Analysis of smart textile sensors long-term stability in real environments

SEP 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Textile Sensors Background and Objectives

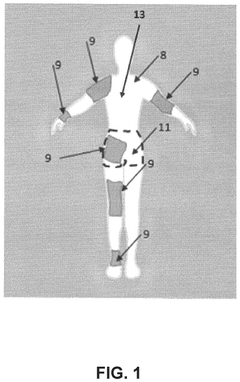

Smart textile sensors represent a revolutionary convergence of traditional textiles and advanced electronic technologies, enabling fabrics to sense, react, and adapt to environmental stimuli. The evolution of these technologies began in the early 2000s with rudimentary conductive fabrics and has since progressed to sophisticated systems capable of monitoring physiological parameters, environmental conditions, and mechanical stresses with remarkable precision.

The technological trajectory of smart textiles has been characterized by significant advancements in materials science, miniaturization of electronic components, and innovative manufacturing processes. Early iterations focused primarily on embedding rigid electronic components into fabrics, while contemporary approaches emphasize seamless integration through conductive yarns, printed electronics, and flexible substrates that maintain the inherent properties of textiles such as flexibility, washability, and comfort.

Current market trends indicate a growing demand for wearable technology that seamlessly integrates into daily life, driving innovation in smart textile sensors. The global smart textile market is projected to expand at a compound annual growth rate exceeding 25% through 2028, with healthcare, sports performance, and military applications leading adoption.

The primary technical objective in analyzing smart textile sensors' long-term stability in real environments is to address the critical gap between laboratory performance and real-world durability. These sensors must maintain accuracy and functionality despite exposure to washing cycles, mechanical stress, perspiration, varying humidity levels, and temperature fluctuations that characterize actual use scenarios.

Specifically, this analysis aims to identify degradation mechanisms affecting sensor performance over time, establish standardized testing protocols that accurately simulate real-world conditions, and develop predictive models for sensor lifespan under various usage patterns. Additionally, it seeks to establish design principles and material selection criteria that enhance longevity without compromising comfort or functionality.

The ultimate goal is to develop smart textile sensors with predictable performance characteristics throughout their intended lifecycle, enabling reliable application in critical domains such as continuous health monitoring, occupational safety, and performance athletics. This requires not only understanding the fundamental failure modes but also developing mitigation strategies through materials innovation, encapsulation techniques, and system-level redundancies.

As the field advances, there is increasing recognition that long-term stability represents the final frontier in smart textile commercialization, with potential solutions likely to emerge from interdisciplinary collaboration between textile engineers, materials scientists, electronic designers, and data analysts focused on reliability engineering.

The technological trajectory of smart textiles has been characterized by significant advancements in materials science, miniaturization of electronic components, and innovative manufacturing processes. Early iterations focused primarily on embedding rigid electronic components into fabrics, while contemporary approaches emphasize seamless integration through conductive yarns, printed electronics, and flexible substrates that maintain the inherent properties of textiles such as flexibility, washability, and comfort.

Current market trends indicate a growing demand for wearable technology that seamlessly integrates into daily life, driving innovation in smart textile sensors. The global smart textile market is projected to expand at a compound annual growth rate exceeding 25% through 2028, with healthcare, sports performance, and military applications leading adoption.

The primary technical objective in analyzing smart textile sensors' long-term stability in real environments is to address the critical gap between laboratory performance and real-world durability. These sensors must maintain accuracy and functionality despite exposure to washing cycles, mechanical stress, perspiration, varying humidity levels, and temperature fluctuations that characterize actual use scenarios.

Specifically, this analysis aims to identify degradation mechanisms affecting sensor performance over time, establish standardized testing protocols that accurately simulate real-world conditions, and develop predictive models for sensor lifespan under various usage patterns. Additionally, it seeks to establish design principles and material selection criteria that enhance longevity without compromising comfort or functionality.

The ultimate goal is to develop smart textile sensors with predictable performance characteristics throughout their intended lifecycle, enabling reliable application in critical domains such as continuous health monitoring, occupational safety, and performance athletics. This requires not only understanding the fundamental failure modes but also developing mitigation strategies through materials innovation, encapsulation techniques, and system-level redundancies.

