Optimizing Sodium Percarbonate for Botanical Research Facility Cleanliness

JUL 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sodium Percarbonate Research Background

Sodium percarbonate, a compound formed by the combination of sodium carbonate and hydrogen peroxide, has gained significant attention in recent years for its potential applications in cleaning and disinfection. This adduct, with the chemical formula 2Na2CO3·3H2O2, has been known since the early 20th century but has seen a resurgence in interest due to its environmentally friendly properties and versatile applications.

The development of sodium percarbonate can be traced back to the 1900s when it was first synthesized and patented. However, it wasn't until the late 20th century that its potential as a cleaning agent began to be fully explored. The compound's ability to release hydrogen peroxide when dissolved in water makes it an effective oxidizing agent, capable of breaking down organic stains and killing bacteria.

In the context of botanical research facilities, maintaining cleanliness is paramount to ensure the integrity of experiments and the health of plant specimens. Traditional cleaning methods often involve harsh chemicals that can be detrimental to both the environment and the delicate balance of botanical ecosystems. This has led to a growing interest in more sustainable and plant-friendly cleaning solutions, with sodium percarbonate emerging as a promising candidate.

The evolution of sodium percarbonate technology has been driven by several factors, including increasing environmental awareness, stricter regulations on chemical use, and the demand for more efficient cleaning processes. Research has focused on improving the stability of the compound, enhancing its effectiveness against various types of contaminants, and developing formulations that are safe for use around sensitive plant life.

Recent technological advancements have aimed at optimizing the performance of sodium percarbonate in specific applications. These include the development of coated particles to improve storage stability, the creation of effervescent formulations for better dispersion, and the incorporation of activators to enhance cleaning efficacy at lower temperatures. Such innovations have expanded the potential uses of sodium percarbonate beyond simple household applications to more specialized fields like botanical research.

The current technological landscape surrounding sodium percarbonate is characterized by a push towards greater sustainability and efficiency. Researchers are exploring ways to produce the compound using renewable energy sources and investigating its potential synergies with other eco-friendly cleaning agents. Additionally, there is ongoing work to understand and mitigate any potential long-term effects of sodium percarbonate use on plant health and soil microbiology.

As the botanical research community continues to seek out cleaner, safer, and more effective methods for maintaining facility hygiene, the optimization of sodium percarbonate presents an exciting avenue for innovation. The challenge lies in balancing its cleaning power with the need to preserve the delicate ecosystems within research environments, paving the way for further technological developments in this field.

The development of sodium percarbonate can be traced back to the 1900s when it was first synthesized and patented. However, it wasn't until the late 20th century that its potential as a cleaning agent began to be fully explored. The compound's ability to release hydrogen peroxide when dissolved in water makes it an effective oxidizing agent, capable of breaking down organic stains and killing bacteria.

In the context of botanical research facilities, maintaining cleanliness is paramount to ensure the integrity of experiments and the health of plant specimens. Traditional cleaning methods often involve harsh chemicals that can be detrimental to both the environment and the delicate balance of botanical ecosystems. This has led to a growing interest in more sustainable and plant-friendly cleaning solutions, with sodium percarbonate emerging as a promising candidate.

The evolution of sodium percarbonate technology has been driven by several factors, including increasing environmental awareness, stricter regulations on chemical use, and the demand for more efficient cleaning processes. Research has focused on improving the stability of the compound, enhancing its effectiveness against various types of contaminants, and developing formulations that are safe for use around sensitive plant life.

Recent technological advancements have aimed at optimizing the performance of sodium percarbonate in specific applications. These include the development of coated particles to improve storage stability, the creation of effervescent formulations for better dispersion, and the incorporation of activators to enhance cleaning efficacy at lower temperatures. Such innovations have expanded the potential uses of sodium percarbonate beyond simple household applications to more specialized fields like botanical research.

