Use of Sodium Percarbonate in Miniature Golf Course Cleanliness

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Percarbonate in Golf Course Maintenance

Sodium percarbonate, a compound of sodium carbonate and hydrogen peroxide, has emerged as a versatile and eco-friendly cleaning agent in various industries, including golf course maintenance. Its application in miniature golf course cleanliness has gained significant attention due to its effectiveness and environmental benefits.

The use of sodium percarbonate in golf course maintenance addresses several key challenges faced by groundskeepers and facility managers. Primarily, it offers a powerful cleaning solution for removing algae, mold, and other organic stains that commonly accumulate on artificial turf, concrete paths, and other surfaces found in miniature golf courses. This compound's ability to release oxygen when dissolved in water creates a potent oxidizing effect, breaking down organic matter and lifting stubborn stains without the need for harsh chemicals.

One of the most significant advantages of sodium percarbonate in this context is its environmentally friendly nature. As it decomposes, it leaves behind only water, oxygen, and sodium carbonate, making it a safe option for use in areas where runoff may affect local ecosystems. This characteristic aligns well with the growing trend towards sustainable practices in golf course management and the broader sports and recreation industry.

The application method for sodium percarbonate in miniature golf course maintenance typically involves dissolving the compound in water to create a cleaning solution. This solution can be applied through spraying, mopping, or pressure washing, depending on the specific surface and level of cleaning required. The versatility of application methods allows for efficient cleaning of various course elements, from putting surfaces to obstacles and decorative features.

Moreover, sodium percarbonate's effectiveness extends beyond mere surface cleaning. Its oxidizing properties can help control algae growth in water features commonly found in miniature golf courses, such as ponds or streams. This dual functionality as both a cleaner and algaecide enhances its value in comprehensive course maintenance strategies.

The adoption of sodium percarbonate in golf course maintenance also reflects a broader shift towards safer working conditions for maintenance staff. Traditional cleaning agents often contain harsh chemicals that can pose health risks through inhalation or skin contact. In contrast, sodium percarbonate offers a safer alternative that reduces exposure to potentially harmful substances while maintaining high cleaning standards.

As the miniature golf industry continues to evolve, with courses becoming more elaborate and thematically diverse, the demand for effective yet environmentally responsible cleaning solutions grows. Sodium percarbonate's role in meeting this demand positions it as a key component in modern golf course maintenance practices, balancing the need for pristine playing conditions with environmental stewardship and worker safety.

The use of sodium percarbonate in golf course maintenance addresses several key challenges faced by groundskeepers and facility managers. Primarily, it offers a powerful cleaning solution for removing algae, mold, and other organic stains that commonly accumulate on artificial turf, concrete paths, and other surfaces found in miniature golf courses. This compound's ability to release oxygen when dissolved in water creates a potent oxidizing effect, breaking down organic matter and lifting stubborn stains without the need for harsh chemicals.

One of the most significant advantages of sodium percarbonate in this context is its environmentally friendly nature. As it decomposes, it leaves behind only water, oxygen, and sodium carbonate, making it a safe option for use in areas where runoff may affect local ecosystems. This characteristic aligns well with the growing trend towards sustainable practices in golf course management and the broader sports and recreation industry.

The application method for sodium percarbonate in miniature golf course maintenance typically involves dissolving the compound in water to create a cleaning solution. This solution can be applied through spraying, mopping, or pressure washing, depending on the specific surface and level of cleaning required. The versatility of application methods allows for efficient cleaning of various course elements, from putting surfaces to obstacles and decorative features.

Moreover, sodium percarbonate's effectiveness extends beyond mere surface cleaning. Its oxidizing properties can help control algae growth in water features commonly found in miniature golf courses, such as ponds or streams. This dual functionality as both a cleaner and algaecide enhances its value in comprehensive course maintenance strategies.

