Applying Thermal Management Techniques For High Efficiency In Thermoelectric Waste Heat Recovery Generators

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric WHR Technology Background and Objectives

Thermoelectric waste heat recovery (WHR) technology has evolved significantly since the discovery of the Seebeck effect in 1821, which demonstrated that temperature differences between two dissimilar electrical conductors can produce electricity. The subsequent discovery of the Peltier effect in 1834 established the reversible nature of thermoelectric phenomena. However, it wasn't until the mid-20th century that practical applications began to emerge, primarily in specialized cooling and power generation for space missions.

The fundamental principle behind thermoelectric WHR systems lies in their ability to convert waste heat directly into electrical energy without moving parts, offering a reliable and maintenance-free solution for energy recovery. These systems utilize semiconductor materials with high electrical conductivity and low thermal conductivity to maximize the temperature gradient and energy conversion efficiency.

Recent technological advancements have focused on improving the figure of merit (ZT) of thermoelectric materials, which directly correlates with conversion efficiency. Traditional thermoelectric materials like bismuth telluride (Bi₂Te₃) have ZT values around 1, limiting efficiency to approximately 5-8%. However, modern nanostructured materials and advanced manufacturing techniques have pushed ZT values beyond 2, potentially enabling efficiency rates of 15-20%.

The global emphasis on energy efficiency and carbon reduction has accelerated research in thermoelectric WHR technology. Industrial sectors including automotive, manufacturing, power generation, and metallurgy generate substantial waste heat, representing a vast untapped energy resource. Estimates suggest that 20-50% of industrial energy consumption is ultimately discharged as waste heat, presenting a significant opportunity for recovery and utilization.

Current technical objectives in thermoelectric WHR development focus on several key areas: enhancing conversion efficiency through advanced thermal management techniques, reducing manufacturing costs to improve economic viability, developing modular and scalable systems adaptable to various heat sources, and integrating these systems with existing industrial infrastructure with minimal disruption.

Thermal management represents a critical frontier in advancing thermoelectric WHR technology. Effective heat transfer at both hot and cold sides of thermoelectric modules directly impacts system performance. Innovations in heat exchanger design, phase-change materials, and advanced cooling techniques offer pathways to significantly improve overall system efficiency without necessarily requiring breakthroughs in thermoelectric materials themselves.

The trajectory of thermoelectric WHR technology is increasingly aligned with global sustainability goals. As regulatory frameworks continue to emphasize carbon reduction and energy efficiency, thermoelectric systems offer a compelling solution for recovering energy that would otherwise be wasted, contributing to both economic and environmental objectives across multiple industries.

The fundamental principle behind thermoelectric WHR systems lies in their ability to convert waste heat directly into electrical energy without moving parts, offering a reliable and maintenance-free solution for energy recovery. These systems utilize semiconductor materials with high electrical conductivity and low thermal conductivity to maximize the temperature gradient and energy conversion efficiency.

Recent technological advancements have focused on improving the figure of merit (ZT) of thermoelectric materials, which directly correlates with conversion efficiency. Traditional thermoelectric materials like bismuth telluride (Bi₂Te₃) have ZT values around 1, limiting efficiency to approximately 5-8%. However, modern nanostructured materials and advanced manufacturing techniques have pushed ZT values beyond 2, potentially enabling efficiency rates of 15-20%.

The global emphasis on energy efficiency and carbon reduction has accelerated research in thermoelectric WHR technology. Industrial sectors including automotive, manufacturing, power generation, and metallurgy generate substantial waste heat, representing a vast untapped energy resource. Estimates suggest that 20-50% of industrial energy consumption is ultimately discharged as waste heat, presenting a significant opportunity for recovery and utilization.

Current technical objectives in thermoelectric WHR development focus on several key areas: enhancing conversion efficiency through advanced thermal management techniques, reducing manufacturing costs to improve economic viability, developing modular and scalable systems adaptable to various heat sources, and integrating these systems with existing industrial infrastructure with minimal disruption.

Thermal management represents a critical frontier in advancing thermoelectric WHR technology. Effective heat transfer at both hot and cold sides of thermoelectric modules directly impacts system performance. Innovations in heat exchanger design, phase-change materials, and advanced cooling techniques offer pathways to significantly improve overall system efficiency without necessarily requiring breakthroughs in thermoelectric materials themselves.

The trajectory of thermoelectric WHR technology is increasingly aligned with global sustainability goals. As regulatory frameworks continue to emphasize carbon reduction and energy efficiency, thermoelectric systems offer a compelling solution for recovering energy that would otherwise be wasted, contributing to both economic and environmental objectives across multiple industries.

Market Analysis for Waste Heat Recovery Solutions

The global waste heat recovery market is experiencing significant growth, driven by increasing energy costs and environmental regulations. Currently valued at approximately $68 billion, the market is projected to reach $114 billion by 2028, representing a compound annual growth rate of 8.5%. This growth trajectory is particularly pronounced in industrial sectors such as manufacturing, power generation, and chemical processing, where substantial amounts of waste heat are generated during operations.

