Research on smart textile sensors wireless data transmission reliability

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Textile Sensors Background and Objectives

Smart textile sensors represent a revolutionary convergence of traditional textiles and advanced electronic technologies, enabling fabrics to sense, react, and communicate with their environment. The evolution of these technologies began in the early 2000s with rudimentary conductive fabrics and has rapidly accelerated over the past decade with the miniaturization of electronics and advancements in material science. Today's smart textiles incorporate sophisticated sensing capabilities including pressure detection, temperature monitoring, moisture sensing, and biometric data collection, all integrated seamlessly into wearable fabrics.

The global trajectory of smart textile development has been characterized by increasing sophistication in sensor integration and functionality, moving from simple conductive pathways to complex, multi-functional sensing arrays. This progression has been driven by innovations in conductive yarns, flexible electronics, and novel manufacturing techniques that preserve the comfort and wearability of traditional textiles while adding electronic capabilities.

Wireless data transmission represents a critical component in the smart textile ecosystem, enabling the collection and utilization of sensor data without cumbersome wired connections. However, reliability challenges persist due to the unique constraints of textile-embedded systems, including power limitations, signal interference from body movements, and the harsh conditions textiles may encounter during normal use and maintenance.

The primary technical objectives in this field focus on enhancing the reliability of wireless data transmission from textile-embedded sensors while maintaining the essential characteristics of traditional textiles. This includes developing robust communication protocols specifically optimized for textile applications, improving power efficiency to extend operational lifetimes, and creating resilient sensor designs that can withstand washing, folding, and stretching without performance degradation.

Additionally, there is a growing emphasis on standardization within the industry to ensure interoperability between different smart textile systems and conventional electronic devices. This standardization effort aims to establish common protocols for data formatting, transmission frequencies, and security measures, facilitating broader adoption across various application domains including healthcare monitoring, athletic performance tracking, and occupational safety.

The ultimate goal of research in this area is to create smart textile systems with wireless communication capabilities that are as reliable and user-friendly as conventional electronic devices, while maintaining the comfort, flexibility, and aesthetic qualities expected from textiles. This represents a significant technical challenge requiring interdisciplinary collaboration between textile engineers, electronic system designers, and wireless communication specialists to develop truly integrated solutions.

The global trajectory of smart textile development has been characterized by increasing sophistication in sensor integration and functionality, moving from simple conductive pathways to complex, multi-functional sensing arrays. This progression has been driven by innovations in conductive yarns, flexible electronics, and novel manufacturing techniques that preserve the comfort and wearability of traditional textiles while adding electronic capabilities.

Wireless data transmission represents a critical component in the smart textile ecosystem, enabling the collection and utilization of sensor data without cumbersome wired connections. However, reliability challenges persist due to the unique constraints of textile-embedded systems, including power limitations, signal interference from body movements, and the harsh conditions textiles may encounter during normal use and maintenance.

The primary technical objectives in this field focus on enhancing the reliability of wireless data transmission from textile-embedded sensors while maintaining the essential characteristics of traditional textiles. This includes developing robust communication protocols specifically optimized for textile applications, improving power efficiency to extend operational lifetimes, and creating resilient sensor designs that can withstand washing, folding, and stretching without performance degradation.

Additionally, there is a growing emphasis on standardization within the industry to ensure interoperability between different smart textile systems and conventional electronic devices. This standardization effort aims to establish common protocols for data formatting, transmission frequencies, and security measures, facilitating broader adoption across various application domains including healthcare monitoring, athletic performance tracking, and occupational safety.

The ultimate goal of research in this area is to create smart textile systems with wireless communication capabilities that are as reliable and user-friendly as conventional electronic devices, while maintaining the comfort, flexibility, and aesthetic qualities expected from textiles. This represents a significant technical challenge requiring interdisciplinary collaboration between textile engineers, electronic system designers, and wireless communication specialists to develop truly integrated solutions.

Market Analysis for Wireless Smart Textiles

The global market for wireless smart textiles is experiencing robust growth, driven by increasing demand for wearable technology across multiple sectors. Current market valuations place the smart textile industry at approximately 3.6 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 26.2% through 2030. The wireless data transmission segment represents a significant portion of this market, estimated at 1.2 billion USD, highlighting the critical importance of reliable connectivity solutions in smart textile applications.

Healthcare and medical monitoring applications currently dominate the market landscape, accounting for roughly 38% of smart textile sensor implementations. This sector's prominence stems from the growing need for remote patient monitoring systems and the integration of continuous health tracking into everyday garments. The sports and fitness segment follows closely at 32% market share, where performance monitoring and biometric data collection drive adoption among both professional athletes and fitness enthusiasts.

