Application of High Pass Filters in Electromagnetic Interference Reduction

JUL 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EMI Reduction Background and Objectives

Electromagnetic Interference (EMI) has become a critical concern in modern electronic systems due to the increasing complexity and density of electronic devices. As technology advances, the need for effective EMI reduction techniques has grown exponentially. High Pass Filters (HPFs) have emerged as a promising solution in this field, offering a way to mitigate electromagnetic interference while maintaining signal integrity.

The evolution of EMI reduction techniques can be traced back to the early days of electronics, where simple shielding methods were employed. However, as electronic systems became more sophisticated, these rudimentary approaches proved insufficient. The introduction of filtering techniques, particularly HPFs, marked a significant milestone in EMI reduction strategies. HPFs allow high-frequency signals to pass while attenuating lower frequencies, making them particularly effective in suppressing low-frequency noise and interference.

The primary objective of applying HPFs in EMI reduction is to enhance the electromagnetic compatibility (EMC) of electronic systems. This involves minimizing the emission of electromagnetic energy that could interfere with other devices, as well as improving the immunity of the system to external electromagnetic disturbances. By achieving these goals, HPFs contribute to the overall reliability and performance of electronic equipment across various industries.

In recent years, the demand for EMI reduction solutions has been driven by several factors. The proliferation of wireless communication technologies, the Internet of Things (IoT), and the increasing electrification of automotive systems have all contributed to a more complex electromagnetic environment. This has led to stricter regulatory standards and industry requirements for EMC, further emphasizing the importance of effective EMI reduction techniques.

The application of HPFs in EMI reduction spans a wide range of industries, including telecommunications, automotive, aerospace, and consumer electronics. Each sector presents unique challenges and requirements, necessitating tailored approaches to filter design and implementation. For instance, in the automotive industry, the shift towards electric and hybrid vehicles has intensified the need for robust EMI reduction solutions to ensure the safe and reliable operation of both power electronics and sensitive control systems.

As we look towards the future, the continued advancement of HPF technology in EMI reduction is expected to focus on several key areas. These include the development of more compact and efficient filter designs, the integration of smart filtering techniques that can adapt to changing electromagnetic environments, and the exploration of new materials and manufacturing processes to enhance filter performance. Additionally, there is a growing emphasis on holistic EMI reduction strategies that combine HPFs with other techniques such as shielding and grounding to achieve comprehensive electromagnetic compatibility.

The evolution of EMI reduction techniques can be traced back to the early days of electronics, where simple shielding methods were employed. However, as electronic systems became more sophisticated, these rudimentary approaches proved insufficient. The introduction of filtering techniques, particularly HPFs, marked a significant milestone in EMI reduction strategies. HPFs allow high-frequency signals to pass while attenuating lower frequencies, making them particularly effective in suppressing low-frequency noise and interference.

The primary objective of applying HPFs in EMI reduction is to enhance the electromagnetic compatibility (EMC) of electronic systems. This involves minimizing the emission of electromagnetic energy that could interfere with other devices, as well as improving the immunity of the system to external electromagnetic disturbances. By achieving these goals, HPFs contribute to the overall reliability and performance of electronic equipment across various industries.

In recent years, the demand for EMI reduction solutions has been driven by several factors. The proliferation of wireless communication technologies, the Internet of Things (IoT), and the increasing electrification of automotive systems have all contributed to a more complex electromagnetic environment. This has led to stricter regulatory standards and industry requirements for EMC, further emphasizing the importance of effective EMI reduction techniques.

The application of HPFs in EMI reduction spans a wide range of industries, including telecommunications, automotive, aerospace, and consumer electronics. Each sector presents unique challenges and requirements, necessitating tailored approaches to filter design and implementation. For instance, in the automotive industry, the shift towards electric and hybrid vehicles has intensified the need for robust EMI reduction solutions to ensure the safe and reliable operation of both power electronics and sensitive control systems.

