Applications of Sodium Percarbonate in Biodegradable Packaging

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Percarbonate in Packaging: Background and Objectives

Sodium percarbonate, a compound formed by sodium carbonate and hydrogen peroxide, has gained significant attention in recent years due to its potential applications in biodegradable packaging. This technology has emerged as a promising solution to address the growing environmental concerns associated with traditional packaging materials.

The evolution of packaging technology has been driven by the need for more sustainable and eco-friendly alternatives. As global awareness of plastic pollution and its detrimental effects on the environment has increased, there has been a shift towards developing biodegradable packaging solutions. Sodium percarbonate has emerged as a key player in this technological landscape, offering unique properties that align with the goals of sustainability and environmental responsibility.

The primary objective of incorporating sodium percarbonate into biodegradable packaging is to enhance the material's degradation process while maintaining its functional properties. This compound acts as an oxidizing agent, facilitating the breakdown of organic materials and accelerating the decomposition of the packaging after disposal. By integrating sodium percarbonate into packaging materials, researchers aim to create products that can effectively protect goods during storage and transportation, yet rapidly degrade once discarded.

Another crucial goal is to develop packaging solutions that are both cost-effective and environmentally friendly. Sodium percarbonate offers a balance between these two aspects, as it is relatively inexpensive to produce and can be easily incorporated into existing manufacturing processes. This makes it an attractive option for industries seeking to transition towards more sustainable packaging without incurring significant additional costs.

The technology trend in this field is moving towards the development of multi-functional packaging materials. Sodium percarbonate not only contributes to biodegradability but also possesses antimicrobial properties, which can help extend the shelf life of packaged products. This dual functionality aligns with the growing demand for packaging solutions that offer both environmental benefits and improved product preservation.

As research in this area progresses, the focus is on optimizing the integration of sodium percarbonate into various packaging materials, such as films, coatings, and molded products. Scientists are exploring different formulations and manufacturing techniques to enhance the compound's effectiveness while ensuring the structural integrity and performance of the packaging.

In conclusion, the application of sodium percarbonate in biodegradable packaging represents a significant step towards more sustainable packaging solutions. By addressing both environmental concerns and practical packaging requirements, this technology has the potential to revolutionize the packaging industry and contribute to global efforts in reducing plastic waste and pollution.

The evolution of packaging technology has been driven by the need for more sustainable and eco-friendly alternatives. As global awareness of plastic pollution and its detrimental effects on the environment has increased, there has been a shift towards developing biodegradable packaging solutions. Sodium percarbonate has emerged as a key player in this technological landscape, offering unique properties that align with the goals of sustainability and environmental responsibility.

The primary objective of incorporating sodium percarbonate into biodegradable packaging is to enhance the material's degradation process while maintaining its functional properties. This compound acts as an oxidizing agent, facilitating the breakdown of organic materials and accelerating the decomposition of the packaging after disposal. By integrating sodium percarbonate into packaging materials, researchers aim to create products that can effectively protect goods during storage and transportation, yet rapidly degrade once discarded.

Another crucial goal is to develop packaging solutions that are both cost-effective and environmentally friendly. Sodium percarbonate offers a balance between these two aspects, as it is relatively inexpensive to produce and can be easily incorporated into existing manufacturing processes. This makes it an attractive option for industries seeking to transition towards more sustainable packaging without incurring significant additional costs.

The technology trend in this field is moving towards the development of multi-functional packaging materials. Sodium percarbonate not only contributes to biodegradability but also possesses antimicrobial properties, which can help extend the shelf life of packaged products. This dual functionality aligns with the growing demand for packaging solutions that offer both environmental benefits and improved product preservation.

As research in this area progresses, the focus is on optimizing the integration of sodium percarbonate into various packaging materials, such as films, coatings, and molded products. Scientists are exploring different formulations and manufacturing techniques to enhance the compound's effectiveness while ensuring the structural integrity and performance of the packaging.

In conclusion, the application of sodium percarbonate in biodegradable packaging represents a significant step towards more sustainable packaging solutions. By addressing both environmental concerns and practical packaging requirements, this technology has the potential to revolutionize the packaging industry and contribute to global efforts in reducing plastic waste and pollution.

Market Analysis for Eco-Friendly Packaging Solutions

The eco-friendly packaging market has experienced significant growth in recent years, driven by increasing environmental awareness and stringent regulations on plastic waste. The global biodegradable packaging market is projected to reach $21.7 billion by 2025, with a compound annual growth rate of 17.4% from 2020 to 2025. This growth is primarily fueled by consumer demand for sustainable packaging solutions and corporate commitments to reduce environmental impact.

