Calculating System-Level Economics And Payback Periods For Thermoelectric Generators In Waste Heat Recovery

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

TEG Waste Heat Recovery Background and Objectives

Thermoelectric generators (TEGs) represent a promising technology for waste heat recovery, converting thermal energy directly into electrical power through the Seebeck effect. This technology has evolved significantly since its discovery in the early 19th century, with substantial advancements in materials science and manufacturing techniques enabling increasingly efficient energy conversion systems. The historical trajectory of TEG development shows a clear progression from simple metallic junctions to sophisticated semiconductor-based devices with enhanced performance characteristics.

The global emphasis on energy efficiency and sustainability has accelerated interest in waste heat recovery technologies. Industrial processes, transportation systems, and power generation facilities collectively discharge vast amounts of low-grade thermal energy into the environment. According to recent estimates, between 20-50% of industrial energy consumption is ultimately released as waste heat, representing both an environmental challenge and a significant untapped energy resource.

TEG technology offers a unique value proposition in this context, providing a solid-state solution with no moving parts, minimal maintenance requirements, and the ability to operate in harsh environments where conventional heat recovery systems may be impractical. The absence of working fluids and mechanical components contributes to exceptional reliability and longevity, with operational lifespans potentially exceeding two decades under appropriate conditions.

The primary technical objective in TEG waste heat recovery is to develop economically viable systems that deliver meaningful energy conversion efficiency at competitive cost points. This involves optimizing the entire thermal-to-electrical energy conversion pathway, from heat capture and thermal management to electrical power conditioning and system integration. Achieving favorable economics requires balancing material costs, manufacturing complexity, and system performance to deliver solutions with reasonable payback periods.

Secondary objectives include enhancing TEG durability under thermal cycling conditions, improving power density to reduce form factors, and developing standardized methodologies for system-level economic assessment. The latter is particularly crucial as inconsistent economic evaluation approaches have historically complicated technology comparisons and investment decisions in this domain.

The evolution of TEG technology is increasingly guided by sustainability considerations beyond mere energy efficiency. This includes developing materials with reduced environmental impact, designing for end-of-life recyclability, and quantifying lifecycle carbon benefits. As regulatory frameworks increasingly incentivize decarbonization, the ability to accurately calculate and communicate the economic and environmental benefits of TEG systems becomes essential for technology adoption and market growth.

The global emphasis on energy efficiency and sustainability has accelerated interest in waste heat recovery technologies. Industrial processes, transportation systems, and power generation facilities collectively discharge vast amounts of low-grade thermal energy into the environment. According to recent estimates, between 20-50% of industrial energy consumption is ultimately released as waste heat, representing both an environmental challenge and a significant untapped energy resource.

TEG technology offers a unique value proposition in this context, providing a solid-state solution with no moving parts, minimal maintenance requirements, and the ability to operate in harsh environments where conventional heat recovery systems may be impractical. The absence of working fluids and mechanical components contributes to exceptional reliability and longevity, with operational lifespans potentially exceeding two decades under appropriate conditions.

The primary technical objective in TEG waste heat recovery is to develop economically viable systems that deliver meaningful energy conversion efficiency at competitive cost points. This involves optimizing the entire thermal-to-electrical energy conversion pathway, from heat capture and thermal management to electrical power conditioning and system integration. Achieving favorable economics requires balancing material costs, manufacturing complexity, and system performance to deliver solutions with reasonable payback periods.

Secondary objectives include enhancing TEG durability under thermal cycling conditions, improving power density to reduce form factors, and developing standardized methodologies for system-level economic assessment. The latter is particularly crucial as inconsistent economic evaluation approaches have historically complicated technology comparisons and investment decisions in this domain.

The evolution of TEG technology is increasingly guided by sustainability considerations beyond mere energy efficiency. This includes developing materials with reduced environmental impact, designing for end-of-life recyclability, and quantifying lifecycle carbon benefits. As regulatory frameworks increasingly incentivize decarbonization, the ability to accurately calculate and communicate the economic and environmental benefits of TEG systems becomes essential for technology adoption and market growth.

Market Analysis for Thermoelectric Waste Heat Recovery

The global market for thermoelectric waste heat recovery systems is experiencing significant growth, driven by increasing energy costs and environmental regulations. The market was valued at approximately $626 million in 2022 and is projected to reach $1.4 billion by 2030, representing a compound annual growth rate (CAGR) of 10.6%. This growth trajectory is supported by the vast untapped potential of waste heat recovery across multiple industries.

Industrial sectors contribute the largest market share, with manufacturing, power generation, and chemical processing facilities generating substantial waste heat. These sectors collectively account for over 60% of the current market demand. Automotive applications represent the fastest-growing segment, expanding at nearly 12% annually as vehicle manufacturers seek to meet stringent emission standards and improve fuel efficiency.

Geographically, Asia-Pacific dominates the market with approximately 40% share, led by China's massive industrial base and Japan's technological innovation. North America and Europe follow with 25% and 22% market shares respectively, driven by stringent environmental regulations and sustainability initiatives.

Customer demand is increasingly focused on system-level economics rather than just component performance. End-users require comprehensive economic analyses that demonstrate clear return on investment (ROI) and reasonable payback periods, typically seeking systems that can achieve payback within 2-5 years depending on the application.