The adoption of sodium percarbonate in golf course maintenance also reflects a broader shift towards safer working conditions for maintenance staff. Traditional cleaning agents often contain harsh chemicals that can pose health risks through inhalation or skin contact. In contrast, sodium percarbonate offers a safer alternative that reduces exposure to potentially harmful substances while maintaining high cleaning standards.

As the miniature golf industry continues to evolve, with courses becoming more elaborate and thematically diverse, the demand for effective yet environmentally responsible cleaning solutions grows. Sodium percarbonate's role in meeting this demand positions it as a key component in modern golf course maintenance practices, balancing the need for pristine playing conditions with environmental stewardship and worker safety.

Market Analysis for Eco-Friendly Golf Course Cleaning

The market for eco-friendly golf course cleaning solutions has been experiencing significant growth in recent years, driven by increasing environmental awareness and stricter regulations on chemical use in recreational facilities. Sodium percarbonate, a key component in many eco-friendly cleaning products, has emerged as a promising alternative to traditional, more harmful cleaning agents.

The global golf course market is projected to reach $19.9 billion by 2026, with a compound annual growth rate (CAGR) of 4.3% from 2021 to 2026. Within this market, the demand for environmentally friendly maintenance solutions is growing at an even faster rate, estimated at 6.5% CAGR. This trend is particularly pronounced in developed countries, where environmental regulations are more stringent and public awareness of ecological issues is higher.

Miniature golf courses, a subset of the broader golf industry, are also seeing increased demand for eco-friendly cleaning solutions. The global mini-golf market was valued at $2.3 billion in 2020 and is expected to grow at a CAGR of 3.8% from 2021 to 2028. The use of sodium percarbonate in this sector is gaining traction due to its effectiveness in removing algae, mold, and other organic stains without harming the surrounding environment or posing risks to players.

The adoption of sodium percarbonate-based cleaning solutions in golf courses is driven by several factors. Firstly, there is growing pressure from regulatory bodies to reduce the use of harmful chemicals in recreational areas. Secondly, golf course operators are increasingly recognizing the long-term cost benefits of using eco-friendly products, which can help preserve course infrastructure and reduce water consumption. Lastly, there is a rising consumer preference for environmentally responsible businesses, which can translate into increased patronage and improved brand image for golf courses that adopt green practices.

Regional analysis shows that North America and Europe are currently the largest markets for eco-friendly golf course cleaning solutions, accounting for approximately 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by the rapid expansion of golf tourism and increasing environmental consciousness in countries like China, Japan, and South Korea.

The market for sodium percarbonate in golf course cleaning is not without challenges. Competition from other eco-friendly alternatives, such as enzymatic cleaners and microbial solutions, is intensifying. Additionally, the higher initial cost of some eco-friendly products compared to traditional chemicals can be a barrier to adoption, particularly for smaller golf courses or those operating on tight budgets.

The global golf course market is projected to reach $19.9 billion by 2026, with a compound annual growth rate (CAGR) of 4.3% from 2021 to 2026. Within this market, the demand for environmentally friendly maintenance solutions is growing at an even faster rate, estimated at 6.5% CAGR. This trend is particularly pronounced in developed countries, where environmental regulations are more stringent and public awareness of ecological issues is higher.

Miniature golf courses, a subset of the broader golf industry, are also seeing increased demand for eco-friendly cleaning solutions. The global mini-golf market was valued at $2.3 billion in 2020 and is expected to grow at a CAGR of 3.8% from 2021 to 2028. The use of sodium percarbonate in this sector is gaining traction due to its effectiveness in removing algae, mold, and other organic stains without harming the surrounding environment or posing risks to players.

The adoption of sodium percarbonate-based cleaning solutions in golf courses is driven by several factors. Firstly, there is growing pressure from regulatory bodies to reduce the use of harmful chemicals in recreational areas. Secondly, golf course operators are increasingly recognizing the long-term cost benefits of using eco-friendly products, which can help preserve course infrastructure and reduce water consumption. Lastly, there is a rising consumer preference for environmentally responsible businesses, which can translate into increased patronage and improved brand image for golf courses that adopt green practices.