As we look towards the future, the continued advancement of HPF technology in EMI reduction is expected to focus on several key areas. These include the development of more compact and efficient filter designs, the integration of smart filtering techniques that can adapt to changing electromagnetic environments, and the exploration of new materials and manufacturing processes to enhance filter performance. Additionally, there is a growing emphasis on holistic EMI reduction strategies that combine HPFs with other techniques such as shielding and grounding to achieve comprehensive electromagnetic compatibility.

Market Demand for EMI Mitigation Solutions

The market demand for Electromagnetic Interference (EMI) mitigation solutions has been steadily increasing due to the proliferation of electronic devices and the growing complexity of electrical systems across various industries. High pass filters, as a crucial component in EMI reduction, have seen a significant surge in demand, particularly in sectors such as automotive, aerospace, telecommunications, and consumer electronics.

In the automotive industry, the shift towards electric and hybrid vehicles has intensified the need for effective EMI mitigation solutions. These vehicles incorporate numerous electronic systems, including power inverters, electric motors, and battery management systems, all of which can generate substantial electromagnetic interference. The market for high pass filters in this sector is expected to grow rapidly as manufacturers strive to meet stringent electromagnetic compatibility (EMC) standards and ensure the reliable operation of vehicle electronics.

The aerospace industry also presents a substantial market for EMI mitigation solutions. Modern aircraft rely heavily on sophisticated avionics systems that are susceptible to electromagnetic interference. High pass filters play a critical role in protecting these sensitive systems from EMI, ensuring the safety and reliability of aircraft operations. As the aerospace industry continues to advance, with the development of more electric aircraft and unmanned aerial vehicles, the demand for high-performance EMI filters is projected to increase significantly.

In the telecommunications sector, the ongoing rollout of 5G networks has created a new wave of demand for EMI mitigation solutions. The higher frequencies used in 5G systems are more susceptible to interference, necessitating advanced filtering techniques to maintain signal integrity and network performance. High pass filters are essential in 5G base stations and user equipment to suppress low-frequency noise and interference, driving market growth in this area.

Consumer electronics represent another major market for EMI mitigation solutions. With the increasing integration of wireless technologies and the miniaturization of devices, managing electromagnetic interference has become more challenging. High pass filters are widely used in smartphones, tablets, laptops, and wearable devices to reduce EMI and improve overall device performance. The growing consumer demand for faster, more reliable electronic devices continues to fuel the market for EMI mitigation solutions in this sector.

The industrial automation sector is also experiencing a rising demand for EMI mitigation solutions. As factories become more digitized and interconnected through Industrial Internet of Things (IIoT) technologies, the need to protect sensitive equipment from electromagnetic interference has become paramount. High pass filters are crucial in ensuring the reliable operation of industrial control systems, sensors, and communication networks in harsh electromagnetic environments.

Overall, the market for EMI mitigation solutions, including high pass filters, is driven by the increasing complexity of electronic systems, stricter regulatory standards, and the growing awareness of the importance of electromagnetic compatibility. As technology continues to advance and new applications emerge, the demand for innovative and effective EMI mitigation solutions is expected to remain strong across multiple industries.

In the automotive industry, the shift towards electric and hybrid vehicles has intensified the need for effective EMI mitigation solutions. These vehicles incorporate numerous electronic systems, including power inverters, electric motors, and battery management systems, all of which can generate substantial electromagnetic interference. The market for high pass filters in this sector is expected to grow rapidly as manufacturers strive to meet stringent electromagnetic compatibility (EMC) standards and ensure the reliable operation of vehicle electronics.

The aerospace industry also presents a substantial market for EMI mitigation solutions. Modern aircraft rely heavily on sophisticated avionics systems that are susceptible to electromagnetic interference. High pass filters play a critical role in protecting these sensitive systems from EMI, ensuring the safety and reliability of aircraft operations. As the aerospace industry continues to advance, with the development of more electric aircraft and unmanned aerial vehicles, the demand for high-performance EMI filters is projected to increase significantly.

In the telecommunications sector, the ongoing rollout of 5G networks has created a new wave of demand for EMI mitigation solutions. The higher frequencies used in 5G systems are more susceptible to interference, necessitating advanced filtering techniques to maintain signal integrity and network performance. High pass filters are essential in 5G base stations and user equipment to suppress low-frequency noise and interference, driving market growth in this area.