Military and defense applications represent a smaller but rapidly growing segment at 15% market share, with stringent requirements for data transmission reliability in mission-critical scenarios. The remaining market share is distributed across industrial safety (8%), automotive (4%), and emerging consumer applications (3%).

Regional analysis reveals North America leading the market with approximately 42% share, followed by Europe (31%) and Asia-Pacific (21%). The Asia-Pacific region, however, demonstrates the highest growth rate at 29.8% annually, primarily driven by manufacturing innovations in countries like China, South Korea, and Japan.

Consumer demand patterns indicate strong preference for solutions offering extended battery life, with 76% of surveyed users citing power efficiency as a primary concern. Data security ranks second (68%), followed by transmission reliability (65%) and comfort (61%). These preferences are reshaping product development priorities across the industry.

Key market challenges include price sensitivity among consumers, with current premium pricing limiting mass-market adoption. The average retail price point for consumer-grade smart textile products with wireless capabilities remains approximately 2.5 times higher than conventional alternatives, creating significant barriers to widespread adoption.

Regulatory considerations also impact market dynamics, with medical-grade smart textiles facing lengthy approval processes in major markets. The FDA in the United States and the European Medicines Agency impose stringent requirements for data reliability and transmission security, particularly for devices collecting and transmitting health-related information.

Healthcare and medical monitoring applications currently dominate the market landscape, accounting for roughly 38% of smart textile sensor implementations. This sector's prominence stems from the growing need for remote patient monitoring systems and the integration of continuous health tracking into everyday garments. The sports and fitness segment follows closely at 32% market share, where performance monitoring and biometric data collection drive adoption among both professional athletes and fitness enthusiasts.

Military and defense applications represent a smaller but rapidly growing segment at 15% market share, with stringent requirements for data transmission reliability in mission-critical scenarios. The remaining market share is distributed across industrial safety (8%), automotive (4%), and emerging consumer applications (3%).

Regional analysis reveals North America leading the market with approximately 42% share, followed by Europe (31%) and Asia-Pacific (21%). The Asia-Pacific region, however, demonstrates the highest growth rate at 29.8% annually, primarily driven by manufacturing innovations in countries like China, South Korea, and Japan.

Consumer demand patterns indicate strong preference for solutions offering extended battery life, with 76% of surveyed users citing power efficiency as a primary concern. Data security ranks second (68%), followed by transmission reliability (65%) and comfort (61%). These preferences are reshaping product development priorities across the industry.

Key market challenges include price sensitivity among consumers, with current premium pricing limiting mass-market adoption. The average retail price point for consumer-grade smart textile products with wireless capabilities remains approximately 2.5 times higher than conventional alternatives, creating significant barriers to widespread adoption.

Regulatory considerations also impact market dynamics, with medical-grade smart textiles facing lengthy approval processes in major markets. The FDA in the United States and the European Medicines Agency impose stringent requirements for data reliability and transmission security, particularly for devices collecting and transmitting health-related information.

Current Challenges in Textile Sensor Data Transmission

Despite significant advancements in smart textile sensor technologies, wireless data transmission from these sensors continues to face substantial reliability challenges. The integration of electronic components with flexible textile substrates creates unique signal integrity issues not encountered in conventional rigid electronics. Signal attenuation occurs as electromagnetic waves travel through textile materials with varying densities and moisture content, resulting in unpredictable transmission patterns and potential data loss.

Power management represents another critical challenge, as textile-integrated sensors typically rely on small, lightweight batteries with limited capacity. The continuous wireless transmission of data rapidly depletes these power sources, creating a fundamental tension between transmission reliability and operational longevity. This constraint often forces designers to implement aggressive power-saving protocols that may compromise data sampling rates and transmission frequency.

Environmental factors significantly impact transmission reliability in smart textile applications. Body movement, varying distances between sensors and receivers, and physical obstructions can cause intermittent connectivity issues. Additionally, textile sensors deployed in healthcare or industrial settings must maintain reliable transmission despite exposure to moisture, temperature variations, and electromagnetic interference from surrounding equipment.

The miniaturization requirements of textile-integrated components further complicate reliable data transmission. Antenna design becomes particularly challenging when constrained by the need for flexibility, comfort, and inconspicuous integration. Conventional antenna geometries often perform suboptimally when deformed or compressed during normal textile use, leading to unpredictable transmission characteristics and reduced range.

Protocol selection presents another significant challenge. While Bluetooth Low Energy (BLE) offers energy efficiency advantages, its limited bandwidth may be insufficient for applications requiring high-frequency sampling or multi-sensor data streams. Alternatives like Wi-Fi provide greater bandwidth but at the cost of substantially higher power consumption. ZigBee and proprietary protocols offer various trade-offs, but none fully addresses the unique constraints of textile-embedded systems.

