth area. The development of industry-specific solutions tailored to unique occupational hazards also presents significant market potential, particularly in specialized fields like emergency response, military applications, and extreme environment operations.

Smart textile sensors represent a rapidly expanding segment within this market, with an estimated market share of 18% that is expected to reach 25% by 2025. These advanced textiles integrate seamlessly into workwear and personal protective equipment (PPE), offering real-time monitoring capabilities without compromising comfort or mobility. The demand is especially strong in regions with stringent workplace safety regulations, with North America and Europe collectively accounting for over 60% of the global market.

Key market drivers include the rising costs associated with workplace injuries, which exceed 170 billion USD annually in direct and indirect expenses in the US alone. Insurance companies and employers are increasingly recognizing the return on investment from preventative safety technologies, creating a favorable environment for smart textile sensor adoption. Additionally, the COVID-19 pandemic has accelerated interest in wearable health monitoring solutions, with 78% of surveyed companies reporting increased consideration of such technologies since 2020.

Consumer preferences within this market demonstrate a clear trend toward non-intrusive, comfortable solutions that offer comprehensive data collection without hindering worker performance. Battery life remains a critical consideration, with 82% of potential enterprise customers citing extended operational duration as a "very important" or "extremely important" purchasing factor. Interoperability with existing safety systems and data platforms represents another significant market requirement.

Market barriers include concerns regarding data privacy, with 64% of workers expressing reservations about continuous monitoring. Initial implementation costs also present adoption challenges, particularly for small and medium enterprises. The absence of universally accepted qualification standards for smart textile sensors specifically designed for occupational safety applications creates market uncertainty and slows adoption rates in risk-averse industries.

Emerging market opportunities include the integration of artificial intelligence for predictive safety analytics, with 89% of industry experts identifying this as a high-potential growth area. The development of industry-specific solutions tailored to unique occupational hazards also presents significant market potential, particularly in specialized fields like emergency response, military applications, and extreme environment operations.

Current Standards and Technical Challenges

The current landscape of smart textile sensors in occupational safety devices reveals a fragmented standardization environment. ISO 13506 and EN 469 provide baseline requirements for protective clothing performance but lack specific provisions for integrated electronic components. ASTM F2370 addresses electrical resistance in textiles, yet falls short in comprehensively covering smart textile functionalities in safety applications.

Technical qualification challenges primarily stem from the interdisciplinary nature of smart textiles, which bridge traditional textile manufacturing with electronics and data processing. The IEC 63203 series represents progress toward standardization but remains in development for many critical aspects. This creates significant barriers for manufacturers attempting to validate their products against consistent benchmarks.

Durability testing presents a particular challenge, as smart textile sensors must withstand harsh industrial environments while maintaining accuracy. Current standards inadequately address the combined effects of mechanical stress, chemical exposure, and electromagnetic interference that characterize real-world occupational settings. AATCC Test Method 135 covers basic wash durability but doesn't account for industrial cleaning processes often used for safety equipment.

Calibration and measurement accuracy standards remain underdeveloped, with no unified approach to validating sensor readings across different environmental conditions. Temperature variations, humidity, and physical deformation can significantly impact sensor performance, yet standardized testing protocols addressing these variables collectively are absent from current frameworks.

Interoperability issues further complicate qualification efforts. The lack of standardized communication protocols for smart textile components hinders integration with broader safety systems. While IEC 61000 provides electromagnetic compatibility guidelines, it doesn't specifically address the unique challenges of body-worn textile sensors operating in industrial environments.

Biocompatibility and user safety standards represent another critical gap. ISO 10993 covers biocompatibility for medical devices but doesn't fully address the specific concerns of prolonged contact with smart textiles in occupational settings. This leaves manufacturers uncertain about appropriate testing protocols for skin irritation, allergic reactions, and potential long-term health effects.

Certification pathways remain unclear, with regulatory bodies across different regions applying inconsistent approaches to smart textile safety devices. The EU's PPE Regulation 2016/425 provides a framework for personal protective equipment but lacks specific provisions for integrated smart technologies, creating market access barriers and regulatory uncertainty for innovative products.

Technical qualification challenges primarily stem from the interdisciplinary nature of smart textiles, which bridge traditional textile manufacturing with electronics and data processing. The IEC 63203 series represents progress toward standardization but remains in development for many critical aspects. This creates significant barriers for manufacturers attempting to validate their products against consistent benchmarks.