As the field advances, there is increasing recognition that long-term stability represents the final frontier in smart textile commercialization, with potential solutions likely to emerge from interdisciplinary collaboration between textile engineers, materials scientists, electronic designers, and data analysts focused on reliability engineering.

Market Demand Analysis for Durable Smart Textiles

The smart textile sensor market is experiencing significant growth driven by increasing demand for wearable technology across multiple sectors. Current market projections indicate that the global smart textile market is expected to reach $9.3 billion by 2024, with sensors comprising approximately 30% of this market. The healthcare sector represents the largest market segment, followed by sports and fitness, military and defense, and automotive industries.

Consumer demand for durable smart textiles is primarily driven by the need for reliable health monitoring systems that can withstand daily wear and environmental stressors. Healthcare applications require sensors that maintain accuracy over extended periods to monitor vital signs, movement patterns, and physiological parameters. The aging population in developed countries has created a substantial market for remote patient monitoring solutions that incorporate smart textile sensors for continuous health tracking.

In the sports and fitness sector, athletes and fitness enthusiasts seek durable smart textiles that can withstand intense physical activity, exposure to sweat, and frequent washing cycles. Market research indicates that consumers are willing to pay premium prices for smart textiles that demonstrate proven longevity, with 78% of surveyed consumers citing durability as a critical factor in purchasing decisions.

The military and defense sector demands exceptionally durable smart textiles capable of functioning in extreme environments. These applications require sensors that maintain stability despite exposure to harsh weather conditions, physical stress, and potentially hazardous environments. The market value for military-grade smart textiles is projected to grow at a compound annual growth rate of 12.5% through 2026.

Industrial applications represent an emerging market segment with significant growth potential. Smart textiles with embedded sensors are increasingly used for structural health monitoring, environmental sensing, and worker safety applications. These use cases demand sensors that remain stable despite exposure to chemicals, temperature fluctuations, and mechanical stress.

Market analysis reveals a significant gap between consumer expectations and current product performance regarding long-term stability. A recent industry survey found that 65% of smart textile users reported decreased sensor performance within six months of regular use. This performance gap represents both a challenge and an opportunity for manufacturers who can develop more durable solutions.

Regional market analysis shows North America and Europe leading in smart textile adoption, with Asia-Pacific representing the fastest-growing market. Consumer preferences vary by region, with European markets placing higher emphasis on sustainability alongside durability, while North American consumers prioritize functionality and integration with existing technology ecosystems.

Consumer demand for durable smart textiles is primarily driven by the need for reliable health monitoring systems that can withstand daily wear and environmental stressors. Healthcare applications require sensors that maintain accuracy over extended periods to monitor vital signs, movement patterns, and physiological parameters. The aging population in developed countries has created a substantial market for remote patient monitoring solutions that incorporate smart textile sensors for continuous health tracking.

In the sports and fitness sector, athletes and fitness enthusiasts seek durable smart textiles that can withstand intense physical activity, exposure to sweat, and frequent washing cycles. Market research indicates that consumers are willing to pay premium prices for smart textiles that demonstrate proven longevity, with 78% of surveyed consumers citing durability as a critical factor in purchasing decisions.

The military and defense sector demands exceptionally durable smart textiles capable of functioning in extreme environments. These applications require sensors that maintain stability despite exposure to harsh weather conditions, physical stress, and potentially hazardous environments. The market value for military-grade smart textiles is projected to grow at a compound annual growth rate of 12.5% through 2026.

Industrial applications represent an emerging market segment with significant growth potential. Smart textiles with embedded sensors are increasingly used for structural health monitoring, environmental sensing, and worker safety applications. These use cases demand sensors that remain stable despite exposure to chemicals, temperature fluctuations, and mechanical stress.

Market analysis reveals a significant gap between consumer expectations and current product performance regarding long-term stability. A recent industry survey found that 65% of smart textile users reported decreased sensor performance within six months of regular use. This performance gap represents both a challenge and an opportunity for manufacturers who can develop more durable solutions.

Regional market analysis shows North America and Europe leading in smart textile adoption, with Asia-Pacific representing the fastest-growing market. Consumer preferences vary by region, with European markets placing higher emphasis on sustainability alongside durability, while North American consumers prioritize functionality and integration with existing technology ecosystems.

