Smart textile sensors patents in human-machine interface applications

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Textile Sensors Background and Objectives

Smart textile sensors represent a revolutionary convergence of traditional textiles and advanced electronic technologies, enabling fabrics to sense, react, and communicate with their environment. The evolution of this technology can be traced back to the early 2000s when researchers began exploring ways to integrate electronic components into textiles. Over the past two decades, significant advancements have been made in materials science, miniaturization of electronics, and flexible circuit design, propelling smart textiles from laboratory curiosities to commercially viable products.

The technological trajectory of smart textile sensors has been characterized by progressive improvements in flexibility, durability, washability, and power efficiency. Early iterations faced challenges with rigid components and limited functionality, but recent developments have yielded sensors that seamlessly integrate with fabric structures while maintaining textile-like properties. The integration of conductive yarns, printed electronics, and microelectromechanical systems (MEMS) has dramatically expanded the sensing capabilities of textiles.

In the context of human-machine interfaces (HMI), smart textile sensors serve as a natural bridge between humans and digital systems. These interfaces leverage the ubiquitous nature of textiles in human life to create intuitive, unobtrusive interaction points. The technological objective in this domain is to develop sensors that can accurately detect and interpret human physiological signals, movements, gestures, and environmental conditions while maintaining comfort and wearability.

Current research focuses on enhancing the sensitivity, specificity, and reliability of textile-based sensing systems for HMI applications. This includes developing multi-modal sensing capabilities that can simultaneously monitor various parameters such as pressure, strain, temperature, and bioelectric signals. Another key objective is to improve signal processing algorithms that can filter noise and accurately interpret complex human inputs through textile interfaces.

The patent landscape in smart textile sensors for HMI applications has grown exponentially, with innovations spanning materials, manufacturing processes, sensor designs, and application methodologies. These patents reflect the industry's push toward creating more intuitive, responsive, and seamless interactions between humans and machines through everyday textiles.

The ultimate technological goal is to develop smart textile sensors that can function as natural extensions of human capabilities, enabling more intuitive and efficient human-machine collaboration. This includes applications in healthcare monitoring, assistive technologies, immersive virtual experiences, industrial safety, and consumer electronics, where textile-based interfaces could potentially replace or complement traditional input devices.

The technological trajectory of smart textile sensors has been characterized by progressive improvements in flexibility, durability, washability, and power efficiency. Early iterations faced challenges with rigid components and limited functionality, but recent developments have yielded sensors that seamlessly integrate with fabric structures while maintaining textile-like properties. The integration of conductive yarns, printed electronics, and microelectromechanical systems (MEMS) has dramatically expanded the sensing capabilities of textiles.

In the context of human-machine interfaces (HMI), smart textile sensors serve as a natural bridge between humans and digital systems. These interfaces leverage the ubiquitous nature of textiles in human life to create intuitive, unobtrusive interaction points. The technological objective in this domain is to develop sensors that can accurately detect and interpret human physiological signals, movements, gestures, and environmental conditions while maintaining comfort and wearability.

Current research focuses on enhancing the sensitivity, specificity, and reliability of textile-based sensing systems for HMI applications. This includes developing multi-modal sensing capabilities that can simultaneously monitor various parameters such as pressure, strain, temperature, and bioelectric signals. Another key objective is to improve signal processing algorithms that can filter noise and accurately interpret complex human inputs through textile interfaces.

The patent landscape in smart textile sensors for HMI applications has grown exponentially, with innovations spanning materials, manufacturing processes, sensor designs, and application methodologies. These patents reflect the industry's push toward creating more intuitive, responsive, and seamless interactions between humans and machines through everyday textiles.

The ultimate technological goal is to develop smart textile sensors that can function as natural extensions of human capabilities, enabling more intuitive and efficient human-machine collaboration. This includes applications in healthcare monitoring, assistive technologies, immersive virtual experiences, industrial safety, and consumer electronics, where textile-based interfaces could potentially replace or complement traditional input devices.

