Analyzing environmental impacts of submersible pumps.

JUL 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Submersible Pump Tech Evolution and Objectives

Submersible pumps have undergone significant technological evolution since their inception in the early 20th century. Initially designed for dewatering applications in mines, these pumps have evolved to serve a wide range of industries, including oil and gas, wastewater treatment, and agriculture. The primary objective of submersible pump technology has been to enhance efficiency, reliability, and environmental sustainability.

The development of submersible pumps has been driven by the need for more robust and versatile pumping solutions capable of operating in challenging underwater environments. Early models were limited in their capabilities and durability, but advancements in materials science and engineering have led to pumps that can withstand harsh conditions, including corrosive fluids and high pressures.

A key milestone in the evolution of submersible pumps was the introduction of variable frequency drives (VFDs) in the 1980s. This technology allowed for precise control of pump speed, resulting in significant energy savings and improved operational flexibility. The integration of VFDs marked a shift towards more energy-efficient and environmentally conscious pump designs.

In recent years, the focus has shifted towards minimizing the environmental impact of submersible pumps. This has led to the development of oil-free designs that eliminate the risk of oil leakage into water bodies. Additionally, manufacturers have been exploring the use of biodegradable lubricants and environmentally friendly materials in pump construction.

The advent of smart technologies has ushered in a new era for submersible pumps. Internet of Things (IoT) integration and advanced sensors now allow for real-time monitoring and predictive maintenance, reducing downtime and extending pump lifespan. These innovations contribute to more efficient operations and reduced environmental impact through optimized energy consumption and timely maintenance.

Current technological objectives in the field of submersible pumps include further improvements in energy efficiency, the development of more compact and powerful designs, and the integration of advanced materials to enhance durability and reduce environmental impact. There is also a growing emphasis on creating pumps that can operate effectively in extreme conditions, such as ultra-deep water or highly abrasive environments.

Looking forward, the industry is exploring the potential of renewable energy integration, with solar-powered submersible pumps gaining traction in remote locations. Research is also underway to develop pumps with self-cleaning mechanisms to reduce maintenance requirements and improve long-term performance in challenging environments.

As environmental concerns continue to shape technological development, the future of submersible pump technology is likely to focus on creating more sustainable, efficient, and intelligent pumping solutions that minimize ecological impact while meeting the growing demands of various industries.

The development of submersible pumps has been driven by the need for more robust and versatile pumping solutions capable of operating in challenging underwater environments. Early models were limited in their capabilities and durability, but advancements in materials science and engineering have led to pumps that can withstand harsh conditions, including corrosive fluids and high pressures.

A key milestone in the evolution of submersible pumps was the introduction of variable frequency drives (VFDs) in the 1980s. This technology allowed for precise control of pump speed, resulting in significant energy savings and improved operational flexibility. The integration of VFDs marked a shift towards more energy-efficient and environmentally conscious pump designs.

In recent years, the focus has shifted towards minimizing the environmental impact of submersible pumps. This has led to the development of oil-free designs that eliminate the risk of oil leakage into water bodies. Additionally, manufacturers have been exploring the use of biodegradable lubricants and environmentally friendly materials in pump construction.

The advent of smart technologies has ushered in a new era for submersible pumps. Internet of Things (IoT) integration and advanced sensors now allow for real-time monitoring and predictive maintenance, reducing downtime and extending pump lifespan. These innovations contribute to more efficient operations and reduced environmental impact through optimized energy consumption and timely maintenance.

Current technological objectives in the field of submersible pumps include further improvements in energy efficiency, the development of more compact and powerful designs, and the integration of advanced materials to enhance durability and reduce environmental impact. There is also a growing emphasis on creating pumps that can operate effectively in extreme conditions, such as ultra-deep water or highly abrasive environments.

Looking forward, the industry is exploring the potential of renewable energy integration, with solar-powered submersible pumps gaining traction in remote locations. Research is also underway to develop pumps with self-cleaning mechanisms to reduce maintenance requirements and improve long-term performance in challenging environments.