Consumer electronics represent another major market for EMI mitigation solutions. With the increasing integration of wireless technologies and the miniaturization of devices, managing electromagnetic interference has become more challenging. High pass filters are widely used in smartphones, tablets, laptops, and wearable devices to reduce EMI and improve overall device performance. The growing consumer demand for faster, more reliable electronic devices continues to fuel the market for EMI mitigation solutions in this sector.

The industrial automation sector is also experiencing a rising demand for EMI mitigation solutions. As factories become more digitized and interconnected through Industrial Internet of Things (IIoT) technologies, the need to protect sensitive equipment from electromagnetic interference has become paramount. High pass filters are crucial in ensuring the reliable operation of industrial control systems, sensors, and communication networks in harsh electromagnetic environments.

Overall, the market for EMI mitigation solutions, including high pass filters, is driven by the increasing complexity of electronic systems, stricter regulatory standards, and the growing awareness of the importance of electromagnetic compatibility. As technology continues to advance and new applications emerge, the demand for innovative and effective EMI mitigation solutions is expected to remain strong across multiple industries.

High Pass Filter Technology Status and Challenges

High pass filter technology has made significant strides in electromagnetic interference (EMI) reduction, yet it still faces several challenges in its current state. The global market for EMI shielding has seen steady growth, with high pass filters playing a crucial role in various industries, including telecommunications, automotive, and consumer electronics.

One of the primary challenges in high pass filter technology for EMI reduction is the trade-off between filter performance and signal integrity. As electronic devices become more compact and operate at higher frequencies, the need for effective EMI suppression increases. However, traditional high pass filter designs often introduce signal distortion or attenuation, particularly at higher frequencies.

Another significant challenge is the integration of high pass filters into increasingly miniaturized electronic systems. As devices shrink in size, incorporating effective EMI reduction solutions without compromising overall system performance becomes more difficult. This has led to a growing demand for innovative filter designs that can maintain high performance while occupying minimal space.

The advent of 5G technology and the Internet of Things (IoT) has further complicated the EMI landscape. These technologies operate at higher frequencies and require more sophisticated EMI reduction techniques. High pass filters must evolve to address the unique challenges posed by these emerging technologies, including handling wider frequency ranges and dealing with complex, multi-band signals.

Material limitations also present ongoing challenges in high pass filter technology. While advancements have been made in developing materials with improved electromagnetic properties, there is still a need for materials that can provide better EMI shielding across a broader frequency spectrum while remaining cost-effective and easy to manufacture.

From a geographical perspective, the development of high pass filter technology for EMI reduction is primarily concentrated in regions with strong electronics manufacturing bases, such as East Asia, North America, and Europe. However, there is a growing trend of research and development activities in emerging markets, particularly in India and Southeast Asia, as these regions seek to bolster their electronics industries.

In terms of technological distribution, there is a noticeable divide between cutting-edge research in academic institutions and practical implementations in industry. While universities and research labs are exploring novel filter designs and materials, the industrial adoption of these innovations often lags due to cost considerations and the need for proven reliability in real-world applications.

Looking ahead, the future of high pass filter technology in EMI reduction lies in addressing these challenges through interdisciplinary approaches. This includes exploring advanced materials science, leveraging artificial intelligence for optimized filter designs, and developing adaptive filtering techniques that can dynamically respond to changing EMI environments.

One of the primary challenges in high pass filter technology for EMI reduction is the trade-off between filter performance and signal integrity. As electronic devices become more compact and operate at higher frequencies, the need for effective EMI suppression increases. However, traditional high pass filter designs often introduce signal distortion or attenuation, particularly at higher frequencies.

Another significant challenge is the integration of high pass filters into increasingly miniaturized electronic systems. As devices shrink in size, incorporating effective EMI reduction solutions without compromising overall system performance becomes more difficult. This has led to a growing demand for innovative filter designs that can maintain high performance while occupying minimal space.

The advent of 5G technology and the Internet of Things (IoT) has further complicated the EMI landscape. These technologies operate at higher frequencies and require more sophisticated EMI reduction techniques. High pass filters must evolve to address the unique challenges posed by these emerging technologies, including handling wider frequency ranges and dealing with complex, multi-band signals.