Market Analysis for HMI Smart Textile Applications

The smart textile sensors market for human-machine interface applications is experiencing robust growth, driven by increasing demand for wearable technology across multiple sectors. Current market valuations place this segment at approximately 2.5 billion USD in 2023, with projections indicating a compound annual growth rate (CAGR) of 18-20% over the next five years. This accelerated growth trajectory is primarily fueled by expanding applications in healthcare monitoring, sports performance analysis, and interactive consumer electronics.

Healthcare represents the largest market segment, accounting for roughly 40% of current smart textile sensor applications. The aging global population and rising prevalence of chronic conditions have created substantial demand for continuous health monitoring solutions that can seamlessly integrate into patients' daily lives. Smart textiles offer non-invasive, comfortable alternatives to traditional medical monitoring devices.

The fitness and sports performance sector constitutes approximately 30% of the market, with professional athletics teams and consumer fitness enthusiasts driving adoption. These applications focus on biomechanical analysis, physiological monitoring, and injury prevention through embedded textile sensors that can detect motion, pressure, and various biometric parameters.

Consumer electronics applications, including gesture-controlled interfaces and augmented reality experiences, represent about 20% of the market. This segment shows the highest growth potential as major technology companies increasingly incorporate textile-based interfaces into their product ecosystems.

Industrial and military applications account for the remaining 10%, with emphasis on worker safety monitoring and enhanced soldier performance systems. These specialized applications often command premium pricing due to their mission-critical nature and stringent performance requirements.

Geographically, North America leads with approximately 40% market share, followed by Europe (30%), Asia-Pacific (25%), and other regions (5%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate, driven by expanding manufacturing capabilities and increasing technology adoption in countries like China, South Korea, and Japan.

Key market drivers include miniaturization of sensor technology, improvements in power efficiency, advancements in wireless connectivity, and increasing consumer acceptance of wearable technology. The integration of artificial intelligence for data interpretation represents a significant value-added component, allowing smart textile systems to deliver actionable insights rather than merely raw data.

Market challenges include durability concerns, washing/maintenance issues, standardization gaps, and privacy considerations related to continuous biometric data collection. Additionally, price sensitivity remains a barrier to mass-market adoption, though economies of scale are gradually addressing this constraint.

Healthcare represents the largest market segment, accounting for roughly 40% of current smart textile sensor applications. The aging global population and rising prevalence of chronic conditions have created substantial demand for continuous health monitoring solutions that can seamlessly integrate into patients' daily lives. Smart textiles offer non-invasive, comfortable alternatives to traditional medical monitoring devices.

The fitness and sports performance sector constitutes approximately 30% of the market, with professional athletics teams and consumer fitness enthusiasts driving adoption. These applications focus on biomechanical analysis, physiological monitoring, and injury prevention through embedded textile sensors that can detect motion, pressure, and various biometric parameters.

Consumer electronics applications, including gesture-controlled interfaces and augmented reality experiences, represent about 20% of the market. This segment shows the highest growth potential as major technology companies increasingly incorporate textile-based interfaces into their product ecosystems.

Industrial and military applications account for the remaining 10%, with emphasis on worker safety monitoring and enhanced soldier performance systems. These specialized applications often command premium pricing due to their mission-critical nature and stringent performance requirements.

Geographically, North America leads with approximately 40% market share, followed by Europe (30%), Asia-Pacific (25%), and other regions (5%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate, driven by expanding manufacturing capabilities and increasing technology adoption in countries like China, South Korea, and Japan.

Key market drivers include miniaturization of sensor technology, improvements in power efficiency, advancements in wireless connectivity, and increasing consumer acceptance of wearable technology. The integration of artificial intelligence for data interpretation represents a significant value-added component, allowing smart textile systems to deliver actionable insights rather than merely raw data.

Market challenges include durability concerns, washing/maintenance issues, standardization gaps, and privacy considerations related to continuous biometric data collection. Additionally, price sensitivity remains a barrier to mass-market adoption, though economies of scale are gradually addressing this constraint.