Regional analysis shows that North America and Europe are currently the largest markets for eco-friendly golf course cleaning solutions, accounting for approximately 60% of the global market share. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by the rapid expansion of golf tourism and increasing environmental consciousness in countries like China, Japan, and South Korea.

The market for sodium percarbonate in golf course cleaning is not without challenges. Competition from other eco-friendly alternatives, such as enzymatic cleaners and microbial solutions, is intensifying. Additionally, the higher initial cost of some eco-friendly products compared to traditional chemicals can be a barrier to adoption, particularly for smaller golf courses or those operating on tight budgets.

Current Challenges in Miniature Golf Sanitation

Miniature golf courses face several significant challenges in maintaining cleanliness and sanitation, which are crucial for player safety and overall course attractiveness. One of the primary issues is the persistent growth of algae, moss, and mildew on various surfaces, particularly in damp or shaded areas. These microorganisms not only create unsightly appearances but can also make surfaces slippery, posing safety risks to players.

Another major challenge is the accumulation of dirt, debris, and stains on artificial turf, concrete paths, and obstacles. Regular foot traffic, exposure to outdoor elements, and occasional spills contribute to this problem. Traditional cleaning methods often prove inadequate in effectively removing these stubborn marks without damaging the delicate surfaces of the course.

Water conservation is an increasingly important concern for miniature golf course operators. Many conventional cleaning techniques require substantial amounts of water, which can be both costly and environmentally unsustainable. This challenge is particularly acute in regions facing water scarcity or drought conditions.

The use of harsh chemicals in cleaning solutions presents another significant hurdle. While effective in removing stains and killing microorganisms, these chemicals can be harmful to the environment, potentially contaminating local water sources and damaging surrounding vegetation. Additionally, they may pose health risks to maintenance staff and players if not properly handled or thoroughly rinsed.

Maintaining consistent cleanliness across the entire course is also challenging due to varying surface materials and environmental conditions. Different cleaning approaches may be required for artificial turf, concrete, wood, and plastic elements, making the sanitation process more complex and time-consuming.

Weather-related issues further complicate sanitation efforts. Rain can lead to water pooling and increased algae growth, while hot, humid conditions accelerate the proliferation of mold and mildew. Conversely, dry, dusty conditions can make it difficult to keep surfaces clean without excessive water use.

The frequency of cleaning required to maintain high standards of cleanliness poses operational challenges. Regular maintenance can disrupt play and potentially reduce revenue, forcing operators to balance cleanliness with course availability.

Lastly, the cost of effective cleaning equipment and materials can be substantial for smaller miniature golf operations. This financial burden may lead to compromises in cleaning frequency or quality, potentially impacting the overall player experience and the longevity of course elements.

Another major challenge is the accumulation of dirt, debris, and stains on artificial turf, concrete paths, and obstacles. Regular foot traffic, exposure to outdoor elements, and occasional spills contribute to this problem. Traditional cleaning methods often prove inadequate in effectively removing these stubborn marks without damaging the delicate surfaces of the course.

Water conservation is an increasingly important concern for miniature golf course operators. Many conventional cleaning techniques require substantial amounts of water, which can be both costly and environmentally unsustainable. This challenge is particularly acute in regions facing water scarcity or drought conditions.

The use of harsh chemicals in cleaning solutions presents another significant hurdle. While effective in removing stains and killing microorganisms, these chemicals can be harmful to the environment, potentially contaminating local water sources and damaging surrounding vegetation. Additionally, they may pose health risks to maintenance staff and players if not properly handled or thoroughly rinsed.

Maintaining consistent cleanliness across the entire course is also challenging due to varying surface materials and environmental conditions. Different cleaning approaches may be required for artificial turf, concrete, wood, and plastic elements, making the sanitation process more complex and time-consuming.

Weather-related issues further complicate sanitation efforts. Rain can lead to water pooling and increased algae growth, while hot, humid conditions accelerate the proliferation of mold and mildew. Conversely, dry, dusty conditions can make it difficult to keep surfaces clean without excessive water use.