Material limitations also present ongoing challenges in high pass filter technology. While advancements have been made in developing materials with improved electromagnetic properties, there is still a need for materials that can provide better EMI shielding across a broader frequency spectrum while remaining cost-effective and easy to manufacture.

From a geographical perspective, the development of high pass filter technology for EMI reduction is primarily concentrated in regions with strong electronics manufacturing bases, such as East Asia, North America, and Europe. However, there is a growing trend of research and development activities in emerging markets, particularly in India and Southeast Asia, as these regions seek to bolster their electronics industries.

In terms of technological distribution, there is a noticeable divide between cutting-edge research in academic institutions and practical implementations in industry. While universities and research labs are exploring novel filter designs and materials, the industrial adoption of these innovations often lags due to cost considerations and the need for proven reliability in real-world applications.

Looking ahead, the future of high pass filter technology in EMI reduction lies in addressing these challenges through interdisciplinary approaches. This includes exploring advanced materials science, leveraging artificial intelligence for optimized filter designs, and developing adaptive filtering techniques that can dynamically respond to changing EMI environments.

Current High Pass Filter Solutions for EMI

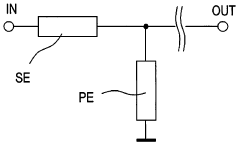

01 High-pass filter design for EMI reduction

High-pass filters are designed to attenuate low-frequency electromagnetic interference while allowing higher frequencies to pass through. These filters can be implemented in various electronic circuits and power systems to reduce EMI and improve overall system performance.- High-pass filter design for EMI reduction: High-pass filters are designed to attenuate low-frequency electromagnetic interference while allowing higher frequencies to pass through. These filters can be implemented in various electronic circuits and power systems to reduce electromagnetic noise and improve signal integrity.

- EMI suppression in LED lighting systems: High-pass filters are utilized in LED lighting systems to mitigate electromagnetic interference. These filters help reduce conducted and radiated emissions, ensuring compliance with EMC standards and improving the overall performance of LED lighting products.

- Integration of high-pass filters in power converters: Power converters, such as switch-mode power supplies, incorporate high-pass filters to suppress electromagnetic interference generated during switching operations. These filters help maintain power quality and reduce EMI emissions in various electronic devices and systems.

- EMI filtering in medical devices: High-pass filters are employed in medical devices to minimize electromagnetic interference, ensuring accurate signal processing and reliable operation. These filters are crucial for maintaining the integrity of sensitive medical equipment and protecting patients from potential EMI-related hazards.

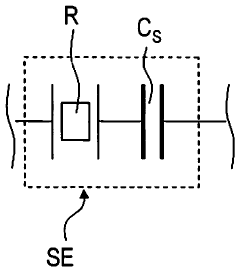

- Advanced high-pass filter topologies for EMI reduction: Novel high-pass filter designs and topologies are developed to enhance electromagnetic interference suppression. These advanced filters may incorporate multiple stages, adaptive components, or innovative materials to achieve superior EMI reduction across a wide frequency range.

02 EMI suppression in LED lighting systems

High-pass filters are utilized in LED lighting systems to mitigate electromagnetic interference. These filters help reduce conducted and radiated emissions, ensuring compliance with EMC standards and improving the overall performance of LED lighting products.Expand Specific Solutions03 Integration of high-pass filters in power converters

Power converters, such as switch-mode power supplies, incorporate high-pass filters to reduce electromagnetic interference. These filters are designed to attenuate low-frequency noise generated by switching operations, improving the overall EMC performance of the power conversion system.Expand Specific Solutions04 EMI reduction in wireless communication devices

High-pass filters are employed in wireless communication devices to minimize electromagnetic interference. These filters help improve signal quality, reduce noise, and enhance the overall performance of wireless communication systems by attenuating low-frequency EMI.Expand Specific Solutions05 Automotive EMI suppression using high-pass filters