As environmental concerns continue to shape technological development, the future of submersible pump technology is likely to focus on creating more sustainable, efficient, and intelligent pumping solutions that minimize ecological impact while meeting the growing demands of various industries.

Market Demand for Eco-Friendly Submersible Pumps

The market demand for eco-friendly submersible pumps has been steadily increasing in recent years, driven by growing environmental concerns and stricter regulations on water usage and energy efficiency. This trend is particularly evident in industries such as agriculture, mining, and wastewater treatment, where submersible pumps are extensively used.

In the agricultural sector, farmers are increasingly seeking sustainable irrigation solutions that minimize water waste and reduce energy consumption. Eco-friendly submersible pumps offer improved efficiency and lower operating costs, making them an attractive option for large-scale farming operations. The market for these pumps in agriculture is expected to grow significantly as water scarcity becomes a more pressing issue in many regions.

The mining industry, traditionally known for its high environmental impact, is also showing a growing interest in eco-friendly submersible pumps. These pumps are crucial for dewatering operations and managing mine water. As mining companies face increasing pressure to reduce their environmental footprint, the demand for more sustainable pump solutions is rising.

In the wastewater treatment sector, there is a strong push towards energy-efficient and environmentally friendly equipment. Eco-friendly submersible pumps play a vital role in reducing the overall energy consumption of treatment plants while ensuring effective water management. This sector represents a substantial market opportunity for manufacturers of green pump technologies.

The construction industry is another significant market for eco-friendly submersible pumps. With the rise of green building practices and sustainable urban development, there is an increasing demand for pumps that can efficiently manage groundwater and stormwater while minimizing environmental impact.

Municipal water management systems are also driving demand for eco-friendly submersible pumps. Cities and towns are investing in upgrading their water infrastructure to improve efficiency and reduce environmental impact. This includes the adoption of smart water management systems that incorporate energy-efficient pumps.

The market for eco-friendly submersible pumps is not limited to specific regions but is growing globally. Developed countries are focusing on replacing older, less efficient systems, while developing nations are increasingly incorporating sustainable technologies in their expanding infrastructure projects.

Manufacturers are responding to this market demand by developing innovative pump designs that offer higher efficiency, lower energy consumption, and reduced environmental impact. Features such as variable speed drives, advanced materials for improved durability, and smart monitoring systems are becoming standard in eco-friendly pump models.

In the agricultural sector, farmers are increasingly seeking sustainable irrigation solutions that minimize water waste and reduce energy consumption. Eco-friendly submersible pumps offer improved efficiency and lower operating costs, making them an attractive option for large-scale farming operations. The market for these pumps in agriculture is expected to grow significantly as water scarcity becomes a more pressing issue in many regions.

The mining industry, traditionally known for its high environmental impact, is also showing a growing interest in eco-friendly submersible pumps. These pumps are crucial for dewatering operations and managing mine water. As mining companies face increasing pressure to reduce their environmental footprint, the demand for more sustainable pump solutions is rising.

In the wastewater treatment sector, there is a strong push towards energy-efficient and environmentally friendly equipment. Eco-friendly submersible pumps play a vital role in reducing the overall energy consumption of treatment plants while ensuring effective water management. This sector represents a substantial market opportunity for manufacturers of green pump technologies.

The construction industry is another significant market for eco-friendly submersible pumps. With the rise of green building practices and sustainable urban development, there is an increasing demand for pumps that can efficiently manage groundwater and stormwater while minimizing environmental impact.

Municipal water management systems are also driving demand for eco-friendly submersible pumps. Cities and towns are investing in upgrading their water infrastructure to improve efficiency and reduce environmental impact. This includes the adoption of smart water management systems that incorporate energy-efficient pumps.

The market for eco-friendly submersible pumps is not limited to specific regions but is growing globally. Developed countries are focusing on replacing older, less efficient systems, while developing nations are increasingly incorporating sustainable technologies in their expanding infrastructure projects.

