Sodium Percarbonate's Impact on Vertical Farming Irrigation System Sterility

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Percarbonate in Vertical Farming: Background and Objectives

Sodium percarbonate, a compound formed by the combination of sodium carbonate and hydrogen peroxide, has emerged as a promising solution for maintaining sterility in vertical farming irrigation systems. The evolution of this technology can be traced back to the early 2000s when vertical farming began gaining traction as a sustainable agricultural method. As the industry grew, so did the need for effective and environmentally friendly sterilization techniques for irrigation systems.

The primary objective of incorporating sodium percarbonate into vertical farming is to address the critical challenge of maintaining a sterile environment within the complex network of irrigation pipes and channels. This is essential for preventing the growth and spread of harmful microorganisms that can compromise crop health and yield. By leveraging the oxidizing properties of sodium percarbonate, vertical farming operations aim to achieve a balance between effective sterilization and minimal environmental impact.

The development of sodium percarbonate as a sterilization agent in vertical farming has been driven by several key factors. First, the increasing global focus on sustainable agriculture has necessitated the adoption of eco-friendly solutions in all aspects of farming, including irrigation system maintenance. Second, the rapid expansion of vertical farming operations has highlighted the need for scalable and efficient sterilization methods that can keep pace with the industry's growth.

As the technology has progressed, researchers and industry professionals have explored various applications of sodium percarbonate in vertical farming systems. These efforts have led to the refinement of dosing techniques, the development of automated dispensing systems, and the optimization of treatment cycles to maximize effectiveness while minimizing resource consumption. The goal is to create a robust and reliable sterilization protocol that can be seamlessly integrated into existing vertical farming operations.

Looking ahead, the continued evolution of sodium percarbonate technology in vertical farming is expected to focus on several key areas. These include enhancing the compound's stability and longevity within irrigation systems, improving its efficacy against a broader spectrum of pathogens, and developing more sophisticated monitoring and control systems to ensure optimal performance. Additionally, there is ongoing research into potential synergies between sodium percarbonate and other complementary technologies, such as UV sterilization or advanced filtration systems, to create comprehensive sterilization solutions for vertical farms of all scales.

The primary objective of incorporating sodium percarbonate into vertical farming is to address the critical challenge of maintaining a sterile environment within the complex network of irrigation pipes and channels. This is essential for preventing the growth and spread of harmful microorganisms that can compromise crop health and yield. By leveraging the oxidizing properties of sodium percarbonate, vertical farming operations aim to achieve a balance between effective sterilization and minimal environmental impact.

The development of sodium percarbonate as a sterilization agent in vertical farming has been driven by several key factors. First, the increasing global focus on sustainable agriculture has necessitated the adoption of eco-friendly solutions in all aspects of farming, including irrigation system maintenance. Second, the rapid expansion of vertical farming operations has highlighted the need for scalable and efficient sterilization methods that can keep pace with the industry's growth.

As the technology has progressed, researchers and industry professionals have explored various applications of sodium percarbonate in vertical farming systems. These efforts have led to the refinement of dosing techniques, the development of automated dispensing systems, and the optimization of treatment cycles to maximize effectiveness while minimizing resource consumption. The goal is to create a robust and reliable sterilization protocol that can be seamlessly integrated into existing vertical farming operations.

Looking ahead, the continued evolution of sodium percarbonate technology in vertical farming is expected to focus on several key areas. These include enhancing the compound's stability and longevity within irrigation systems, improving its efficacy against a broader spectrum of pathogens, and developing more sophisticated monitoring and control systems to ensure optimal performance. Additionally, there is ongoing research into potential synergies between sodium percarbonate and other complementary technologies, such as UV sterilization or advanced filtration systems, to create comprehensive sterilization solutions for vertical farms of all scales.

Market Analysis of Sterile Irrigation Systems in Vertical Farming

The market for sterile irrigation systems in vertical farming is experiencing significant growth, driven by the increasing adoption of vertical farming practices and the growing emphasis on food safety and crop quality. As urban populations continue to expand and arable land becomes scarcer, vertical farming has emerged as a viable solution to meet the rising demand for fresh produce in densely populated areas.

The global vertical farming market is projected to reach substantial value in the coming years, with a considerable portion attributed to irrigation systems. The sterile irrigation segment, in particular, is gaining traction due to its ability to minimize the risk of waterborne pathogens and enhance crop yields. This growth is further fueled by stringent food safety regulations and consumer demand for pesticide-free, locally grown produce.