High-pass filters are implemented in automotive electrical systems to reduce electromagnetic interference. These filters help improve the performance and reliability of various electronic components in vehicles by attenuating low-frequency EMI generated by automotive systems.Expand Specific Solutions

Key Players in EMI Filtering Industry

The application of high pass filters in electromagnetic interference reduction is in a mature stage of development, with a significant market size driven by the growing demand for electronic devices across various industries. The technology's maturity is evident from the involvement of established players like Murata Manufacturing, TDK Corp., and Infineon Technologies AG, who have extensive experience in developing EMI reduction solutions. These companies, along with others such as Allegro MicroSystems and Texas Instruments, are continuously innovating to improve filter performance and efficiency. The competitive landscape is characterized by a mix of large multinational corporations and specialized component manufacturers, all vying for market share in this critical area of electronic design.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced high-pass filter solutions for electromagnetic interference (EMI) reduction in various electronic applications. Their approach involves the use of multilayer ceramic capacitors (MLCCs) with optimized electrode structures to achieve high-frequency performance[1]. These filters are designed to effectively attenuate low-frequency noise while allowing high-frequency signals to pass through. Murata's high-pass filters incorporate proprietary materials and manufacturing techniques to enhance their EMI suppression capabilities, particularly in the GHz range[2]. The company has also introduced miniaturized high-pass filter arrays that can be integrated into compact electronic devices, addressing the growing demand for EMI reduction in smaller form factors[3].

Strengths: Excellent high-frequency performance, miniaturization capabilities, and wide range of applications. Weaknesses: Potential cost implications for high-end solutions and possible limitations in extremely low-frequency noise suppression.

TDK Corp.

Technical Solution: TDK has developed a comprehensive range of high-pass filters for EMI reduction, focusing on both passive and active solutions. Their passive high-pass filters utilize advanced magnetic materials and innovative designs to achieve superior noise suppression characteristics[1]. TDK's active EMI filters incorporate proprietary integrated circuit technology to provide adaptive noise cancellation, particularly effective in dynamic EMI environments[2]. The company has also introduced thin-film high-pass filters that offer excellent high-frequency performance while maintaining a low profile, suitable for space-constrained applications[3]. TDK's filters are designed to meet stringent automotive and industrial standards, ensuring reliability in harsh electromagnetic environments[4].

Strengths: Diverse product portfolio, advanced materials technology, and compliance with industry standards. Weaknesses: Potential higher costs for advanced solutions and possible complexity in implementation for some active filter designs.

Core Innovations in High Pass Filter Design

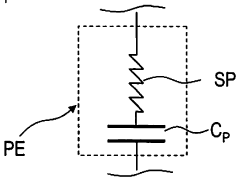

Antenna amplifier for a vehicle with means for ESD protection in the input thereof

PatentInactiveEP1794838A1

Innovation

- A high-pass filter is used to filter out the spectral damaging portions of high-frequency signals, specifically ESD pulses, while allowing useful radio-frequency signals to pass through, with a cut-off frequency designed to suppress interference without degrading the useful signal, and implemented using discrete components and printed strip lines for efficient and cost-effective ESD protection.

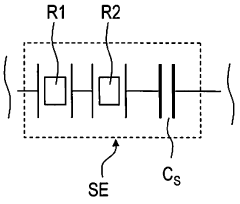

High-pass filter and use thereof

PatentWO2009010537A1

Innovation

- A high-pass filter design featuring a series element with an acoustic resonator and capacitor in series, and a parallel element with an inductor and capacitor in shunt, arranged on a carrier substrate, which increases stopband bandwidth to over 30% and achieves a steep slope between passband and stopband with a narrow transition range, ensuring low insertion loss.

EMC Standards and Regulations

Electromagnetic Compatibility (EMC) standards and regulations play a crucial role in ensuring the reliable operation of electronic devices and systems in the presence of electromagnetic interference. These standards are established by various international and national organizations to define acceptable limits for electromagnetic emissions and immunity levels.

The International Electrotechnical Commission (IEC) is a key player in developing global EMC standards. Their IEC 61000 series provides a comprehensive framework for EMC testing and compliance. Specifically, IEC 61000-4 focuses on testing and measurement techniques for electromagnetic compatibility.