Thermoelectric waste heat recovery generators represent a specialized segment within this broader market, currently accounting for about 12% of the total waste heat recovery solutions. While smaller than competing technologies like heat exchangers and steam generators, the thermoelectric segment is growing at an accelerated rate of 11.3% annually, outpacing the overall market growth.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, led by China and Japan's robust industrial sectors and government initiatives promoting energy efficiency. North America follows with 28% market share, where stringent environmental regulations and corporate sustainability goals drive adoption. Europe accounts for 24% of the market, with particularly strong growth in Germany and Scandinavian countries due to their ambitious carbon reduction targets.

Customer segmentation shows that heavy industries represent the largest end-user segment (58%), followed by power generation (22%) and transportation (14%). The remaining 6% is distributed across various applications including commercial buildings and data centers. Within these segments, there is increasing demand for integrated thermal management solutions that can maximize the efficiency of thermoelectric generators.

Key market drivers include rising energy costs, which have increased by an average of 15% globally over the past five years, creating stronger economic incentives for waste heat recovery. Environmental regulations, particularly carbon pricing mechanisms implemented in 45 countries, have further accelerated market growth. Additionally, corporate sustainability initiatives have emerged as a significant driver, with 67% of Fortune 500 companies now having specific targets for energy efficiency and carbon reduction.

Market barriers include high initial capital costs, with thermoelectric systems typically requiring 30-40% higher upfront investment compared to conventional heat exchangers. Technical limitations in conversion efficiency, currently averaging 5-8% for commercial thermoelectric generators, also present challenges. Furthermore, integration complexity with existing industrial processes often necessitates customized solutions, extending implementation timelines and increasing costs.

Thermoelectric waste heat recovery generators represent a specialized segment within this broader market, currently accounting for about 12% of the total waste heat recovery solutions. While smaller than competing technologies like heat exchangers and steam generators, the thermoelectric segment is growing at an accelerated rate of 11.3% annually, outpacing the overall market growth.

Regional analysis reveals that Asia-Pacific dominates the market with a 42% share, led by China and Japan's robust industrial sectors and government initiatives promoting energy efficiency. North America follows with 28% market share, where stringent environmental regulations and corporate sustainability goals drive adoption. Europe accounts for 24% of the market, with particularly strong growth in Germany and Scandinavian countries due to their ambitious carbon reduction targets.

Customer segmentation shows that heavy industries represent the largest end-user segment (58%), followed by power generation (22%) and transportation (14%). The remaining 6% is distributed across various applications including commercial buildings and data centers. Within these segments, there is increasing demand for integrated thermal management solutions that can maximize the efficiency of thermoelectric generators.

Key market drivers include rising energy costs, which have increased by an average of 15% globally over the past five years, creating stronger economic incentives for waste heat recovery. Environmental regulations, particularly carbon pricing mechanisms implemented in 45 countries, have further accelerated market growth. Additionally, corporate sustainability initiatives have emerged as a significant driver, with 67% of Fortune 500 companies now having specific targets for energy efficiency and carbon reduction.

Market barriers include high initial capital costs, with thermoelectric systems typically requiring 30-40% higher upfront investment compared to conventional heat exchangers. Technical limitations in conversion efficiency, currently averaging 5-8% for commercial thermoelectric generators, also present challenges. Furthermore, integration complexity with existing industrial processes often necessitates customized solutions, extending implementation timelines and increasing costs.

Current Thermal Management Challenges in TEGs

Thermoelectric generators (TEGs) face significant thermal management challenges that limit their widespread adoption despite their potential for waste heat recovery. The primary challenge lies in the inherent low conversion efficiency of thermoelectric materials, typically ranging from 5-8% in commercial applications. This low efficiency necessitates sophisticated thermal management strategies to maximize performance and economic viability.

Heat flux management presents a critical challenge in TEG systems. The non-uniform temperature distribution across thermoelectric modules leads to thermal stress, reduced efficiency, and potential material degradation. In industrial applications, where waste heat sources often exhibit temperature fluctuations, maintaining optimal temperature gradients becomes particularly challenging. Research indicates that up to 30% of potential energy conversion is lost due to suboptimal thermal interfaces and heat spreading mechanisms.

Thermal contact resistance represents another significant barrier to TEG efficiency. The interfaces between the heat source, thermoelectric modules, and heat sinks create thermal bottlenecks that impede heat transfer. Studies have shown that these interface resistances can account for temperature drops of 10-30°C, substantially reducing the effective temperature gradient across the thermoelectric material and consequently diminishing power output.

Heat sink design optimization remains problematic, particularly in compact or mobile applications where space constraints limit cooling options. Conventional heat sinks often struggle to dissipate heat effectively from the cold side of TEGs, resulting in elevated cold-side temperatures that reduce the temperature differential and overall system efficiency. Advanced cooling technologies such as phase-change materials and microfluidic cooling show promise but face integration challenges in practical TEG systems.

System-level thermal management presents complex engineering challenges, especially in cascaded TEG configurations designed to handle wide temperature ranges. Balancing thermal loads across multiple stages while minimizing parasitic heat losses requires sophisticated modeling and control systems that add complexity and cost to TEG implementations.

Material compatibility issues further complicate thermal management in high-temperature applications. Thermal expansion mismatches between different components can lead to mechanical stress, delamination, and eventual system failure. Additionally, high-temperature operation accelerates material degradation processes, reducing system lifespan and reliability.