Durability testing presents a particular challenge, as smart textile sensors must withstand harsh industrial environments while maintaining accuracy. Current standards inadequately address the combined effects of mechanical stress, chemical exposure, and electromagnetic interference that characterize real-world occupational settings. AATCC Test Method 135 covers basic wash durability but doesn't account for industrial cleaning processes often used for safety equipment.

Calibration and measurement accuracy standards remain underdeveloped, with no unified approach to validating sensor readings across different environmental conditions. Temperature variations, humidity, and physical deformation can significantly impact sensor performance, yet standardized testing protocols addressing these variables collectively are absent from current frameworks.

Interoperability issues further complicate qualification efforts. The lack of standardized communication protocols for smart textile components hinders integration with broader safety systems. While IEC 61000 provides electromagnetic compatibility guidelines, it doesn't specifically address the unique challenges of body-worn textile sensors operating in industrial environments.

Biocompatibility and user safety standards represent another critical gap. ISO 10993 covers biocompatibility for medical devices but doesn't fully address the specific concerns of prolonged contact with smart textiles in occupational settings. This leaves manufacturers uncertain about appropriate testing protocols for skin irritation, allergic reactions, and potential long-term health effects.

Certification pathways remain unclear, with regulatory bodies across different regions applying inconsistent approaches to smart textile safety devices. The EU's PPE Regulation 2016/425 provides a framework for personal protective equipment but lacks specific provisions for integrated smart technologies, creating market access barriers and regulatory uncertainty for innovative products.

Existing Qualification Methodologies

01 Testing and certification standards for smart textile sensors

Smart textile sensors require specific testing and certification standards to ensure their reliability and performance. These standards cover aspects such as durability, accuracy, and safety when integrated into textiles. Qualification procedures typically involve testing under various environmental conditions, mechanical stress tests, and validation of sensor data accuracy. Standardized testing protocols help manufacturers ensure their smart textile sensors meet industry requirements and regulatory compliance.- Testing and certification standards for smart textile sensors: Smart textile sensors require specific testing and certification standards to ensure their reliability and performance. These standards cover various aspects including electrical safety, durability under washing conditions, and accuracy of sensor readings. Qualification procedures typically involve testing under simulated use conditions, environmental stress testing, and validation against established measurement standards. Certification bodies have developed specialized protocols for evaluating smart textiles that combine electronic components with traditional textile materials.

- Quality control methods for smart textile sensor manufacturing: Manufacturing smart textile sensors requires specialized quality control methods to ensure consistent performance. These methods include in-line testing during production, statistical process control for sensor calibration, and automated inspection systems for detecting defects in conductive elements. Quality assurance protocols address challenges unique to textile-integrated electronics, such as maintaining sensor functionality after textile processing steps like cutting, sewing, and finishing. Manufacturers implement multi-stage verification processes to validate sensor accuracy, durability, and reliability before market release.

- Biocompatibility and wearability standards for on-body textile sensors: Smart textile sensors worn directly on the body must meet specific biocompatibility and wearability standards. These standards address skin compatibility, hypoallergenic properties, and comfort during extended wear. Qualification requirements include testing for skin irritation, cytotoxicity, and sensitization according to medical device standards. Additionally, wearability standards evaluate factors such as breathability, moisture management, flexibility, and weight distribution. These standards ensure that smart textile sensors can be safely worn for their intended duration while maintaining user comfort and preventing adverse skin reactions.

- Performance validation protocols for specific sensing applications: Different smart textile sensing applications require specialized performance validation protocols. For health monitoring textiles, standards focus on accuracy of vital sign measurements compared to medical-grade devices. For environmental sensing textiles, protocols verify detection thresholds and response times to specific stimuli. For motion and position sensing textiles, validation includes precision of movement detection and spatial resolution testing. These application-specific protocols establish minimum performance requirements and testing methodologies to ensure that smart textile sensors function reliably in their intended use cases.

- Durability and lifecycle testing requirements: Smart textile sensors must undergo rigorous durability and lifecycle testing to qualify for commercial use. Standards in this area address washing resistance, with requirements for maintaining functionality after multiple laundering cycles. Physical stress testing evaluates sensor performance after repeated bending, stretching, and compression. Environmental testing assesses functionality across temperature ranges, humidity levels, and exposure to sweat or other bodily fluids. Lifecycle testing protocols determine expected operational lifespan and degradation patterns to establish replacement intervals and warranty periods for smart textile sensor products.