The frequency of cleaning required to maintain high standards of cleanliness poses operational challenges. Regular maintenance can disrupt play and potentially reduce revenue, forcing operators to balance cleanliness with course availability.

Lastly, the cost of effective cleaning equipment and materials can be substantial for smaller miniature golf operations. This financial burden may lead to compromises in cleaning frequency or quality, potentially impacting the overall player experience and the longevity of course elements.

Existing Sodium Percarbonate Cleaning Solutions

01 Composition and preparation of sodium percarbonate

Sodium percarbonate is a compound of sodium carbonate and hydrogen peroxide. It can be prepared through various methods, including crystallization or spray drying processes. The composition and preparation methods are crucial for its effectiveness as a cleaning agent.- Sodium percarbonate as a cleaning agent: Sodium percarbonate is widely used as an effective cleaning agent in various applications. It releases hydrogen peroxide when dissolved in water, providing powerful oxidizing and bleaching properties. This makes it suitable for removing stains, disinfecting surfaces, and general cleaning purposes.

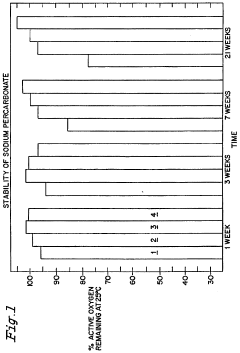

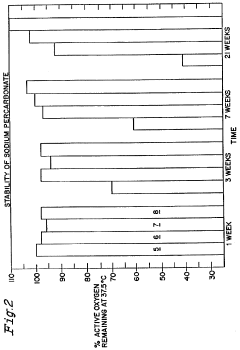

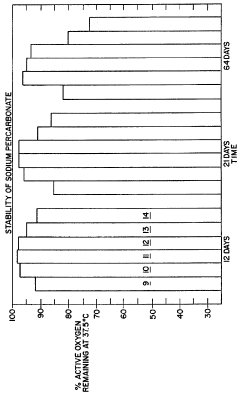

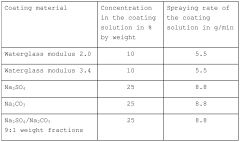

- Stabilization of sodium percarbonate: Various methods and additives are used to stabilize sodium percarbonate, improving its shelf life and effectiveness. These may include coating the particles, adding stabilizing agents, or modifying the crystal structure. Stabilization helps maintain the cleaning power of sodium percarbonate during storage and use.

- Formulation of cleaning products with sodium percarbonate: Sodium percarbonate is incorporated into various cleaning product formulations, including laundry detergents, dishwashing agents, and all-purpose cleaners. The formulations may include additional ingredients such as surfactants, enzymes, and other cleaning agents to enhance overall performance.

- Environmental and safety aspects of sodium percarbonate: Sodium percarbonate is considered an environmentally friendly cleaning agent as it breaks down into harmless byproducts. It is biodegradable and does not leave harmful residues. Safety considerations include proper handling and storage to prevent decomposition and potential skin or eye irritation.

- Manufacturing processes for sodium percarbonate: Various manufacturing processes are used to produce sodium percarbonate with desired properties. These may include spray drying, fluidized bed processes, or crystallization methods. The manufacturing process can affect the stability, particle size, and overall quality of the sodium percarbonate product.

02 Stabilization of sodium percarbonate

Stabilizing agents are often added to sodium percarbonate to improve its shelf life and maintain its cleaning efficacy. These stabilizers can include inorganic salts, organic compounds, or coatings that protect the percarbonate from moisture and premature decomposition.Expand Specific Solutions03 Application in cleaning formulations

Sodium percarbonate is widely used in various cleaning formulations, including laundry detergents, dishwashing products, and general-purpose cleaners. Its oxygen-releasing properties make it effective for stain removal and disinfection, contributing to improved cleanliness.Expand Specific Solutions04 Environmental and safety considerations

