Smart textile sensors sensitivity optimization via nanomaterial coatings

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Textile Nanomaterial Evolution & Objectives

Smart textile technology has evolved significantly over the past two decades, transitioning from simple conductive fabrics to sophisticated sensing platforms capable of monitoring physiological parameters, environmental conditions, and biomechanical movements. The integration of nanomaterials into textile substrates represents a pivotal advancement in this evolution, enabling unprecedented levels of sensitivity, flexibility, and functionality. Early developments in smart textiles primarily focused on incorporating metallic threads or conductive polymers, which offered limited sensing capabilities and often compromised the textile's inherent properties such as comfort and breathability.

The emergence of nanomaterial science in the early 2000s opened new frontiers for smart textile development. Carbon-based nanomaterials including carbon nanotubes (CNTs), graphene, and their derivatives introduced exceptional electrical conductivity and mechanical properties at the nanoscale. Metal nanoparticles, metal oxide nanostructures, and conductive polymer nanocomposites further expanded the toolkit for enhancing textile sensor performance. These nanomaterials, when properly engineered and applied as coatings, can transform conventional textiles into highly sensitive, multifunctional sensing platforms.

Current technological trends indicate a growing convergence between materials science, electronics miniaturization, and textile engineering. The development of stretchable electronics, washable interconnects, and energy harvesting capabilities has accelerated the practical implementation of smart textile sensors in real-world applications. Additionally, advancements in nanomaterial synthesis techniques have enabled better control over particle size, morphology, and surface chemistry, which directly influence coating uniformity and sensor performance.

The primary objective of nanomaterial coating optimization for smart textile sensors is to achieve maximum sensitivity while maintaining the textile's inherent properties. This involves developing coating methodologies that ensure uniform nanomaterial distribution, strong adhesion to textile fibers, and stable electrical properties under mechanical deformation and environmental stressors. Furthermore, the optimization process aims to enhance selectivity toward specific analytes, minimize cross-sensitivity, and extend sensor lifespan through improved resistance to washing cycles and wear.

Another critical objective is scalability—transitioning from laboratory-scale demonstrations to industrial-scale production processes that are economically viable and environmentally sustainable. This includes developing green synthesis routes for nanomaterials, water-based coating formulations, and energy-efficient deposition techniques that align with the textile industry's sustainability goals. Ultimately, the evolution of smart textile sensors through nanomaterial coatings seeks to enable seamless integration of sensing capabilities into everyday garments, creating ubiquitous, unobtrusive monitoring systems for healthcare, sports performance, occupational safety, and consumer wellness applications.

The emergence of nanomaterial science in the early 2000s opened new frontiers for smart textile development. Carbon-based nanomaterials including carbon nanotubes (CNTs), graphene, and their derivatives introduced exceptional electrical conductivity and mechanical properties at the nanoscale. Metal nanoparticles, metal oxide nanostructures, and conductive polymer nanocomposites further expanded the toolkit for enhancing textile sensor performance. These nanomaterials, when properly engineered and applied as coatings, can transform conventional textiles into highly sensitive, multifunctional sensing platforms.

Current technological trends indicate a growing convergence between materials science, electronics miniaturization, and textile engineering. The development of stretchable electronics, washable interconnects, and energy harvesting capabilities has accelerated the practical implementation of smart textile sensors in real-world applications. Additionally, advancements in nanomaterial synthesis techniques have enabled better control over particle size, morphology, and surface chemistry, which directly influence coating uniformity and sensor performance.

The primary objective of nanomaterial coating optimization for smart textile sensors is to achieve maximum sensitivity while maintaining the textile's inherent properties. This involves developing coating methodologies that ensure uniform nanomaterial distribution, strong adhesion to textile fibers, and stable electrical properties under mechanical deformation and environmental stressors. Furthermore, the optimization process aims to enhance selectivity toward specific analytes, minimize cross-sensitivity, and extend sensor lifespan through improved resistance to washing cycles and wear.