Data security and privacy concerns add another layer of complexity. The transmission of potentially sensitive biometric or location data requires robust encryption, which increases computational demands and power consumption. This security-performance trade-off becomes particularly acute in medical applications where both data integrity and patient privacy are paramount.

Standardization remains underdeveloped in this emerging field, with various manufacturers implementing proprietary transmission solutions that limit interoperability. This fragmentation impedes the development of comprehensive testing methodologies to evaluate and improve transmission reliability across different textile sensor platforms and use cases.

Power management represents another critical challenge, as textile-integrated sensors typically rely on small, lightweight batteries with limited capacity. The continuous wireless transmission of data rapidly depletes these power sources, creating a fundamental tension between transmission reliability and operational longevity. This constraint often forces designers to implement aggressive power-saving protocols that may compromise data sampling rates and transmission frequency.

Environmental factors significantly impact transmission reliability in smart textile applications. Body movement, varying distances between sensors and receivers, and physical obstructions can cause intermittent connectivity issues. Additionally, textile sensors deployed in healthcare or industrial settings must maintain reliable transmission despite exposure to moisture, temperature variations, and electromagnetic interference from surrounding equipment.

The miniaturization requirements of textile-integrated components further complicate reliable data transmission. Antenna design becomes particularly challenging when constrained by the need for flexibility, comfort, and inconspicuous integration. Conventional antenna geometries often perform suboptimally when deformed or compressed during normal textile use, leading to unpredictable transmission characteristics and reduced range.

Protocol selection presents another significant challenge. While Bluetooth Low Energy (BLE) offers energy efficiency advantages, its limited bandwidth may be insufficient for applications requiring high-frequency sampling or multi-sensor data streams. Alternatives like Wi-Fi provide greater bandwidth but at the cost of substantially higher power consumption. ZigBee and proprietary protocols offer various trade-offs, but none fully addresses the unique constraints of textile-embedded systems.

Data security and privacy concerns add another layer of complexity. The transmission of potentially sensitive biometric or location data requires robust encryption, which increases computational demands and power consumption. This security-performance trade-off becomes particularly acute in medical applications where both data integrity and patient privacy are paramount.

Standardization remains underdeveloped in this emerging field, with various manufacturers implementing proprietary transmission solutions that limit interoperability. This fragmentation impedes the development of comprehensive testing methodologies to evaluate and improve transmission reliability across different textile sensor platforms and use cases.

Existing Wireless Protocols for Textile Integration

01 Wireless communication protocols for textile sensors

Various wireless communication protocols can be implemented in smart textile sensors to ensure reliable data transmission. These protocols include Bluetooth, ZigBee, Wi-Fi, and proprietary low-power protocols specifically designed for wearable applications. The selection of an appropriate protocol depends on factors such as power consumption, range requirements, and data throughput needs. Implementing robust protocols helps minimize data loss and ensures consistent connectivity between the textile sensors and receiving devices.- Wireless communication protocols for textile sensors: Various wireless communication protocols can be implemented in smart textile sensors to ensure reliable data transmission. These protocols include Bluetooth, ZigBee, Wi-Fi, and proprietary low-power protocols specifically designed for wearable applications. The selection of an appropriate protocol depends on factors such as power consumption, range requirements, and data throughput needs. Implementing robust protocols helps minimize data loss and ensures consistent connectivity between the textile sensors and receiving devices.

- Error correction and data redundancy techniques: Smart textile sensors can incorporate error correction and data redundancy techniques to improve wireless transmission reliability. These techniques include forward error correction, packet retransmission protocols, and data duplication strategies. By implementing these methods, the system can detect and recover from transmission errors caused by interference, signal attenuation, or other environmental factors. This ensures that critical data from textile sensors reaches the receiving system accurately, even in challenging wireless environments.

- Power management for reliable wireless transmission: Effective power management strategies are essential for maintaining reliable wireless data transmission in smart textile sensors. These include adaptive power control, duty cycling, and energy harvesting techniques. By optimizing power consumption, the system can maintain consistent signal strength and prevent transmission failures due to power depletion. Advanced power management also extends the operational lifetime of the textile sensors, ensuring continuous and reliable data collection and transmission over extended periods.

- Sensor integration and signal processing techniques: The reliability of wireless data transmission in smart textiles depends significantly on sensor integration and signal processing techniques. This includes methods for noise reduction, signal amplification, and data compression before transmission. Advanced integration techniques ensure that sensors are properly embedded within the textile structure without compromising comfort or functionality. Effective signal processing reduces the amount of data that needs to be transmitted wirelessly, thereby improving transmission reliability and reducing power consumption.