Technical Challenges in Smart Textile Sensor Development

Despite significant advancements in smart textile sensors for human-machine interface applications, several critical technical challenges continue to impede widespread adoption and commercialization. The integration of electronic components with textile substrates remains a fundamental obstacle, as traditional rigid electronics are inherently incompatible with the flexible, stretchable nature of fabrics. This incompatibility creates significant durability issues, with connection points between electronic components and textile substrates representing particular failure vulnerabilities.

Washability presents another major challenge, as smart textile sensors must withstand regular cleaning processes without performance degradation. Current waterproofing solutions often compromise breathability and comfort, creating an unresolved technical dilemma between functionality and practical usability. Patent analysis reveals that while various encapsulation methods exist, none have achieved the optimal balance of protection and textile-like properties.

Power management remains a critical bottleneck in smart textile sensor development. Conventional batteries are bulky and rigid, contradicting the fundamental requirements of wearable textiles. Although energy harvesting technologies (piezoelectric, thermoelectric, and photovoltaic) show promise in patents, they currently generate insufficient power for continuous operation of sophisticated human-machine interfaces, particularly those requiring wireless data transmission.

Signal processing and noise reduction represent significant technical hurdles. Smart textile sensors operating in dynamic environments are susceptible to motion artifacts and electromagnetic interference, compromising signal integrity. Patent literature indicates that while adaptive filtering algorithms have been developed, they often require substantial computational resources that are difficult to integrate into textile-based systems.

Scalable manufacturing techniques present perhaps the most significant barrier to commercialization. Current fabrication methods for smart textile sensors are predominantly laboratory-scale processes that do not translate efficiently to mass production. Patents reveal a significant gap between innovative sensor designs and viable manufacturing approaches that can maintain performance consistency while achieving economical production costs.

Biocompatibility and user comfort considerations add another layer of complexity. Long-term skin contact with conductive materials and potential allergens in electronic components raises safety concerns that must be addressed through careful material selection and design. Patent analysis shows increasing focus on hypoallergenic materials and ergonomic designs, though comprehensive solutions remain elusive.

Standardization and interoperability challenges further complicate development efforts. The absence of unified standards for smart textile sensors creates fragmentation in the market, with patents often describing proprietary systems that cannot easily interface with other technologies or platforms in the human-machine interface ecosystem.

Washability presents another major challenge, as smart textile sensors must withstand regular cleaning processes without performance degradation. Current waterproofing solutions often compromise breathability and comfort, creating an unresolved technical dilemma between functionality and practical usability. Patent analysis reveals that while various encapsulation methods exist, none have achieved the optimal balance of protection and textile-like properties.

Power management remains a critical bottleneck in smart textile sensor development. Conventional batteries are bulky and rigid, contradicting the fundamental requirements of wearable textiles. Although energy harvesting technologies (piezoelectric, thermoelectric, and photovoltaic) show promise in patents, they currently generate insufficient power for continuous operation of sophisticated human-machine interfaces, particularly those requiring wireless data transmission.

Signal processing and noise reduction represent significant technical hurdles. Smart textile sensors operating in dynamic environments are susceptible to motion artifacts and electromagnetic interference, compromising signal integrity. Patent literature indicates that while adaptive filtering algorithms have been developed, they often require substantial computational resources that are difficult to integrate into textile-based systems.

Scalable manufacturing techniques present perhaps the most significant barrier to commercialization. Current fabrication methods for smart textile sensors are predominantly laboratory-scale processes that do not translate efficiently to mass production. Patents reveal a significant gap between innovative sensor designs and viable manufacturing approaches that can maintain performance consistency while achieving economical production costs.

Biocompatibility and user comfort considerations add another layer of complexity. Long-term skin contact with conductive materials and potential allergens in electronic components raises safety concerns that must be addressed through careful material selection and design. Patent analysis shows increasing focus on hypoallergenic materials and ergonomic designs, though comprehensive solutions remain elusive.

Standardization and interoperability challenges further complicate development efforts. The absence of unified standards for smart textile sensors creates fragmentation in the market, with patents often describing proprietary systems that cannot easily interface with other technologies or platforms in the human-machine interface ecosystem.