Vertical farming operations, ranging from small-scale urban farms to large commercial facilities, are increasingly investing in advanced irrigation technologies to optimize water usage and maintain sterile growing conditions. The market for sterile irrigation systems is characterized by a diverse range of products, including UV sterilization units, chemical dosing systems, and advanced filtration technologies.

North America and Europe currently lead the market for sterile irrigation systems in vertical farming, owing to their well-established agricultural technology sectors and supportive regulatory environments. However, Asia-Pacific is emerging as a rapidly growing market, driven by urbanization, food security concerns, and government initiatives promoting sustainable agriculture.

Key market drivers include the need for water conservation, the push for higher crop yields, and the increasing awareness of foodborne illnesses. Sterile irrigation systems offer vertical farmers the ability to recirculate and reuse water while maintaining optimal growing conditions, thereby reducing overall water consumption and operational costs.

The market is also witnessing a trend towards integrated solutions that combine irrigation, nutrient delivery, and monitoring systems. This holistic approach allows for precise control over growing conditions and further enhances the appeal of sterile irrigation systems to vertical farm operators.

Despite the positive outlook, the market faces challenges such as high initial investment costs and the need for specialized technical expertise. These factors may limit adoption, particularly among smaller-scale operations. However, as technology advances and economies of scale are realized, the cost barrier is expected to decrease, further driving market growth.

The global vertical farming market is projected to reach substantial value in the coming years, with a considerable portion attributed to irrigation systems. The sterile irrigation segment, in particular, is gaining traction due to its ability to minimize the risk of waterborne pathogens and enhance crop yields. This growth is further fueled by stringent food safety regulations and consumer demand for pesticide-free, locally grown produce.

Vertical farming operations, ranging from small-scale urban farms to large commercial facilities, are increasingly investing in advanced irrigation technologies to optimize water usage and maintain sterile growing conditions. The market for sterile irrigation systems is characterized by a diverse range of products, including UV sterilization units, chemical dosing systems, and advanced filtration technologies.

North America and Europe currently lead the market for sterile irrigation systems in vertical farming, owing to their well-established agricultural technology sectors and supportive regulatory environments. However, Asia-Pacific is emerging as a rapidly growing market, driven by urbanization, food security concerns, and government initiatives promoting sustainable agriculture.

Key market drivers include the need for water conservation, the push for higher crop yields, and the increasing awareness of foodborne illnesses. Sterile irrigation systems offer vertical farmers the ability to recirculate and reuse water while maintaining optimal growing conditions, thereby reducing overall water consumption and operational costs.

The market is also witnessing a trend towards integrated solutions that combine irrigation, nutrient delivery, and monitoring systems. This holistic approach allows for precise control over growing conditions and further enhances the appeal of sterile irrigation systems to vertical farm operators.

Despite the positive outlook, the market faces challenges such as high initial investment costs and the need for specialized technical expertise. These factors may limit adoption, particularly among smaller-scale operations. However, as technology advances and economies of scale are realized, the cost barrier is expected to decrease, further driving market growth.

Current Challenges in Vertical Farming Irrigation Sterilization

Vertical farming irrigation systems face several critical challenges in maintaining sterility, which is crucial for optimal plant growth and food safety. One of the primary issues is the proliferation of microorganisms in the nutrient-rich water used for irrigation. These microbes can quickly multiply, leading to biofilm formation and potential plant diseases.

The recirculating nature of many vertical farming systems exacerbates this problem, as pathogens can spread rapidly throughout the entire system if not properly managed. Traditional sterilization methods, such as chlorination or UV treatment, often prove inadequate in these complex, closed-loop environments. They may not effectively penetrate biofilms or reach all system components, leaving pockets of contamination.

Another significant challenge is the balance between effective sterilization and maintaining beneficial microorganisms. Overly aggressive sterilization can eliminate not only harmful pathogens but also beneficial bacteria that contribute to plant health and nutrient uptake. This delicate balance is particularly crucial in hydroponic and aquaponic systems where microbial communities play a vital role in nutrient cycling.

The high humidity and constant moisture in vertical farming environments create ideal conditions for fungal growth. Controlling fungal pathogens without resorting to harmful chemical fungicides presents a significant hurdle. Many current sterilization methods are not sufficiently effective against fungal spores, which can persist in the system and cause recurring outbreaks.

Scale and cost-effectiveness pose additional challenges. As vertical farms grow in size and complexity, ensuring uniform sterilization across all irrigation components becomes increasingly difficult. Traditional methods may require significant energy inputs or frequent chemical replenishment, impacting operational costs and sustainability.