- Environmental adaptation and interference mitigation: Smart textile sensors can implement environmental adaptation and interference mitigation techniques to maintain reliable wireless data transmission across various conditions. These include adaptive frequency selection, channel hopping, and interference detection algorithms. The systems can dynamically adjust transmission parameters based on the surrounding electromagnetic environment, movement of the wearer, and physical obstructions. This adaptive capability ensures consistent data transmission reliability even when the textile sensors are used in challenging environments with high levels of electromagnetic interference.

02 Error correction and data redundancy techniques

To improve wireless data transmission reliability in smart textile sensors, various error correction and data redundancy techniques can be employed. These include forward error correction, cyclic redundancy checks, and packet retransmission protocols. By implementing these techniques, the system can detect and recover from transmission errors caused by interference, signal attenuation, or other environmental factors. This ensures that critical data from textile sensors is accurately received even in challenging wireless environments.Expand Specific Solutions03 Power management for reliable transmission

Effective power management strategies are crucial for maintaining reliable wireless data transmission in smart textile sensors. These strategies include adaptive power control, duty cycling, and energy harvesting techniques. By optimizing power consumption, the system can maintain consistent signal strength and prevent transmission failures due to power depletion. Advanced power management also extends the operational life of the textile sensors, ensuring continuous and reliable data collection and transmission.Expand Specific Solutions04 Sensor integration and signal processing

The reliability of wireless data transmission in smart textiles depends significantly on proper sensor integration and signal processing techniques. This includes optimal placement of sensors within the textile, signal conditioning, noise filtering, and data compression algorithms. By processing and refining the sensor data before transmission, the system can reduce bandwidth requirements and improve transmission efficiency. Advanced signal processing also helps in distinguishing between actual sensor readings and artifacts, ensuring that only relevant data is transmitted.Expand Specific Solutions05 Environmental adaptation and interference mitigation

Smart textile sensors must adapt to various environmental conditions and mitigate interference to maintain reliable wireless data transmission. Techniques include frequency hopping, channel selection algorithms, and adaptive modulation schemes. These approaches help the system navigate around sources of interference and adjust to changing environmental conditions such as humidity, temperature, and proximity to other electronic devices. By dynamically adapting to the environment, smart textile sensors can maintain consistent and reliable wireless communication even in challenging conditions.Expand Specific Solutions