Manufacturers are responding to this market demand by developing innovative pump designs that offer higher efficiency, lower energy consumption, and reduced environmental impact. Features such as variable speed drives, advanced materials for improved durability, and smart monitoring systems are becoming standard in eco-friendly pump models.

Environmental Challenges in Submersible Pump Usage

The use of submersible pumps in various industries has raised significant environmental concerns, particularly regarding their impact on aquatic ecosystems and water resources. One of the primary challenges is the potential for habitat disruption and biodiversity loss. When submersible pumps are installed in natural water bodies, they can alter the physical environment, disturbing sediment and potentially damaging aquatic vegetation. This disturbance can lead to the displacement of native species and the creation of conditions favorable for invasive species.

Water quality degradation is another critical environmental challenge associated with submersible pump usage. The operation of these pumps can result in increased turbidity due to the resuspension of sediments. This not only affects the aesthetic quality of water but also impacts aquatic life by reducing light penetration and altering the chemical composition of the water. Additionally, the pumps may introduce contaminants from lubricants or other mechanical components, further compromising water quality.

Energy consumption and associated carbon emissions present a significant environmental concern. Submersible pumps, especially those used in large-scale operations such as mining or oil extraction, require substantial amounts of electricity. This high energy demand often translates to increased greenhouse gas emissions, contributing to climate change if the energy source is not renewable.

The potential for groundwater depletion is a pressing issue, particularly in regions where submersible pumps are used for irrigation or water supply. Overexploitation of aquifers can lead to long-term environmental consequences, including land subsidence, saltwater intrusion in coastal areas, and the drying up of surface water bodies connected to the groundwater system.

Noise pollution is an often-overlooked environmental challenge of submersible pump usage. While these pumps operate underwater, they can still generate significant noise that may disrupt aquatic ecosystems. This acoustic disturbance can affect the behavior and communication of marine life, potentially impacting breeding patterns and migration routes of various species.

The disposal and replacement of submersible pumps also pose environmental risks. As these devices reach the end of their operational life, they contribute to electronic waste streams. Improper disposal can lead to the leaching of hazardous materials into soil and water systems, causing long-term environmental contamination.

Lastly, the installation and maintenance of submersible pumps can lead to temporary but significant environmental disturbances. Construction activities for pump installation may involve dredging, which can release pollutants trapped in sediments and cause short-term but severe impacts on local ecosystems. Regular maintenance operations can also result in periodic disturbances to aquatic habitats.

Water quality degradation is another critical environmental challenge associated with submersible pump usage. The operation of these pumps can result in increased turbidity due to the resuspension of sediments. This not only affects the aesthetic quality of water but also impacts aquatic life by reducing light penetration and altering the chemical composition of the water. Additionally, the pumps may introduce contaminants from lubricants or other mechanical components, further compromising water quality.

Energy consumption and associated carbon emissions present a significant environmental concern. Submersible pumps, especially those used in large-scale operations such as mining or oil extraction, require substantial amounts of electricity. This high energy demand often translates to increased greenhouse gas emissions, contributing to climate change if the energy source is not renewable.

The potential for groundwater depletion is a pressing issue, particularly in regions where submersible pumps are used for irrigation or water supply. Overexploitation of aquifers can lead to long-term environmental consequences, including land subsidence, saltwater intrusion in coastal areas, and the drying up of surface water bodies connected to the groundwater system.

Noise pollution is an often-overlooked environmental challenge of submersible pump usage. While these pumps operate underwater, they can still generate significant noise that may disrupt aquatic ecosystems. This acoustic disturbance can affect the behavior and communication of marine life, potentially impacting breeding patterns and migration routes of various species.

The disposal and replacement of submersible pumps also pose environmental risks. As these devices reach the end of their operational life, they contribute to electronic waste streams. Improper disposal can lead to the leaching of hazardous materials into soil and water systems, causing long-term environmental contamination.

Lastly, the installation and maintenance of submersible pumps can lead to temporary but significant environmental disturbances. Construction activities for pump installation may involve dredging, which can release pollutants trapped in sediments and cause short-term but severe impacts on local ecosystems. Regular maintenance operations can also result in periodic disturbances to aquatic habitats.