The current technological landscape surrounding sodium percarbonate is characterized by a push towards greater sustainability and efficiency. Researchers are exploring ways to produce the compound using renewable energy sources and investigating its potential synergies with other eco-friendly cleaning agents. Additionally, there is ongoing work to understand and mitigate any potential long-term effects of sodium percarbonate use on plant health and soil microbiology.

As the botanical research community continues to seek out cleaner, safer, and more effective methods for maintaining facility hygiene, the optimization of sodium percarbonate presents an exciting avenue for innovation. The challenge lies in balancing its cleaning power with the need to preserve the delicate ecosystems within research environments, paving the way for further technological developments in this field.

Market Analysis for Botanical Facility Cleaning

The market for botanical facility cleaning solutions, particularly those utilizing sodium percarbonate, has shown significant growth in recent years. This trend is driven by the increasing emphasis on maintaining sterile environments in research facilities, coupled with a growing preference for eco-friendly cleaning agents. The global market for specialized cleaning products in scientific and research settings is estimated to reach several billion dollars by 2025, with a compound annual growth rate exceeding 5%.

Sodium percarbonate, as an effective and environmentally friendly oxidizing agent, has gained traction in this niche market. Its ability to break down into hydrogen peroxide and sodium carbonate makes it particularly attractive for botanical research facilities where residue-free cleaning is crucial. The demand for such cleaning solutions is further bolstered by stringent regulations governing laboratory cleanliness and the need to prevent cross-contamination in plant research.

Key market drivers include the expansion of botanical research activities, increased funding for plant sciences, and the growing number of specialized research facilities worldwide. Additionally, the shift towards sustainable practices in scientific research has created a favorable environment for sodium percarbonate-based cleaning products. These products align well with the green chemistry principles increasingly adopted by research institutions.

The market landscape is characterized by a mix of established chemical companies and specialized laboratory supply firms. Major players are investing in research and development to enhance the efficacy and safety profiles of their sodium percarbonate formulations. There is also a noticeable trend towards developing integrated cleaning systems that combine sodium percarbonate with other complementary agents to provide comprehensive cleaning solutions for botanical facilities.

Regional analysis indicates that North America and Europe currently dominate the market, owing to their advanced research infrastructure and stringent cleanliness standards. However, Asia-Pacific is emerging as a rapidly growing market, driven by increasing investments in life sciences research and the establishment of new botanical research centers in countries like China and India.

Customer segmentation reveals that large-scale research institutions and government-funded botanical gardens are the primary consumers of specialized cleaning products. However, there is a growing market among smaller, private research facilities and educational institutions with botanical research programs. This diversification of the customer base presents opportunities for tailored product offerings and targeted marketing strategies.

Looking ahead, the market for botanical facility cleaning solutions is poised for continued growth. Factors such as the increasing focus on plant-based medicines, the expansion of urban farming research, and the growing importance of plant conservation studies are expected to drive demand for specialized cleaning products. The challenge for suppliers will be to continuously innovate, ensuring their products meet the evolving needs of botanical research facilities while maintaining high standards of efficacy and environmental sustainability.

Sodium percarbonate, as an effective and environmentally friendly oxidizing agent, has gained traction in this niche market. Its ability to break down into hydrogen peroxide and sodium carbonate makes it particularly attractive for botanical research facilities where residue-free cleaning is crucial. The demand for such cleaning solutions is further bolstered by stringent regulations governing laboratory cleanliness and the need to prevent cross-contamination in plant research.

Key market drivers include the expansion of botanical research activities, increased funding for plant sciences, and the growing number of specialized research facilities worldwide. Additionally, the shift towards sustainable practices in scientific research has created a favorable environment for sodium percarbonate-based cleaning products. These products align well with the green chemistry principles increasingly adopted by research institutions.

The market landscape is characterized by a mix of established chemical companies and specialized laboratory supply firms. Major players are investing in research and development to enhance the efficacy and safety profiles of their sodium percarbonate formulations. There is also a noticeable trend towards developing integrated cleaning systems that combine sodium percarbonate with other complementary agents to provide comprehensive cleaning solutions for botanical facilities.