Cost-effective thermal management solutions remain elusive, with advanced thermal interface materials and heat transfer enhancements often representing a significant portion of total system costs. This economic barrier hinders the commercial viability of TEG systems despite their potential environmental benefits in waste heat recovery applications.

Heat flux management presents a critical challenge in TEG systems. The non-uniform temperature distribution across thermoelectric modules leads to thermal stress, reduced efficiency, and potential material degradation. In industrial applications, where waste heat sources often exhibit temperature fluctuations, maintaining optimal temperature gradients becomes particularly challenging. Research indicates that up to 30% of potential energy conversion is lost due to suboptimal thermal interfaces and heat spreading mechanisms.

Thermal contact resistance represents another significant barrier to TEG efficiency. The interfaces between the heat source, thermoelectric modules, and heat sinks create thermal bottlenecks that impede heat transfer. Studies have shown that these interface resistances can account for temperature drops of 10-30°C, substantially reducing the effective temperature gradient across the thermoelectric material and consequently diminishing power output.

Heat sink design optimization remains problematic, particularly in compact or mobile applications where space constraints limit cooling options. Conventional heat sinks often struggle to dissipate heat effectively from the cold side of TEGs, resulting in elevated cold-side temperatures that reduce the temperature differential and overall system efficiency. Advanced cooling technologies such as phase-change materials and microfluidic cooling show promise but face integration challenges in practical TEG systems.

System-level thermal management presents complex engineering challenges, especially in cascaded TEG configurations designed to handle wide temperature ranges. Balancing thermal loads across multiple stages while minimizing parasitic heat losses requires sophisticated modeling and control systems that add complexity and cost to TEG implementations.

Material compatibility issues further complicate thermal management in high-temperature applications. Thermal expansion mismatches between different components can lead to mechanical stress, delamination, and eventual system failure. Additionally, high-temperature operation accelerates material degradation processes, reducing system lifespan and reliability.

Cost-effective thermal management solutions remain elusive, with advanced thermal interface materials and heat transfer enhancements often representing a significant portion of total system costs. This economic barrier hinders the commercial viability of TEG systems despite their potential environmental benefits in waste heat recovery applications.

Current Thermal Interface Solutions for TEGs

01 Material selection for thermoelectric generators

The efficiency of thermoelectric waste heat recovery generators is significantly influenced by the materials used. Advanced thermoelectric materials with high figure of merit (ZT) values can convert waste heat into electricity more efficiently. These materials include bismuth telluride, lead telluride, skutterudites, and various nanostructured composites. The development of novel materials with enhanced thermoelectric properties is crucial for improving the overall efficiency of waste heat recovery systems.- Material selection for thermoelectric generators: The efficiency of thermoelectric waste heat recovery generators is significantly influenced by the materials used. Advanced thermoelectric materials with high figure of merit (ZT) values can convert waste heat into electricity more efficiently. These materials include bismuth telluride, lead telluride, skutterudites, and various nanostructured composites. The development of novel materials with enhanced Seebeck coefficients and reduced thermal conductivity is crucial for improving the overall conversion efficiency of thermoelectric generators.