Current Eco-Solutions for Submersible Pumps

01 Noise reduction in submersible pumps

Submersible pumps can generate significant noise pollution in aquatic environments. Innovative designs focus on reducing operational noise through improved impeller designs, acoustic insulation, and vibration dampening technologies. These advancements help minimize the impact on marine life and surrounding ecosystems.- Noise reduction in submersible pumps: Submersible pumps can generate significant noise pollution in aquatic environments. To mitigate this, various noise reduction techniques are employed, such as using sound-absorbing materials, optimizing impeller design, and implementing vibration dampening systems. These methods help minimize the impact on marine life and surrounding ecosystems.

- Energy efficiency and reduced carbon footprint: Improving the energy efficiency of submersible pumps is crucial for reducing their environmental impact. This can be achieved through advanced motor designs, variable frequency drives, and intelligent control systems. By optimizing power consumption, these pumps can significantly reduce their carbon footprint and contribute to more sustainable operations in various industries.

- Prevention of fluid contamination: Submersible pumps used in sensitive environments must prevent contamination of the surrounding fluid. This is achieved through advanced sealing technologies, corrosion-resistant materials, and leak detection systems. These features help maintain water quality and protect aquatic ecosystems from potential pollutants associated with pump operation.

- Eco-friendly materials and manufacturing processes: The use of environmentally friendly materials and sustainable manufacturing processes in submersible pump production can significantly reduce their overall environmental impact. This includes utilizing recycled materials, implementing cleaner production techniques, and designing pumps for easier disassembly and recycling at the end of their lifecycle.

- Habitat protection and restoration: Submersible pumps can be designed and operated to minimize disturbance to aquatic habitats. This includes features such as fish-friendly impellers, reduced sediment disturbance, and the ability to operate in shallow waters without damaging vegetation. Some pumps are even used in environmental restoration projects to improve water quality and support ecosystem recovery.

02 Energy efficiency and reduced carbon footprint

Developing energy-efficient submersible pumps is crucial for reducing environmental impact. Advanced motor designs, variable frequency drives, and optimized hydraulics contribute to lower energy consumption. This results in decreased greenhouse gas emissions and a smaller carbon footprint associated with pump operation.Expand Specific Solutions03 Prevention of oil and chemical leaks

Submersible pumps used in oil and gas industries pose risks of contamination through leaks. Improved sealing technologies, leak detection systems, and environmentally friendly lubricants are being developed to prevent oil and chemical spills, protecting aquatic ecosystems from potential harm.Expand Specific Solutions04 Habitat preservation and marine life protection

The installation and operation of submersible pumps can disrupt marine habitats. Designs that minimize physical footprint, reduce sediment disturbance, and incorporate fish-friendly features are being developed. These innovations aim to protect marine life and preserve the integrity of underwater ecosystems.Expand Specific Solutions05 Water quality management and filtration

Submersible pumps play a role in water treatment and environmental remediation. Advanced filtration systems integrated into pumps help remove contaminants, improve water quality, and support ecosystem restoration efforts. This technology contributes to the overall health of aquatic environments and aids in pollution control.Expand Specific Solutions

Key Players in Submersible Pump Industry

The environmental impact analysis of submersible pumps is in a mature stage, with a growing market driven by increasing awareness of water management and energy efficiency. The technology's maturity is evident in the diverse range of companies involved, from oil and gas giants like Schlumberger and Halliburton to specialized pump manufacturers such as Guangzhou Xinheng and Zhejiang Doyin. Research institutions like China Waterborne Transport Research Institute and universities such as Shandong University of Science & Technology are contributing to advancements in this field. The market is characterized by a mix of established players and innovative startups, indicating a competitive landscape with ongoing technological improvements focused on reducing environmental footprint and enhancing operational efficiency.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed eco-friendly submersible pump systems that significantly reduce environmental impacts. Their REDA Continuum ESP system incorporates advanced materials and designs to minimize energy consumption and extend operational life[1]. The system uses high-efficiency permanent magnet motors that reduce power requirements by up to 20% compared to conventional induction motors[2]. Additionally, Schlumberger has implemented a rigorous lifecycle assessment process to evaluate and mitigate the environmental impacts of their submersible pumps from production to disposal[3]. This includes using recyclable materials where possible and optimizing manufacturing processes to reduce waste and emissions.