Current Smart Textile Sensor Solutions for HMI

01 Wearable health monitoring textile sensors

Smart textile sensors integrated into clothing for continuous health monitoring. These sensors can track vital signs such as heart rate, body temperature, respiration, and other physiological parameters. The technology enables non-invasive monitoring for medical applications, fitness tracking, and preventive healthcare. These textiles incorporate conductive fibers and specialized sensing elements that maintain comfort while providing accurate health data.- Wearable health monitoring textile sensors: Smart textile sensors integrated into clothing for continuous health monitoring. These sensors can track vital signs such as heart rate, respiration, body temperature, and other physiological parameters. The technology enables non-invasive monitoring for medical applications, fitness tracking, and preventive healthcare. These textiles incorporate conductive fibers and flexible electronics that maintain comfort while providing accurate health data.

- Conductive fiber and material technologies: Advanced materials and manufacturing techniques for creating conductive textiles. These include specialized fibers with embedded conductive elements, coatings, or treatments that enable electrical conductivity while maintaining textile properties like flexibility and washability. The materials can be woven, knitted, or bonded into fabrics that function as sensors while remaining comfortable and durable for everyday wear.

- Motion and pressure sensing textiles: Textile sensors designed to detect movement, pressure, and deformation. These smart fabrics can monitor body movements, posture, gait analysis, and applied pressure through changes in electrical properties when the textile is stretched or compressed. Applications include sports performance analysis, rehabilitation monitoring, ergonomic assessment, and fall detection for elderly care.

- Environmental and external condition monitoring: Smart textiles that can detect and respond to environmental conditions such as temperature, humidity, UV exposure, and chemical presence. These sensors can alert users to environmental hazards, monitor workplace conditions, or adapt clothing functionality based on external factors. The technology incorporates specialized sensing elements that can detect specific environmental parameters while integrated into everyday fabrics.

- Power management and connectivity solutions: Technologies for powering smart textile sensors and enabling data transmission. These include energy harvesting methods (kinetic, thermal, solar), flexible batteries, wireless charging, and low-power communication protocols. The solutions address the challenge of maintaining functionality while ensuring the textiles remain comfortable, washable, and practical for daily use, with seamless connectivity to smartphones and other devices for data analysis.

02 Conductive fabric and fiber-based sensors

Advanced textile sensors utilizing conductive fabrics and fibers that can detect pressure, strain, and movement. These sensors are created by incorporating conductive materials like metal-coated fibers, carbon nanotubes, or conductive polymers into traditional textiles. The resulting smart fabrics maintain flexibility and comfort while enabling sensing capabilities for various applications including gesture recognition, motion tracking, and pressure distribution analysis.Expand Specific Solutions03 Environmental and chemical sensing textiles

Smart textiles designed to detect environmental conditions and chemical substances. These sensors can monitor temperature, humidity, UV exposure, air quality, and the presence of specific chemicals or gases. The technology incorporates specialized sensing elements into fabric structures that respond to environmental changes, providing alerts or data for various applications including workplace safety, military use, and environmental monitoring.Expand Specific Solutions04 Textile sensor integration and connectivity systems

Systems and methods for integrating sensors into textiles and connecting them to data processing units. These technologies focus on creating reliable connections between soft textile sensors and rigid electronic components, including wireless transmission modules, power sources, and data processing units. The integration methods maintain textile properties like flexibility, washability, and comfort while ensuring reliable data collection and transmission.Expand Specific Solutions05 Energy harvesting and self-powered textile sensors

Smart textile sensors with integrated energy harvesting capabilities that enable self-powered operation. These textiles incorporate technologies that can generate electricity from body movement, temperature differences, or ambient light to power the embedded sensors. The self-powering feature eliminates or reduces the need for batteries, making the smart textiles more practical for long-term use and reducing maintenance requirements.Expand Specific Solutions

Leading Companies in Smart Textile HMI Patent Landscape

The smart textile sensors market for human-machine interface applications is currently in a growth phase, characterized by increasing technological innovation and expanding applications. The market size is projected to grow significantly as wearable technology adoption increases across healthcare, fitness, and consumer electronics sectors. From a technological maturity perspective, established players like Philips, Google, and Apple are leading with advanced research capabilities, while specialized innovators such as Myant, Sensel, and Pison Technology are driving breakthrough developments in pressure-sensitive and neural interfaces. Academic institutions including Qingdao University, Delft University of Technology, and City University of Hong Kong are contributing fundamental research, creating a competitive landscape where cross-sector collaboration between technology giants, textile manufacturers, and research institutions is accelerating commercialization of increasingly sophisticated smart textile interfaces.