Another critical objective is scalability—transitioning from laboratory-scale demonstrations to industrial-scale production processes that are economically viable and environmentally sustainable. This includes developing green synthesis routes for nanomaterials, water-based coating formulations, and energy-efficient deposition techniques that align with the textile industry's sustainability goals. Ultimately, the evolution of smart textile sensors through nanomaterial coatings seeks to enable seamless integration of sensing capabilities into everyday garments, creating ubiquitous, unobtrusive monitoring systems for healthcare, sports performance, occupational safety, and consumer wellness applications.

Market Analysis for High-Sensitivity Smart Textiles

The smart textile sensors market is experiencing significant growth, driven by increasing demand for wearable technology across healthcare, sports, military, and consumer electronics sectors. Current market valuations place the global smart textile industry at approximately $3.8 billion in 2023, with projections indicating a compound annual growth rate (CAGR) of 26.2% through 2030. High-sensitivity smart textiles enhanced with nanomaterial coatings represent a particularly promising segment, expected to capture over 40% of the overall smart textile market by 2028.

Healthcare applications dominate the high-sensitivity smart textile market, accounting for roughly 35% of current demand. The aging population in developed economies and increasing prevalence of chronic diseases necessitate continuous health monitoring solutions that are comfortable and unobtrusive. Smart textiles with optimized sensitivity through nanomaterial coatings offer superior capabilities in detecting vital signs, body temperature, and biochemical markers.

The sports and fitness sector represents the fastest-growing application area, with an estimated CAGR of 31.7%. Professional athletes and fitness enthusiasts increasingly rely on performance-monitoring garments that can accurately track physiological parameters during activity. Market research indicates consumers are willing to pay premium prices for garments offering enhanced sensitivity and reliability.

Regional analysis reveals North America currently leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate due to expanding manufacturing capabilities, increasing disposable income, and growing adoption of wearable technology in countries like China, Japan, and South Korea.

Consumer preferences are shifting toward multifunctional smart textiles that combine high sensitivity with durability, washability, and aesthetic appeal. Market surveys indicate 78% of potential users consider sensitivity and accuracy as "very important" factors in purchasing decisions, while 65% express concerns about durability after repeated washing cycles.

Key market restraints include relatively high production costs, technical challenges in maintaining sensor performance after repeated use, and regulatory uncertainties regarding data privacy. The average price premium for nanomaterial-enhanced smart textiles remains 40-60% higher than conventional alternatives, potentially limiting mass-market adoption in price-sensitive segments.

Emerging opportunities include integration with Internet of Things (IoT) platforms, development of self-powered sensing textiles, and expansion into new application areas such as automotive interiors and smart home furnishings. Market forecasts suggest these emerging applications could generate additional revenue streams exceeding $1.2 billion by 2027.

Healthcare applications dominate the high-sensitivity smart textile market, accounting for roughly 35% of current demand. The aging population in developed economies and increasing prevalence of chronic diseases necessitate continuous health monitoring solutions that are comfortable and unobtrusive. Smart textiles with optimized sensitivity through nanomaterial coatings offer superior capabilities in detecting vital signs, body temperature, and biochemical markers.

The sports and fitness sector represents the fastest-growing application area, with an estimated CAGR of 31.7%. Professional athletes and fitness enthusiasts increasingly rely on performance-monitoring garments that can accurately track physiological parameters during activity. Market research indicates consumers are willing to pay premium prices for garments offering enhanced sensitivity and reliability.

Regional analysis reveals North America currently leads the market with approximately 38% share, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region is expected to witness the highest growth rate due to expanding manufacturing capabilities, increasing disposable income, and growing adoption of wearable technology in countries like China, Japan, and South Korea.

Consumer preferences are shifting toward multifunctional smart textiles that combine high sensitivity with durability, washability, and aesthetic appeal. Market surveys indicate 78% of potential users consider sensitivity and accuracy as "very important" factors in purchasing decisions, while 65% express concerns about durability after repeated washing cycles.