Strengths: Industry-leading technology, comprehensive lifecycle approach, significant energy efficiency improvements. Weaknesses: Higher initial costs, may require specialized maintenance.

Halliburton Energy Services, Inc.

Technical Solution: Halliburton has focused on developing submersible pump technologies that minimize environmental impact while maximizing efficiency. Their Summit ESP systems incorporate advanced materials and designs to reduce energy consumption and extend operational life[4]. The company has implemented a comprehensive environmental management system that includes regular audits and continuous improvement processes for their submersible pump manufacturing and operations[5]. Halliburton's pumps feature advanced monitoring and control systems that optimize performance and reduce unnecessary energy consumption, potentially lowering CO2 emissions by up to 30% compared to conventional systems[6]. They have also invested in research to develop biodegradable lubricants and environmentally friendly sealing solutions for their submersible pumps.

Strengths: Advanced monitoring and control systems, focus on biodegradable components, significant reduction in CO2 emissions. Weaknesses: May have higher upfront costs, potential challenges in retrofitting existing systems.

Innovative Green Technologies in Pump Design

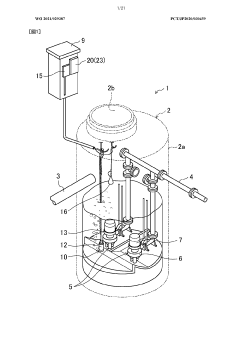

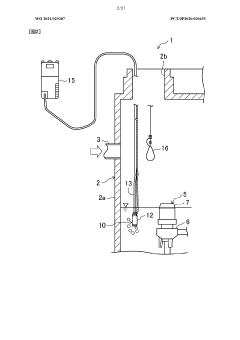

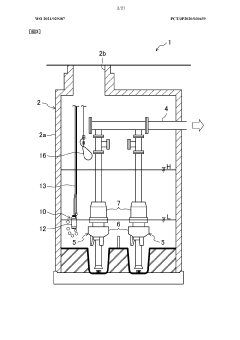

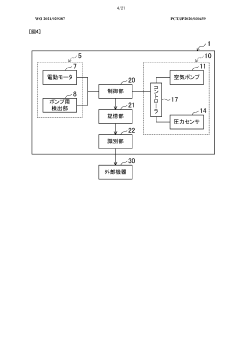

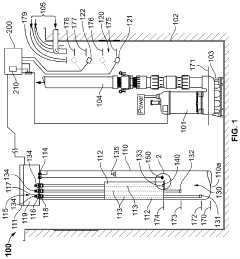

Underwater pump system, information processing device, and computer program

PatentWO2021029387A1

Innovation

- A submersible pump system that includes a current detection unit to analyze temporal changes in the drive current, calculating specific current parameters to determine the presence and type of abnormal operations such as airlock, dry running, or foreign object blockage, and integrates a water level detector to enhance the accuracy of failure identification.

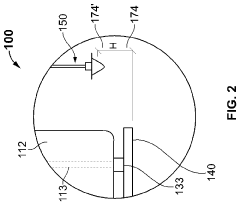

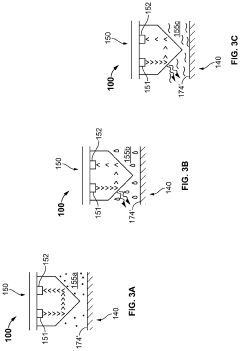

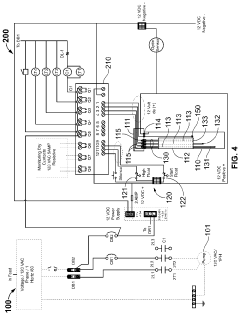

Submersible pump contaminant detection system

PatentPendingUS20230340952A1

Innovation

- A system comprising a stilling tube with integrated sensors, including conductivity and optical sensors, that calms turbulence and accurately detects hydrocarbon layers as thin as 1/16 inches, using a programmable logic controller and capacitive sensors to distinguish between media based on physical properties, ensuring precise contaminant detection and control.