Sodium percarbonate is considered an environmentally friendly alternative to chlorine-based bleaches. It breaks down into harmless byproducts and is generally safe for use in household cleaning applications. However, proper handling and storage are essential to maintain its effectiveness and safety.Expand Specific Solutions05 Synergistic effects with other cleaning agents

Sodium percarbonate can be combined with other cleaning agents to enhance its effectiveness. These combinations may include enzymes, surfactants, or other oxidizing agents, resulting in improved cleaning performance and broader spectrum of action against various types of soils and stains.Expand Specific Solutions

Key Players in Golf Maintenance Chemical Industry

The use of sodium percarbonate in miniature golf course cleanliness represents a niche market within the broader cleaning chemicals industry. This sector is in a mature stage, with established players like Solvay SA, Henkel AG & Co. KGaA, and Evonik Operations GmbH dominating the market. The global sodium percarbonate market size is estimated to be in the hundreds of millions of dollars, with steady growth projected. Technologically, sodium percarbonate is well-established, with companies like Kemira Oyj and Unilever Plc continuously improving formulations for specific applications. However, its use in miniature golf courses is still an emerging application, presenting opportunities for innovation and market expansion.

Solvay SA

Technical Solution: Solvay SA has developed an advanced sodium percarbonate formulation specifically designed for miniature golf course cleanliness. Their product, OxySpring, utilizes a stabilized form of sodium percarbonate that releases oxygen slowly upon contact with water, providing prolonged cleaning action. The formulation includes surfactants and chelating agents to enhance its effectiveness against organic stains and algae growth common on miniature golf courses. OxySpring's controlled release mechanism ensures a consistent cleaning performance over time, reducing the frequency of application needed[1]. Solvay has also incorporated eco-friendly additives that minimize environmental impact, making it suitable for use in sensitive outdoor recreational areas[3].

Strengths: Prolonged cleaning action, effective against organic stains and algae, environmentally friendly. Weaknesses: May require specialized application equipment, potentially higher cost compared to traditional cleaning agents.

Henkel AG & Co. KGaA

Technical Solution: Henkel has introduced a novel sodium percarbonate-based cleaning solution tailored for miniature golf courses called GolfGuard Pro. This product combines sodium percarbonate with proprietary enzymes that target specific types of stains and organic matter commonly found on golf course surfaces. The enzymatic action enhances the oxidizing power of sodium percarbonate, allowing for more efficient cleaning at lower concentrations. GolfGuard Pro is formulated as a granular product that dissolves quickly in water, creating an easy-to-apply solution. Henkel has also incorporated a pH buffer system to maintain optimal cleaning efficiency across various water conditions[2]. The product is designed to be safe for use on multiple surface types, including artificial turf and painted concrete, which are common in miniature golf settings[4].

Strengths: Enhanced cleaning efficiency through enzymatic action, versatile application on various surfaces. Weaknesses: May be more expensive than basic sodium percarbonate products, requires proper storage to maintain enzyme activity.

Innovations in Sodium Percarbonate Formulations

Stable sodium percarbonate formulation

PatentInactiveUS5676933A

Innovation

- A formulation comprising 55-90% polyalkylene glycol, 5-20% sodium percarbonate, 0.5-6% colloidal silica, 0-12% alkali metal pyrophosphate, and 0.2-1 part water per part sodium percarbonate, with optional stabilizers like sodium silicate, magnesium silicate, or magnesium sulfate, enhances stability and active oxygen release.

Coated sodium percarbonate particles

PatentWO2014198804A1

Innovation

- The development of coated sodium percarbonate particles with a three-layered coating structure, where the inner layer consists predominantly of sodium sulphate, the middle layer of alkali metal silicate, and the outer layer of sodium sulphate and/or sodium carbonate, providing enhanced stability and preventing moisture-induced decomposition.

Environmental Impact Assessment

The use of sodium percarbonate in miniature golf course cleanliness raises important environmental considerations that require thorough assessment. This compound, while effective for cleaning purposes, has potential impacts on surrounding ecosystems and water resources that must be carefully evaluated.

