High Pass Filters in Industrial Automation Systems for Real-Time Data Processing

JUL 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High Pass Filter Evolution and Objectives

High pass filters have played a crucial role in industrial automation systems for decades, evolving alongside the rapid advancements in technology. Initially developed in the early 20th century, these filters have undergone significant transformations to meet the ever-increasing demands of real-time data processing in modern industrial environments.

The evolution of high pass filters can be traced back to the fundamental concepts of signal processing and electrical engineering. As industrial processes became more complex and data-intensive, the need for efficient noise reduction and signal clarity became paramount. This led to the development of more sophisticated filter designs, incorporating advanced materials and circuit topologies to enhance performance and reliability.

In recent years, the advent of digital signal processing has revolutionized the implementation of high pass filters in industrial automation systems. Digital filters offer greater flexibility, precision, and adaptability compared to their analog counterparts. This shift has enabled more accurate real-time data processing, crucial for maintaining the integrity of industrial control systems and ensuring optimal performance of automated processes.

The objectives of high pass filter research in industrial automation systems are multifaceted. Primarily, there is a focus on improving the filter's ability to effectively remove low-frequency noise and DC offsets from sensor signals, ensuring that only relevant high-frequency components are processed. This is essential for maintaining the accuracy and reliability of control systems in dynamic industrial environments.

Another key objective is to enhance the filter's response time and reduce latency. In real-time data processing applications, even milliseconds of delay can have significant implications for system performance and safety. Researchers are exploring novel filter architectures and algorithms to minimize processing time while maintaining high accuracy and stability.

Energy efficiency is also a critical consideration in the evolution of high pass filters. As industrial automation systems become more complex and widespread, the power consumption of individual components becomes increasingly important. Developing low-power filter designs that can operate efficiently in various industrial settings is a priority for researchers and engineers in the field.

Furthermore, there is a growing emphasis on developing adaptive and self-tuning high pass filters. These advanced filters can automatically adjust their parameters based on changing environmental conditions or signal characteristics, ensuring optimal performance across a wide range of operating scenarios. This adaptability is particularly valuable in industrial settings where conditions can vary significantly over time.

As we look to the future, the objectives of high pass filter research in industrial automation systems will likely expand to include integration with emerging technologies such as artificial intelligence and machine learning. These advancements promise to further enhance the capabilities of high pass filters, enabling more intelligent and context-aware signal processing in industrial environments.

The evolution of high pass filters can be traced back to the fundamental concepts of signal processing and electrical engineering. As industrial processes became more complex and data-intensive, the need for efficient noise reduction and signal clarity became paramount. This led to the development of more sophisticated filter designs, incorporating advanced materials and circuit topologies to enhance performance and reliability.

In recent years, the advent of digital signal processing has revolutionized the implementation of high pass filters in industrial automation systems. Digital filters offer greater flexibility, precision, and adaptability compared to their analog counterparts. This shift has enabled more accurate real-time data processing, crucial for maintaining the integrity of industrial control systems and ensuring optimal performance of automated processes.

The objectives of high pass filter research in industrial automation systems are multifaceted. Primarily, there is a focus on improving the filter's ability to effectively remove low-frequency noise and DC offsets from sensor signals, ensuring that only relevant high-frequency components are processed. This is essential for maintaining the accuracy and reliability of control systems in dynamic industrial environments.

Another key objective is to enhance the filter's response time and reduce latency. In real-time data processing applications, even milliseconds of delay can have significant implications for system performance and safety. Researchers are exploring novel filter architectures and algorithms to minimize processing time while maintaining high accuracy and stability.

Energy efficiency is also a critical consideration in the evolution of high pass filters. As industrial automation systems become more complex and widespread, the power consumption of individual components becomes increasingly important. Developing low-power filter designs that can operate efficiently in various industrial settings is a priority for researchers and engineers in the field.