Key market restraints include relatively high production costs, technical challenges in maintaining sensor performance after repeated use, and regulatory uncertainties regarding data privacy. The average price premium for nanomaterial-enhanced smart textiles remains 40-60% higher than conventional alternatives, potentially limiting mass-market adoption in price-sensitive segments.

Emerging opportunities include integration with Internet of Things (IoT) platforms, development of self-powered sensing textiles, and expansion into new application areas such as automotive interiors and smart home furnishings. Market forecasts suggest these emerging applications could generate additional revenue streams exceeding $1.2 billion by 2027.

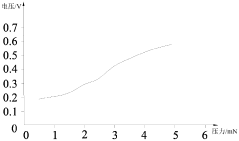

Current Limitations in Textile Sensor Sensitivity

Despite significant advancements in smart textile sensor technology, several critical limitations persist in achieving optimal sensitivity for practical applications. Current textile sensors exhibit inconsistent performance across varying environmental conditions, particularly in response to humidity and temperature fluctuations. This environmental susceptibility significantly compromises reliability in real-world scenarios where conditions cannot be tightly controlled, limiting their deployment in critical applications such as healthcare monitoring.

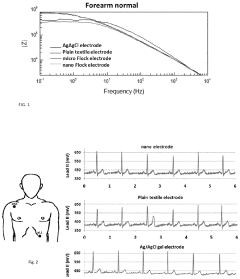

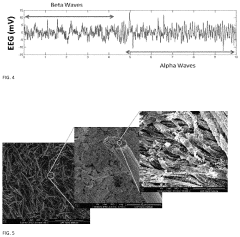

Signal-to-noise ratio remains a fundamental challenge, with textile-based sensors typically demonstrating lower sensitivity compared to their rigid counterparts. The inherent flexibility and porous nature of textile substrates create signal interference and baseline drift issues, particularly problematic for detecting subtle physiological signals like respiratory patterns or small changes in bioelectric potentials.

Durability constraints further impede sensitivity optimization, as repeated mechanical stress from washing, bending, and stretching degrades sensor performance over time. Current nanomaterial coatings often demonstrate diminished sensitivity after multiple wash cycles or extended wear periods, failing to maintain consistent electrical properties throughout the product lifecycle.

Integration challenges between the sensing nanomaterials and textile substrates create additional sensitivity barriers. Poor adhesion between nanomaterial coatings and textile fibers leads to delamination and cracking, disrupting the conductive pathways essential for signal transmission. The heterogeneous surface morphology of textiles complicates the uniform application of nanomaterial coatings, resulting in inconsistent sensor response across the fabric surface.

Manufacturing scalability presents another significant limitation, as laboratory-scale techniques for applying nanomaterial coatings often fail to translate to industrial production environments without compromising sensitivity. Current processes struggle to maintain precise control over coating thickness and uniformity at scale, leading to batch-to-batch variations in sensor performance.

Power requirements for signal amplification and processing represent an additional constraint, as highly sensitive detection often necessitates complex circuitry that conflicts with the need for lightweight, flexible, and energy-efficient wearable systems. This creates a fundamental trade-off between sensitivity and practical wearability.

Cross-sensitivity issues further complicate reliable measurements, with current sensors often responding to multiple stimuli simultaneously, making it difficult to isolate the specific parameter of interest. For instance, pressure sensors may inadvertently respond to temperature changes, creating false readings that compromise data integrity.

These limitations collectively highlight the need for innovative approaches to nanomaterial selection, coating methodologies, and interface engineering to overcome the current sensitivity barriers in smart textile sensor technology.

Signal-to-noise ratio remains a fundamental challenge, with textile-based sensors typically demonstrating lower sensitivity compared to their rigid counterparts. The inherent flexibility and porous nature of textile substrates create signal interference and baseline drift issues, particularly problematic for detecting subtle physiological signals like respiratory patterns or small changes in bioelectric potentials.