02 Quality control methods for wearable sensor integration

Quality control methods for integrating sensors into textiles involve specialized techniques to verify proper functionality after manufacturing. These methods include automated inspection systems, calibration procedures, and performance validation under simulated use conditions. Quality assurance protocols ensure that sensor components maintain their integrity when embedded in fabrics and that electrical connections remain stable during normal wear and washing. Standardized quality control procedures help maintain consistency across production batches of smart textile products.Expand Specific Solutions03 Durability and washability standards for textile-integrated electronics

Smart textile sensors must meet specific durability and washability standards to ensure longevity in real-world applications. These standards define requirements for water resistance, chemical compatibility with detergents, and mechanical resilience during repeated washing cycles. Test protocols typically specify the number of wash cycles, temperature conditions, and mechanical agitation parameters that textile sensors must withstand while maintaining functionality. Standardized testing helps manufacturers develop encapsulation and protection methods for electronic components embedded in textiles.Expand Specific Solutions04 Biocompatibility and safety certification for on-body sensors

Smart textile sensors worn against the skin require biocompatibility and safety certification to ensure they don't cause irritation, allergic reactions, or other health issues. These standards address material selection, chemical leaching, and electrical safety aspects of wearable technology. Certification processes typically involve dermatological testing, biocompatibility assessments according to ISO standards, and evaluation of electrical isolation properties. Safety standards also cover electromagnetic radiation limits and heat generation parameters for continuous skin contact applications.Expand Specific Solutions05 Data accuracy and calibration requirements for health monitoring textiles

Health monitoring textiles with integrated sensors must meet specific data accuracy and calibration requirements to provide reliable physiological measurements. These standards define acceptable error margins, calibration procedures, and validation methods against reference instruments. Qualification protocols typically include testing across different user demographics, activity levels, and environmental conditions to ensure consistent performance. Standardized accuracy requirements help ensure that smart textile sensors provide clinically relevant data for health monitoring applications.Expand Specific Solutions

Key Industry Players and Manufacturers

The smart textile sensors market for occupational safety devices is in an early growth phase, characterized by increasing adoption but still evolving qualification standards. The global market is projected to expand significantly as industries prioritize worker safety through wearable technology integration. Technologically, the field shows varied maturity levels with established industrial players like Robert Bosch GmbH, SICK AG, and Honeywell International leading innovation alongside specialized textile technology companies such as Myant Corp. and Fibra Inc. Academic-industry collaborations with institutions like the University of Nottingham and National University of Singapore are accelerating development. The sector faces challenges in standardization across different regulatory environments, with companies focusing on durability, reliability, and seamless integration of sensors into workplace safety equipment.

Myant, Corp.

Technical Solution: Myant has developed the Skiin platform, an advanced smart textile sensing system with comprehensive qualification standards for occupational safety applications. Their technology integrates multiple sensing modalities directly into everyday workwear through knitted sensors and conductive yarns. Myant's qualification framework addresses both technical performance and human factors, with standards for sensor accuracy across dynamic movement conditions (maintaining ±3% accuracy during full range of motion). Their textile sensors undergo qualification testing for up to 100 industrial wash cycles while maintaining sensor integrity and are required to meet IP67 standards for dust and water resistance in industrial environments. Myant's platform includes continuous monitoring capabilities for core body temperature (±0.2°C accuracy), heart rate, respiration, and posture, with qualification standards requiring 99.5% data capture rates during normal work activities. Their standards also include specific protocols for textile comfort assessment, requiring that sensor integration does not reduce breathability by more than 5% compared to standard workwear.

Strengths: Superior comfort and wearability; excellent integration of sensors into everyday workwear; comprehensive physiological monitoring capabilities. Weaknesses: Less established presence in heavy industrial applications; higher unit costs for specialized garments; more complex data interpretation requirements.

SICK AG

Technical Solution: SICK AG has pioneered a smart textile sensor qualification framework specifically designed for hazardous industrial environments. Their approach centers on textile-integrated gas and particulate matter sensors that provide early warning of exposure to harmful substances. The qualification standards they've developed include specialized testing for sensor response in extreme temperature conditions (-40°C to +85°C), with performance requirements maintaining 95% accuracy across the full temperature range. SICK's textile sensors undergo rigorous chemical resistance testing against 200+ industrial chemicals and solvents, with qualification requiring maintained functionality after repeated exposure. Their standards mandate sensor response times under 3 seconds for critical safety applications and include specialized electromagnetic interference testing for industrial settings with high EMI levels. SICK has also developed industry-specific calibration protocols for different sectors (mining, chemical manufacturing, oil & gas) to ensure contextually appropriate sensor performance.