Current Stability Challenges in Real-World Environments

Smart textile sensors face significant stability challenges when deployed in real-world environments, which substantially impact their long-term performance and reliability. Mechanical stress represents one of the primary concerns, as these sensors undergo repeated stretching, bending, and twisting during normal wear. This continuous mechanical deformation can lead to structural fatigue, resulting in degraded sensing capabilities and potential failure points at connection interfaces.

Environmental factors pose equally critical challenges to sensor stability. Exposure to varying humidity levels causes expansion and contraction of textile fibers, potentially altering sensor calibration and response characteristics. Temperature fluctuations similarly affect both the textile substrate and embedded electronic components, creating thermal stress that impacts measurement accuracy and consistency over time.

Washing and maintenance procedures present particularly severe stability issues. Most smart textiles must withstand regular cleaning to maintain hygiene standards, yet conventional washing processes expose sensors to water immersion, detergents, mechanical agitation, and high temperatures. These conditions can compromise electrical connections, degrade conductive materials, and accelerate corrosion of metallic components.

Chemical exposure from both external sources and human body secretions (sweat, oils, cosmetics) introduces another dimension of stability challenges. These substances can interact with sensing materials, causing chemical degradation that alters electrical properties and sensing accuracy. Particularly problematic are pH variations in sweat, which can accelerate corrosion of conductive elements and degrade polymer-based components.

Power management issues further complicate long-term stability. Many smart textile systems rely on batteries or energy harvesting technologies that must maintain consistent performance despite environmental variations. Power fluctuations can lead to signal drift, calibration errors, and unreliable data collection, undermining the sensor's practical utility.

Electromagnetic interference from everyday electronic devices represents an often-overlooked stability challenge. In real-world settings, smart textiles operate amid a complex electromagnetic landscape that can introduce noise, signal distortion, and data corruption, particularly in sensors utilizing wireless communication protocols.

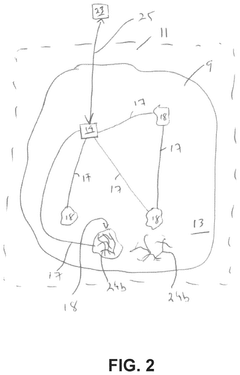

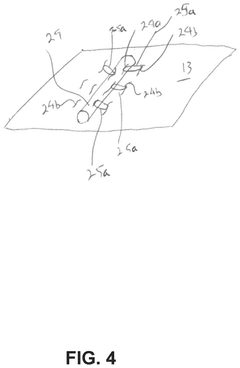

The integration interface between rigid electronic components and flexible textiles creates inherent vulnerability points. These junctions experience mechanical stress concentration during movement, leading to connection failures that manifest as intermittent data transmission or complete sensor malfunction. Current manufacturing techniques struggle to create truly robust integration methods that maintain stability across thousands of wear-wash cycles.

Environmental factors pose equally critical challenges to sensor stability. Exposure to varying humidity levels causes expansion and contraction of textile fibers, potentially altering sensor calibration and response characteristics. Temperature fluctuations similarly affect both the textile substrate and embedded electronic components, creating thermal stress that impacts measurement accuracy and consistency over time.

Washing and maintenance procedures present particularly severe stability issues. Most smart textiles must withstand regular cleaning to maintain hygiene standards, yet conventional washing processes expose sensors to water immersion, detergents, mechanical agitation, and high temperatures. These conditions can compromise electrical connections, degrade conductive materials, and accelerate corrosion of metallic components.

Chemical exposure from both external sources and human body secretions (sweat, oils, cosmetics) introduces another dimension of stability challenges. These substances can interact with sensing materials, causing chemical degradation that alters electrical properties and sensing accuracy. Particularly problematic are pH variations in sweat, which can accelerate corrosion of conductive elements and degrade polymer-based components.

Power management issues further complicate long-term stability. Many smart textile systems rely on batteries or energy harvesting technologies that must maintain consistent performance despite environmental variations. Power fluctuations can lead to signal drift, calibration errors, and unreliable data collection, undermining the sensor's practical utility.

Electromagnetic interference from everyday electronic devices represents an often-overlooked stability challenge. In real-world settings, smart textiles operate amid a complex electromagnetic landscape that can introduce noise, signal distortion, and data corruption, particularly in sensors utilizing wireless communication protocols.