Regional analysis indicates that North America and Europe currently dominate the market, owing to their advanced research infrastructure and stringent cleanliness standards. However, Asia-Pacific is emerging as a rapidly growing market, driven by increasing investments in life sciences research and the establishment of new botanical research centers in countries like China and India.

Customer segmentation reveals that large-scale research institutions and government-funded botanical gardens are the primary consumers of specialized cleaning products. However, there is a growing market among smaller, private research facilities and educational institutions with botanical research programs. This diversification of the customer base presents opportunities for tailored product offerings and targeted marketing strategies.

Looking ahead, the market for botanical facility cleaning solutions is poised for continued growth. Factors such as the increasing focus on plant-based medicines, the expansion of urban farming research, and the growing importance of plant conservation studies are expected to drive demand for specialized cleaning products. The challenge for suppliers will be to continuously innovate, ensuring their products meet the evolving needs of botanical research facilities while maintaining high standards of efficacy and environmental sustainability.

Current Challenges in Sodium Percarbonate Use

Despite its widespread use in cleaning applications, sodium percarbonate faces several challenges in optimizing its effectiveness for botanical research facility cleanliness. One of the primary issues is its stability in aqueous solutions. When dissolved in water, sodium percarbonate rapidly decomposes into hydrogen peroxide and sodium carbonate, which can lead to a decrease in cleaning efficacy over time. This instability necessitates careful handling and storage procedures to maintain its potency.

Another significant challenge is the potential for phytotoxicity when used in botanical environments. While sodium percarbonate is generally considered environmentally friendly, excessive concentrations or prolonged exposure can harm sensitive plant tissues. Striking the right balance between effective cleaning and plant safety requires precise dosing and application methods, which can be difficult to achieve consistently across diverse botanical specimens.

The alkaline nature of sodium percarbonate solutions presents additional complications. The high pH can interfere with the delicate pH balance required for optimal plant growth and research conditions. This is particularly problematic in hydroponic systems or when cleaning surfaces that come into direct contact with plant roots or nutrient solutions.

Temperature sensitivity is another factor that impacts the performance of sodium percarbonate in botanical research facilities. Its decomposition rate accelerates at higher temperatures, potentially reducing its cleaning power in warm greenhouse environments. Conversely, lower temperatures can slow down its oxidizing action, necessitating longer contact times or higher concentrations to achieve the desired cleaning results.

The presence of organic matter and soil in botanical research settings can significantly reduce the effectiveness of sodium percarbonate. These materials can rapidly consume the active oxygen released by the compound, diminishing its cleaning and disinfecting capabilities. This challenge is particularly acute in areas with high organic load, such as potting benches or composting zones.

Furthermore, the potential for material compatibility issues cannot be overlooked. While sodium percarbonate is generally safe for use on many surfaces, it can cause discoloration or degradation of certain materials commonly found in botanical research facilities, such as specific plastics, rubbers, or metal alloys used in equipment and infrastructure.

Lastly, the need for proper rinsing after application poses logistical challenges in large or complex botanical research environments. Inadequate rinsing can leave residues that may interfere with plant growth or research outcomes, while excessive rinsing can be time-consuming and potentially wasteful of water resources.

Another significant challenge is the potential for phytotoxicity when used in botanical environments. While sodium percarbonate is generally considered environmentally friendly, excessive concentrations or prolonged exposure can harm sensitive plant tissues. Striking the right balance between effective cleaning and plant safety requires precise dosing and application methods, which can be difficult to achieve consistently across diverse botanical specimens.

The alkaline nature of sodium percarbonate solutions presents additional complications. The high pH can interfere with the delicate pH balance required for optimal plant growth and research conditions. This is particularly problematic in hydroponic systems or when cleaning surfaces that come into direct contact with plant roots or nutrient solutions.

Temperature sensitivity is another factor that impacts the performance of sodium percarbonate in botanical research facilities. Its decomposition rate accelerates at higher temperatures, potentially reducing its cleaning power in warm greenhouse environments. Conversely, lower temperatures can slow down its oxidizing action, necessitating longer contact times or higher concentrations to achieve the desired cleaning results.