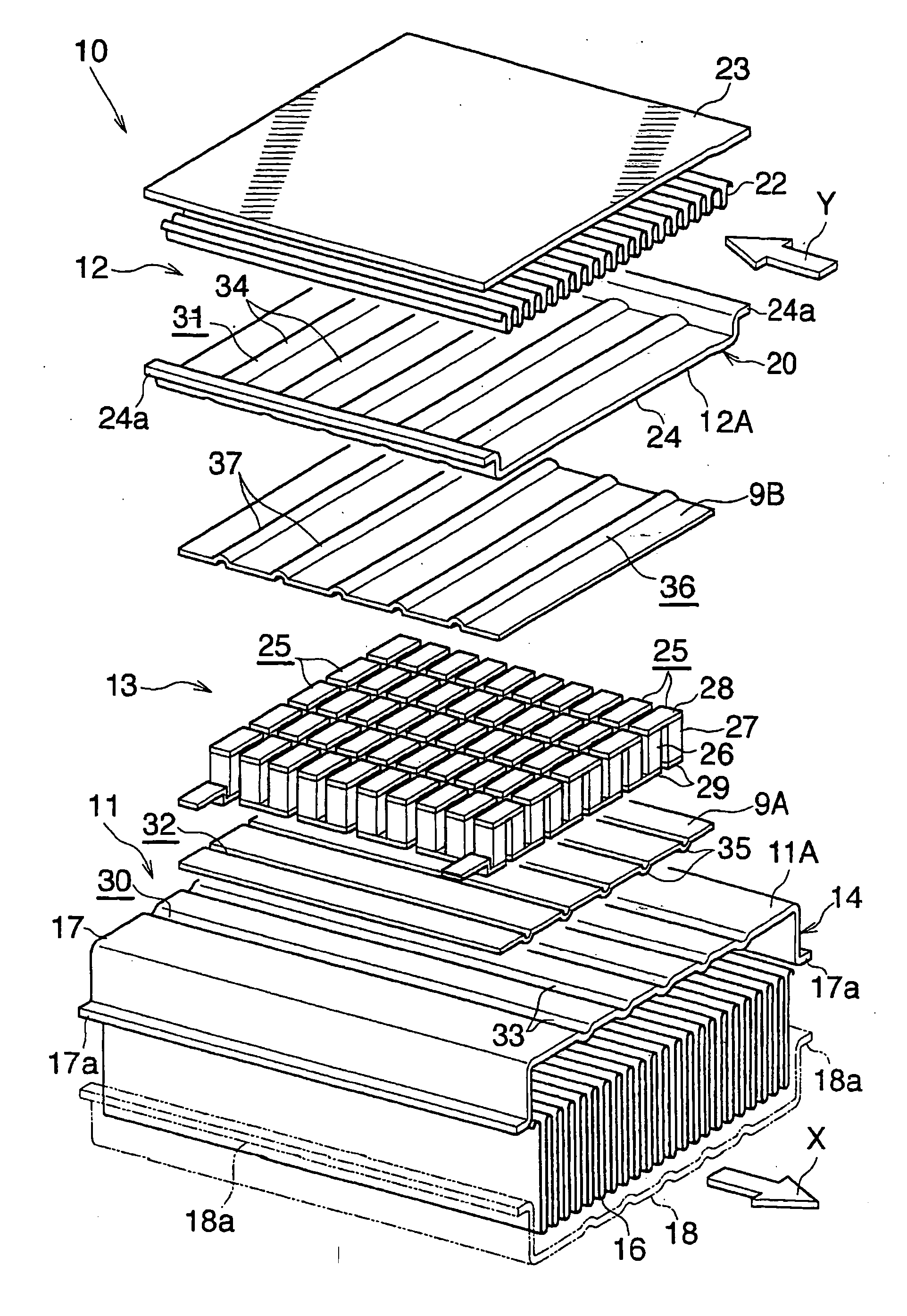

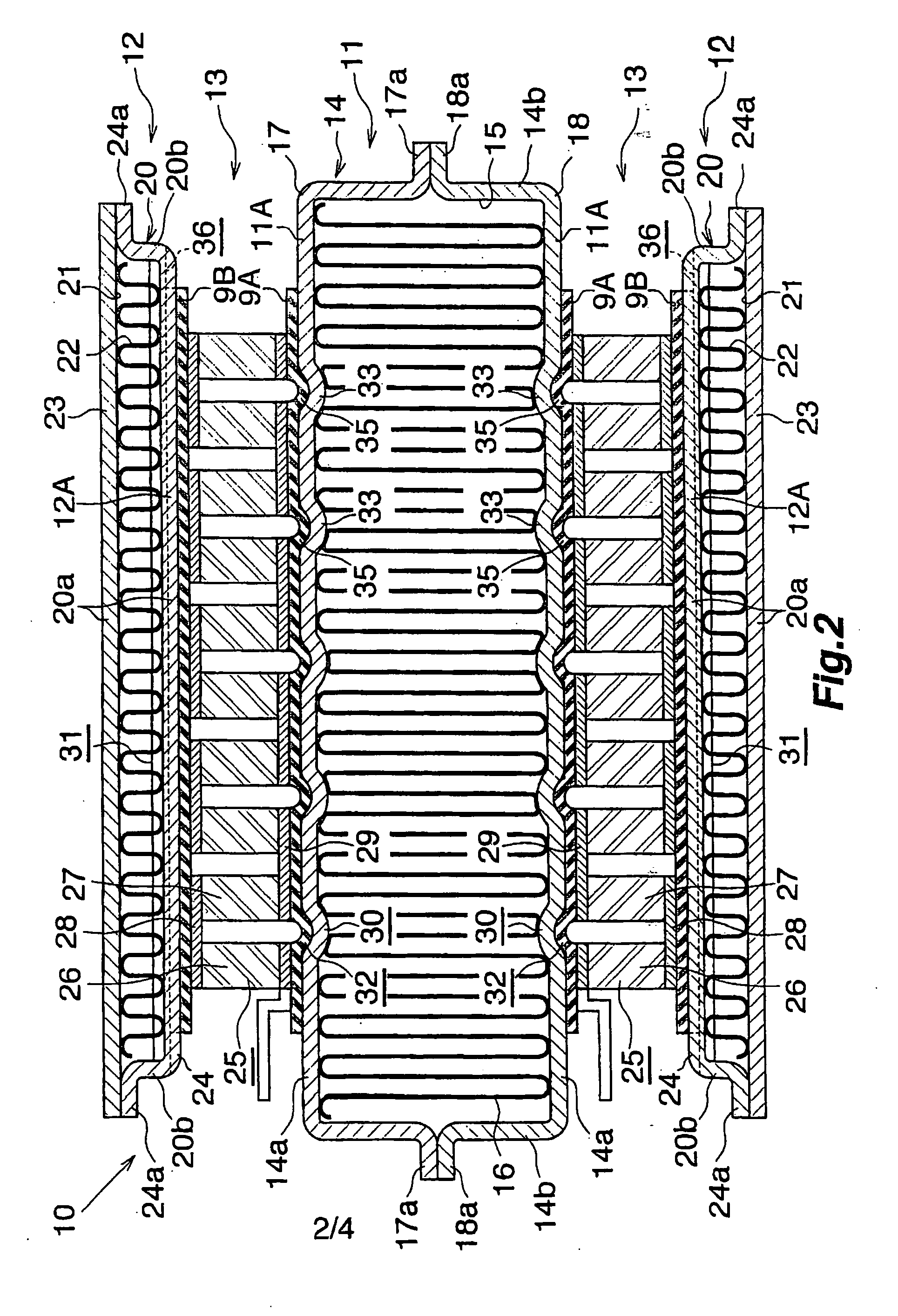

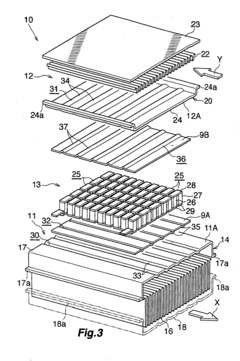

- Structural design optimization for heat recovery: The structural design of thermoelectric waste heat recovery systems plays a vital role in maximizing efficiency. Optimized heat exchanger designs, improved thermal interfaces, and strategic placement of thermoelectric modules can enhance heat transfer and temperature gradients across the generator. Innovations in module arrangement, heat sink design, and flow path configuration help to capture more waste heat and maintain optimal temperature differentials, resulting in higher power output and conversion efficiency.