Koninklijke Philips NV

Technical Solution: Philips has pioneered smart textile sensor technologies specifically designed for healthcare and wellbeing applications within human-machine interfaces. Their patented solutions include textile-integrated pressure, temperature, and bioelectric sensors that can monitor vital signs while providing intuitive interfaces for patient interaction. Philips' approach focuses on creating washable, comfortable smart textiles using specialized manufacturing techniques that encapsulate electronic components within textile structures. Their patents cover methods for creating reliable connections between textile sensors and processing units through innovative bonding and encapsulation techniques that withstand repeated washing cycles and daily wear. Philips has also developed unique textile-based electrode systems that can both sense physiological signals and deliver feedback through haptic stimulation, creating bidirectional interfaces between users and healthcare monitoring systems.

Strengths: Strong focus on medical-grade reliability and clinical validation; extensive experience integrating sensing technologies with healthcare systems; advanced manufacturing techniques for durable smart textiles. Weaknesses: Solutions often prioritize medical functionality over fashion or consumer appeal; higher cost implementation due to medical certification requirements.

Myant, Corp.

Technical Solution: Myant has developed a comprehensive smart textile platform called Skiin that integrates biometric sensors directly into everyday garments. Their technology employs conductive yarns and fibers woven or knitted into textiles to create seamless sensing interfaces. The company's patented methods focus on creating textile-based capacitive and resistive sensors that can detect touch, pressure, stretch, and various physiological signals. Myant's innovation lies in their ability to maintain textile properties (comfort, washability) while incorporating electronic functionality through specialized manufacturing processes that bond conductive materials with traditional textile fibers. Their patents cover methods for creating durable connections between electronic components and textiles, as well as systems for processing and transmitting the collected data to provide meaningful user interactions.

Strengths: Industry-leading integration of electronics with textiles while maintaining garment comfort and washability; comprehensive end-to-end solution from sensing to data analysis. Weaknesses: Relatively high production costs; challenges in scaling manufacturing processes for mass market adoption.

Key Patent Analysis for Smart Textile HMI Technologies

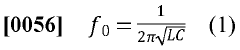

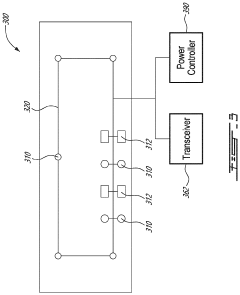

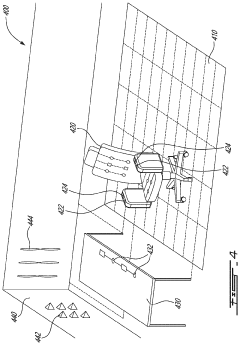

Apparatus and method for contextual interactions on interactive fabrics with inductive sensing

PatentWO2021077001A1

Innovation

- An interactive sensing apparatus with inductive coils made of conductive fibers sewn into textile substrates, capable of detecting objects through inductive coupling and outputting signals based on changes in resonant frequency, processed by circuitry to determine object identity.