The presence of organic matter and soil in botanical research settings can significantly reduce the effectiveness of sodium percarbonate. These materials can rapidly consume the active oxygen released by the compound, diminishing its cleaning and disinfecting capabilities. This challenge is particularly acute in areas with high organic load, such as potting benches or composting zones.

Furthermore, the potential for material compatibility issues cannot be overlooked. While sodium percarbonate is generally safe for use on many surfaces, it can cause discoloration or degradation of certain materials commonly found in botanical research facilities, such as specific plastics, rubbers, or metal alloys used in equipment and infrastructure.

Lastly, the need for proper rinsing after application poses logistical challenges in large or complex botanical research environments. Inadequate rinsing can leave residues that may interfere with plant growth or research outcomes, while excessive rinsing can be time-consuming and potentially wasteful of water resources.

Existing Sodium Percarbonate Optimization Methods

01 Composition and preparation of sodium percarbonate

Sodium percarbonate is a compound of sodium carbonate and hydrogen peroxide. It can be prepared through various methods, including crystallization or spray drying processes. The composition and preparation methods affect its stability, particle size, and cleaning effectiveness.- Sodium percarbonate as a cleaning agent: Sodium percarbonate is widely used as an effective cleaning agent in various applications. It releases hydrogen peroxide when dissolved in water, providing powerful oxidizing and bleaching properties. This makes it suitable for removing stains, disinfecting surfaces, and general cleaning purposes.

- Stabilization of sodium percarbonate: Various methods and additives are used to stabilize sodium percarbonate, improving its shelf life and effectiveness. These may include coating the particles, adding stabilizing agents, or modifying the crystal structure. Stabilization helps maintain the cleaning power of sodium percarbonate during storage and use.

- Formulation of cleaning products with sodium percarbonate: Sodium percarbonate is incorporated into various cleaning product formulations, including laundry detergents, dishwashing agents, and all-purpose cleaners. The formulations may include additional ingredients such as surfactants, enzymes, and other cleaning agents to enhance overall performance.

- Environmental and safety aspects of sodium percarbonate: Sodium percarbonate is considered an environmentally friendly cleaning agent as it breaks down into harmless substances (sodium carbonate and water) after use. Its non-toxic nature and biodegradability make it a preferred choice for eco-friendly cleaning products. Safety considerations for handling and storage are also important aspects of its use.

- Manufacturing processes for sodium percarbonate: Various manufacturing processes are employed to produce sodium percarbonate with desired properties. These may include spray drying, fluidized bed processes, or crystallization methods. The choice of manufacturing process can affect the particle size, stability, and overall quality of the sodium percarbonate product.

02 Cleaning applications of sodium percarbonate

Sodium percarbonate is widely used in cleaning products due to its ability to release hydrogen peroxide when dissolved in water. It is effective in removing stains, whitening, and disinfecting. Applications include laundry detergents, dishwashing agents, and general household cleaners.Expand Specific Solutions03 Stability and storage of sodium percarbonate

Improving the stability of sodium percarbonate is crucial for maintaining its cleaning effectiveness during storage and use. Various methods, such as coating or adding stabilizing agents, can enhance its shelf life and prevent decomposition in the presence of moisture or heat.Expand Specific Solutions04 Formulation with other cleaning agents

Sodium percarbonate is often combined with other cleaning agents to enhance overall cleaning performance. These formulations may include surfactants, enzymes, or other oxidizing agents. The synergistic effects of these combinations can improve stain removal and general cleanliness.Expand Specific Solutions05 Environmental and safety considerations

Sodium percarbonate is considered an environmentally friendly cleaning agent as it breaks down into harmless substances. However, proper handling and storage are necessary to ensure safety. Research focuses on optimizing its use while minimizing any potential negative impacts on the environment or human health.Expand Specific Solutions

Key Players in Sodium Percarbonate Industry

The optimization of sodium percarbonate for botanical research facility cleanliness is in a mature stage of industry development, with a stable market size and established applications. The technology has reached a high level of maturity, as evidenced by the involvement of major chemical companies like Solvay SA, Evonik Operations GmbH, and Ecolab USA, Inc. These industry leaders have extensive experience in developing and refining sodium percarbonate-based cleaning solutions. The market is characterized by a mix of global players and specialized regional companies, indicating a competitive landscape with opportunities for both large-scale production and niche applications in the botanical research sector.