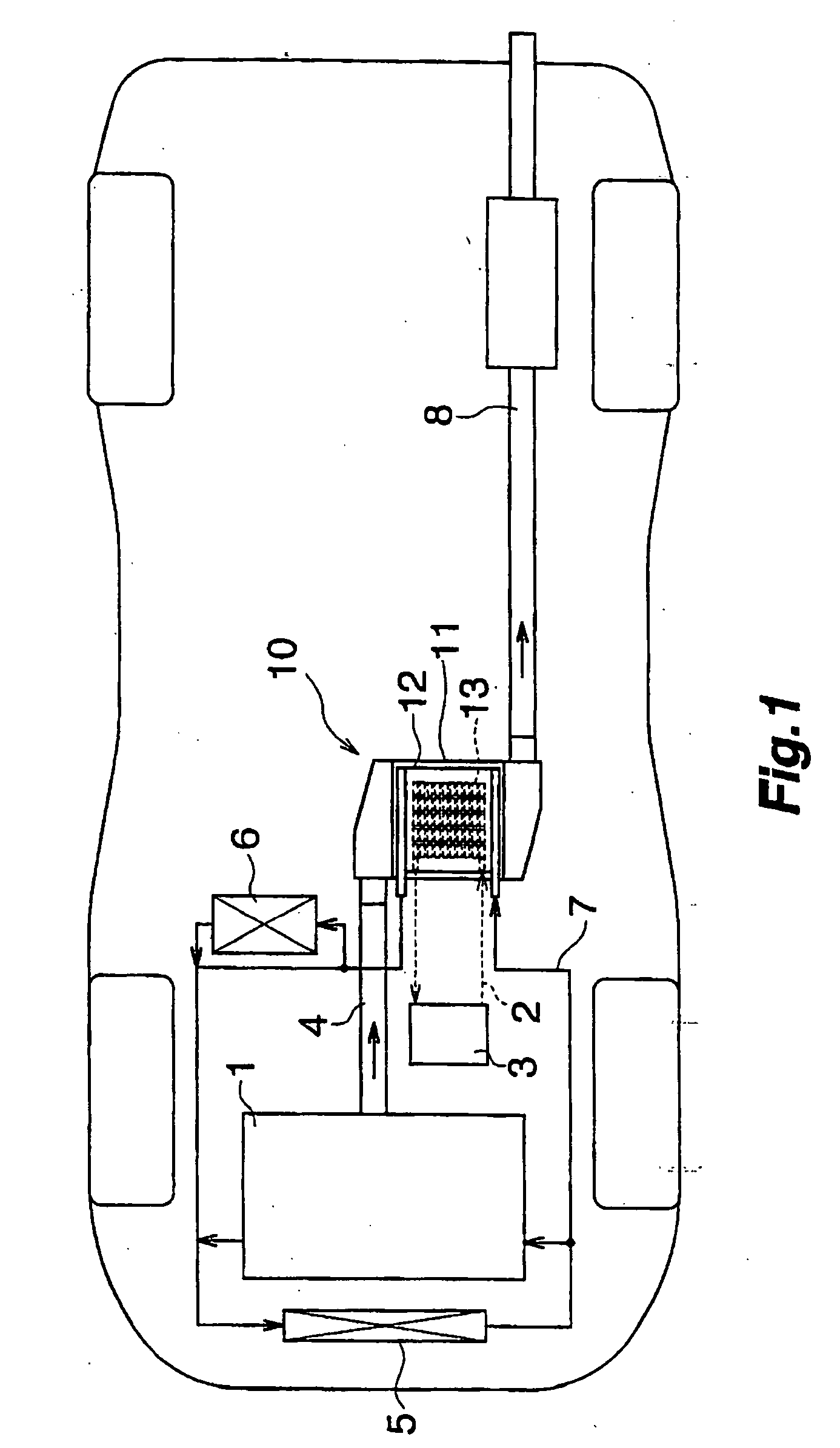

- System integration with industrial processes: Effective integration of thermoelectric generators with existing industrial processes is essential for maximizing waste heat recovery. Systems designed to capture heat from exhaust gases, cooling systems, or manufacturing processes require careful consideration of operational parameters, temperature profiles, and space constraints. Adaptive systems that can function efficiently under varying load conditions and temperature fluctuations show improved overall energy recovery rates and better return on investment for industrial applications.