Durability constraints further impede sensitivity optimization, as repeated mechanical stress from washing, bending, and stretching degrades sensor performance over time. Current nanomaterial coatings often demonstrate diminished sensitivity after multiple wash cycles or extended wear periods, failing to maintain consistent electrical properties throughout the product lifecycle.

Integration challenges between the sensing nanomaterials and textile substrates create additional sensitivity barriers. Poor adhesion between nanomaterial coatings and textile fibers leads to delamination and cracking, disrupting the conductive pathways essential for signal transmission. The heterogeneous surface morphology of textiles complicates the uniform application of nanomaterial coatings, resulting in inconsistent sensor response across the fabric surface.

Manufacturing scalability presents another significant limitation, as laboratory-scale techniques for applying nanomaterial coatings often fail to translate to industrial production environments without compromising sensitivity. Current processes struggle to maintain precise control over coating thickness and uniformity at scale, leading to batch-to-batch variations in sensor performance.

Power requirements for signal amplification and processing represent an additional constraint, as highly sensitive detection often necessitates complex circuitry that conflicts with the need for lightweight, flexible, and energy-efficient wearable systems. This creates a fundamental trade-off between sensitivity and practical wearability.

Cross-sensitivity issues further complicate reliable measurements, with current sensors often responding to multiple stimuli simultaneously, making it difficult to isolate the specific parameter of interest. For instance, pressure sensors may inadvertently respond to temperature changes, creating false readings that compromise data integrity.

These limitations collectively highlight the need for innovative approaches to nanomaterial selection, coating methodologies, and interface engineering to overcome the current sensitivity barriers in smart textile sensor technology.

Current Nanomaterial Coating Methodologies

01 Conductive materials for enhanced sensitivity

Smart textile sensors can incorporate conductive materials such as carbon nanotubes, conductive polymers, or metal-coated fibers to enhance sensitivity. These materials create conductive pathways within the textile structure that respond to external stimuli like pressure, strain, or temperature changes. The integration of these materials at the fiber or yarn level allows for high sensitivity while maintaining textile flexibility and comfort.- Conductive materials for enhanced sensitivity in textile sensors: Various conductive materials can be incorporated into textile structures to create sensors with high sensitivity. These materials include conductive polymers, carbon-based materials (such as carbon nanotubes and graphene), and metallic nanoparticles or wires. The integration of these materials into textile substrates enables the development of sensors that can detect subtle changes in pressure, strain, or other physical parameters with high precision, making them suitable for applications requiring fine sensitivity measurements.

- Structural design approaches for improving sensor sensitivity: The structural design of textile sensors plays a crucial role in determining their sensitivity. Various approaches include knitted or woven structures with specific patterns, layered composites, and 3D textile architectures. These designs can optimize the deformation behavior of the textile under external stimuli, leading to enhanced electrical response and improved sensitivity. Strategic placement of sensing elements within the textile structure can also create localized areas of higher sensitivity for targeted applications.

- Signal processing techniques for sensitivity enhancement: Advanced signal processing techniques can significantly improve the sensitivity of smart textile sensors. These include noise filtering algorithms, signal amplification methods, and machine learning approaches for pattern recognition. By implementing these techniques, weak signals can be effectively detected and processed, reducing the signal-to-noise ratio and enhancing the overall sensitivity of the textile sensing system. Real-time data processing capabilities further enable the detection of subtle changes in measured parameters.

- Multi-parameter sensing for comprehensive sensitivity: Smart textile sensors can be designed to detect multiple parameters simultaneously, providing comprehensive sensitivity across different physical and chemical variables. These multi-parameter sensing systems can monitor combinations of pressure, strain, temperature, humidity, and biochemical markers. The integration of different sensing mechanisms within a single textile platform enables cross-validation of measurements and compensates for environmental factors that might affect individual sensor performance, resulting in more reliable and sensitive detection capabilities.