Key Patents in Reliable Textile Data Transmission

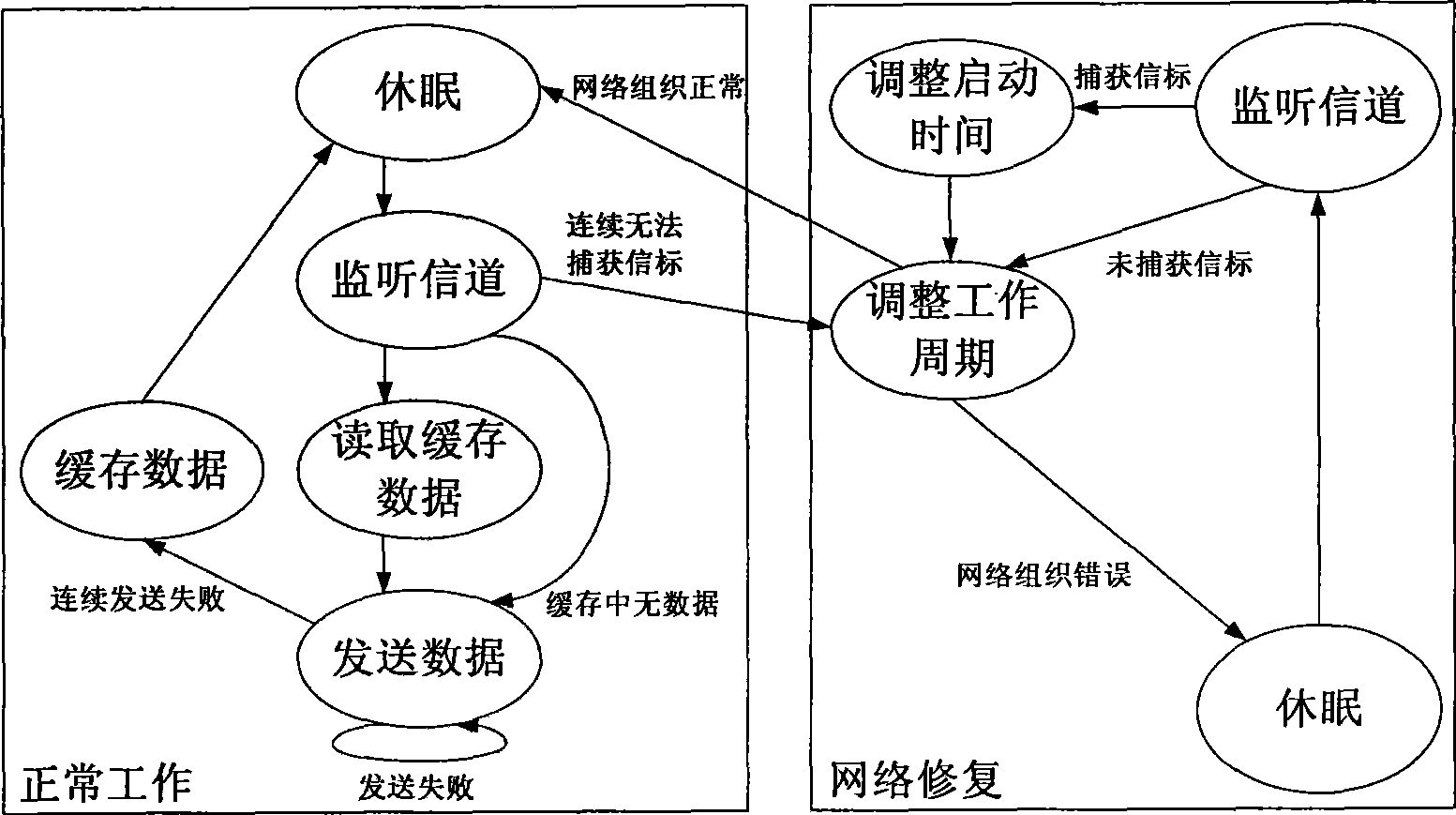

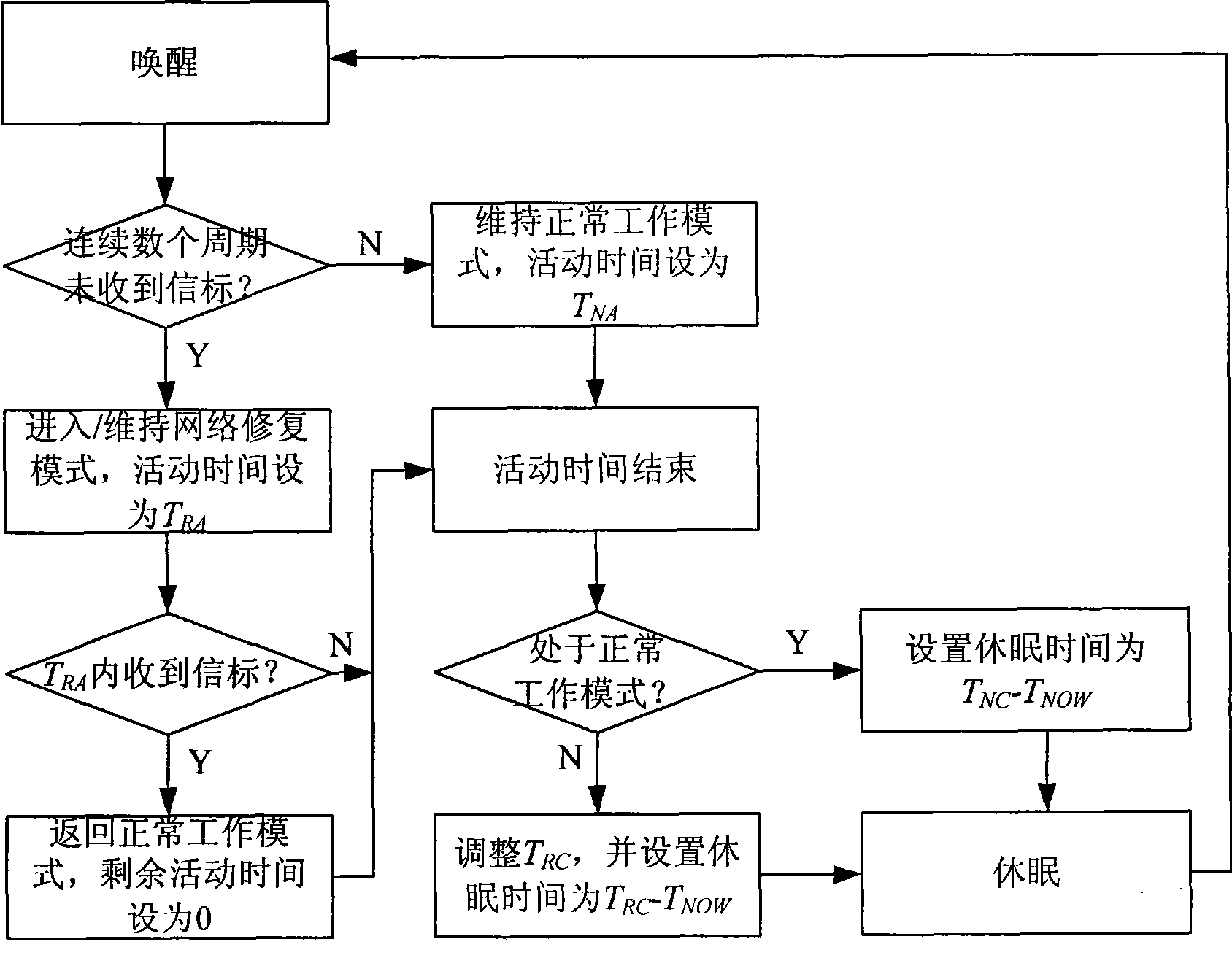

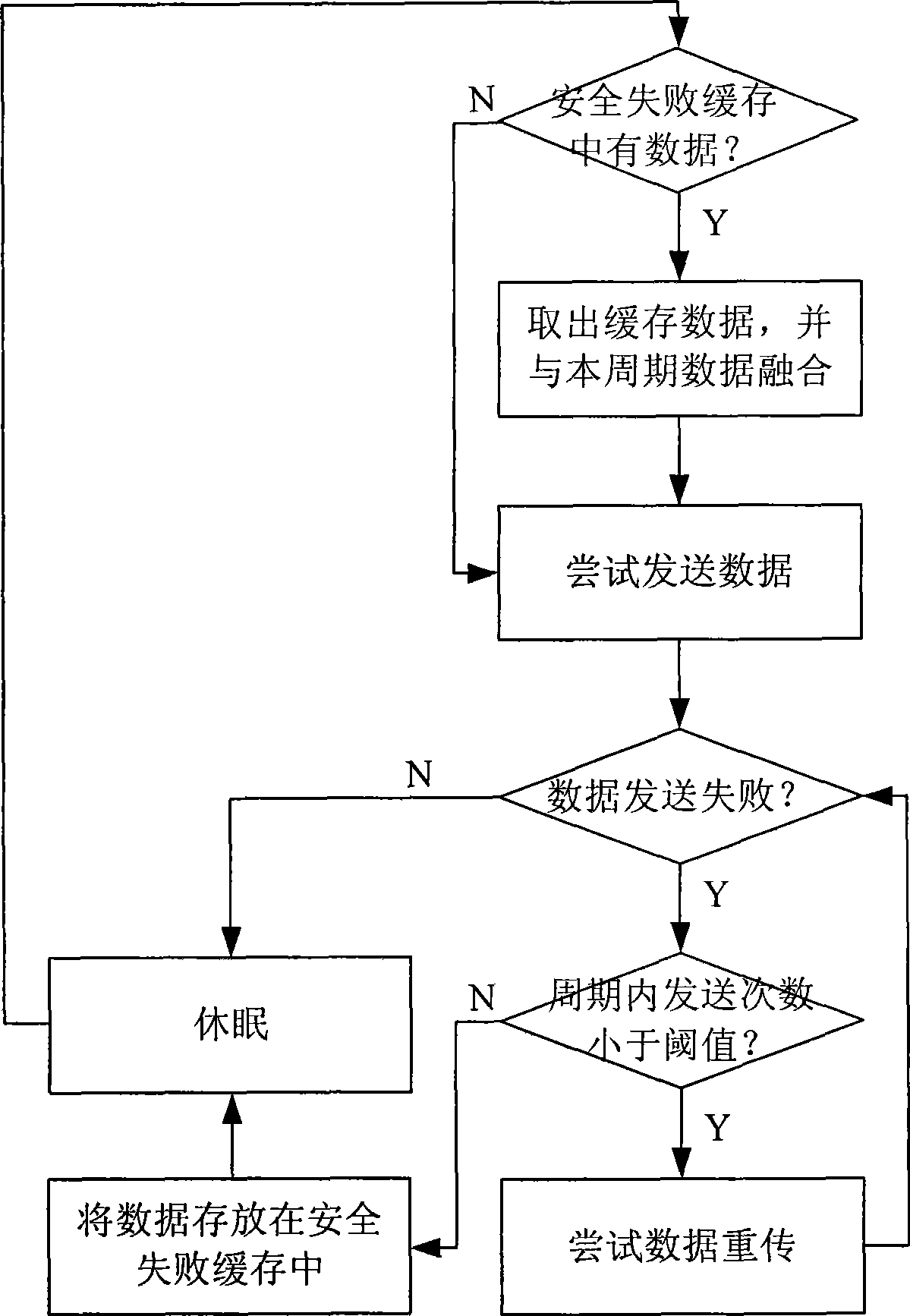

Data collection transmission reliable guarantee method in wireless sensor network

PatentInactiveCN101459978A

Innovation

- Adopt periodic beacon-based broadcast technology and dynamic duty cycle adjustment method for network organization, combined with hop-by-hop data transmission and 2-stage retransmission mechanism to ensure low power consumption and fast network repair capabilities of nodes in different working modes, and through small capacity The secondary cache mechanism of EEPROM and large-capacity FLASH reduces data writing frequency and ensures data integrity.