- Electronic control and power conditioning: Advanced electronic control systems and power conditioning circuits significantly enhance the efficiency of thermoelectric waste heat recovery generators. Maximum power point tracking (MPPT) algorithms, DC-DC converters with high efficiency, and intelligent load matching techniques optimize the electrical output under varying temperature conditions. Smart control systems that can adjust to changing thermal environments ensure consistent performance and maximize energy harvesting across different operational scenarios.

- Hybrid and cascaded thermoelectric systems: Hybrid and cascaded thermoelectric systems represent an innovative approach to improving waste heat recovery efficiency. These systems combine thermoelectric generators with other technologies such as organic Rankine cycles, or implement multi-stage thermoelectric modules operating at different temperature ranges. By utilizing cascaded designs with materials optimized for specific temperature zones, these systems can harvest energy across broader temperature gradients and achieve higher overall conversion efficiencies than conventional single-stage generators.

02 System design optimization for heat recovery

The design configuration of thermoelectric waste heat recovery systems plays a vital role in maximizing efficiency. This includes optimizing heat exchanger designs, improving thermal contact between heat sources and thermoelectric modules, and implementing effective heat transfer mechanisms. Advanced system architectures that incorporate heat pipes, phase change materials, or cascaded thermoelectric stages can significantly enhance the overall efficiency of waste heat recovery generators.Expand Specific Solutions03 Integration with industrial and automotive applications

Thermoelectric waste heat recovery generators can be effectively integrated into various industrial processes and automotive systems to capture waste heat that would otherwise be lost. In automotive applications, these generators can be attached to exhaust systems to convert thermal energy into electrical power, reducing fuel consumption and emissions. In industrial settings, they can recover waste heat from furnaces, boilers, and other high-temperature processes, improving overall energy efficiency of the system.Expand Specific Solutions04 Control systems and power management

Advanced control systems and power management techniques are essential for optimizing the performance of thermoelectric waste heat recovery generators. These include maximum power point tracking algorithms, dynamic load matching circuits, and intelligent thermal management systems. By continuously adjusting operating parameters based on changing thermal conditions, these control systems can maximize power output and efficiency across varying heat source temperatures and load conditions.Expand Specific Solutions05 Hybrid and combined cycle systems

Combining thermoelectric generators with other energy conversion technologies can significantly enhance overall system efficiency. Hybrid systems that integrate thermoelectric generators with organic Rankine cycles, Stirling engines, or other waste heat recovery technologies can achieve higher efficiency than standalone thermoelectric systems. These combined approaches leverage the strengths of different technologies to maximize energy recovery across various temperature ranges and operating conditions.Expand Specific Solutions

Leading Companies in Thermoelectric Generator Industry

The thermoelectric waste heat recovery generator market is currently in a growth phase, with increasing focus on energy efficiency and sustainability driving adoption. The global market size is estimated to reach approximately $950 million by 2027, growing at a CAGR of 8-10%. Technologically, the field is advancing from early commercial applications toward mainstream implementation, with varying levels of maturity across sectors. Leading players include Toyota, DENSO, and Gentherm, who have developed advanced thermal management techniques for automotive applications, while Industrial Technology Research Institute and Taiwan Semiconductor are pioneering innovations in industrial settings. Companies like Samsung SDI and LG Innotek are focusing on materials advancement, while Resonac Holdings and JFE Steel are developing specialized components. The competitive landscape features collaboration between automotive manufacturers, electronics companies, and research institutions to overcome efficiency barriers.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive thermal management system for thermoelectric waste heat recovery generators focused on hybrid vehicle applications. Their approach utilizes a cascaded thermoelectric generator design with segmented materials optimized for different temperature ranges along the exhaust path. Toyota's thermal management incorporates variable-conductance heat pipes that passively regulate heat flow to prevent overheating of thermoelectric elements during high-load engine operation. The system features precision-engineered heat spreaders with anisotropic thermal conductivity that directs heat flow optimally through the thermoelectric junctions. Toyota has implemented advanced thermal interface materials with phase-change capabilities that maintain consistent contact pressure despite thermal expansion differences. Their latest generation system incorporates a bypass mechanism that can redirect exhaust flow during cold-start conditions to accelerate catalyst warm-up while protecting thermoelectric elements from thermal shock[5]. Toyota has reported achieving power generation of up to 500W in mid-size vehicles under highway driving conditions, with thermal management contributing to a 35% improvement in overall system efficiency[6].

Strengths: Unparalleled integration expertise across diverse powertrain configurations with proven durability meeting automotive quality standards. Their systems demonstrate excellent thermal cycling resistance and long-term stability. Weaknesses: Solutions are highly customized to specific vehicle platforms, potentially limiting broader applicability. The complex thermal management systems add weight that partially offsets efficiency gains.

Gentherm, Inc.