The use of chemical sterilants introduces concerns about residual effects on plants and potential accumulation in recirculating systems. Finding sterilization solutions that are both effective and safe for continuous use in food production environments is an ongoing challenge. This is particularly relevant when considering the potential impact on the nutritional quality and safety of the produced crops.

Lastly, the dynamic nature of vertical farming systems, with varying crop types and growth stages, demands flexible and adaptable sterilization approaches. A one-size-fits-all solution is often impractical, necessitating the development of smart, responsive sterilization systems that can adjust to changing conditions and requirements throughout the crop cycle.

The recirculating nature of many vertical farming systems exacerbates this problem, as pathogens can spread rapidly throughout the entire system if not properly managed. Traditional sterilization methods, such as chlorination or UV treatment, often prove inadequate in these complex, closed-loop environments. They may not effectively penetrate biofilms or reach all system components, leaving pockets of contamination.

Another significant challenge is the balance between effective sterilization and maintaining beneficial microorganisms. Overly aggressive sterilization can eliminate not only harmful pathogens but also beneficial bacteria that contribute to plant health and nutrient uptake. This delicate balance is particularly crucial in hydroponic and aquaponic systems where microbial communities play a vital role in nutrient cycling.

The high humidity and constant moisture in vertical farming environments create ideal conditions for fungal growth. Controlling fungal pathogens without resorting to harmful chemical fungicides presents a significant hurdle. Many current sterilization methods are not sufficiently effective against fungal spores, which can persist in the system and cause recurring outbreaks.

Scale and cost-effectiveness pose additional challenges. As vertical farms grow in size and complexity, ensuring uniform sterilization across all irrigation components becomes increasingly difficult. Traditional methods may require significant energy inputs or frequent chemical replenishment, impacting operational costs and sustainability.

The use of chemical sterilants introduces concerns about residual effects on plants and potential accumulation in recirculating systems. Finding sterilization solutions that are both effective and safe for continuous use in food production environments is an ongoing challenge. This is particularly relevant when considering the potential impact on the nutritional quality and safety of the produced crops.

Lastly, the dynamic nature of vertical farming systems, with varying crop types and growth stages, demands flexible and adaptable sterilization approaches. A one-size-fits-all solution is often impractical, necessitating the development of smart, responsive sterilization systems that can adjust to changing conditions and requirements throughout the crop cycle.

Existing Sodium Percarbonate-based Sterilization Solutions

01 Stabilization of sodium percarbonate

Various methods are employed to stabilize sodium percarbonate, enhancing its shelf life and maintaining its effectiveness. These methods include coating the particles, adding stabilizing agents, or modifying the production process to improve the crystal structure. Stabilization is crucial for maintaining the sterility and efficacy of sodium percarbonate in various applications.- Stabilization of sodium percarbonate: Various methods are employed to stabilize sodium percarbonate, enhancing its shelf life and maintaining its effectiveness. These methods include coating the particles, adding stabilizing agents, or modifying the production process to improve the crystal structure. Stabilization is crucial for preserving the active oxygen content and ensuring the product's efficacy in various applications.

- Sterilization methods for sodium percarbonate: Different sterilization techniques are used to ensure the microbial safety of sodium percarbonate. These may include heat treatment, irradiation, or chemical treatments. The choice of sterilization method is critical to maintain the product's integrity while eliminating potential contaminants.

- Packaging and storage considerations: Proper packaging and storage conditions are essential for maintaining the sterility and stability of sodium percarbonate. This includes using moisture-resistant packaging, controlling temperature and humidity during storage, and implementing appropriate handling procedures to prevent contamination.

- Quality control and testing methods: Various analytical techniques and quality control measures are employed to assess the sterility and purity of sodium percarbonate. These may include microbiological testing, chemical analysis, and physical property evaluations to ensure the product meets specified standards for sterility and effectiveness.

- Applications requiring sterile sodium percarbonate: Certain applications, such as medical or pharmaceutical uses, may require sterile sodium percarbonate. In these cases, specialized production processes and handling procedures are implemented to meet stringent sterility requirements while maintaining the product's active properties.