Strengths: Exceptional performance in harsh industrial environments; specialized expertise in gas and particulate detection; robust qualification standards for chemical exposure. Weaknesses: More limited focus on physiological monitoring compared to competitors; higher initial implementation costs; requires more frequent recalibration in certain applications.

Critical Technical Specifications Analysis

textile safety device

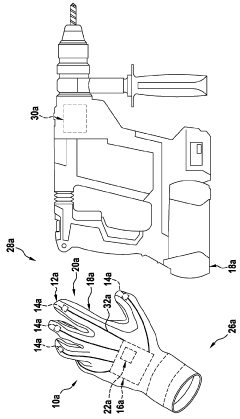

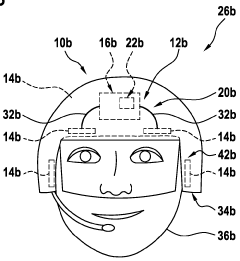

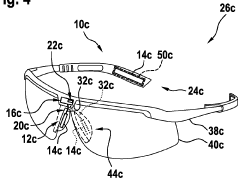

PatentInactiveDE102017208943A1

Innovation

- A textile safety device with sensor units made of flexible conductive material, integrated into safety clothing, that detects operator-specific parameters like skin contact and environmental variables, transmitting these via a communication unit to external units for processing, and includes authorization and connection units for secure and efficient operation.

Regulatory Compliance Framework

The regulatory landscape for smart textile sensors in occupational safety devices operates within a complex framework of international, regional, and national standards. ISO 13506 and IEC 60601-1 serve as foundational international standards, establishing baseline requirements for protective clothing with embedded sensors and medical electrical equipment safety, respectively. These standards provide crucial guidelines for manufacturers developing smart textiles that monitor vital signs or environmental hazards in workplace settings.

At the regional level, the European Union has implemented the Personal Protective Equipment (PPE) Regulation 2016/425, which specifically addresses smart textiles used in occupational safety contexts. This regulation mandates CE marking and conformity assessment procedures based on risk categorization. Similarly, in North America, ANSI/ISEA 201 standards govern performance requirements for electronic components integrated into protective workwear.

Compliance verification processes typically follow a three-tier approach. First, laboratory testing validates sensor accuracy, durability, and electromagnetic compatibility. Second, field trials in actual workplace environments assess real-world performance under various conditions. Finally, documentation review ensures traceability and quality management system adherence throughout the product lifecycle.

Certification pathways vary by jurisdiction but generally require involvement of Notified Bodies or recognized testing laboratories. In the EU, manufacturers must engage with designated Notified Bodies for conformity assessment, while the US system relies on NRTL (Nationally Recognized Testing Laboratory) certification for workplace safety equipment.

Recent regulatory developments have focused on addressing emerging challenges in smart textile sensor implementation. The IEC Technical Committee 124 is developing specialized standards for wearable electronic devices, including those integrated into occupational safety equipment. Concurrently, ASTM International's Committee F23 is working on test methods specifically designed for smart protective clothing.

Harmonization efforts between different regulatory frameworks remain ongoing but incomplete. The International Regulatory Cooperation for Medical Device Regulations has established working groups focused on wearable technologies, aiming to reduce redundant testing requirements across jurisdictions. However, significant gaps persist in standards specifically addressing the unique characteristics of textile-integrated sensors in safety-critical applications.

At the regional level, the European Union has implemented the Personal Protective Equipment (PPE) Regulation 2016/425, which specifically addresses smart textiles used in occupational safety contexts. This regulation mandates CE marking and conformity assessment procedures based on risk categorization. Similarly, in North America, ANSI/ISEA 201 standards govern performance requirements for electronic components integrated into protective workwear.

Compliance verification processes typically follow a three-tier approach. First, laboratory testing validates sensor accuracy, durability, and electromagnetic compatibility. Second, field trials in actual workplace environments assess real-world performance under various conditions. Finally, documentation review ensures traceability and quality management system adherence throughout the product lifecycle.