- Calibration and environmental adaptation for consistent sensitivity: Maintaining consistent sensitivity in varying environmental conditions is crucial for smart textile sensors. Advanced calibration methods and environmental adaptation techniques help ensure reliable performance across different temperatures, humidity levels, and mechanical stresses. Self-calibrating systems that can automatically adjust sensitivity thresholds based on environmental factors provide more consistent measurements. Additionally, protective coatings and encapsulation techniques can shield sensing elements from environmental interference while preserving their sensitivity.

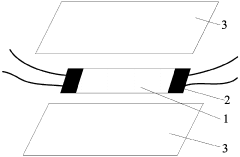

02 Multi-layer sensor structures for improved sensitivity

Layered structures in smart textile sensors can significantly improve sensitivity by optimizing the interaction between sensing layers. These structures typically include a sensing layer, conductive pathways, and protective layers arranged in specific configurations. The design of these multi-layer structures allows for targeted sensitivity to specific stimuli while reducing interference from other environmental factors, resulting in more accurate and reliable sensor performance.Expand Specific Solutions03 Signal processing techniques for sensitivity enhancement

Advanced signal processing techniques can be employed to enhance the sensitivity of smart textile sensors. These include noise filtering algorithms, signal amplification methods, and machine learning approaches for pattern recognition. By implementing these techniques in the sensor system, even small changes in the measured parameters can be detected accurately, effectively increasing the overall sensitivity of the textile sensor without requiring physical modifications to the textile structure.Expand Specific Solutions04 Biomimetic design approaches for sensor sensitivity

Biomimetic approaches in smart textile sensor design involve mimicking biological sensing mechanisms to achieve high sensitivity. These designs often incorporate structures inspired by human skin, plant sensory systems, or other natural sensing mechanisms. By emulating these naturally evolved sensing systems, textile sensors can achieve remarkable sensitivity to touch, pressure, temperature, or chemical stimuli while maintaining comfort and wearability.Expand Specific Solutions05 Environmental adaptation mechanisms for consistent sensitivity

Smart textile sensors can incorporate environmental adaptation mechanisms to maintain consistent sensitivity across varying conditions. These mechanisms include temperature compensation circuits, humidity-resistant coatings, and self-calibrating systems. By adjusting for environmental variables, these sensors can provide reliable and consistent sensitivity regardless of the operating conditions, making them suitable for diverse applications from healthcare monitoring to industrial sensing.Expand Specific Solutions

Leading Companies in Smart Textile Nanomaterials

The smart textile sensors market is currently in a growth phase, with increasing demand driven by healthcare, sports, and military applications. The market size is projected to expand significantly due to rising interest in wearable technology. Technologically, nanomaterial coatings for sensitivity optimization represent an emerging frontier with varying maturity levels across players. Academic institutions like University of California, North Carolina State University, and Zhejiang University lead fundamental research, while specialized companies such as Nanowear and Direct-C are commercializing applications. Established corporations including IBM, Toray Industries, and Bang & Olufsen are investing in integration capabilities. The competitive landscape shows a collaborative ecosystem between research institutions and industry partners working to overcome sensitivity, durability, and manufacturing challenges.

Nanowear, Inc.

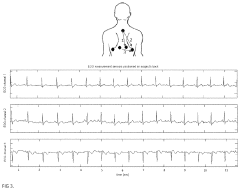

Technical Solution: Nanowear has developed a proprietary nanotechnology platform for smart textiles that utilizes cloth-based nanosensors with enhanced sensitivity through specialized nanomaterial coatings. Their technology employs carbon nanotube (CNT) and metal nanoparticle composites applied to textile substrates through a patented deposition process that creates highly conductive, flexible sensing elements. The company's approach involves precise control of nanomaterial density and distribution on textile fibers to optimize electrical conductivity while maintaining fabric flexibility. Their smart textile sensors can detect multiple physiological signals simultaneously, including cardiac, pulmonary, and muscular activity with clinical-grade accuracy. Nanowear's technology incorporates specialized surface functionalization techniques that protect the nanomaterial coatings from degradation during washing cycles and everyday wear, significantly extending sensor lifespan compared to conventional approaches.