Sodium percarbonate, a key component in biodegradable packaging applications, is gaining traction due to its dual functionality as both a cleaning agent and an oxygen source. The market for sodium percarbonate in packaging is expected to grow alongside the broader eco-friendly packaging sector, with particular emphasis on food and beverage, personal care, and household goods industries.

In the food and beverage sector, which accounts for the largest share of the biodegradable packaging market, sodium percarbonate-based packaging solutions are being developed to extend shelf life and maintain product freshness. These innovations are particularly relevant for perishable goods and ready-to-eat meals, where packaging plays a crucial role in preserving quality and reducing food waste.

The personal care industry is another significant driver for eco-friendly packaging solutions incorporating sodium percarbonate. Consumers are increasingly seeking products with minimal environmental impact, leading to a surge in demand for biodegradable packaging for cosmetics, toiletries, and other personal care items. Sodium percarbonate's ability to act as a gentle bleaching agent also makes it attractive for packaging applications in this sector.

Geographically, Europe leads the market for eco-friendly packaging solutions, followed closely by North America. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India.

Key market players in the eco-friendly packaging sector are investing heavily in research and development to create innovative solutions using sodium percarbonate. These efforts are focused on improving the material's stability, enhancing its oxygen-releasing properties, and optimizing its integration with various biodegradable polymers to create high-performance packaging materials.

As the market for eco-friendly packaging continues to expand, challenges such as cost competitiveness and scalability of production remain. However, ongoing technological advancements and increasing economies of scale are expected to address these issues, further driving the adoption of sodium percarbonate-based biodegradable packaging solutions across various industries.

Sodium percarbonate, a key component in biodegradable packaging applications, is gaining traction due to its dual functionality as both a cleaning agent and an oxygen source. The market for sodium percarbonate in packaging is expected to grow alongside the broader eco-friendly packaging sector, with particular emphasis on food and beverage, personal care, and household goods industries.

In the food and beverage sector, which accounts for the largest share of the biodegradable packaging market, sodium percarbonate-based packaging solutions are being developed to extend shelf life and maintain product freshness. These innovations are particularly relevant for perishable goods and ready-to-eat meals, where packaging plays a crucial role in preserving quality and reducing food waste.

The personal care industry is another significant driver for eco-friendly packaging solutions incorporating sodium percarbonate. Consumers are increasingly seeking products with minimal environmental impact, leading to a surge in demand for biodegradable packaging for cosmetics, toiletries, and other personal care items. Sodium percarbonate's ability to act as a gentle bleaching agent also makes it attractive for packaging applications in this sector.

Geographically, Europe leads the market for eco-friendly packaging solutions, followed closely by North America. However, the Asia-Pacific region is expected to witness the highest growth rate in the coming years, driven by rapid industrialization, urbanization, and increasing environmental regulations in countries like China and India.

Key market players in the eco-friendly packaging sector are investing heavily in research and development to create innovative solutions using sodium percarbonate. These efforts are focused on improving the material's stability, enhancing its oxygen-releasing properties, and optimizing its integration with various biodegradable polymers to create high-performance packaging materials.

As the market for eco-friendly packaging continues to expand, challenges such as cost competitiveness and scalability of production remain. However, ongoing technological advancements and increasing economies of scale are expected to address these issues, further driving the adoption of sodium percarbonate-based biodegradable packaging solutions across various industries.

Current Challenges in Biodegradable Packaging Technology

The field of biodegradable packaging technology faces several significant challenges that hinder its widespread adoption and effectiveness. One of the primary obstacles is the limited performance of current biodegradable materials compared to traditional plastics. Many biodegradable alternatives struggle to match the durability, barrier properties, and shelf life of conventional packaging materials, particularly in demanding applications such as food preservation.

Cost remains a major hurdle for biodegradable packaging solutions. The production processes and raw materials for these eco-friendly alternatives are often more expensive than those used in traditional plastic manufacturing. This price disparity makes it difficult for companies to justify the switch to biodegradable options, especially in price-sensitive markets.

Another challenge lies in the inconsistent degradation rates of biodegradable materials. Depending on environmental conditions, some products may break down too quickly, compromising their functionality, while others may persist longer than expected, potentially contributing to pollution. This variability makes it challenging to predict and control the lifecycle of biodegradable packaging in different disposal scenarios.