02 Sterilization methods for sodium percarbonate

Different sterilization techniques are used to ensure the sterility of sodium percarbonate. These may include heat treatment, chemical sterilization, or radiation. The choice of method depends on the intended application and the need to maintain the chemical integrity of the compound while achieving sterility.Expand Specific Solutions03 Packaging and storage considerations

Proper packaging and storage are essential for maintaining the sterility of sodium percarbonate. This includes using moisture-resistant packaging, controlling storage temperature and humidity, and implementing appropriate handling procedures to prevent contamination during storage and transportation.Expand Specific Solutions04 Testing and quality control measures

Rigorous testing and quality control measures are implemented to ensure the sterility of sodium percarbonate. These may include microbiological testing, chemical analysis, and stability studies. Regular monitoring and documentation of these processes are crucial for maintaining consistent product quality and sterility.Expand Specific Solutions05 Applications requiring sterile sodium percarbonate

Sterile sodium percarbonate finds applications in various industries where maintaining sterility is critical. These may include medical and pharmaceutical uses, water treatment, and certain industrial processes. The specific sterility requirements and methods may vary depending on the intended application and regulatory standards.Expand Specific Solutions

Key Players in Vertical Farming and Irrigation Technology

The sodium percarbonate market in vertical farming irrigation systems is in its early growth stage, with increasing adoption driven by the need for sterile environments in controlled agriculture. The market size is expanding as vertical farming gains traction globally, though exact figures are limited. Technologically, sodium percarbonate's application in this context is still evolving, with companies like BASF Agricultural Solutions and Deerpoint Group leading innovation. Research institutions such as China Agricultural University and King Abdullah University of Science & Technology are contributing to advancements in this field. The technology's maturity is progressing, but there's room for further optimization in efficacy and sustainability for vertical farming applications.

BASF Agricultural Solutions Seed US LLC

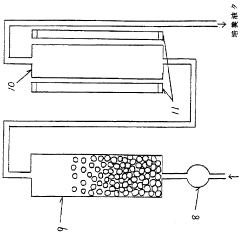

Technical Solution: BASF has developed an innovative approach to vertical farming irrigation using sodium percarbonate as a sterilizing agent. Their system incorporates a controlled release mechanism that gradually introduces sodium percarbonate into the irrigation water, maintaining a consistent level of sterility throughout the growing cycle[1]. This method effectively reduces microbial contamination while minimizing the impact on plant growth. The company has also integrated sensors to monitor the concentration of sodium percarbonate in real-time, allowing for precise adjustments to maintain optimal sterility levels[3]. Additionally, BASF has engineered a filtration system that removes any excess sodium percarbonate before the water reaches the plants, ensuring that the chemical does not accumulate in the growing medium[5].

Strengths: Precise control of sterility levels, reduced risk of microbial contamination, and minimal impact on plant growth. Weaknesses: Potential complexity in system maintenance and the need for specialized sensors and filtration equipment.

Shandong Tianli Energy Co., Ltd.

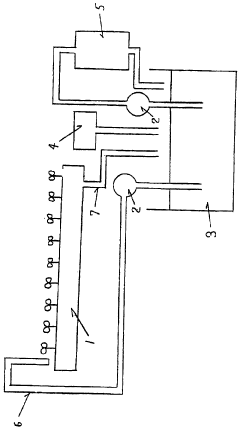

Technical Solution: Shandong Tianli Energy has developed a sodium percarbonate-based irrigation system specifically tailored for vertical farming applications. Their approach involves a patented slow-release formulation of sodium percarbonate that gradually dissolves in the irrigation water, providing continuous sterilization over an extended period[2]. The company has also implemented a dual-chamber system that separates the sodium percarbonate solution from the main water supply, allowing for precise control of the sterilization process[4]. This design enables farmers to adjust the concentration of sodium percarbonate based on specific crop requirements and environmental conditions. Furthermore, Shandong Tianli Energy has incorporated a UV light treatment stage after the sodium percarbonate application to enhance the overall sterility of the irrigation system[6].

Strengths: Long-lasting sterilization effect, adaptability to different crop needs, and enhanced sterility through combined treatment methods. Weaknesses: Potential higher initial setup costs and the need for regular monitoring of the slow-release mechanism.

Core Innovations in Sodium Percarbonate Application

Sterilization method

PatentInactiveJP2012101825A

Innovation

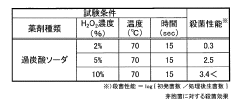

- Sodium percarbonate, a stable alkaline granular powder, is used as a sterilizing agent, which is dissolved in sterile water to generate hydrogen peroxide and sodium carbonate, allowing for stable storage and reduced transportation costs, while maintaining effective sterilization performance.