Sodium percarbonate, when dissolved in water, releases hydrogen peroxide and sodium carbonate. The hydrogen peroxide acts as a powerful oxidizing agent, breaking down organic matter and disinfecting surfaces. However, its release into the environment can have both positive and negative effects. On one hand, it can help reduce harmful bacteria and algae in water bodies, potentially improving water quality. On the other hand, excessive amounts may disrupt aquatic ecosystems by affecting the balance of microorganisms and potentially harming sensitive aquatic life.

The sodium carbonate component of the compound can lead to increased alkalinity in water bodies, which may impact pH levels. This change in water chemistry can affect aquatic organisms, particularly in freshwater environments where species are adapted to specific pH ranges. Monitoring and controlling the runoff from treated areas is crucial to mitigate these potential impacts.

Soil ecosystems may also be affected by the use of sodium percarbonate. While the compound breaks down relatively quickly, repeated applications could lead to changes in soil chemistry and microbial communities. This may have implications for plant growth and soil health in areas surrounding the golf course.

The biodegradability of sodium percarbonate is a positive aspect from an environmental perspective. Unlike some persistent chemicals, it decomposes into water, oxygen, and sodium carbonate, which are generally considered environmentally benign. However, the rate of decomposition and the potential for accumulation in soil or water bodies over time should be carefully studied.

Water consumption is another environmental factor to consider. The use of sodium percarbonate for cleaning may require significant amounts of water for application and rinsing. In areas where water resources are scarce, this could contribute to water stress and compete with other essential uses.

To mitigate potential environmental impacts, several strategies should be considered. These include optimizing the concentration and frequency of application, implementing proper drainage systems to control runoff, and using targeted application methods to minimize overspray. Regular monitoring of soil and water quality in and around the golf course can help detect any long-term environmental changes and allow for timely adjustments to the cleaning practices.

In conclusion, while sodium percarbonate offers effective cleaning properties for miniature golf courses, its environmental impact must be carefully managed. A comprehensive environmental management plan, including regular assessments and adaptive strategies, is essential to ensure the sustainable use of this compound in recreational settings.

Sodium percarbonate, when dissolved in water, releases hydrogen peroxide and sodium carbonate. The hydrogen peroxide acts as a powerful oxidizing agent, breaking down organic matter and disinfecting surfaces. However, its release into the environment can have both positive and negative effects. On one hand, it can help reduce harmful bacteria and algae in water bodies, potentially improving water quality. On the other hand, excessive amounts may disrupt aquatic ecosystems by affecting the balance of microorganisms and potentially harming sensitive aquatic life.

The sodium carbonate component of the compound can lead to increased alkalinity in water bodies, which may impact pH levels. This change in water chemistry can affect aquatic organisms, particularly in freshwater environments where species are adapted to specific pH ranges. Monitoring and controlling the runoff from treated areas is crucial to mitigate these potential impacts.

Soil ecosystems may also be affected by the use of sodium percarbonate. While the compound breaks down relatively quickly, repeated applications could lead to changes in soil chemistry and microbial communities. This may have implications for plant growth and soil health in areas surrounding the golf course.

The biodegradability of sodium percarbonate is a positive aspect from an environmental perspective. Unlike some persistent chemicals, it decomposes into water, oxygen, and sodium carbonate, which are generally considered environmentally benign. However, the rate of decomposition and the potential for accumulation in soil or water bodies over time should be carefully studied.

Water consumption is another environmental factor to consider. The use of sodium percarbonate for cleaning may require significant amounts of water for application and rinsing. In areas where water resources are scarce, this could contribute to water stress and compete with other essential uses.

To mitigate potential environmental impacts, several strategies should be considered. These include optimizing the concentration and frequency of application, implementing proper drainage systems to control runoff, and using targeted application methods to minimize overspray. Regular monitoring of soil and water quality in and around the golf course can help detect any long-term environmental changes and allow for timely adjustments to the cleaning practices.