Furthermore, there is a growing emphasis on developing adaptive and self-tuning high pass filters. These advanced filters can automatically adjust their parameters based on changing environmental conditions or signal characteristics, ensuring optimal performance across a wide range of operating scenarios. This adaptability is particularly valuable in industrial settings where conditions can vary significantly over time.

As we look to the future, the objectives of high pass filter research in industrial automation systems will likely expand to include integration with emerging technologies such as artificial intelligence and machine learning. These advancements promise to further enhance the capabilities of high pass filters, enabling more intelligent and context-aware signal processing in industrial environments.

Industrial Automation Market Analysis

The industrial automation market has been experiencing significant growth in recent years, driven by the increasing demand for efficient and cost-effective manufacturing processes. This growth is particularly evident in the adoption of high pass filters for real-time data processing in automation systems. The global industrial automation market was valued at $191.89 billion in 2021 and is projected to reach $395.09 billion by 2029, growing at a CAGR of 9.8% during the forecast period.

The demand for high pass filters in industrial automation systems is primarily fueled by the need for accurate and rapid data processing in real-time applications. These filters play a crucial role in eliminating low-frequency noise and interference, allowing for more precise control and monitoring of industrial processes. The market for high pass filters in industrial automation is expected to grow at a CAGR of 6.5% from 2022 to 2030, reaching a value of $1.2 billion by the end of the forecast period.

Key industries driving the adoption of high pass filters in automation systems include manufacturing, oil and gas, automotive, and pharmaceuticals. The manufacturing sector, in particular, is witnessing a surge in demand for these filters due to the increasing implementation of Industry 4.0 technologies and smart manufacturing practices. The automotive industry is also a significant contributor to market growth, with high pass filters being utilized in various applications such as engine control systems and sensor networks.

Geographically, North America and Europe are the leading markets for high pass filters in industrial automation, owing to their advanced manufacturing infrastructure and early adoption of automation technologies. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization in countries like China and India.

The market landscape for high pass filters in industrial automation is characterized by intense competition among key players such as Analog Devices, Texas Instruments, and Maxim Integrated. These companies are focusing on developing innovative filter designs that offer improved performance, reduced power consumption, and enhanced integration capabilities. Additionally, there is a growing trend towards the development of software-defined filters that provide greater flexibility and adaptability in industrial automation applications.

As the industrial automation market continues to evolve, the demand for high pass filters is expected to increase further, driven by the growing need for real-time data processing and analysis in smart manufacturing environments. This trend is likely to create new opportunities for filter manufacturers and automation solution providers in the coming years.

The demand for high pass filters in industrial automation systems is primarily fueled by the need for accurate and rapid data processing in real-time applications. These filters play a crucial role in eliminating low-frequency noise and interference, allowing for more precise control and monitoring of industrial processes. The market for high pass filters in industrial automation is expected to grow at a CAGR of 6.5% from 2022 to 2030, reaching a value of $1.2 billion by the end of the forecast period.

Key industries driving the adoption of high pass filters in automation systems include manufacturing, oil and gas, automotive, and pharmaceuticals. The manufacturing sector, in particular, is witnessing a surge in demand for these filters due to the increasing implementation of Industry 4.0 technologies and smart manufacturing practices. The automotive industry is also a significant contributor to market growth, with high pass filters being utilized in various applications such as engine control systems and sensor networks.

Geographically, North America and Europe are the leading markets for high pass filters in industrial automation, owing to their advanced manufacturing infrastructure and early adoption of automation technologies. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization in countries like China and India.

The market landscape for high pass filters in industrial automation is characterized by intense competition among key players such as Analog Devices, Texas Instruments, and Maxim Integrated. These companies are focusing on developing innovative filter designs that offer improved performance, reduced power consumption, and enhanced integration capabilities. Additionally, there is a growing trend towards the development of software-defined filters that provide greater flexibility and adaptability in industrial automation applications.

As the industrial automation market continues to evolve, the demand for high pass filters is expected to increase further, driven by the growing need for real-time data processing and analysis in smart manufacturing environments. This trend is likely to create new opportunities for filter manufacturers and automation solution providers in the coming years.