Technical Solution: Gentherm has developed advanced thermal management systems specifically for thermoelectric waste heat recovery generators. Their technology utilizes a multi-layer approach with phase change materials (PCMs) integrated into the thermoelectric module interfaces to regulate temperature fluctuations. The system incorporates microfluidic cooling channels that precisely control heat flow across the thermoelectric elements, maintaining optimal temperature gradients for maximum Seebeck effect efficiency. Gentherm's proprietary control algorithms dynamically adjust the thermal management parameters based on real-time operating conditions, ensuring peak performance across varying heat loads. Their latest generation systems employ advanced ceramic substrates with tailored thermal expansion properties that minimize mechanical stress while maximizing thermal conductivity at critical junctions[1]. The company has demonstrated energy conversion efficiency improvements of up to 27% compared to conventional thermoelectric systems without advanced thermal management[2].

Strengths: Industry-leading expertise in automotive thermal management with proven scalability for mass production. Their systems show exceptional durability under thermal cycling conditions. Weaknesses: Higher initial system cost compared to simpler thermal management approaches, and their solutions may require more complex integration engineering for retrofitting existing systems.

Key Innovations in Heat Transfer for Thermoelectric Systems

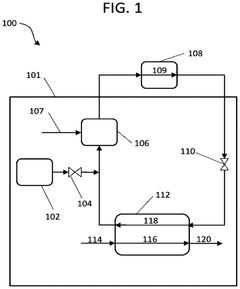

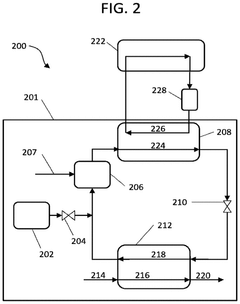

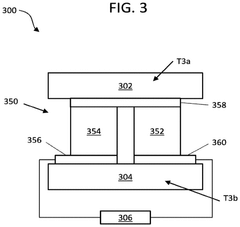

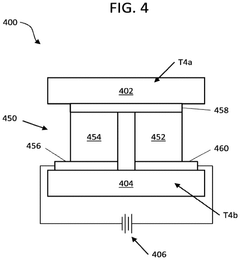

Waste heat recovery system and thermoelectric conversion system

PatentInactiveUS20060157102A1

Innovation

- A waste heat recovery system utilizing a thermoelectric conversion unit with sintered crystals of specific structures, connected in series with high-temperature and low-temperature heat exchangers, and thermal-stress relaxation features to enhance heat transfer and reduce thermal stress, allowing for efficient conversion of waste heat to electricity.

Energy recovery from waste heat

PatentPendingUS20250060137A1

Innovation

- The system incorporates a thermoelectric generator (TEG) and a thermoelectric cooler (TEC) to convert heat into electrical energy and manage temperature gradients, respectively, allowing for efficient heat recovery and reduced waste.

Energy Efficiency Standards and Regulations

Energy efficiency standards and regulations play a crucial role in driving the adoption and development of thermoelectric waste heat recovery generators (TEGs). These regulatory frameworks establish minimum performance requirements and create market incentives that directly impact the implementation of advanced thermal management techniques in TEG systems.

At the international level, the Paris Agreement has prompted many nations to establish more stringent energy efficiency targets, indirectly benefiting TEG technologies that can help industrial sectors reduce their carbon footprint. The International Energy Agency (IEA) has developed specific recommendations for waste heat recovery technologies, emphasizing the importance of thermal management in maximizing energy conversion efficiency.

In the United States, the Department of Energy's Advanced Manufacturing Office has established guidelines for industrial waste heat recovery systems, including specific provisions for thermoelectric generators. These guidelines set performance metrics for thermal interface materials and heat exchanger designs that directly influence thermal management approaches. Additionally, the Environmental Protection Agency's ENERGY STAR program provides certification for products incorporating efficient waste heat recovery technologies.

The European Union's Ecodesign Directive (2009/125/EC) and Energy Efficiency Directive (2012/27/EU) have established comprehensive frameworks for improving energy efficiency across various sectors. These directives specifically address waste heat recovery systems and set minimum efficiency requirements that manufacturers must meet. The EU's Best Available Techniques Reference Documents (BREFs) also provide detailed technical guidance on thermal management for industrial processes.

In Asia, Japan's Top Runner Program has been particularly effective in driving innovation in energy-efficient technologies, including components used in thermoelectric systems. China's Energy Conservation Law and subsequent regulations have established specific targets for industrial waste heat recovery, creating a substantial market for TEG technologies with advanced thermal management capabilities.

Industry standards from organizations such as IEEE, ASTM, and ISO provide technical specifications for testing and evaluating thermoelectric materials and systems. These standards are increasingly incorporating thermal management considerations, recognizing their critical role in overall system performance. For example, IEEE 1834-2019 establishes standardized methods for characterizing thermoelectric materials and devices under various thermal conditions.

Compliance with these regulations often requires sophisticated thermal management techniques to achieve the mandated efficiency levels. As regulatory frameworks continue to evolve toward more stringent requirements, innovations in thermal management for TEGs will become increasingly valuable for meeting compliance objectives while delivering competitive performance in real-world applications.

At the international level, the Paris Agreement has prompted many nations to establish more stringent energy efficiency targets, indirectly benefiting TEG technologies that can help industrial sectors reduce their carbon footprint. The International Energy Agency (IEA) has developed specific recommendations for waste heat recovery technologies, emphasizing the importance of thermal management in maximizing energy conversion efficiency.