In conclusion, while sodium percarbonate offers effective cleaning properties for miniature golf courses, its environmental impact must be carefully managed. A comprehensive environmental management plan, including regular assessments and adaptive strategies, is essential to ensure the sustainable use of this compound in recreational settings.

Safety Regulations for Chemical Use in Recreation

The use of sodium percarbonate in miniature golf course maintenance necessitates adherence to strict safety regulations for chemical use in recreational settings. These regulations are designed to protect both workers and patrons while ensuring environmental safety. The Occupational Safety and Health Administration (OSHA) mandates that all employees handling sodium percarbonate receive proper training on its safe use, storage, and disposal. This includes understanding the chemical's Material Safety Data Sheet (MSDS) and wearing appropriate personal protective equipment (PPE) such as gloves, eye protection, and respiratory gear when necessary.

Recreational facilities must comply with the Environmental Protection Agency (EPA) guidelines regarding the application of chemicals in public spaces. This involves using sodium percarbonate in concentrations that are effective for cleaning but do not pose risks to human health or the environment. The EPA also requires proper dilution and application methods to prevent runoff into water sources or surrounding ecosystems. Facilities must maintain detailed records of chemical usage, including dates, quantities, and areas of application, to ensure compliance with regulatory standards.

Local health departments often impose additional regulations specific to recreational areas. These may include restrictions on the timing of chemical applications to minimize exposure to patrons, mandatory waiting periods before allowing access to treated areas, and requirements for clear signage indicating recent chemical use. Some jurisdictions may require facilities to obtain permits or certifications for using certain chemicals, including sodium percarbonate, in public recreational spaces.

The Consumer Product Safety Commission (CPSC) provides guidelines for the safe use of chemicals in areas frequented by children. For miniature golf courses, this may involve additional precautions such as using child-resistant storage containers and implementing strict protocols to ensure all chemicals are securely stored and inaccessible to unauthorized individuals. The CPSC also recommends regular safety audits and the development of emergency response plans in case of accidental exposure or spills.

International standards, such as those set by the International Organization for Standardization (ISO), may also apply to chemical use in recreational settings. ISO 45001, which focuses on occupational health and safety management systems, provides a framework for organizations to identify and control health and safety risks, reduce potential accidents, and improve overall safety performance. Adherence to these standards can help miniature golf courses demonstrate their commitment to safety and potentially reduce liability risks.

Recreational facilities must comply with the Environmental Protection Agency (EPA) guidelines regarding the application of chemicals in public spaces. This involves using sodium percarbonate in concentrations that are effective for cleaning but do not pose risks to human health or the environment. The EPA also requires proper dilution and application methods to prevent runoff into water sources or surrounding ecosystems. Facilities must maintain detailed records of chemical usage, including dates, quantities, and areas of application, to ensure compliance with regulatory standards.

Local health departments often impose additional regulations specific to recreational areas. These may include restrictions on the timing of chemical applications to minimize exposure to patrons, mandatory waiting periods before allowing access to treated areas, and requirements for clear signage indicating recent chemical use. Some jurisdictions may require facilities to obtain permits or certifications for using certain chemicals, including sodium percarbonate, in public recreational spaces.

The Consumer Product Safety Commission (CPSC) provides guidelines for the safe use of chemicals in areas frequented by children. For miniature golf courses, this may involve additional precautions such as using child-resistant storage containers and implementing strict protocols to ensure all chemicals are securely stored and inaccessible to unauthorized individuals. The CPSC also recommends regular safety audits and the development of emergency response plans in case of accidental exposure or spills.

International standards, such as those set by the International Organization for Standardization (ISO), may also apply to chemical use in recreational settings. ISO 45001, which focuses on occupational health and safety management systems, provides a framework for organizations to identify and control health and safety risks, reduce potential accidents, and improve overall safety performance. Adherence to these standards can help miniature golf courses demonstrate their commitment to safety and potentially reduce liability risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!