Current HPF Challenges in Real-Time Processing

High pass filters (HPFs) play a crucial role in industrial automation systems for real-time data processing. However, several challenges persist in their implementation and optimization. One of the primary issues is the trade-off between filter performance and computational efficiency. As industrial systems demand increasingly faster processing speeds, the need for HPFs that can operate with minimal latency becomes paramount.

The design of HPFs for real-time applications faces the challenge of balancing frequency response characteristics with phase distortion. Ideal HPFs should provide sharp cutoff frequencies while maintaining linear phase response to prevent signal distortion. However, achieving both simultaneously often requires complex filter structures that may introduce additional processing delays, conflicting with the real-time requirements of industrial systems.

Another significant challenge is the adaptability of HPFs to varying signal conditions in dynamic industrial environments. Traditional fixed-coefficient filters may not perform optimally when input signal characteristics change rapidly. This necessitates the development of adaptive HPF algorithms that can adjust their parameters on-the-fly, a task that is computationally intensive and difficult to implement in real-time systems with limited processing resources.

The presence of noise and interference in industrial settings further complicates the design of effective HPFs. High-frequency noise can be particularly problematic, as it may fall within the passband of the filter. Developing HPFs that can discriminate between desired high-frequency signals and unwanted noise without introducing significant delay remains a challenge.

Implementation of HPFs in embedded systems, which are common in industrial automation, presents additional hurdles. These systems often have constrained computational resources and power limitations. Designing HPFs that can operate efficiently within these constraints while maintaining the required performance metrics is an ongoing challenge for engineers and researchers.

Furthermore, the integration of HPFs into complex signal processing chains in industrial systems poses challenges related to overall system stability and performance. The interaction between multiple filtering stages and other signal processing elements can lead to unexpected behaviors, requiring careful system-level design and optimization.

Lastly, the increasing demand for edge computing in industrial automation introduces new challenges for HPF implementation. Edge devices require filters that can operate with minimal latency and power consumption while still providing high-quality signal processing. Developing HPFs that meet these stringent requirements without compromising on performance is a significant challenge in the field of real-time data processing for industrial automation systems.

The design of HPFs for real-time applications faces the challenge of balancing frequency response characteristics with phase distortion. Ideal HPFs should provide sharp cutoff frequencies while maintaining linear phase response to prevent signal distortion. However, achieving both simultaneously often requires complex filter structures that may introduce additional processing delays, conflicting with the real-time requirements of industrial systems.

Another significant challenge is the adaptability of HPFs to varying signal conditions in dynamic industrial environments. Traditional fixed-coefficient filters may not perform optimally when input signal characteristics change rapidly. This necessitates the development of adaptive HPF algorithms that can adjust their parameters on-the-fly, a task that is computationally intensive and difficult to implement in real-time systems with limited processing resources.

The presence of noise and interference in industrial settings further complicates the design of effective HPFs. High-frequency noise can be particularly problematic, as it may fall within the passband of the filter. Developing HPFs that can discriminate between desired high-frequency signals and unwanted noise without introducing significant delay remains a challenge.

Implementation of HPFs in embedded systems, which are common in industrial automation, presents additional hurdles. These systems often have constrained computational resources and power limitations. Designing HPFs that can operate efficiently within these constraints while maintaining the required performance metrics is an ongoing challenge for engineers and researchers.

Furthermore, the integration of HPFs into complex signal processing chains in industrial systems poses challenges related to overall system stability and performance. The interaction between multiple filtering stages and other signal processing elements can lead to unexpected behaviors, requiring careful system-level design and optimization.

Lastly, the increasing demand for edge computing in industrial automation introduces new challenges for HPF implementation. Edge devices require filters that can operate with minimal latency and power consumption while still providing high-quality signal processing. Developing HPFs that meet these stringent requirements without compromising on performance is a significant challenge in the field of real-time data processing for industrial automation systems.