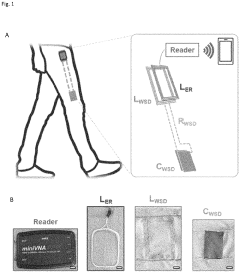

Novel sensors suitable for monitoring movement and other biophysical parameters

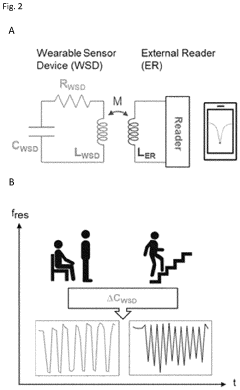

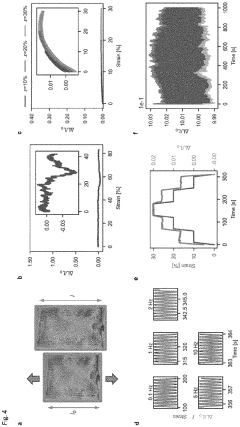

PatentInactiveEP4368941A1

Innovation

- Development of a fully textile-based sensor system using a LC circuit with a capacitive sensing mechanism, incorporating a textile capacitor and inductor made from conductive threads and fabrics, eliminating the need for silicon or polychlorinated biphenyl components, and utilizing helical auxetic yarns for enhanced sensitivity and integration into clothing.

Power Management Solutions for Smart Textiles

Power management represents a critical challenge in smart textile systems, particularly for ensuring reliable wireless data transmission from embedded sensors. The integration of power sources into textiles must balance multiple competing requirements: sufficient energy capacity, minimal physical footprint, flexibility, durability during wear and washing cycles, and user comfort. Current power solutions can be categorized into three primary approaches, each with distinct advantages for wireless transmission reliability.

Battery-based solutions remain the most common power source, with thin-film lithium polymer batteries offering reasonable energy density while maintaining some flexibility. Recent advancements have produced batteries less than 0.5mm thick that can withstand moderate bending stress, though complete flexibility remains elusive. These solutions provide stable voltage outputs critical for consistent wireless transmission performance but require periodic recharging or replacement, introducing maintenance challenges.

Energy harvesting technologies have emerged as promising alternatives, converting ambient energy into electrical power. Piezoelectric fibers woven into textiles can generate electricity from body movement, while photovoltaic textiles capture light energy. Thermoelectric generators exploit temperature differentials between skin and environment. These solutions offer theoretical perpetual operation without recharging, enhancing long-term transmission reliability, but typically generate inconsistent power levels that must be carefully managed to maintain stable wireless communications.

Hybrid power architectures combine multiple approaches to optimize reliability. A common configuration pairs energy harvesting with small-capacity batteries or supercapacitors, where harvested energy continuously recharges the storage element. This arrangement provides both the energy consistency needed for reliable transmission and extended operational periods. Advanced power management integrated circuits (PMICs) specifically designed for wearable applications play a crucial role in these systems, dynamically adjusting power consumption based on transmission requirements and available energy.

Wireless power transfer represents the newest frontier, with inductive and resonant coupling systems enabling power transmission from external sources to textile-embedded receivers. This approach eliminates the need for onboard energy storage but requires proximity to charging infrastructure, making it suitable for specific use contexts rather than continuous mobile applications.

The selection of appropriate power solutions must be tailored to the specific wireless protocol employed (Bluetooth Low Energy, Zigbee, LoRa, etc.) and the transmission patterns required by the application. Intermittent transmission scenarios can leverage aggressive power-saving modes, while continuous monitoring applications demand more robust and consistent power availability.

Battery-based solutions remain the most common power source, with thin-film lithium polymer batteries offering reasonable energy density while maintaining some flexibility. Recent advancements have produced batteries less than 0.5mm thick that can withstand moderate bending stress, though complete flexibility remains elusive. These solutions provide stable voltage outputs critical for consistent wireless transmission performance but require periodic recharging or replacement, introducing maintenance challenges.

Energy harvesting technologies have emerged as promising alternatives, converting ambient energy into electrical power. Piezoelectric fibers woven into textiles can generate electricity from body movement, while photovoltaic textiles capture light energy. Thermoelectric generators exploit temperature differentials between skin and environment. These solutions offer theoretical perpetual operation without recharging, enhancing long-term transmission reliability, but typically generate inconsistent power levels that must be carefully managed to maintain stable wireless communications.

Hybrid power architectures combine multiple approaches to optimize reliability. A common configuration pairs energy harvesting with small-capacity batteries or supercapacitors, where harvested energy continuously recharges the storage element. This arrangement provides both the energy consistency needed for reliable transmission and extended operational periods. Advanced power management integrated circuits (PMICs) specifically designed for wearable applications play a crucial role in these systems, dynamically adjusting power consumption based on transmission requirements and available energy.