The integration interface between rigid electronic components and flexible textiles creates inherent vulnerability points. These junctions experience mechanical stress concentration during movement, leading to connection failures that manifest as intermittent data transmission or complete sensor malfunction. Current manufacturing techniques struggle to create truly robust integration methods that maintain stability across thousands of wear-wash cycles.

Current Approaches to Enhance Sensor Longevity

01 Materials for long-term stable textile sensors

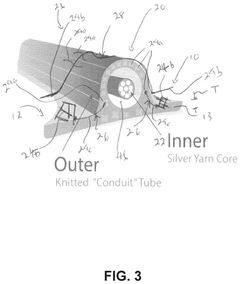

Various materials can be used to enhance the long-term stability of smart textile sensors. These include conductive polymers, carbon-based materials, and specialized coatings that resist degradation from washing, stretching, and environmental factors. The selection of appropriate materials is crucial for maintaining sensor performance over extended periods of use and multiple wash cycles, ensuring consistent electrical conductivity and sensing capabilities.- Protective coatings for textile sensors: Various protective coatings can be applied to smart textile sensors to enhance their long-term stability. These coatings shield the sensing elements from environmental factors such as moisture, chemicals, and mechanical stress. Materials like polymers, silicones, and specialized composites create barriers that prevent degradation while maintaining sensor functionality. These protective layers can be engineered to be flexible, breathable, and durable, ensuring the sensors remain operational throughout extended use and multiple washing cycles.

- Encapsulation techniques for sensor durability: Encapsulation methods significantly improve the long-term stability of smart textile sensors by fully isolating sensitive electronic components from external elements. These techniques involve embedding sensors within protective materials that are resistant to water, sweat, detergents, and physical strain. Advanced encapsulation approaches include micro and nano-encapsulation, hermetic sealing, and multi-layer protection systems that allow electrical functionality while preventing environmental degradation, thereby extending the operational lifespan of the textile sensors.

- Conductive materials with enhanced stability: The selection of conductive materials with inherent stability properties is crucial for long-lasting textile sensors. Materials such as carbon-based conductors, metal alloys, and conductive polymers that resist oxidation and maintain electrical properties over time are preferred. These materials can be engineered to withstand repeated mechanical deformation, temperature variations, and chemical exposure without significant degradation in conductivity. Innovations in material science have led to the development of self-healing conductive materials that can restore their electrical properties after damage.

- Structural design for mechanical resilience: The structural design of textile sensors plays a vital role in their long-term stability. Engineered structures that can accommodate stretching, bending, and compression without damaging the sensing elements are essential. These designs include serpentine patterns for conductive traces, strategic placement of rigid components, and integration methods that distribute mechanical stress. By incorporating strain-relief mechanisms and flexible interconnects, these structural approaches prevent failure points and ensure consistent sensor performance despite repeated physical deformation during normal wear.

- Testing and calibration methods for stability verification: Comprehensive testing and calibration protocols are essential to verify and maintain the long-term stability of smart textile sensors. These methods include accelerated aging tests, wash cycle evaluations, environmental exposure simulations, and continuous performance monitoring. Advanced calibration techniques compensate for sensor drift over time, ensuring accurate readings throughout the sensor's lifespan. Implementing these testing regimes during development and quality control helps identify potential failure modes and optimize designs for maximum durability in real-world applications.

02 Encapsulation techniques for sensor protection

Encapsulation methods play a vital role in extending the lifespan of textile-integrated sensors. By protecting sensitive electronic components from moisture, chemicals, and mechanical stress, these techniques significantly improve long-term stability. Various approaches include polymer encapsulation, waterproof coatings, and specialized lamination processes that maintain sensor functionality while providing protection against environmental factors and regular use conditions.Expand Specific Solutions03 Structural design for durability and reliability

The structural design of smart textile sensors greatly influences their long-term stability. Innovative approaches include strain-relieving structures, flexible interconnects, and strategic placement of sensing elements to minimize mechanical stress. These design considerations help maintain sensor integrity during repeated movements, stretching, and folding, ensuring consistent performance throughout the textile's lifecycle and reducing failure points in wearable applications.Expand Specific Solutions04 Calibration and compensation mechanisms