Existing HPF Solutions for Industrial Data

01 Digital signal processing with high-pass filters

High-pass filters are used in digital signal processing to attenuate low-frequency components while allowing high-frequency components to pass through. This technique is applied in various applications such as audio processing, image enhancement, and noise reduction in communication systems.- Digital signal processing with high-pass filters: High-pass filters are used in digital signal processing to attenuate low-frequency components while allowing high-frequency components to pass through. This technique is applied in various applications such as audio processing, image enhancement, and noise reduction in communication systems.

- High-pass filter design and implementation: Various methods and circuits are employed to design and implement high-pass filters. These include analog and digital filter designs, utilizing components such as capacitors, inductors, and operational amplifiers. Advanced techniques may involve adaptive filtering and software-defined filters for improved performance and flexibility.

- Application of high-pass filters in imaging systems: High-pass filters play a crucial role in image processing and enhancement. They are used to sharpen edges, improve contrast, and remove low-frequency noise in various imaging applications, including medical imaging, satellite imagery, and digital photography.

- High-pass filtering in communication systems: In communication systems, high-pass filters are employed to remove unwanted low-frequency interference, improve signal quality, and enhance the overall performance of transmitters and receivers. This is particularly important in wireless communications and data transmission applications.

- Integration of high-pass filters in audio processing: High-pass filters are extensively used in audio processing to remove low-frequency noise, improve clarity, and balance the frequency response of audio signals. This is applied in various audio equipment, including speakers, microphones, and digital audio workstations.

02 High-pass filter design and implementation

Various methods and circuits are employed to design and implement high-pass filters. These include analog and digital filter designs, utilizing components such as capacitors, inductors, and operational amplifiers. Advanced techniques may involve adaptive filtering and software-defined filters for improved performance and flexibility.Expand Specific Solutions03 Application of high-pass filters in imaging systems

High-pass filters play a crucial role in image processing and enhancement. They are used to sharpen edges, improve contrast, and remove low-frequency noise in various imaging applications, including medical imaging, satellite imagery, and digital photography.Expand Specific Solutions04 High-pass filtering in audio systems

In audio processing, high-pass filters are employed to remove unwanted low-frequency noise, improve clarity, and optimize sound reproduction. They are used in various audio equipment, including speakers, microphones, and mixing consoles, to enhance overall audio quality.Expand Specific Solutions05 High-pass filter applications in communication systems

High-pass filters are essential components in communication systems for signal conditioning, noise reduction, and frequency selection. They are used in radio frequency (RF) circuits, modems, and wireless communication devices to improve signal quality and system performance.Expand Specific Solutions

Key Industrial Automation System Providers

The research on high pass filters in industrial automation systems for real-time data processing is in a mature stage of development, with a significant market size driven by the increasing demand for efficient data processing in industrial applications. The technology has reached a high level of maturity, as evidenced by the involvement of major players such as Siemens AG, Analog Devices, Inc., and Texas Instruments Incorporated. These companies have established strong positions in the market, leveraging their expertise in signal processing and automation technologies. The competitive landscape is characterized by ongoing innovation and product development, with companies like NXP Semiconductors and STMicroelectronics also making significant contributions to the field.

Analog Devices, Inc.

Technical Solution: Analog Devices has developed advanced high-pass filter solutions for industrial automation systems, focusing on real-time data processing. Their approach utilizes precision analog-to-digital converters (ADCs) combined with programmable digital filters[1]. This allows for flexible configuration of cut-off frequencies and filter orders to suit various industrial applications. The company has also introduced innovative sigma-delta ADCs with built-in high-pass filtering capabilities, enabling direct interfacing with sensors and reducing the need for external components[2]. Additionally, Analog Devices has implemented field-programmable gate array (FPGA) based high-pass filter designs, offering high-speed processing for demanding industrial environments[3].

Strengths: Highly customizable solutions, integration of analog and digital technologies, reduced system complexity. Weaknesses: Potential higher cost compared to simpler solutions, may require specialized knowledge for optimal configuration.