Strengths: Superior sensitivity for physiological monitoring with medical-grade accuracy; excellent durability through specialized coating protection techniques; maintains textile comfort and flexibility. Weaknesses: Higher manufacturing costs compared to conventional textiles; potential scalability challenges for mass production; may require specialized washing procedures for long-term maintenance.

University of Maryland

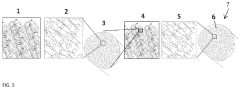

Technical Solution: The University of Maryland has pioneered advanced nanomaterial coating techniques for smart textiles through their specialized "vapor phase infiltration" process. This innovative approach involves depositing metal oxide nanoparticles directly onto individual textile fibers using atomic layer deposition, creating highly uniform and ultrathin coatings that dramatically enhance sensing capabilities while preserving fabric flexibility. Their research team has developed a groundbreaking method combining zinc oxide and silver nanoparticle coatings that creates self-cleaning, antibacterial smart textiles with exceptional sensitivity to pressure, strain, and temperature changes. The university's work includes specialized polymer-nanomaterial composite coatings that can be selectively applied to create sensing zones within garments, allowing for targeted monitoring of specific body regions. Their recent innovations include stimuli-responsive nanomaterial coatings that can dynamically adjust sensitivity based on environmental conditions, significantly improving signal-to-noise ratios in variable environments.

Strengths: Exceptional precision in nanomaterial deposition; multifunctional capabilities combining sensing with antibacterial properties; highly customizable sensing zones. Weaknesses: Complex manufacturing process requiring specialized equipment; higher production costs; potential challenges in scaling from laboratory to industrial production.

Key Patents in Textile Sensor Sensitivity Enhancement

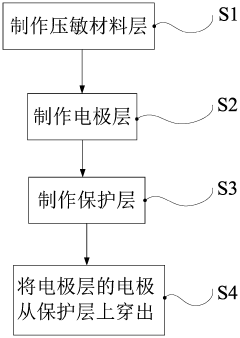

Novel flexible intelligent fabric sensor and manufacturing method thereof

PatentInactiveCN111055554A

Innovation

- The micro-convex lattice carbon nanofiber fabric is prepared using electrospinning technology as a pressure-sensitive material layer, combined with a conductive-coated nanofiber mesh film as an electrode layer, and a low-concentration polymer elastic polymer is formed through ultrasonic atomization spraying technology. The protective layer of the liquid forms an ultra-thin flexible packaging protective film to achieve a sensor with high sensitivity, good flexibility, breathability and washability.

Large scale manufacturing of hybrid nanostructured textile sensors

PatentActiveUS11047051B2

Innovation

- A method for manufacturing hybrid nanostructured textile sensors involves embedding polymer nanofibers into a matrix polymer, dissolving the matrix to expose the nanofibers, and coating them with conductive materials, allowing for the creation of durable, low-noise sensors that can be integrated into clothing for long-term health monitoring.

Durability and Washability Considerations

The durability and washability of smart textile sensors with nanomaterial coatings represent critical challenges that must be addressed for commercial viability. These sensors are expected to maintain their sensitivity and functionality through multiple washing cycles and daily wear conditions, which places significant demands on the coating technology. Current research indicates that nanomaterial coatings often degrade after 5-10 washing cycles, with sensitivity reduction ranging from 15% to 40% depending on the specific nanomaterials used.

Encapsulation methods have emerged as a primary approach to enhance durability. Polymeric encapsulants such as polydimethylsiloxane (PDMS) and parylene-C provide protective barriers against mechanical stress and moisture penetration. Recent studies demonstrate that PDMS-encapsulated graphene sensors can withstand up to 20 washing cycles while maintaining over 85% of their initial sensitivity. However, these encapsulation methods often introduce a trade-off between protection and sensor performance, as thicker protective layers typically reduce sensitivity.