The lack of standardized testing methods and certification processes for biodegradability claims presents another significant issue. This absence of uniformity can lead to confusion among consumers and regulators, potentially undermining trust in biodegradable products and hindering their market acceptance.

Compatibility with existing recycling infrastructure is also a concern. Many biodegradable materials require specific conditions for proper decomposition, which are not always available in standard waste management facilities. This can lead to biodegradable packaging contaminating conventional recycling streams or ending up in landfills where they may not degrade as intended.

The development of biodegradable packaging that can withstand various environmental conditions while maintaining product integrity remains a technical challenge. Factors such as moisture, temperature, and UV exposure can significantly affect the performance and degradation of these materials, limiting their applicability in certain industries or geographic regions.

Lastly, there is an ongoing challenge in balancing the biodegradability of packaging with its functional requirements. While rapid degradation is desirable for environmental reasons, it can compromise the package's ability to protect and preserve its contents effectively. Finding the right balance between these competing demands continues to be a focus of research and development efforts in the field.

Cost remains a major hurdle for biodegradable packaging solutions. The production processes and raw materials for these eco-friendly alternatives are often more expensive than those used in traditional plastic manufacturing. This price disparity makes it difficult for companies to justify the switch to biodegradable options, especially in price-sensitive markets.

Another challenge lies in the inconsistent degradation rates of biodegradable materials. Depending on environmental conditions, some products may break down too quickly, compromising their functionality, while others may persist longer than expected, potentially contributing to pollution. This variability makes it challenging to predict and control the lifecycle of biodegradable packaging in different disposal scenarios.

The lack of standardized testing methods and certification processes for biodegradability claims presents another significant issue. This absence of uniformity can lead to confusion among consumers and regulators, potentially undermining trust in biodegradable products and hindering their market acceptance.

Compatibility with existing recycling infrastructure is also a concern. Many biodegradable materials require specific conditions for proper decomposition, which are not always available in standard waste management facilities. This can lead to biodegradable packaging contaminating conventional recycling streams or ending up in landfills where they may not degrade as intended.

The development of biodegradable packaging that can withstand various environmental conditions while maintaining product integrity remains a technical challenge. Factors such as moisture, temperature, and UV exposure can significantly affect the performance and degradation of these materials, limiting their applicability in certain industries or geographic regions.

Lastly, there is an ongoing challenge in balancing the biodegradability of packaging with its functional requirements. While rapid degradation is desirable for environmental reasons, it can compromise the package's ability to protect and preserve its contents effectively. Finding the right balance between these competing demands continues to be a focus of research and development efforts in the field.

Existing Sodium Percarbonate-Based Packaging Solutions

01 Synthesis and production of sodium percarbonate

Various methods for synthesizing and producing sodium percarbonate are described. These methods involve the reaction of sodium carbonate with hydrogen peroxide under specific conditions to form stable sodium percarbonate crystals. The processes may include steps such as crystallization, drying, and stabilization to improve the quality and stability of the final product.- Synthesis and production of sodium percarbonate: Various methods for synthesizing and producing sodium percarbonate are described. These include processes involving the reaction of sodium carbonate with hydrogen peroxide, as well as techniques for improving the stability and purity of the final product. Different reaction conditions, catalysts, and processing steps are employed to optimize the production of sodium percarbonate.

- Stabilization and coating of sodium percarbonate: Techniques for stabilizing and coating sodium percarbonate particles are discussed. These methods aim to improve the storage stability, handling properties, and performance of sodium percarbonate in various applications. Coating materials and processes are described to enhance the product's resistance to moisture, decomposition, and caking.

- Applications in cleaning and bleaching compositions: Sodium percarbonate is widely used in cleaning and bleaching compositions. Its incorporation into detergents, laundry products, and household cleaners is discussed. The role of sodium percarbonate as an oxygen-based bleaching agent and its effectiveness in removing stains and whitening fabrics are highlighted.

- Environmental and safety considerations: The environmental impact and safety aspects of sodium percarbonate are addressed. Its biodegradability, low toxicity, and eco-friendly nature compared to other bleaching agents are discussed. Safety measures for handling and storage, as well as its potential use in environmentally friendly products, are explored.

- Analytical methods and quality control: Various analytical methods and quality control procedures for sodium percarbonate are described. These include techniques for determining purity, active oxygen content, and stability. Methods for detecting impurities, assessing particle size distribution, and evaluating the effectiveness of coatings are also discussed.