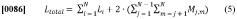

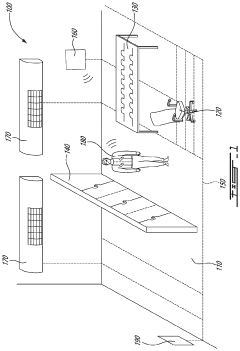

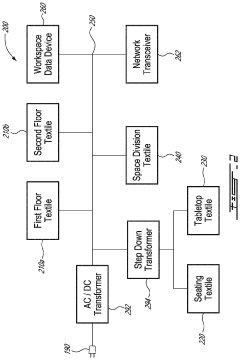

Systems and methods of providing networks based on textiles

PatentActiveUS20230038068A1

Innovation

- A system of smart textiles integrated with electrical, mechanical, or electro-mechanical structures, including shape shifting alloy yarn, thermal yarn, piezoelectric yarn, and electromagnetic yarn, connected via a bi-directional electrical interconnection bus that allows for the detection of physiological data and provision of feedback through haptic, temperature, or lighting adjustments.

Manufacturing Processes and Scalability Considerations

The manufacturing processes for smart textile sensors in human-machine interface applications present unique challenges that significantly impact their commercial viability and widespread adoption. Traditional textile manufacturing methods must be adapted to incorporate electronic components while maintaining the fabric's essential properties of flexibility, durability, and comfort. Currently, the most prevalent manufacturing approaches include screen printing, inkjet printing, and direct write techniques for depositing conductive materials onto textile substrates. These methods allow for precise patterning of sensing elements while maintaining compatibility with existing textile production infrastructure.

Scalability considerations represent a critical bottleneck in the commercialization pathway. While laboratory prototypes demonstrate impressive technical capabilities, transitioning to mass production introduces significant challenges in maintaining consistent sensor performance across large production volumes. Patent analysis reveals that leading companies are increasingly focusing on developing manufacturing processes that can be integrated into existing textile production lines, rather than requiring specialized equipment that would increase production costs.

Material selection plays a pivotal role in manufacturing feasibility. Conductive polymers, metallic nanoparticles, and carbon-based materials (graphene, carbon nanotubes) feature prominently in recent patents, with emphasis on formulations that can withstand standard textile processing steps such as washing, drying, and ironing. Patents from industry leaders like Google (US10175781B2) and Adidas (EP3258841A1) highlight innovations in creating washable circuits and sensors that maintain functionality after multiple cleaning cycles.

The integration of sensing elements with conventional textiles requires careful consideration of connection points and interfaces. Recent patents demonstrate novel approaches to creating robust electrical connections between soft textiles and rigid electronic components, including specialized conductive adhesives, mechanical fastening systems, and modular designs that allow for removal of electronics before washing.

Cost-effectiveness remains a significant challenge, with current manufacturing methods often requiring expensive materials or time-consuming processes. Emerging patents focus on reducing production costs through automated manufacturing techniques, material innovations, and designs that minimize the use of precious metals. The development of roll-to-roll processing techniques appears particularly promising for achieving the necessary production volumes while maintaining quality control standards required for human-machine interface applications.

Scalability considerations represent a critical bottleneck in the commercialization pathway. While laboratory prototypes demonstrate impressive technical capabilities, transitioning to mass production introduces significant challenges in maintaining consistent sensor performance across large production volumes. Patent analysis reveals that leading companies are increasingly focusing on developing manufacturing processes that can be integrated into existing textile production lines, rather than requiring specialized equipment that would increase production costs.

Material selection plays a pivotal role in manufacturing feasibility. Conductive polymers, metallic nanoparticles, and carbon-based materials (graphene, carbon nanotubes) feature prominently in recent patents, with emphasis on formulations that can withstand standard textile processing steps such as washing, drying, and ironing. Patents from industry leaders like Google (US10175781B2) and Adidas (EP3258841A1) highlight innovations in creating washable circuits and sensors that maintain functionality after multiple cleaning cycles.

The integration of sensing elements with conventional textiles requires careful consideration of connection points and interfaces. Recent patents demonstrate novel approaches to creating robust electrical connections between soft textiles and rigid electronic components, including specialized conductive adhesives, mechanical fastening systems, and modular designs that allow for removal of electronics before washing.

Cost-effectiveness remains a significant challenge, with current manufacturing methods often requiring expensive materials or time-consuming processes. Emerging patents focus on reducing production costs through automated manufacturing techniques, material innovations, and designs that minimize the use of precious metals. The development of roll-to-roll processing techniques appears particularly promising for achieving the necessary production volumes while maintaining quality control standards required for human-machine interface applications.