Environmental Regulations for Submersible Pumps

Environmental regulations for submersible pumps have become increasingly stringent in recent years, reflecting growing concerns about the potential ecological impacts of these devices. These regulations aim to minimize the environmental footprint of submersible pumps across their entire lifecycle, from manufacturing to operation and disposal.

At the manufacturing stage, regulations focus on the use of environmentally friendly materials and production processes. Manufacturers are required to limit the use of hazardous substances, such as lead, mercury, and certain flame retardants, in pump components. Additionally, energy efficiency standards during production are enforced to reduce carbon emissions associated with pump manufacturing.

Operational regulations for submersible pumps primarily address water and energy conservation. Many jurisdictions have implemented minimum efficiency standards for pump systems, mandating the use of high-efficiency motors and impellers. These standards not only reduce energy consumption but also minimize the indirect environmental impact through decreased power plant emissions.

Water quality protection is another crucial aspect of submersible pump regulations. Strict guidelines govern the materials used in pump construction to prevent contamination of water sources. Pumps used in potable water systems must meet specific certification requirements to ensure they do not leach harmful substances into the water supply.

Noise pollution from submersible pumps is also subject to regulation, particularly in urban and sensitive ecological areas. Maximum noise levels are often specified, necessitating the use of sound-dampening technologies or strategic pump placement to minimize acoustic disturbances to both human populations and wildlife.

End-of-life management of submersible pumps is increasingly regulated to promote recycling and proper disposal. Many regions have implemented extended producer responsibility programs, requiring manufacturers to establish take-back systems for used pumps. These programs aim to reduce landfill waste and recover valuable materials from decommissioned pumps.

Compliance with these regulations is typically enforced through a combination of certification processes, regular inspections, and reporting requirements. Manufacturers and operators must demonstrate ongoing adherence to environmental standards, often through third-party audits and performance testing.

As environmental concerns continue to grow, regulations for submersible pumps are likely to become more comprehensive and stringent. Future regulatory trends may include stricter energy efficiency targets, expanded material restrictions, and increased focus on the pump's entire environmental lifecycle impact. This evolving regulatory landscape presents both challenges and opportunities for innovation in the submersible pump industry.

At the manufacturing stage, regulations focus on the use of environmentally friendly materials and production processes. Manufacturers are required to limit the use of hazardous substances, such as lead, mercury, and certain flame retardants, in pump components. Additionally, energy efficiency standards during production are enforced to reduce carbon emissions associated with pump manufacturing.

Operational regulations for submersible pumps primarily address water and energy conservation. Many jurisdictions have implemented minimum efficiency standards for pump systems, mandating the use of high-efficiency motors and impellers. These standards not only reduce energy consumption but also minimize the indirect environmental impact through decreased power plant emissions.

Water quality protection is another crucial aspect of submersible pump regulations. Strict guidelines govern the materials used in pump construction to prevent contamination of water sources. Pumps used in potable water systems must meet specific certification requirements to ensure they do not leach harmful substances into the water supply.

Noise pollution from submersible pumps is also subject to regulation, particularly in urban and sensitive ecological areas. Maximum noise levels are often specified, necessitating the use of sound-dampening technologies or strategic pump placement to minimize acoustic disturbances to both human populations and wildlife.

End-of-life management of submersible pumps is increasingly regulated to promote recycling and proper disposal. Many regions have implemented extended producer responsibility programs, requiring manufacturers to establish take-back systems for used pumps. These programs aim to reduce landfill waste and recover valuable materials from decommissioned pumps.

Compliance with these regulations is typically enforced through a combination of certification processes, regular inspections, and reporting requirements. Manufacturers and operators must demonstrate ongoing adherence to environmental standards, often through third-party audits and performance testing.