Siemens AG

Technical Solution: Siemens AG has developed a comprehensive approach to high-pass filtering in industrial automation systems, integrating it into their SIMATIC series of programmable logic controllers (PLCs). Their solution incorporates both hardware and software components, allowing for real-time data processing across various industrial applications. Siemens' high-pass filters are designed to work seamlessly with their industrial communication protocols, such as PROFINET and PROFIBUS, ensuring minimal latency in data transmission[1]. The company has also introduced adaptive filtering techniques that automatically adjust filter parameters based on changing process conditions, enhancing system responsiveness and reliability[2]. Furthermore, Siemens has implemented distributed filtering architectures in their automation systems, enabling processing closer to the data source and reducing network load[3].

Strengths: Seamless integration with existing Siemens automation systems, adaptive filtering capabilities, distributed processing architecture. Weaknesses: Potential vendor lock-in, may require significant investment in Siemens ecosystem.

Core HPF Innovations for Real-Time Processing

Method for equalising a sensor signal, in particular the input signal of a control device for an internal combustion engine

PatentWO2006081876A1

Innovation

- A method involving a high-pass filter to determine the time constant of a first-order low-pass filter, allowing for adjustable initial and final behavior, and combining with a gradient limiter to avoid overshooting and simplify parameterization, thereby ensuring smooth engine operation and quick response to changes.

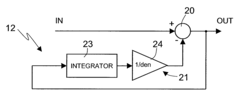

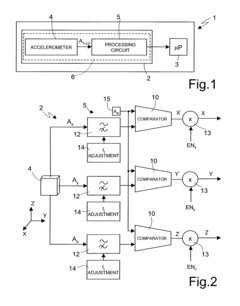

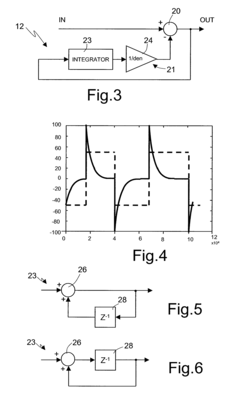

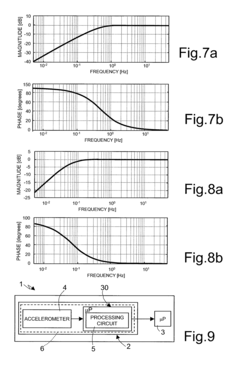

Digital high-pass filter for a displacement detection device of a portable apparatus

PatentActiveUS7783449B2

Innovation

- A digital high-pass filter with a recursive structure and adjustable cutoff frequency, implemented using a subtractor, recursive branch, integrator, and divider stages, which reduces the continuous component of acceleration signals due to gravity, allowing for independent displacement detection and easy configuration.

Industrial Standards and Regulations

In the realm of industrial automation systems, adherence to standards and regulations is paramount for ensuring safety, reliability, and interoperability. The implementation of high pass filters for real-time data processing must comply with various industry-specific standards and regulatory requirements. These standards are established by international organizations and national bodies to maintain consistency and quality across the industry.

One of the primary standards governing industrial automation systems is IEC 61131, which provides guidelines for programmable controllers. This standard includes specifications for programming languages, communication protocols, and functional safety. When implementing high pass filters, developers must ensure that their designs align with the relevant sections of IEC 61131, particularly those related to data processing and signal filtering.

The IEC 61000 series of standards is crucial for electromagnetic compatibility (EMC) in industrial environments. High pass filters must be designed and implemented in accordance with these standards to minimize electromagnetic interference and ensure reliable operation of automation systems. Compliance with IEC 61000-4-4 is especially important for protecting against electrical fast transients and bursts that can affect data integrity.

For real-time data processing applications, the IEEE 1588 Precision Time Protocol (PTP) standard is often employed to achieve precise time synchronization across distributed systems. High pass filters integrated into such systems must be compatible with PTP to maintain accurate timing and data coherence.