Solvay SA

Technical Solution: Solvay SA has developed an advanced sodium percarbonate (SPC) formulation optimized for botanical research facility cleanliness. Their approach involves a proprietary coating technology that enhances the stability and controlled release of active oxygen. This formulation, known as OXYPER®, is designed to provide superior cleaning efficacy while being gentle on sensitive botanical specimens. The SPC particles are engineered with a protective layer that prevents premature decomposition, ensuring a longer shelf life and consistent performance[1]. Solvay's process also incorporates a unique particle size distribution that optimizes dissolution rates, allowing for efficient cleaning in various water temperatures commonly used in botanical research settings[2].

Strengths: Enhanced stability and controlled release of active oxygen, longer shelf life, and consistent performance across various conditions. Weaknesses: Potentially higher cost due to advanced formulation and coating technology.

Evonik Operations GmbH

Technical Solution: Evonik has innovated a sodium percarbonate solution specifically tailored for botanical research facilities, focusing on eco-friendly and efficient cleaning. Their approach utilizes a novel stabilization technique that incorporates silica-based nanoparticles to enhance the stability of SPC in storage and during use. This technology, branded as PERCARB-ECO®, ensures a gradual release of active oxygen, providing sustained cleaning power without harsh immediate effects that could damage delicate plant specimens[3]. Evonik's formulation also includes biodegradable surfactants that improve the wetting and penetration capabilities of the cleaning solution, allowing for effective removal of organic residues and contaminants commonly found in botanical research environments[4].

Strengths: Eco-friendly formulation, sustained release of active oxygen, and improved stability. Weaknesses: May require specialized handling and storage conditions due to nanoparticle incorporation.

Innovative Approaches in Percarbonate Technology

Process for preparing a sodium percarbonate product

PatentWO1996019408A1

Innovation

- A process involving the reaction of sodium bicarbonate with an aqueous hydrogen peroxide solution, followed by heating and drying, to produce a sodium percarbonate/sodium bicarbonate mixed compound with controlled active oxygen content and pH stability, using stabilizers like organic phosphonates and chelating agents to enhance bleaching performance.

Method for the preparation of sodium percarbonate granules having enhanced stability

PatentInactiveCA2368410C

Innovation

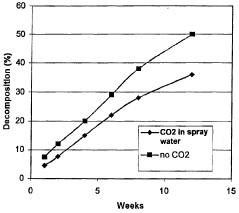

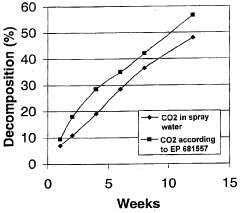

- A method involving the formation of a dense thin sodium bicarbonate film on the surface of sodium percarbonate granules using carbon dioxide dissolved in water, followed by a spray application and drying, which can be further enhanced with additional coating layers, optimizing the surface modification process to improve stability.

Environmental Impact Assessment

The use of sodium percarbonate in botanical research facility cleaning processes necessitates a thorough environmental impact assessment. This compound, while effective for disinfection and cleaning, can have significant effects on surrounding ecosystems if not managed properly.

Sodium percarbonate, when dissolved in water, releases hydrogen peroxide and sodium carbonate. The hydrogen peroxide component acts as a powerful oxidizing agent, which can be harmful to aquatic life if discharged into water bodies in high concentrations. It is crucial to monitor and control the levels of effluent containing these chemicals to prevent adverse effects on local flora and fauna.