Certification pathways vary by jurisdiction but generally require involvement of Notified Bodies or recognized testing laboratories. In the EU, manufacturers must engage with designated Notified Bodies for conformity assessment, while the US system relies on NRTL (Nationally Recognized Testing Laboratory) certification for workplace safety equipment.

Recent regulatory developments have focused on addressing emerging challenges in smart textile sensor implementation. The IEC Technical Committee 124 is developing specialized standards for wearable electronic devices, including those integrated into occupational safety equipment. Concurrently, ASTM International's Committee F23 is working on test methods specifically designed for smart protective clothing.

Harmonization efforts between different regulatory frameworks remain ongoing but incomplete. The International Regulatory Cooperation for Medical Device Regulations has established working groups focused on wearable technologies, aiming to reduce redundant testing requirements across jurisdictions. However, significant gaps persist in standards specifically addressing the unique characteristics of textile-integrated sensors in safety-critical applications.

Risk Assessment Protocols

Risk assessment protocols for smart textile sensors in occupational safety devices require systematic evaluation frameworks to ensure these technologies meet safety and performance standards. The assessment begins with hazard identification, where potential risks associated with sensor integration, electrical components, and material interactions are cataloged. This process involves examining both the inherent properties of the smart textiles and their behavior in various occupational environments, including extreme temperatures, moisture exposure, and chemical contact scenarios.

Following hazard identification, exposure assessment becomes critical to understand the frequency and duration of potential risk factors. This includes analyzing how workers interact with smart textile sensors during regular operations, maintenance procedures, and emergency situations. Exposure patterns vary significantly across industries, necessitating customized assessment approaches for construction, manufacturing, healthcare, and other sectors where these technologies are deployed.

Risk characterization methodologies for smart textile sensors must incorporate both qualitative and quantitative measures. Quantitative assessments typically involve electrical safety parameters, mechanical durability metrics, and data reliability indicators. These are complemented by qualitative evaluations of user comfort, ergonomic impact, and potential distraction factors that could introduce secondary safety risks in workplace environments.

Testing protocols for risk assessment should simulate real-world conditions through accelerated aging tests, wash cycle durability, electromagnetic interference resistance, and performance under mechanical stress. International standards organizations have begun developing specific testing methodologies for smart textiles, though many current assessments still adapt protocols from related fields such as wearable electronics and personal protective equipment testing.

Documentation requirements constitute another essential component of risk assessment protocols. Manufacturers must maintain comprehensive records of material safety data, sensor calibration procedures, failure mode analyses, and mitigation strategies. This documentation serves both compliance purposes and provides critical information for ongoing risk management throughout the product lifecycle.

Risk communication frameworks ensure that assessment findings are effectively translated into actionable information for end-users. This includes clear labeling of limitations, proper training materials for workers and safety managers, and established channels for reporting incidents or unexpected behaviors of smart textile sensors in occupational settings.

Following hazard identification, exposure assessment becomes critical to understand the frequency and duration of potential risk factors. This includes analyzing how workers interact with smart textile sensors during regular operations, maintenance procedures, and emergency situations. Exposure patterns vary significantly across industries, necessitating customized assessment approaches for construction, manufacturing, healthcare, and other sectors where these technologies are deployed.

Risk characterization methodologies for smart textile sensors must incorporate both qualitative and quantitative measures. Quantitative assessments typically involve electrical safety parameters, mechanical durability metrics, and data reliability indicators. These are complemented by qualitative evaluations of user comfort, ergonomic impact, and potential distraction factors that could introduce secondary safety risks in workplace environments.

Testing protocols for risk assessment should simulate real-world conditions through accelerated aging tests, wash cycle durability, electromagnetic interference resistance, and performance under mechanical stress. International standards organizations have begun developing specific testing methodologies for smart textiles, though many current assessments still adapt protocols from related fields such as wearable electronics and personal protective equipment testing.

Documentation requirements constitute another essential component of risk assessment protocols. Manufacturers must maintain comprehensive records of material safety data, sensor calibration procedures, failure mode analyses, and mitigation strategies. This documentation serves both compliance purposes and provides critical information for ongoing risk management throughout the product lifecycle.

Risk communication frameworks ensure that assessment findings are effectively translated into actionable information for end-users. This includes clear labeling of limitations, proper training materials for workers and safety managers, and established channels for reporting incidents or unexpected behaviors of smart textile sensors in occupational settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!