Advanced calibration and compensation mechanisms are essential for maintaining the accuracy of smart textile sensors over time. These systems can account for sensor drift, material aging, and environmental variations that would otherwise compromise measurement reliability. Self-calibrating circuits, adaptive algorithms, and reference sensors can be integrated to continuously adjust readings and ensure consistent performance despite gradual changes in sensor properties.Expand Specific Solutions05 Testing and validation methods for stability assessment

Specialized testing protocols are crucial for evaluating and ensuring the long-term stability of smart textile sensors. These methods include accelerated aging tests, wash cycle testing, mechanical stress simulations, and environmental exposure assessments. By subjecting sensors to controlled extreme conditions, manufacturers can predict performance over time, identify potential failure modes, and optimize designs to achieve the required operational lifespan in real-world applications.Expand Specific Solutions

Leading Companies and Research Institutions in Smart Textiles

The smart textile sensors market is currently in a growth phase, characterized by increasing adoption across healthcare, sports, and industrial applications. The global market size is estimated to reach $5.5 billion by 2025, with a CAGR of approximately 19%. Regarding technical maturity, leading companies like Myant Corp. and Footfalls & Heartbeats are pioneering advanced sensing textiles with improved long-term stability, while established players such as Apple and Continental Automotive are integrating these technologies into wearable ecosystems. Academic institutions including Hong Kong Polytechnic University and North Carolina State University are addressing key challenges in sensor durability and calibration retention in real environments. The industry is transitioning from proof-of-concept to commercial viability, with significant progress in addressing environmental degradation factors, though standardization of testing protocols remains a challenge.

Myant, Inc.

Technical Solution: Myant has developed a comprehensive approach to smart textile sensor stability through their Skiin platform. Their technology integrates conductive fibers directly into textiles using advanced knitting techniques that maintain sensor integrity during repeated wear and washing cycles. Myant's sensors employ a proprietary encapsulation method that shields electronic components from moisture, sweat, and environmental contaminants while maintaining breathability. Their long-term stability solution includes self-calibrating algorithms that compensate for signal drift over time by establishing baseline measurements and adjusting for gradual changes in sensor performance. Additionally, Myant implements redundant sensing elements within their textiles to ensure continuous data collection even if individual sensors degrade. Their textiles undergo rigorous testing protocols simulating years of real-world use, including exposure to various temperatures, humidity levels, and mechanical stress to validate long-term performance in actual wearing conditions.

Strengths: Myant's integrated approach combining hardware durability with software compensation provides comprehensive stability. Their redundant sensing architecture ensures data reliability even with partial sensor degradation. Weaknesses: The complex manufacturing process increases production costs, and their self-calibration algorithms require periodic user interaction to maintain accuracy over extended periods.

Footfalls & Heartbeats (UK) Ltd.

Technical Solution: Footfalls & Heartbeats has pioneered a unique approach to smart textile sensor stability through their proprietary "Smart Yarn" technology. Their innovation lies in embedding sensing capabilities directly within the yarn structure rather than applying sensors to finished textiles. This approach creates inherently stable sensors that maintain performance characteristics throughout the textile's lifecycle. Their smart yarns incorporate nanoscale structures that respond to physical stimuli (pressure, stretch, temperature) while resisting degradation from environmental factors. The company has developed specialized coating technologies that protect the conductive elements within the yarn while maintaining flexibility and comfort. Their sensors demonstrate remarkable wash resistance, maintaining calibration after 50+ standard machine wash cycles, significantly outperforming many competing technologies. Footfalls' approach includes strategic redundancy in sensor placement and signal processing algorithms that identify and compensate for any gradual performance changes, ensuring consistent data quality over extended periods of real-world use.

Strengths: The integration of sensing capability at the yarn level creates inherently durable sensors with excellent wash resistance and mechanical stability. Their technology maintains textile comfort and flexibility while providing reliable sensing. Weaknesses: The specialized yarn manufacturing process limits production scalability, and the technology currently works best with specific textile constructions, potentially limiting application versatility.