Wireless power transfer represents the newest frontier, with inductive and resonant coupling systems enabling power transmission from external sources to textile-embedded receivers. This approach eliminates the need for onboard energy storage but requires proximity to charging infrastructure, making it suitable for specific use contexts rather than continuous mobile applications.

The selection of appropriate power solutions must be tailored to the specific wireless protocol employed (Bluetooth Low Energy, Zigbee, LoRa, etc.) and the transmission patterns required by the application. Intermittent transmission scenarios can leverage aggressive power-saving modes, while continuous monitoring applications demand more robust and consistent power availability.

Standardization Efforts in Smart Textile Communications

The standardization landscape for smart textile communications is rapidly evolving to address the critical challenges in wireless data transmission reliability. Several international standards organizations have established working groups specifically focused on smart textiles, including the IEEE P1906.1 (Recommended Practice for Nanoscale and Molecular Communication Framework) and ISO/TC 38 (Textiles) which now includes smart textile considerations.

The International Electrotechnical Commission (IEC) has developed standards like IEC 63203-201-1 that specifically address wearable electronic devices and technologies, providing guidelines for reliable wireless communication in textile-integrated systems. These standards define testing methodologies for signal integrity under various conditions including movement, washing cycles, and environmental factors that typically affect textile-based sensors.

ASTM International has contributed through its Committee F42 on Additive Manufacturing Technologies, which now includes specifications for e-textile manufacturing processes that impact communication reliability. Their standards address conductive material integration and durability requirements essential for maintaining signal quality over the textile's lifetime.

The European Telecommunications Standards Institute (ETSI) has developed protocols specifically for low-power wireless communications suitable for smart textile applications, focusing on optimizing power consumption while maintaining transmission reliability. Their Smart Body Area Network standards are particularly relevant for medical and health monitoring textile applications.

Bluetooth Special Interest Group (SIG) has introduced Bluetooth Low Energy (BLE) profiles optimized for wearable technology, which many smart textile manufacturers have adopted as a de facto standard for short-range communications. These profiles include specific provisions for handling intermittent connections common in textile-based systems.

Industry consortia like the Industrial Internet Consortium (IIC) and the Open Connectivity Foundation (OCF) have also developed reference architectures and certification programs that include considerations for textile-integrated IoT devices. These frameworks help ensure interoperability between smart textiles and broader IoT ecosystems.

The standardization efforts also extend to data formats and security protocols, with organizations like the W3C contributing web standards that enable seamless integration of smart textile data into cloud services and applications. These standards address data integrity throughout the transmission chain, from textile sensor to end application.

Despite these advances, significant gaps remain in standardization, particularly regarding textile-specific interference patterns, power management during extended wear, and resilience testing methodologies that accurately reflect real-world usage conditions of smart textiles.

The International Electrotechnical Commission (IEC) has developed standards like IEC 63203-201-1 that specifically address wearable electronic devices and technologies, providing guidelines for reliable wireless communication in textile-integrated systems. These standards define testing methodologies for signal integrity under various conditions including movement, washing cycles, and environmental factors that typically affect textile-based sensors.

ASTM International has contributed through its Committee F42 on Additive Manufacturing Technologies, which now includes specifications for e-textile manufacturing processes that impact communication reliability. Their standards address conductive material integration and durability requirements essential for maintaining signal quality over the textile's lifetime.

The European Telecommunications Standards Institute (ETSI) has developed protocols specifically for low-power wireless communications suitable for smart textile applications, focusing on optimizing power consumption while maintaining transmission reliability. Their Smart Body Area Network standards are particularly relevant for medical and health monitoring textile applications.

Bluetooth Special Interest Group (SIG) has introduced Bluetooth Low Energy (BLE) profiles optimized for wearable technology, which many smart textile manufacturers have adopted as a de facto standard for short-range communications. These profiles include specific provisions for handling intermittent connections common in textile-based systems.

Industry consortia like the Industrial Internet Consortium (IIC) and the Open Connectivity Foundation (OCF) have also developed reference architectures and certification programs that include considerations for textile-integrated IoT devices. These frameworks help ensure interoperability between smart textiles and broader IoT ecosystems.

The standardization efforts also extend to data formats and security protocols, with organizations like the W3C contributing web standards that enable seamless integration of smart textile data into cloud services and applications. These standards address data integrity throughout the transmission chain, from textile sensor to end application.

Despite these advances, significant gaps remain in standardization, particularly regarding textile-specific interference patterns, power management during extended wear, and resilience testing methodologies that accurately reflect real-world usage conditions of smart textiles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!