02 Stabilization of sodium percarbonate

Techniques for stabilizing sodium percarbonate to improve its shelf life and performance are discussed. These may include coating the particles with stabilizing agents, incorporating additives, or modifying the crystal structure. The stabilization methods aim to prevent decomposition and maintain the active oxygen content of the compound during storage and use.Expand Specific Solutions03 Applications in cleaning and bleaching products

Sodium percarbonate is widely used in cleaning and bleaching formulations. It serves as an effective oxygen-based bleaching agent in laundry detergents, dishwashing products, and other household cleaners. The compound releases hydrogen peroxide when dissolved in water, providing stain removal and disinfecting properties.Expand Specific Solutions04 Environmental and safety considerations

The environmental impact and safety aspects of sodium percarbonate are addressed. As an oxygen-based compound, it is considered more environmentally friendly compared to chlorine-based bleaches. Safety measures for handling, storage, and disposal of sodium percarbonate are discussed, as well as its biodegradability and potential effects on aquatic ecosystems.Expand Specific Solutions05 Formulation with other active ingredients

Sodium percarbonate is often combined with other active ingredients in various formulations to enhance its effectiveness or provide additional benefits. These may include surfactants, enzymes, or other cleaning agents. The synergistic effects of these combinations and their impact on cleaning performance are explored.Expand Specific Solutions

Key Players in Sustainable Packaging Industry

The applications of sodium percarbonate in biodegradable packaging are in an emerging stage, with the market showing promising growth potential. The industry is transitioning from research to early commercialization, driven by increasing demand for sustainable packaging solutions. Key players like Solvay SA, Evonik Operations GmbH, and Henkel AG & Co. KGaA are investing in R&D to improve the technology's efficiency and scalability. The market size is expanding, fueled by growing environmental concerns and stringent regulations. While the technology is still evolving, companies such as BIOTEC Biologische Naturverpackungen GmbH & Co. KG are making significant strides in developing innovative, biodegradable packaging solutions incorporating sodium percarbonate.

Solvay SA

Technical Solution: Solvay has developed a sodium percarbonate-based solution for biodegradable packaging applications. Their approach involves incorporating sodium percarbonate into polymer matrices to create active packaging materials. These materials release oxygen and hydrogen peroxide when exposed to moisture, providing antimicrobial properties and extending the shelf life of packaged goods[1]. Solvay's technology also includes a controlled release mechanism, ensuring a sustained effect over time[2]. The company has further enhanced the stability of sodium percarbonate in the polymer matrix by using specialized coating techniques, which prevent premature decomposition during the packaging manufacturing process[3].

Strengths: Extensive experience in chemical manufacturing, strong R&D capabilities, and a global presence. Weaknesses: Potential higher costs due to specialized formulations and coating processes.

Evonik Operations GmbH

Technical Solution: Evonik has developed a novel approach to incorporating sodium percarbonate into biodegradable packaging materials. Their technology focuses on creating a synergistic effect between sodium percarbonate and biodegradable polymers, such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA)[4]. By carefully controlling the particle size and distribution of sodium percarbonate within the polymer matrix, Evonik has achieved improved oxygen barrier properties and enhanced biodegradability[5]. The company has also developed a proprietary encapsulation technique that protects the sodium percarbonate from premature activation, ensuring its effectiveness throughout the packaging's lifecycle[6].

Strengths: Strong expertise in specialty chemicals and polymers, innovative encapsulation techniques. Weaknesses: May face challenges in scaling up production for mass market applications.

Innovative Sodium Percarbonate Formulations for Packaging

Packing material and method for producing packing material

PatentWO2024080233A1

Innovation

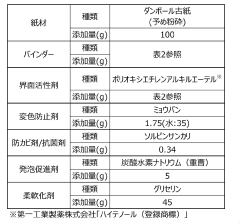

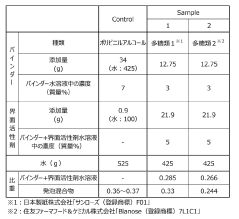

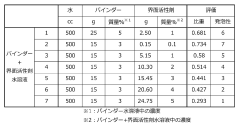

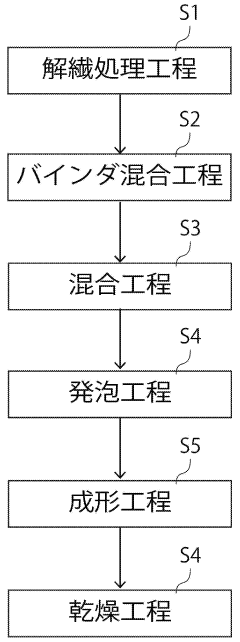

- A packaging material composed of a fibrous material containing waste paper or pulp, a binder selected from polysaccharides and proteins, sodium bicarbonate as a foaming accelerator, a surfactant, and a water-soluble softener, optionally including a discoloration inhibitor and antibacterial agent, formed into a foamed structure with a base layer and structure layer, using a method involving mixing, foaming, molding, and drying to enhance elasticity and recyclability.