Cross-linking strategies represent another promising approach, where chemical bonds are formed between the nanomaterial coating and textile substrate. Researchers have successfully implemented glutaraldehyde and carbodiimide cross-linking agents to secure carbon nanotube networks to cotton fibers, improving washing durability by approximately 300% compared to non-cross-linked counterparts.

Hydrophobic treatments using fluorinated compounds or silane-based coatings have shown effectiveness in repelling water and detergents during washing processes. These treatments create a protective barrier that prevents the infiltration of washing agents while allowing the sensor to maintain its electrical properties. Tests indicate that hydrophobic-treated graphene oxide sensors retain up to 92% functionality after 15 standard washing cycles.

The testing methodologies for durability assessment require standardization across the industry. Currently, researchers employ various protocols ranging from simulated washing in laboratory settings to actual machine washing cycles. The International Electrotechnical Commission (IEC) has begun developing specific standards for wearable electronic textiles, which will likely include protocols for evaluating the washability of smart textile sensors.

Future research directions should focus on developing multi-layer protection systems that combine the advantages of different approaches. Biomimetic strategies inspired by natural water-repellent structures, such as lotus leaf surfaces, offer promising avenues for creating self-cleaning and highly durable sensor coatings. Additionally, the development of self-healing nanomaterial composites could potentially address the degradation issues by autonomously restoring damaged coating areas after mechanical stress or washing.

Encapsulation methods have emerged as a primary approach to enhance durability. Polymeric encapsulants such as polydimethylsiloxane (PDMS) and parylene-C provide protective barriers against mechanical stress and moisture penetration. Recent studies demonstrate that PDMS-encapsulated graphene sensors can withstand up to 20 washing cycles while maintaining over 85% of their initial sensitivity. However, these encapsulation methods often introduce a trade-off between protection and sensor performance, as thicker protective layers typically reduce sensitivity.

Cross-linking strategies represent another promising approach, where chemical bonds are formed between the nanomaterial coating and textile substrate. Researchers have successfully implemented glutaraldehyde and carbodiimide cross-linking agents to secure carbon nanotube networks to cotton fibers, improving washing durability by approximately 300% compared to non-cross-linked counterparts.

Hydrophobic treatments using fluorinated compounds or silane-based coatings have shown effectiveness in repelling water and detergents during washing processes. These treatments create a protective barrier that prevents the infiltration of washing agents while allowing the sensor to maintain its electrical properties. Tests indicate that hydrophobic-treated graphene oxide sensors retain up to 92% functionality after 15 standard washing cycles.

The testing methodologies for durability assessment require standardization across the industry. Currently, researchers employ various protocols ranging from simulated washing in laboratory settings to actual machine washing cycles. The International Electrotechnical Commission (IEC) has begun developing specific standards for wearable electronic textiles, which will likely include protocols for evaluating the washability of smart textile sensors.

Future research directions should focus on developing multi-layer protection systems that combine the advantages of different approaches. Biomimetic strategies inspired by natural water-repellent structures, such as lotus leaf surfaces, offer promising avenues for creating self-cleaning and highly durable sensor coatings. Additionally, the development of self-healing nanomaterial composites could potentially address the degradation issues by autonomously restoring damaged coating areas after mechanical stress or washing.

Sustainability of Nanomaterial-Enhanced Textiles

The sustainability of nanomaterial-enhanced textiles represents a critical consideration in the development of smart textile sensors with optimized sensitivity. As these advanced materials gain prominence in wearable technology applications, their environmental impact throughout the entire lifecycle demands thorough assessment.

Nanomaterial coatings used for enhancing textile sensor sensitivity—such as carbon nanotubes, graphene, and metal nanoparticles—present unique sustainability challenges. The production processes for these nanomaterials often require significant energy inputs and potentially hazardous chemicals, raising concerns about their carbon footprint and environmental toxicity during manufacturing.