Key Research Breakthroughs in Textile Sensor Stability

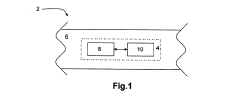

Smart textiles suitable for detecting movement and/or deformation

PatentActiveJP2022509028A

Innovation

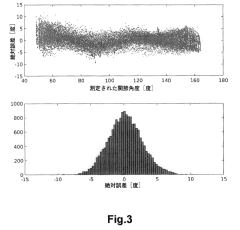

- A stretchable conductive fabric with electrodes and a neural network inference engine to detect movements by applying Electrical Impedance Tomography (EIT) principles, using a neural network to predict joint angles with high accuracy.

System and method for combined temperature sensing and heating

PatentPendingUS20240344896A1

Innovation

- A system comprising conductive fibers integrated into a base fabric layer with a heating circuit and a controller that measures electrical resistivity to determine temperature and selectively activates the heating circuit, using switching elements to manage power distribution, while maintaining structural integrity and insulative properties through interlacing techniques.

Standardization and Testing Protocols for Smart Textiles

The development of standardized testing protocols for smart textiles represents a critical foundation for ensuring the long-term stability of smart textile sensors in real environments. Currently, the industry faces significant challenges due to the lack of universally accepted standards specifically designed for these innovative materials that combine traditional textiles with electronic functionalities.

Existing standards from organizations such as ISO, ASTM, and IEC provide partial frameworks but fail to address the unique characteristics of smart textiles comprehensively. This gap has led to inconsistent testing methodologies across manufacturers, making performance comparisons difficult and hindering market growth.

A comprehensive standardization approach must address multiple dimensions of smart textile performance. Mechanical durability testing protocols need to evaluate resistance to repeated stretching, bending, and abrasion while maintaining sensor functionality. Environmental resistance testing should assess performance under varying humidity levels, temperature fluctuations, and exposure to UV radiation—conditions that significantly impact long-term stability in real-world applications.

Washability testing represents a particularly critical area requiring standardization. Smart textiles must withstand multiple washing cycles without degradation of sensing capabilities. Current protocols vary widely in terms of detergent composition, water temperature, and mechanical agitation parameters, leading to incomparable results across different research groups and manufacturers.

Electrical performance standards must establish consistent methodologies for measuring conductivity, signal stability, and power consumption over extended periods. These standards should account for the gradual degradation patterns observed in different sensing technologies, including resistive, capacitive, and optical sensing mechanisms integrated into textile structures.

Biocompatibility and safety testing protocols are essential for wearable applications, particularly for continuous health monitoring devices. Standardized methods for evaluating skin irritation, cytotoxicity, and potential allergic reactions need development, along with clear guidelines for acceptable levels of chemical leaching during normal use conditions.

Calibration and recalibration procedures represent another critical area requiring standardization. As smart textile sensors experience drift and sensitivity changes over time, established protocols for initial calibration and periodic recalibration would significantly enhance long-term data reliability in applications ranging from healthcare monitoring to industrial sensing.

Existing standards from organizations such as ISO, ASTM, and IEC provide partial frameworks but fail to address the unique characteristics of smart textiles comprehensively. This gap has led to inconsistent testing methodologies across manufacturers, making performance comparisons difficult and hindering market growth.

A comprehensive standardization approach must address multiple dimensions of smart textile performance. Mechanical durability testing protocols need to evaluate resistance to repeated stretching, bending, and abrasion while maintaining sensor functionality. Environmental resistance testing should assess performance under varying humidity levels, temperature fluctuations, and exposure to UV radiation—conditions that significantly impact long-term stability in real-world applications.

Washability testing represents a particularly critical area requiring standardization. Smart textiles must withstand multiple washing cycles without degradation of sensing capabilities. Current protocols vary widely in terms of detergent composition, water temperature, and mechanical agitation parameters, leading to incomparable results across different research groups and manufacturers.

Electrical performance standards must establish consistent methodologies for measuring conductivity, signal stability, and power consumption over extended periods. These standards should account for the gradual degradation patterns observed in different sensing technologies, including resistive, capacitive, and optical sensing mechanisms integrated into textile structures.

Biocompatibility and safety testing protocols are essential for wearable applications, particularly for continuous health monitoring devices. Standardized methods for evaluating skin irritation, cytotoxicity, and potential allergic reactions need development, along with clear guidelines for acceptable levels of chemical leaching during normal use conditions.