In the United States, the Federal Communications Commission (FCC) regulates EMC through its Part 15 rules. These regulations set limits on unintentional radiators and require manufacturers to certify their products before market release. The FCC's approach emphasizes protecting radio communications from interference caused by electronic devices.

The European Union has established the EMC Directive (2014/30/EU) as part of its CE marking requirements. This directive mandates that all electronic equipment sold in the EU must meet specific EMC standards, ensuring a harmonized approach across member states.

For automotive applications, the United Nations Economic Commission for Europe (UNECE) Regulation No. 10 addresses EMC requirements for vehicles and their electronic sub-assemblies. This regulation is widely adopted globally, influencing automotive EMC standards beyond Europe.

In the context of high-pass filters for electromagnetic interference reduction, these standards often specify the frequency ranges and attenuation levels required for effective EMI mitigation. For instance, CISPR 25 provides limits and methods of measurement for radio disturbances in vehicles, which directly impacts the design of high-pass filters in automotive applications.

Military and aerospace sectors have their own stringent EMC standards, such as MIL-STD-461 in the United States. These standards often require more robust EMI suppression techniques, including advanced high-pass filter designs to meet the demanding electromagnetic environments encountered in these applications.

As technology evolves, EMC standards are continuously updated to address new challenges. The increasing prevalence of wireless communications and the push towards higher-frequency operations in 5G and beyond are driving the development of new EMC regulations. This evolution necessitates ongoing innovation in high-pass filter design to meet these emerging requirements.

Compliance with EMC standards is not only a legal requirement but also a critical factor in ensuring product quality and market acceptance. Manufacturers must consider these regulations from the early stages of product development, integrating appropriate EMI reduction techniques, including high-pass filters, to meet the specified limits and ensure electromagnetic compatibility across various operating environments.

The International Electrotechnical Commission (IEC) is a key player in developing global EMC standards. Their IEC 61000 series provides a comprehensive framework for EMC testing and compliance. Specifically, IEC 61000-4 focuses on testing and measurement techniques for electromagnetic compatibility.

In the United States, the Federal Communications Commission (FCC) regulates EMC through its Part 15 rules. These regulations set limits on unintentional radiators and require manufacturers to certify their products before market release. The FCC's approach emphasizes protecting radio communications from interference caused by electronic devices.

The European Union has established the EMC Directive (2014/30/EU) as part of its CE marking requirements. This directive mandates that all electronic equipment sold in the EU must meet specific EMC standards, ensuring a harmonized approach across member states.

For automotive applications, the United Nations Economic Commission for Europe (UNECE) Regulation No. 10 addresses EMC requirements for vehicles and their electronic sub-assemblies. This regulation is widely adopted globally, influencing automotive EMC standards beyond Europe.

In the context of high-pass filters for electromagnetic interference reduction, these standards often specify the frequency ranges and attenuation levels required for effective EMI mitigation. For instance, CISPR 25 provides limits and methods of measurement for radio disturbances in vehicles, which directly impacts the design of high-pass filters in automotive applications.

Military and aerospace sectors have their own stringent EMC standards, such as MIL-STD-461 in the United States. These standards often require more robust EMI suppression techniques, including advanced high-pass filter designs to meet the demanding electromagnetic environments encountered in these applications.

As technology evolves, EMC standards are continuously updated to address new challenges. The increasing prevalence of wireless communications and the push towards higher-frequency operations in 5G and beyond are driving the development of new EMC regulations. This evolution necessitates ongoing innovation in high-pass filter design to meet these emerging requirements.

Compliance with EMC standards is not only a legal requirement but also a critical factor in ensuring product quality and market acceptance. Manufacturers must consider these regulations from the early stages of product development, integrating appropriate EMI reduction techniques, including high-pass filters, to meet the specified limits and ensure electromagnetic compatibility across various operating environments.

Cost-Benefit Analysis of HPF Implementation

The implementation of High Pass Filters (HPFs) in electromagnetic interference (EMI) reduction requires a thorough cost-benefit analysis to determine its feasibility and effectiveness. This analysis encompasses both the financial aspects and the technical advantages gained from incorporating HPFs into EMI reduction strategies.