Environmental Impact Assessment of Sodium Percarbonate Packaging

The environmental impact assessment of sodium percarbonate packaging is a crucial aspect of its application in biodegradable packaging solutions. Sodium percarbonate, a compound of sodium carbonate and hydrogen peroxide, has gained attention for its potential to enhance the biodegradability of packaging materials while providing additional functional benefits.

One of the primary environmental advantages of sodium percarbonate in packaging is its ability to decompose into environmentally benign substances. When exposed to moisture, sodium percarbonate breaks down into sodium carbonate, water, and oxygen. This decomposition process leaves no harmful residues, making it an attractive option for eco-friendly packaging solutions.

The incorporation of sodium percarbonate into biodegradable packaging materials can potentially accelerate the degradation process. This is particularly beneficial in addressing the growing concern of plastic pollution, as it can help reduce the persistence of packaging waste in the environment. However, the rate and extent of biodegradation may vary depending on environmental conditions and the specific formulation of the packaging material.

From a life cycle perspective, the production of sodium percarbonate does have some environmental implications. The manufacturing process typically involves the reaction of sodium carbonate with hydrogen peroxide, which requires energy input and may result in some emissions. However, when compared to traditional packaging materials, the overall environmental footprint of sodium percarbonate-enhanced biodegradable packaging is generally considered to be lower.

Water quality is another important consideration in the environmental assessment. While sodium percarbonate itself is not toxic to aquatic life in normal concentrations, its decomposition products can temporarily increase the pH and oxygen levels in water bodies. This effect is usually localized and short-lived but should be monitored in sensitive aquatic ecosystems.

The use of sodium percarbonate in packaging may also contribute to reduced chemical pollution. As a safer alternative to some traditional bleaching and cleaning agents, it can minimize the release of harmful chemicals into the environment during the packaging production and disposal processes.

In terms of resource conservation, sodium percarbonate-enhanced packaging could lead to more efficient use of raw materials. By improving the biodegradability of packaging, it may reduce the need for virgin materials in packaging production and decrease the volume of waste sent to landfills or incineration facilities.

However, it is important to note that the environmental benefits of sodium percarbonate in packaging are contingent upon proper waste management practices. Appropriate collection and processing systems must be in place to ensure that the biodegradable packaging reaches the correct end-of-life treatment facilities where it can degrade as intended.

One of the primary environmental advantages of sodium percarbonate in packaging is its ability to decompose into environmentally benign substances. When exposed to moisture, sodium percarbonate breaks down into sodium carbonate, water, and oxygen. This decomposition process leaves no harmful residues, making it an attractive option for eco-friendly packaging solutions.

The incorporation of sodium percarbonate into biodegradable packaging materials can potentially accelerate the degradation process. This is particularly beneficial in addressing the growing concern of plastic pollution, as it can help reduce the persistence of packaging waste in the environment. However, the rate and extent of biodegradation may vary depending on environmental conditions and the specific formulation of the packaging material.

From a life cycle perspective, the production of sodium percarbonate does have some environmental implications. The manufacturing process typically involves the reaction of sodium carbonate with hydrogen peroxide, which requires energy input and may result in some emissions. However, when compared to traditional packaging materials, the overall environmental footprint of sodium percarbonate-enhanced biodegradable packaging is generally considered to be lower.

Water quality is another important consideration in the environmental assessment. While sodium percarbonate itself is not toxic to aquatic life in normal concentrations, its decomposition products can temporarily increase the pH and oxygen levels in water bodies. This effect is usually localized and short-lived but should be monitored in sensitive aquatic ecosystems.

The use of sodium percarbonate in packaging may also contribute to reduced chemical pollution. As a safer alternative to some traditional bleaching and cleaning agents, it can minimize the release of harmful chemicals into the environment during the packaging production and disposal processes.

In terms of resource conservation, sodium percarbonate-enhanced packaging could lead to more efficient use of raw materials. By improving the biodegradability of packaging, it may reduce the need for virgin materials in packaging production and decrease the volume of waste sent to landfills or incineration facilities.