As environmental concerns continue to grow, regulations for submersible pumps are likely to become more comprehensive and stringent. Future regulatory trends may include stricter energy efficiency targets, expanded material restrictions, and increased focus on the pump's entire environmental lifecycle impact. This evolving regulatory landscape presents both challenges and opportunities for innovation in the submersible pump industry.

Life Cycle Assessment of Submersible Pumps

Life Cycle Assessment (LCA) is a crucial tool for analyzing the environmental impacts of submersible pumps throughout their entire lifecycle. This comprehensive approach considers all stages, from raw material extraction to manufacturing, use, and disposal. For submersible pumps, the LCA typically focuses on energy consumption, resource depletion, emissions, and waste generation.

The assessment begins with the extraction and processing of raw materials, primarily metals like stainless steel, cast iron, and copper. These processes often involve significant energy consumption and emissions. The manufacturing phase includes the production of pump components, assembly, and packaging. This stage may contribute to air and water pollution, as well as generate solid waste.

During the use phase, which is often the most impactful, the primary environmental concern is energy consumption. Submersible pumps operate continuously in many applications, leading to substantial electricity usage over their lifespan. The efficiency of the pump plays a critical role in determining its overall environmental impact. More efficient pumps consume less energy, reducing their carbon footprint and operational costs.

Water contamination is another potential environmental issue during the use phase. Lubricants and other materials used in the pump may leach into the surrounding water, affecting aquatic ecosystems. The choice of materials and proper maintenance can mitigate these risks.

The end-of-life stage involves the disposal or recycling of the pump. Proper recycling of metal components can significantly reduce the overall environmental impact by conserving resources and energy. However, electronic components and certain materials may pose challenges for recycling and require special handling to prevent environmental contamination.

LCA studies on submersible pumps often reveal that the use phase dominates the overall environmental impact due to long-term energy consumption. This insight drives manufacturers to focus on improving energy efficiency and developing more durable products to extend the operational lifespan.

Comparative LCAs between different pump designs or materials can guide decision-making for both manufacturers and consumers. These assessments may consider factors such as pump efficiency, material choices, manufacturing processes, and end-of-life options to determine the most environmentally friendly solutions.

By conducting thorough Life Cycle Assessments, stakeholders in the submersible pump industry can identify hotspots for environmental improvement, optimize product design, and make informed decisions to reduce the overall ecological footprint of these essential devices.

The assessment begins with the extraction and processing of raw materials, primarily metals like stainless steel, cast iron, and copper. These processes often involve significant energy consumption and emissions. The manufacturing phase includes the production of pump components, assembly, and packaging. This stage may contribute to air and water pollution, as well as generate solid waste.

During the use phase, which is often the most impactful, the primary environmental concern is energy consumption. Submersible pumps operate continuously in many applications, leading to substantial electricity usage over their lifespan. The efficiency of the pump plays a critical role in determining its overall environmental impact. More efficient pumps consume less energy, reducing their carbon footprint and operational costs.

Water contamination is another potential environmental issue during the use phase. Lubricants and other materials used in the pump may leach into the surrounding water, affecting aquatic ecosystems. The choice of materials and proper maintenance can mitigate these risks.

The end-of-life stage involves the disposal or recycling of the pump. Proper recycling of metal components can significantly reduce the overall environmental impact by conserving resources and energy. However, electronic components and certain materials may pose challenges for recycling and require special handling to prevent environmental contamination.

LCA studies on submersible pumps often reveal that the use phase dominates the overall environmental impact due to long-term energy consumption. This insight drives manufacturers to focus on improving energy efficiency and developing more durable products to extend the operational lifespan.

Comparative LCAs between different pump designs or materials can guide decision-making for both manufacturers and consumers. These assessments may consider factors such as pump efficiency, material choices, manufacturing processes, and end-of-life options to determine the most environmentally friendly solutions.

By conducting thorough Life Cycle Assessments, stakeholders in the submersible pump industry can identify hotspots for environmental improvement, optimize product design, and make informed decisions to reduce the overall ecological footprint of these essential devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!