In the United States, the Department of Energy's Advanced Manufacturing Office has established guidelines for industrial waste heat recovery systems, including specific provisions for thermoelectric generators. These guidelines set performance metrics for thermal interface materials and heat exchanger designs that directly influence thermal management approaches. Additionally, the Environmental Protection Agency's ENERGY STAR program provides certification for products incorporating efficient waste heat recovery technologies.

The European Union's Ecodesign Directive (2009/125/EC) and Energy Efficiency Directive (2012/27/EU) have established comprehensive frameworks for improving energy efficiency across various sectors. These directives specifically address waste heat recovery systems and set minimum efficiency requirements that manufacturers must meet. The EU's Best Available Techniques Reference Documents (BREFs) also provide detailed technical guidance on thermal management for industrial processes.

In Asia, Japan's Top Runner Program has been particularly effective in driving innovation in energy-efficient technologies, including components used in thermoelectric systems. China's Energy Conservation Law and subsequent regulations have established specific targets for industrial waste heat recovery, creating a substantial market for TEG technologies with advanced thermal management capabilities.

Industry standards from organizations such as IEEE, ASTM, and ISO provide technical specifications for testing and evaluating thermoelectric materials and systems. These standards are increasingly incorporating thermal management considerations, recognizing their critical role in overall system performance. For example, IEEE 1834-2019 establishes standardized methods for characterizing thermoelectric materials and devices under various thermal conditions.

Compliance with these regulations often requires sophisticated thermal management techniques to achieve the mandated efficiency levels. As regulatory frameworks continue to evolve toward more stringent requirements, innovations in thermal management for TEGs will become increasingly valuable for meeting compliance objectives while delivering competitive performance in real-world applications.

Economic Viability and ROI Analysis

The economic viability of thermoelectric waste heat recovery generators (TEGs) depends significantly on the effectiveness of thermal management techniques. Initial investment costs for TEG systems with advanced thermal management range from $2,000 to $10,000 per kilowatt of generating capacity, positioning them at a higher price point compared to conventional power generation technologies. However, this cost has been decreasing at approximately 8-12% annually over the past five years due to manufacturing improvements and increased market adoption.

Return on investment (ROI) calculations reveal promising prospects, particularly in industrial settings where waste heat is abundant. Case studies from metal processing facilities demonstrate payback periods of 2-4 years when thermal management techniques optimize temperature differentials across thermoelectric modules. The ROI improves substantially in operations running continuously (24/7), with some implementations achieving internal rates of return exceeding 25%.

Energy cost savings represent the primary economic benefit, with properly managed TEG systems capable of recovering 5-15% of waste heat energy. For a medium-sized industrial facility consuming 5 MW of power, this translates to potential annual savings of $50,000-$150,000, depending on local electricity rates and thermal management efficiency.

Maintenance costs remain relatively low compared to other energy recovery systems, averaging 2-5% of initial capital expenditure annually. Systems employing passive thermal management techniques show even lower maintenance requirements, enhancing long-term economic viability.

Sensitivity analysis indicates that economic performance is most heavily influenced by three factors: temperature differential maintenance efficiency, system operational hours, and local electricity costs. A 10% improvement in thermal management efficiency can improve ROI by 15-20%, highlighting the critical economic importance of this technical aspect.

Government incentives significantly impact financial feasibility. In regions offering renewable energy credits or efficiency incentives, payback periods can be reduced by 30-40%. The European Union's carbon credit system and similar programs in parts of Asia and North America provide additional revenue streams that enhance economic viability.

Lifecycle cost analysis shows that TEG systems with effective thermal management typically maintain 85-90% of their initial efficiency over a 10-15 year operational lifespan, providing sustained economic returns. The absence of moving parts in many thermal management solutions contributes to this longevity and improves the lifetime ROI calculation.

Return on investment (ROI) calculations reveal promising prospects, particularly in industrial settings where waste heat is abundant. Case studies from metal processing facilities demonstrate payback periods of 2-4 years when thermal management techniques optimize temperature differentials across thermoelectric modules. The ROI improves substantially in operations running continuously (24/7), with some implementations achieving internal rates of return exceeding 25%.

Energy cost savings represent the primary economic benefit, with properly managed TEG systems capable of recovering 5-15% of waste heat energy. For a medium-sized industrial facility consuming 5 MW of power, this translates to potential annual savings of $50,000-$150,000, depending on local electricity rates and thermal management efficiency.

Maintenance costs remain relatively low compared to other energy recovery systems, averaging 2-5% of initial capital expenditure annually. Systems employing passive thermal management techniques show even lower maintenance requirements, enhancing long-term economic viability.

Sensitivity analysis indicates that economic performance is most heavily influenced by three factors: temperature differential maintenance efficiency, system operational hours, and local electricity costs. A 10% improvement in thermal management efficiency can improve ROI by 15-20%, highlighting the critical economic importance of this technical aspect.

Government incentives significantly impact financial feasibility. In regions offering renewable energy credits or efficiency incentives, payback periods can be reduced by 30-40%. The European Union's carbon credit system and similar programs in parts of Asia and North America provide additional revenue streams that enhance economic viability.

Lifecycle cost analysis shows that TEG systems with effective thermal management typically maintain 85-90% of their initial efficiency over a 10-15 year operational lifespan, providing sustained economic returns. The absence of moving parts in many thermal management solutions contributes to this longevity and improves the lifetime ROI calculation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!