However, it is important to note that the environmental benefits of sodium percarbonate in packaging are contingent upon proper waste management practices. Appropriate collection and processing systems must be in place to ensure that the biodegradable packaging reaches the correct end-of-life treatment facilities where it can degrade as intended.

Regulatory Framework for Biodegradable Packaging Materials

The regulatory framework for biodegradable packaging materials is a complex and evolving landscape that plays a crucial role in the adoption and implementation of sustainable packaging solutions. As the use of sodium percarbonate in biodegradable packaging gains traction, it is essential to understand the regulatory environment that governs these materials.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards for biodegradable plastics, including ISO 17088 and ISO 14855. These standards provide guidelines for the testing and certification of biodegradable materials, ensuring consistency across different regions and facilitating global trade.

In the European Union, the regulatory framework is particularly advanced. The EU Packaging and Packaging Waste Directive (94/62/EC) sets targets for the recovery and recycling of packaging waste, including biodegradable materials. The EN 13432 standard, which is harmonized with the EU directive, specifies requirements for packaging recoverable through composting and biodegradation.

The United States has a more fragmented approach, with regulations varying at the federal, state, and local levels. The Federal Trade Commission (FTC) provides guidelines on environmental marketing claims, including those related to biodegradability. Several states, such as California, have enacted their own laws regulating the labeling and disposal of biodegradable plastics.

In Asia, countries like Japan and South Korea have established certification systems for biodegradable plastics. Japan's GreenPla certification and South Korea's EL724 standard provide frameworks for assessing the biodegradability and compostability of packaging materials.

Regulatory bodies are increasingly focusing on the chemical composition of biodegradable packaging materials. The use of sodium percarbonate in such applications must comply with food contact regulations, such as those set by the U.S. Food and Drug Administration (FDA) or the European Food Safety Authority (EFSA). These agencies evaluate the safety of chemicals used in food packaging and set migration limits to ensure consumer safety.

As environmental concerns grow, many countries are implementing extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their packaging products. This regulatory approach encourages the development of more sustainable packaging solutions, potentially favoring the use of biodegradable materials like those incorporating sodium percarbonate.

The regulatory landscape is continuously evolving, with new legislation being proposed and implemented globally. For instance, the EU's Single-Use Plastics Directive, which came into effect in 2021, aims to reduce plastic pollution by banning certain single-use plastic items and promoting the use of sustainable alternatives. Such regulations are likely to drive further innovation in biodegradable packaging technologies, including those utilizing sodium percarbonate.

At the international level, organizations such as the International Organization for Standardization (ISO) have developed standards for biodegradable plastics, including ISO 17088 and ISO 14855. These standards provide guidelines for the testing and certification of biodegradable materials, ensuring consistency across different regions and facilitating global trade.

In the European Union, the regulatory framework is particularly advanced. The EU Packaging and Packaging Waste Directive (94/62/EC) sets targets for the recovery and recycling of packaging waste, including biodegradable materials. The EN 13432 standard, which is harmonized with the EU directive, specifies requirements for packaging recoverable through composting and biodegradation.

The United States has a more fragmented approach, with regulations varying at the federal, state, and local levels. The Federal Trade Commission (FTC) provides guidelines on environmental marketing claims, including those related to biodegradability. Several states, such as California, have enacted their own laws regulating the labeling and disposal of biodegradable plastics.

In Asia, countries like Japan and South Korea have established certification systems for biodegradable plastics. Japan's GreenPla certification and South Korea's EL724 standard provide frameworks for assessing the biodegradability and compostability of packaging materials.

Regulatory bodies are increasingly focusing on the chemical composition of biodegradable packaging materials. The use of sodium percarbonate in such applications must comply with food contact regulations, such as those set by the U.S. Food and Drug Administration (FDA) or the European Food Safety Authority (EFSA). These agencies evaluate the safety of chemicals used in food packaging and set migration limits to ensure consumer safety.

As environmental concerns grow, many countries are implementing extended producer responsibility (EPR) schemes, which hold manufacturers accountable for the entire lifecycle of their packaging products. This regulatory approach encourages the development of more sustainable packaging solutions, potentially favoring the use of biodegradable materials like those incorporating sodium percarbonate.

The regulatory landscape is continuously evolving, with new legislation being proposed and implemented globally. For instance, the EU's Single-Use Plastics Directive, which came into effect in 2021, aims to reduce plastic pollution by banning certain single-use plastic items and promoting the use of sustainable alternatives. Such regulations are likely to drive further innovation in biodegradable packaging technologies, including those utilizing sodium percarbonate.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!