The alkaline nature of sodium carbonate, another byproduct of sodium percarbonate decomposition, can alter the pH of soil and water systems. This pH change may impact the growth and development of plants in the vicinity of the research facility, potentially affecting biodiversity and ecosystem balance. Regular soil and water quality testing should be implemented to detect and mitigate any long-term pH alterations.

Consideration must also be given to the potential accumulation of sodium in soil over time. Excessive sodium levels can lead to soil salinization, which may negatively impact plant growth and soil structure. This is particularly relevant for botanical research facilities, where soil quality is paramount for experimental integrity and plant health.

The production and transportation of sodium percarbonate also contribute to its environmental footprint. Manufacturing processes involve energy consumption and potential emissions, while transportation adds to carbon dioxide emissions. A life cycle assessment of the compound's use in the facility should be conducted to quantify these indirect environmental impacts and identify areas for improvement.

Water consumption is another critical factor to consider. The use of sodium percarbonate in cleaning processes may require significant amounts of water for dilution and rinsing. In regions facing water scarcity, this could strain local water resources. Implementing water-efficient cleaning methods and exploring water recycling options can help mitigate this impact.

Proper disposal of cleaning solutions containing sodium percarbonate residues is essential to prevent environmental contamination. Facilities should establish robust waste management protocols, including appropriate treatment of wastewater before discharge and safe disposal of any solid waste generated during the cleaning process.

To minimize environmental impact, botanical research facilities should explore alternative, eco-friendly cleaning agents and methods. This may include the use of enzymatic cleaners, steam cleaning, or other innovative technologies that offer effective sanitation with reduced environmental consequences. Additionally, optimizing the concentration and application methods of sodium percarbonate can help reduce overall usage and associated environmental risks.

Sodium percarbonate, when dissolved in water, releases hydrogen peroxide and sodium carbonate. The hydrogen peroxide component acts as a powerful oxidizing agent, which can be harmful to aquatic life if discharged into water bodies in high concentrations. It is crucial to monitor and control the levels of effluent containing these chemicals to prevent adverse effects on local flora and fauna.

The alkaline nature of sodium carbonate, another byproduct of sodium percarbonate decomposition, can alter the pH of soil and water systems. This pH change may impact the growth and development of plants in the vicinity of the research facility, potentially affecting biodiversity and ecosystem balance. Regular soil and water quality testing should be implemented to detect and mitigate any long-term pH alterations.

Consideration must also be given to the potential accumulation of sodium in soil over time. Excessive sodium levels can lead to soil salinization, which may negatively impact plant growth and soil structure. This is particularly relevant for botanical research facilities, where soil quality is paramount for experimental integrity and plant health.

The production and transportation of sodium percarbonate also contribute to its environmental footprint. Manufacturing processes involve energy consumption and potential emissions, while transportation adds to carbon dioxide emissions. A life cycle assessment of the compound's use in the facility should be conducted to quantify these indirect environmental impacts and identify areas for improvement.

Water consumption is another critical factor to consider. The use of sodium percarbonate in cleaning processes may require significant amounts of water for dilution and rinsing. In regions facing water scarcity, this could strain local water resources. Implementing water-efficient cleaning methods and exploring water recycling options can help mitigate this impact.

Proper disposal of cleaning solutions containing sodium percarbonate residues is essential to prevent environmental contamination. Facilities should establish robust waste management protocols, including appropriate treatment of wastewater before discharge and safe disposal of any solid waste generated during the cleaning process.

To minimize environmental impact, botanical research facilities should explore alternative, eco-friendly cleaning agents and methods. This may include the use of enzymatic cleaners, steam cleaning, or other innovative technologies that offer effective sanitation with reduced environmental consequences. Additionally, optimizing the concentration and application methods of sodium percarbonate can help reduce overall usage and associated environmental risks.

Safety Protocols for Botanical Research Facilities

Safety protocols are paramount in botanical research facilities to ensure the well-being of personnel, protect valuable specimens, and maintain the integrity of research outcomes. When optimizing the use of sodium percarbonate for facility cleanliness, it is crucial to establish comprehensive safety measures that address the unique challenges posed by this chemical compound.