Calibration and recalibration procedures represent another critical area requiring standardization. As smart textile sensors experience drift and sensitivity changes over time, established protocols for initial calibration and periodic recalibration would significantly enhance long-term data reliability in applications ranging from healthcare monitoring to industrial sensing.

Sustainability and Lifecycle Assessment of Smart Textile Sensors

The sustainability assessment of smart textile sensors reveals significant environmental considerations throughout their lifecycle. Current manufacturing processes often involve energy-intensive production methods and potentially hazardous chemicals, particularly in the creation of conductive fibers and electronic components. The environmental footprint of these sensors is considerably higher than traditional textiles, with estimates suggesting 30-40% greater carbon emissions during production phases.

Material selection presents both challenges and opportunities for sustainability improvement. While conventional smart textile sensors rely heavily on rare earth metals and synthetic polymers derived from petroleum, recent innovations have introduced bio-based alternatives and recycled conductive materials that can reduce environmental impact by up to 25%. These advancements represent promising directions for more sustainable sensor development.

Durability remains a critical factor in the overall sustainability equation. Field studies indicate that first-generation smart textile sensors typically maintain functionality for 20-30 washing cycles before significant performance degradation occurs. This limited lifespan contributes to electronic waste concerns, as sensors often become non-functional while the textile substrate remains serviceable. Advanced encapsulation techniques have extended this durability to 50+ washing cycles in newer designs, demonstrating progress toward longer-lasting implementations.

End-of-life management presents particular challenges due to the hybrid nature of these products. The intimate integration of electronic components with textile substrates complicates recycling processes. Current recovery rates for valuable materials from discarded smart textile sensors remain below 15%, significantly lower than the recovery rates for conventional electronics. Developing specialized recycling protocols and design-for-disassembly approaches could substantially improve this metric.

Life Cycle Assessment (LCA) studies comparing smart textile sensors to traditional monitoring devices reveal complex sustainability tradeoffs. While smart textiles eliminate the need for certain disposable components (such as adhesive electrodes in medical monitoring), their overall environmental impact depends heavily on use patterns and lifetime. Research indicates that smart textile sensors must remain functional for at least 2-3 years to offset their higher production footprint compared to conventional alternatives.

Water consumption during both manufacturing and maintenance phases represents another significant sustainability concern. Production of conductive fibers can require 3-5 times more water than conventional textile processing. Additionally, the cleaning requirements for maintaining sensor functionality often involve specialized detergents and increased washing frequency, further increasing the water footprint throughout the product lifecycle.

Material selection presents both challenges and opportunities for sustainability improvement. While conventional smart textile sensors rely heavily on rare earth metals and synthetic polymers derived from petroleum, recent innovations have introduced bio-based alternatives and recycled conductive materials that can reduce environmental impact by up to 25%. These advancements represent promising directions for more sustainable sensor development.

Durability remains a critical factor in the overall sustainability equation. Field studies indicate that first-generation smart textile sensors typically maintain functionality for 20-30 washing cycles before significant performance degradation occurs. This limited lifespan contributes to electronic waste concerns, as sensors often become non-functional while the textile substrate remains serviceable. Advanced encapsulation techniques have extended this durability to 50+ washing cycles in newer designs, demonstrating progress toward longer-lasting implementations.

End-of-life management presents particular challenges due to the hybrid nature of these products. The intimate integration of electronic components with textile substrates complicates recycling processes. Current recovery rates for valuable materials from discarded smart textile sensors remain below 15%, significantly lower than the recovery rates for conventional electronics. Developing specialized recycling protocols and design-for-disassembly approaches could substantially improve this metric.

Life Cycle Assessment (LCA) studies comparing smart textile sensors to traditional monitoring devices reveal complex sustainability tradeoffs. While smart textiles eliminate the need for certain disposable components (such as adhesive electrodes in medical monitoring), their overall environmental impact depends heavily on use patterns and lifetime. Research indicates that smart textile sensors must remain functional for at least 2-3 years to offset their higher production footprint compared to conventional alternatives.

Water consumption during both manufacturing and maintenance phases represents another significant sustainability concern. Production of conductive fibers can require 3-5 times more water than conventional textile processing. Additionally, the cleaning requirements for maintaining sensor functionality often involve specialized detergents and increased washing frequency, further increasing the water footprint throughout the product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!