Water consumption and chemical usage during the application of nanomaterial coatings to textiles present additional sustainability challenges. Traditional textile finishing processes modified for nanomaterial application may require substantial water resources and generate wastewater containing nanoparticle residues that conventional treatment facilities struggle to filter effectively.

Durability factors significantly impact the sustainability profile of nanomaterial-enhanced textiles. While high-performance nanomaterial coatings can extend the functional lifespan of smart textile sensors, their resistance to washing, abrasion, and environmental stressors varies considerably. Sensors requiring frequent replacement due to degraded nanomaterial coatings contribute to increased waste generation and resource consumption.

End-of-life considerations present perhaps the most significant sustainability challenge. The composite nature of nanomaterial-enhanced textiles complicates recycling efforts, as separating nanomaterial coatings from textile substrates remains technically challenging. Additionally, the potential environmental fate of nanomaterials that may leach from discarded textiles into ecosystems requires further investigation.

Recent innovations are addressing these sustainability concerns through several approaches. Bio-based nanomaterials derived from cellulose, chitin, and other renewable resources offer more environmentally friendly alternatives to synthetic nanomaterials. Green chemistry principles are being applied to develop less toxic synthesis methods that reduce hazardous waste generation and energy consumption.

Circular economy approaches are gaining traction, with design strategies focusing on easier disassembly and material recovery. Some manufacturers are implementing take-back programs specifically for nanomaterial-enhanced textiles, ensuring proper handling at end-of-life. Additionally, advances in coating technologies are improving the durability and wash resistance of nanomaterial enhancements, extending product lifespans and reducing replacement frequency.

Regulatory frameworks worldwide are evolving to address the unique sustainability challenges of nanomaterials in consumer products, with the European Union's REACH regulations and similar initiatives establishing reporting requirements and safety standards for nanomaterial applications in textiles.

Nanomaterial coatings used for enhancing textile sensor sensitivity—such as carbon nanotubes, graphene, and metal nanoparticles—present unique sustainability challenges. The production processes for these nanomaterials often require significant energy inputs and potentially hazardous chemicals, raising concerns about their carbon footprint and environmental toxicity during manufacturing.

Water consumption and chemical usage during the application of nanomaterial coatings to textiles present additional sustainability challenges. Traditional textile finishing processes modified for nanomaterial application may require substantial water resources and generate wastewater containing nanoparticle residues that conventional treatment facilities struggle to filter effectively.

Durability factors significantly impact the sustainability profile of nanomaterial-enhanced textiles. While high-performance nanomaterial coatings can extend the functional lifespan of smart textile sensors, their resistance to washing, abrasion, and environmental stressors varies considerably. Sensors requiring frequent replacement due to degraded nanomaterial coatings contribute to increased waste generation and resource consumption.

End-of-life considerations present perhaps the most significant sustainability challenge. The composite nature of nanomaterial-enhanced textiles complicates recycling efforts, as separating nanomaterial coatings from textile substrates remains technically challenging. Additionally, the potential environmental fate of nanomaterials that may leach from discarded textiles into ecosystems requires further investigation.

Recent innovations are addressing these sustainability concerns through several approaches. Bio-based nanomaterials derived from cellulose, chitin, and other renewable resources offer more environmentally friendly alternatives to synthetic nanomaterials. Green chemistry principles are being applied to develop less toxic synthesis methods that reduce hazardous waste generation and energy consumption.

Circular economy approaches are gaining traction, with design strategies focusing on easier disassembly and material recovery. Some manufacturers are implementing take-back programs specifically for nanomaterial-enhanced textiles, ensuring proper handling at end-of-life. Additionally, advances in coating technologies are improving the durability and wash resistance of nanomaterial enhancements, extending product lifespans and reducing replacement frequency.

Regulatory frameworks worldwide are evolving to address the unique sustainability challenges of nanomaterials in consumer products, with the European Union's REACH regulations and similar initiatives establishing reporting requirements and safety standards for nanomaterial applications in textiles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!