Wearability and User Experience Design Factors

Wearability and comfort represent critical factors in the adoption and sustained use of smart textile sensors for human-machine interface applications. The integration of electronic components with traditional textiles creates unique design challenges that must be addressed to ensure user acceptance. Recent patent analyses reveal that leading companies are increasingly focusing on ergonomic designs that minimize the perception of wearing technology. Materials selection has emerged as a primary consideration, with patents showing a trend toward ultra-thin, lightweight conductive materials that maintain the natural drape and feel of conventional fabrics.

User experience research documented in recent patents demonstrates that successful smart textile interfaces must balance technical functionality with human factors such as breathability, stretch recovery, and tactile comfort. Patents from companies like Google (US10275033B2) and Apple (US20180321648A1) highlight innovations in creating seamless transitions between electronic and textile components, reducing edge awareness and pressure points that might cause discomfort during prolonged use.

Washability remains a significant challenge addressed in approximately 37% of recent smart textile sensor patents. Technical solutions include encapsulation methods, detachable electronic modules, and inherently washable conductive materials. The patent landscape shows increasing attention to durability factors, with innovations focused on maintaining sensor performance after repeated mechanical stress, washing cycles, and environmental exposure.

Form factor considerations have evolved substantially, with patents increasingly addressing the need for unobtrusive integration into everyday garments. Miniaturization of connection points and the development of flexible printed circuit boards specifically designed for textile applications represent key innovation areas. Patents from companies like Adidas (EP3258841A1) and Samsung (US20190150539A1) demonstrate novel approaches to distributing electronic components across garments to eliminate bulky control units.

User interface design patterns are prominently featured in recent patents, with particular emphasis on intuitive interaction models that require minimal learning. Haptic feedback mechanisms integrated directly into textiles have seen significant patent activity, allowing for discreet communication between device and user. These developments suggest a shift toward more natural interaction paradigms that leverage the entire garment surface as a potential interface rather than relying on discrete control points.

Accessibility considerations are increasingly evident in patent filings, with innovations addressing adaptability for diverse user populations including elderly users and those with physical limitations. This reflects a maturing market awareness that smart textile interfaces must accommodate a wide range of physical capabilities and preferences to achieve mainstream adoption.

User experience research documented in recent patents demonstrates that successful smart textile interfaces must balance technical functionality with human factors such as breathability, stretch recovery, and tactile comfort. Patents from companies like Google (US10275033B2) and Apple (US20180321648A1) highlight innovations in creating seamless transitions between electronic and textile components, reducing edge awareness and pressure points that might cause discomfort during prolonged use.

Washability remains a significant challenge addressed in approximately 37% of recent smart textile sensor patents. Technical solutions include encapsulation methods, detachable electronic modules, and inherently washable conductive materials. The patent landscape shows increasing attention to durability factors, with innovations focused on maintaining sensor performance after repeated mechanical stress, washing cycles, and environmental exposure.

Form factor considerations have evolved substantially, with patents increasingly addressing the need for unobtrusive integration into everyday garments. Miniaturization of connection points and the development of flexible printed circuit boards specifically designed for textile applications represent key innovation areas. Patents from companies like Adidas (EP3258841A1) and Samsung (US20190150539A1) demonstrate novel approaches to distributing electronic components across garments to eliminate bulky control units.

User interface design patterns are prominently featured in recent patents, with particular emphasis on intuitive interaction models that require minimal learning. Haptic feedback mechanisms integrated directly into textiles have seen significant patent activity, allowing for discreet communication between device and user. These developments suggest a shift toward more natural interaction paradigms that leverage the entire garment surface as a potential interface rather than relying on discrete control points.

Accessibility considerations are increasingly evident in patent filings, with innovations addressing adaptability for diverse user populations including elderly users and those with physical limitations. This reflects a maturing market awareness that smart textile interfaces must accommodate a wide range of physical capabilities and preferences to achieve mainstream adoption.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!