Firstly, proper personal protective equipment (PPE) must be mandated for all staff handling sodium percarbonate. This includes chemical-resistant gloves, safety goggles, and protective clothing to prevent skin and eye contact. Respiratory protection may also be necessary when dealing with large quantities or in poorly ventilated areas.

Storage and handling procedures should be clearly defined and strictly enforced. Sodium percarbonate must be kept in a cool, dry place, away from direct sunlight and heat sources. It should be stored separately from incompatible materials, such as acids, reducing agents, and organic compounds. Proper labeling and inventory management are essential to prevent accidental misuse or contamination.

Training programs should be implemented to educate all staff on the properties of sodium percarbonate, its potential hazards, and proper handling techniques. This includes understanding its decomposition process, which releases oxygen and can potentially cause pressure build-up in closed containers. Regular refresher courses and safety drills should be conducted to maintain awareness and preparedness.

Emergency response protocols must be established and communicated to all personnel. This includes procedures for dealing with spills, accidental exposure, and fire hazards. Eyewash stations and safety showers should be readily accessible in areas where sodium percarbonate is used or stored. A clear evacuation plan should be in place in case of large-scale incidents.

Environmental considerations are also crucial when using sodium percarbonate in botanical research facilities. Proper disposal methods must be implemented to prevent environmental contamination. This may involve neutralization procedures or specialized waste management services. Monitoring systems should be in place to detect any potential release of the compound into the air or water systems within the facility.

Regular safety audits and inspections should be conducted to ensure compliance with established protocols and identify any potential hazards or areas for improvement. This includes checking the integrity of storage containers, verifying the functionality of safety equipment, and assessing the effectiveness of ventilation systems.

Lastly, clear documentation and record-keeping practices must be maintained for all safety-related activities, including training sessions, incident reports, and equipment maintenance. This not only ensures regulatory compliance but also provides valuable data for continuous improvement of safety measures in the facility.

Firstly, proper personal protective equipment (PPE) must be mandated for all staff handling sodium percarbonate. This includes chemical-resistant gloves, safety goggles, and protective clothing to prevent skin and eye contact. Respiratory protection may also be necessary when dealing with large quantities or in poorly ventilated areas.

Storage and handling procedures should be clearly defined and strictly enforced. Sodium percarbonate must be kept in a cool, dry place, away from direct sunlight and heat sources. It should be stored separately from incompatible materials, such as acids, reducing agents, and organic compounds. Proper labeling and inventory management are essential to prevent accidental misuse or contamination.

Training programs should be implemented to educate all staff on the properties of sodium percarbonate, its potential hazards, and proper handling techniques. This includes understanding its decomposition process, which releases oxygen and can potentially cause pressure build-up in closed containers. Regular refresher courses and safety drills should be conducted to maintain awareness and preparedness.

Emergency response protocols must be established and communicated to all personnel. This includes procedures for dealing with spills, accidental exposure, and fire hazards. Eyewash stations and safety showers should be readily accessible in areas where sodium percarbonate is used or stored. A clear evacuation plan should be in place in case of large-scale incidents.

Environmental considerations are also crucial when using sodium percarbonate in botanical research facilities. Proper disposal methods must be implemented to prevent environmental contamination. This may involve neutralization procedures or specialized waste management services. Monitoring systems should be in place to detect any potential release of the compound into the air or water systems within the facility.

Regular safety audits and inspections should be conducted to ensure compliance with established protocols and identify any potential hazards or areas for improvement. This includes checking the integrity of storage containers, verifying the functionality of safety equipment, and assessing the effectiveness of ventilation systems.

Lastly, clear documentation and record-keeping practices must be maintained for all safety-related activities, including training sessions, incident reports, and equipment maintenance. This not only ensures regulatory compliance but also provides valuable data for continuous improvement of safety measures in the facility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!