In the United States, the National Electrical Manufacturers Association (NEMA) provides standards that are widely adopted in industrial automation. NEMA standards, such as NEMA ICS 1-2000, offer guidelines for industrial control and systems that may influence the design and implementation of high pass filters.

The International Society of Automation (ISA) has developed the ISA-95 standard, which addresses the integration of enterprise and control systems. This standard is relevant when considering how high pass filters fit into the broader automation architecture and data flow within an organization.

Safety considerations are addressed by standards such as IEC 61508 for functional safety of electrical/electronic/programmable electronic safety-related systems. When high pass filters are part of safety-critical systems, compliance with this standard is essential to ensure that the filtering process does not compromise system safety integrity.

Regulatory bodies like the Federal Communications Commission (FCC) in the United States and the European Union's CE marking requirements also play a significant role. These regulations ensure that industrial automation equipment, including systems utilizing high pass filters, meet electromagnetic compatibility and safety standards before they can be marketed or used in industrial settings.

As industrial automation systems increasingly incorporate Internet of Things (IoT) technologies, standards related to cybersecurity become crucial. The IEC 62443 series provides guidelines for industrial communication networks and system security, which must be considered when implementing networked high pass filter solutions for real-time data processing.

One of the primary standards governing industrial automation systems is IEC 61131, which provides guidelines for programmable controllers. This standard includes specifications for programming languages, communication protocols, and functional safety. When implementing high pass filters, developers must ensure that their designs align with the relevant sections of IEC 61131, particularly those related to data processing and signal filtering.

The IEC 61000 series of standards is crucial for electromagnetic compatibility (EMC) in industrial environments. High pass filters must be designed and implemented in accordance with these standards to minimize electromagnetic interference and ensure reliable operation of automation systems. Compliance with IEC 61000-4-4 is especially important for protecting against electrical fast transients and bursts that can affect data integrity.

For real-time data processing applications, the IEEE 1588 Precision Time Protocol (PTP) standard is often employed to achieve precise time synchronization across distributed systems. High pass filters integrated into such systems must be compatible with PTP to maintain accurate timing and data coherence.

In the United States, the National Electrical Manufacturers Association (NEMA) provides standards that are widely adopted in industrial automation. NEMA standards, such as NEMA ICS 1-2000, offer guidelines for industrial control and systems that may influence the design and implementation of high pass filters.

The International Society of Automation (ISA) has developed the ISA-95 standard, which addresses the integration of enterprise and control systems. This standard is relevant when considering how high pass filters fit into the broader automation architecture and data flow within an organization.

Safety considerations are addressed by standards such as IEC 61508 for functional safety of electrical/electronic/programmable electronic safety-related systems. When high pass filters are part of safety-critical systems, compliance with this standard is essential to ensure that the filtering process does not compromise system safety integrity.

Regulatory bodies like the Federal Communications Commission (FCC) in the United States and the European Union's CE marking requirements also play a significant role. These regulations ensure that industrial automation equipment, including systems utilizing high pass filters, meet electromagnetic compatibility and safety standards before they can be marketed or used in industrial settings.

As industrial automation systems increasingly incorporate Internet of Things (IoT) technologies, standards related to cybersecurity become crucial. The IEC 62443 series provides guidelines for industrial communication networks and system security, which must be considered when implementing networked high pass filter solutions for real-time data processing.

Energy Efficiency in HPF Design

Energy efficiency has become a critical consideration in the design of high pass filters (HPFs) for industrial automation systems. As real-time data processing demands continue to increase, the power consumption of these filters can significantly impact overall system performance and operational costs. To address this challenge, researchers and engineers are exploring innovative approaches to optimize the energy efficiency of HPFs without compromising their filtering capabilities.

One key strategy for improving energy efficiency in HPF design is the implementation of adaptive filtering techniques. These methods allow the filter to dynamically adjust its parameters based on the input signal characteristics, ensuring optimal performance while minimizing power consumption. By employing adaptive algorithms, such as the least mean squares (LMS) or recursive least squares (RLS), HPFs can maintain high accuracy in signal processing while reducing unnecessary computations and energy expenditure.