Sterilizer for circulation nutricultivating apparatus, nutrient solution sterilizing method using the same, and circulation nutricultivating apparatus

PatentWO1997035466A1

Innovation

- Incorporating a sterilizer using silver-impregnated activated carbon and a titanium dioxide tank with ultraviolet irradiation in the hydroponic cultivation system to suppress pathogenic bacteria and remove waste products, allowing for reduced nutrient solution exchange or elimination of the need for replacement.

Environmental Impact of Sodium Percarbonate in Agriculture

The use of sodium percarbonate in agriculture, particularly in vertical farming irrigation systems, has significant environmental implications that warrant careful consideration. As a powerful oxidizing agent, sodium percarbonate can effectively sterilize irrigation systems, reducing the risk of pathogen proliferation and enhancing crop health. However, its widespread application raises concerns about potential ecological impacts.

One of the primary environmental benefits of using sodium percarbonate in vertical farming is the reduction in water consumption. By maintaining sterile irrigation systems, farmers can recirculate water more efficiently, minimizing waste and conserving this precious resource. This is particularly crucial in regions facing water scarcity, where vertical farming presents a sustainable alternative to traditional agricultural practices.

However, the release of sodium percarbonate into the environment, even in small quantities, may have unintended consequences. When decomposed, it releases hydrogen peroxide and sodium carbonate. While hydrogen peroxide quickly breaks down into water and oxygen, the accumulation of sodium carbonate can lead to soil alkalinization over time. This pH shift may alter soil microbial communities and affect nutrient availability for plants in surrounding ecosystems.

Furthermore, the production and transportation of sodium percarbonate contribute to carbon emissions, potentially offsetting some of the environmental benefits gained from water conservation in vertical farming. Manufacturers and farmers must consider the entire life cycle of this compound when assessing its overall environmental impact.

The use of sodium percarbonate may also influence biodiversity in agricultural settings. While it effectively eliminates harmful pathogens, it may also impact beneficial microorganisms crucial for soil health and plant growth. This could lead to a reduction in microbial diversity, potentially affecting the long-term sustainability of vertical farming systems and surrounding ecosystems.

To mitigate these environmental concerns, researchers and farmers are exploring optimized application methods and dosages of sodium percarbonate. By fine-tuning the use of this compound, it may be possible to maximize its benefits in maintaining sterile irrigation systems while minimizing negative environmental impacts. Additionally, the development of closed-loop systems that capture and treat runoff containing sodium percarbonate residues could further reduce its environmental footprint.

In conclusion, while sodium percarbonate offers significant advantages in maintaining sterile vertical farming irrigation systems, its environmental impact must be carefully managed. Balancing the benefits of improved water efficiency and crop health against potential risks to soil chemistry and biodiversity is crucial for the sustainable development of vertical farming practices.

One of the primary environmental benefits of using sodium percarbonate in vertical farming is the reduction in water consumption. By maintaining sterile irrigation systems, farmers can recirculate water more efficiently, minimizing waste and conserving this precious resource. This is particularly crucial in regions facing water scarcity, where vertical farming presents a sustainable alternative to traditional agricultural practices.

However, the release of sodium percarbonate into the environment, even in small quantities, may have unintended consequences. When decomposed, it releases hydrogen peroxide and sodium carbonate. While hydrogen peroxide quickly breaks down into water and oxygen, the accumulation of sodium carbonate can lead to soil alkalinization over time. This pH shift may alter soil microbial communities and affect nutrient availability for plants in surrounding ecosystems.

Furthermore, the production and transportation of sodium percarbonate contribute to carbon emissions, potentially offsetting some of the environmental benefits gained from water conservation in vertical farming. Manufacturers and farmers must consider the entire life cycle of this compound when assessing its overall environmental impact.

The use of sodium percarbonate may also influence biodiversity in agricultural settings. While it effectively eliminates harmful pathogens, it may also impact beneficial microorganisms crucial for soil health and plant growth. This could lead to a reduction in microbial diversity, potentially affecting the long-term sustainability of vertical farming systems and surrounding ecosystems.

To mitigate these environmental concerns, researchers and farmers are exploring optimized application methods and dosages of sodium percarbonate. By fine-tuning the use of this compound, it may be possible to maximize its benefits in maintaining sterile irrigation systems while minimizing negative environmental impacts. Additionally, the development of closed-loop systems that capture and treat runoff containing sodium percarbonate residues could further reduce its environmental footprint.