From a cost perspective, the initial investment in HPF technology can be significant. This includes the expenses associated with designing, manufacturing, and integrating HPFs into existing systems or products. Additionally, there may be costs related to testing and certification to ensure compliance with EMI standards. However, these upfront costs should be weighed against the long-term benefits and potential cost savings.

One of the primary benefits of implementing HPFs is the improved performance and reliability of electronic systems. By effectively reducing electromagnetic interference, HPFs can enhance signal integrity, minimize data errors, and extend the lifespan of sensitive components. This can lead to reduced maintenance costs and fewer product failures in the field, ultimately resulting in higher customer satisfaction and lower warranty claims.

In terms of market competitiveness, products equipped with effective EMI reduction solutions often command premium prices and enjoy a reputation for quality and reliability. This can translate into increased market share and higher profit margins, offsetting the initial implementation costs over time.

The regulatory landscape also plays a crucial role in the cost-benefit analysis of HPF implementation. As EMI standards become increasingly stringent, the cost of non-compliance can be substantial, including fines, product recalls, and damage to brand reputation. Investing in HPF technology can help ensure compliance with current and future regulations, potentially avoiding these costly consequences.

Energy efficiency is another factor to consider. While HPFs themselves may introduce some power consumption, their ability to reduce EMI can lead to overall system efficiency improvements. This is particularly relevant in battery-powered devices or energy-sensitive applications, where even small gains in efficiency can translate to significant cost savings over the product lifecycle.

From a research and development perspective, the knowledge and expertise gained from implementing HPFs can drive innovation and lead to new product opportunities. This intellectual property can become a valuable asset, potentially opening up new revenue streams through licensing or technology partnerships.

In conclusion, while the implementation of HPFs for EMI reduction does involve upfront costs, the long-term benefits in terms of product performance, reliability, regulatory compliance, and market positioning often outweigh these initial investments. A comprehensive cost-benefit analysis should consider not only the immediate financial impact but also the strategic advantages and potential for future growth that effective EMI reduction solutions can provide.

From a cost perspective, the initial investment in HPF technology can be significant. This includes the expenses associated with designing, manufacturing, and integrating HPFs into existing systems or products. Additionally, there may be costs related to testing and certification to ensure compliance with EMI standards. However, these upfront costs should be weighed against the long-term benefits and potential cost savings.

One of the primary benefits of implementing HPFs is the improved performance and reliability of electronic systems. By effectively reducing electromagnetic interference, HPFs can enhance signal integrity, minimize data errors, and extend the lifespan of sensitive components. This can lead to reduced maintenance costs and fewer product failures in the field, ultimately resulting in higher customer satisfaction and lower warranty claims.

In terms of market competitiveness, products equipped with effective EMI reduction solutions often command premium prices and enjoy a reputation for quality and reliability. This can translate into increased market share and higher profit margins, offsetting the initial implementation costs over time.

The regulatory landscape also plays a crucial role in the cost-benefit analysis of HPF implementation. As EMI standards become increasingly stringent, the cost of non-compliance can be substantial, including fines, product recalls, and damage to brand reputation. Investing in HPF technology can help ensure compliance with current and future regulations, potentially avoiding these costly consequences.

Energy efficiency is another factor to consider. While HPFs themselves may introduce some power consumption, their ability to reduce EMI can lead to overall system efficiency improvements. This is particularly relevant in battery-powered devices or energy-sensitive applications, where even small gains in efficiency can translate to significant cost savings over the product lifecycle.

From a research and development perspective, the knowledge and expertise gained from implementing HPFs can drive innovation and lead to new product opportunities. This intellectual property can become a valuable asset, potentially opening up new revenue streams through licensing or technology partnerships.

In conclusion, while the implementation of HPFs for EMI reduction does involve upfront costs, the long-term benefits in terms of product performance, reliability, regulatory compliance, and market positioning often outweigh these initial investments. A comprehensive cost-benefit analysis should consider not only the immediate financial impact but also the strategic advantages and potential for future growth that effective EMI reduction solutions can provide.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!