Another promising approach is the utilization of low-power circuit design techniques. This includes the adoption of sub-threshold operation for transistors, which allows for significant power savings at the expense of slightly reduced speed. Additionally, the use of voltage scaling and power gating techniques can further reduce energy consumption by selectively powering down portions of the filter circuitry when not in use.

The integration of energy-efficient materials and components is also playing a crucial role in enhancing HPF energy efficiency. For instance, the incorporation of high-quality passive components with low parasitic effects can minimize power losses and improve overall filter performance. Furthermore, the use of advanced semiconductor technologies, such as silicon-on-insulator (SOI) or gallium nitride (GaN), can offer superior energy efficiency compared to traditional silicon-based designs.

Researchers are also exploring the potential of energy harvesting techniques to supplement or even replace traditional power sources for HPFs in certain applications. By harnessing ambient energy from sources such as vibrations, thermal gradients, or electromagnetic fields, these systems can potentially operate with minimal external power input, significantly reducing their energy footprint.

The optimization of filter topologies and architectures is another area of focus for improving energy efficiency. Novel filter structures, such as distributed or cascaded designs, can offer improved performance-to-power ratios compared to conventional topologies. Additionally, the exploration of alternative filtering techniques, such as switched-capacitor or current-mode filters, may provide energy-efficient alternatives to traditional voltage-mode designs in specific applications.

As the demand for energy-efficient solutions in industrial automation continues to grow, the development of low-power HPFs remains a critical area of research. By combining innovative circuit design techniques, advanced materials, and intelligent power management strategies, researchers aim to create next-generation HPFs that deliver superior performance while minimizing energy consumption, ultimately contributing to more sustainable and cost-effective industrial automation systems.

One key strategy for improving energy efficiency in HPF design is the implementation of adaptive filtering techniques. These methods allow the filter to dynamically adjust its parameters based on the input signal characteristics, ensuring optimal performance while minimizing power consumption. By employing adaptive algorithms, such as the least mean squares (LMS) or recursive least squares (RLS), HPFs can maintain high accuracy in signal processing while reducing unnecessary computations and energy expenditure.

Another promising approach is the utilization of low-power circuit design techniques. This includes the adoption of sub-threshold operation for transistors, which allows for significant power savings at the expense of slightly reduced speed. Additionally, the use of voltage scaling and power gating techniques can further reduce energy consumption by selectively powering down portions of the filter circuitry when not in use.

The integration of energy-efficient materials and components is also playing a crucial role in enhancing HPF energy efficiency. For instance, the incorporation of high-quality passive components with low parasitic effects can minimize power losses and improve overall filter performance. Furthermore, the use of advanced semiconductor technologies, such as silicon-on-insulator (SOI) or gallium nitride (GaN), can offer superior energy efficiency compared to traditional silicon-based designs.

Researchers are also exploring the potential of energy harvesting techniques to supplement or even replace traditional power sources for HPFs in certain applications. By harnessing ambient energy from sources such as vibrations, thermal gradients, or electromagnetic fields, these systems can potentially operate with minimal external power input, significantly reducing their energy footprint.

The optimization of filter topologies and architectures is another area of focus for improving energy efficiency. Novel filter structures, such as distributed or cascaded designs, can offer improved performance-to-power ratios compared to conventional topologies. Additionally, the exploration of alternative filtering techniques, such as switched-capacitor or current-mode filters, may provide energy-efficient alternatives to traditional voltage-mode designs in specific applications.

As the demand for energy-efficient solutions in industrial automation continues to grow, the development of low-power HPFs remains a critical area of research. By combining innovative circuit design techniques, advanced materials, and intelligent power management strategies, researchers aim to create next-generation HPFs that deliver superior performance while minimizing energy consumption, ultimately contributing to more sustainable and cost-effective industrial automation systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!