In conclusion, while sodium percarbonate offers significant advantages in maintaining sterile vertical farming irrigation systems, its environmental impact must be carefully managed. Balancing the benefits of improved water efficiency and crop health against potential risks to soil chemistry and biodiversity is crucial for the sustainable development of vertical farming practices.

Regulatory Framework for Chemical Use in Vertical Farming

The regulatory framework for chemical use in vertical farming is a critical aspect that governs the implementation of innovative technologies such as sodium percarbonate in irrigation systems. As vertical farming continues to gain traction as a sustainable agricultural solution, regulatory bodies have been adapting existing guidelines and developing new ones to ensure the safe and effective use of chemicals in these controlled environments.

At the federal level in the United States, the Environmental Protection Agency (EPA) plays a pivotal role in regulating the use of chemicals in agriculture, including vertical farming operations. The EPA's Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) provides the primary regulatory framework for pesticide registration and use, which extends to chemicals used in irrigation systems. Under FIFRA, sodium percarbonate, when used for antimicrobial purposes in irrigation systems, may require registration as a pesticide, depending on its specific application and claims.

The Food and Drug Administration (FDA) also has jurisdiction over chemical use in vertical farming, particularly through the Food Safety Modernization Act (FSMA). The FSMA's Produce Safety Rule establishes science-based minimum standards for the safe growing, harvesting, packing, and holding of fruits and vegetables grown for human consumption. This rule includes provisions for agricultural water quality and testing, which directly impact the use of chemicals like sodium percarbonate in irrigation systems.

At the state level, regulations can vary significantly, with some states imposing stricter controls on chemical use in agriculture than federal standards. For instance, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm. This could potentially affect the use of sodium percarbonate if it or its byproducts are listed under Proposition 65.

Internationally, the regulatory landscape becomes more complex. The European Union, for example, has stringent regulations on chemical use in agriculture under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. Sodium percarbonate would need to be registered under REACH if used in vertical farming operations within the EU.

As vertical farming technologies evolve, regulatory frameworks are likely to adapt. There is a growing trend towards harmonizing regulations across different jurisdictions to facilitate international trade and ensure consistent safety standards. This may lead to the development of specific guidelines for chemical use in vertical farming, addressing unique aspects such as closed-loop irrigation systems and the potential for chemical accumulation in recirculating water.

Compliance with these regulations requires vertical farming operators to maintain detailed records of chemical use, implement robust monitoring systems, and potentially invest in water treatment technologies to manage chemical residues. As the industry matures, it is anticipated that more tailored regulations will emerge, balancing the need for innovation with environmental and public health protection.

At the federal level in the United States, the Environmental Protection Agency (EPA) plays a pivotal role in regulating the use of chemicals in agriculture, including vertical farming operations. The EPA's Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA) provides the primary regulatory framework for pesticide registration and use, which extends to chemicals used in irrigation systems. Under FIFRA, sodium percarbonate, when used for antimicrobial purposes in irrigation systems, may require registration as a pesticide, depending on its specific application and claims.

The Food and Drug Administration (FDA) also has jurisdiction over chemical use in vertical farming, particularly through the Food Safety Modernization Act (FSMA). The FSMA's Produce Safety Rule establishes science-based minimum standards for the safe growing, harvesting, packing, and holding of fruits and vegetables grown for human consumption. This rule includes provisions for agricultural water quality and testing, which directly impact the use of chemicals like sodium percarbonate in irrigation systems.

At the state level, regulations can vary significantly, with some states imposing stricter controls on chemical use in agriculture than federal standards. For instance, California's Proposition 65 requires businesses to provide warnings about significant exposures to chemicals that cause cancer, birth defects, or other reproductive harm. This could potentially affect the use of sodium percarbonate if it or its byproducts are listed under Proposition 65.

Internationally, the regulatory landscape becomes more complex. The European Union, for example, has stringent regulations on chemical use in agriculture under the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation. Sodium percarbonate would need to be registered under REACH if used in vertical farming operations within the EU.

As vertical farming technologies evolve, regulatory frameworks are likely to adapt. There is a growing trend towards harmonizing regulations across different jurisdictions to facilitate international trade and ensure consistent safety standards. This may lead to the development of specific guidelines for chemical use in vertical farming, addressing unique aspects such as closed-loop irrigation systems and the potential for chemical accumulation in recirculating water.

Compliance with these regulations requires vertical farming operators to maintain detailed records of chemical use, implement robust monitoring systems, and potentially invest in water treatment technologies to manage chemical residues. As the industry matures, it is anticipated that more tailored regulations will emerge, balancing the need for innovation with environmental and public health protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!