Market research indicates that price sensitivity varies significantly by sector. While industrial customers prioritize long-term reliability and total cost of ownership, commercial building operators are more price-sensitive and require shorter payback periods. The average cost per installed kilowatt for thermoelectric waste heat recovery systems ranges from $1,500 to $4,000, with economies of scale significantly impacting larger installations.

A critical market barrier remains the initial capital investment required for thermoelectric generator (TEG) systems. Despite declining component costs, installation and system integration expenses still represent 40-50% of total project costs. This underscores the importance of accurate economic modeling that accounts for all system-level costs and benefits.

Market forecasts suggest that technological improvements driving efficiency gains will reduce average payback periods from the current 3-7 years to 2-4 years by 2028, significantly expanding market adoption. Industries with continuous operations and high-temperature waste streams (above 300°C) represent the most economically viable applications, with payback periods often 30-40% shorter than intermittent or low-temperature applications.

Industrial sectors contribute the largest market share, with manufacturing, power generation, and chemical processing facilities generating substantial waste heat. These sectors collectively account for over 60% of the current market demand. Automotive applications represent the fastest-growing segment, expanding at nearly 12% annually as vehicle manufacturers seek to meet stringent emission standards and improve fuel efficiency.

Geographically, Asia-Pacific dominates the market with approximately 40% share, led by China's massive industrial base and Japan's technological innovation. North America and Europe follow with 25% and 22% market shares respectively, driven by stringent environmental regulations and sustainability initiatives.

Customer demand is increasingly focused on system-level economics rather than just component performance. End-users require comprehensive economic analyses that demonstrate clear return on investment (ROI) and reasonable payback periods, typically seeking systems that can achieve payback within 2-5 years depending on the application.

Market research indicates that price sensitivity varies significantly by sector. While industrial customers prioritize long-term reliability and total cost of ownership, commercial building operators are more price-sensitive and require shorter payback periods. The average cost per installed kilowatt for thermoelectric waste heat recovery systems ranges from $1,500 to $4,000, with economies of scale significantly impacting larger installations.

A critical market barrier remains the initial capital investment required for thermoelectric generator (TEG) systems. Despite declining component costs, installation and system integration expenses still represent 40-50% of total project costs. This underscores the importance of accurate economic modeling that accounts for all system-level costs and benefits.

Market forecasts suggest that technological improvements driving efficiency gains will reduce average payback periods from the current 3-7 years to 2-4 years by 2028, significantly expanding market adoption. Industries with continuous operations and high-temperature waste streams (above 300°C) represent the most economically viable applications, with payback periods often 30-40% shorter than intermittent or low-temperature applications.

Technical Challenges in TEG Implementation

Despite the promising potential of Thermoelectric Generators (TEGs) in waste heat recovery applications, several significant technical challenges impede their widespread implementation and economic viability. The primary obstacle remains the relatively low conversion efficiency of current TEG systems, typically ranging from 3-8% depending on operating conditions and material properties. This efficiency limitation directly impacts the economic calculations and extends payback periods, making it difficult to justify investment in many industrial settings.

Material constraints present another substantial challenge. High-performance thermoelectric materials often contain rare or expensive elements such as tellurium, making large-scale deployment cost-prohibitive. Additionally, many high-efficiency thermoelectric materials exhibit optimal performance only within narrow temperature ranges, limiting their applicability across diverse waste heat sources that may fluctuate in temperature.

Thermal interface management represents a critical engineering challenge that significantly affects system-level economics. Poor thermal contacts between the TEG and both the heat source and heat sink can drastically reduce effective temperature gradients across the device, diminishing power output and extending payback periods. The development of reliable, durable thermal interface materials that maintain performance over extended operational periods remains an ongoing research focus.

System durability and reliability issues further complicate economic calculations. TEGs deployed in industrial environments must withstand thermal cycling, mechanical vibration, and potentially corrosive conditions. Premature system failures or performance degradation over time can invalidate initial economic projections and extend payback periods beyond acceptable limits.

Heat exchanger design optimization presents complex engineering trade-offs between heat transfer effectiveness, pressure drop penalties, and manufacturing costs. Inadequate heat exchanger design can result in insufficient temperature differentials across the TEG modules, while overly complex designs may increase capital costs prohibitively.

Integration challenges with existing industrial processes also impact economic feasibility. Retrofitting TEG systems into operational facilities often requires production interruptions and modifications to existing equipment, adding significant indirect costs that must be factored into payback calculations but are frequently underestimated in preliminary analyses.

Finally, accurate measurement and verification of actual energy recovery performance in field conditions remains difficult. Laboratory performance metrics often fail to translate directly to real-world applications, creating uncertainty in economic projections and complicating investment decisions for potential adopters of TEG technology.

Material constraints present another substantial challenge. High-performance thermoelectric materials often contain rare or expensive elements such as tellurium, making large-scale deployment cost-prohibitive. Additionally, many high-efficiency thermoelectric materials exhibit optimal performance only within narrow temperature ranges, limiting their applicability across diverse waste heat sources that may fluctuate in temperature.

Thermal interface management represents a critical engineering challenge that significantly affects system-level economics. Poor thermal contacts between the TEG and both the heat source and heat sink can drastically reduce effective temperature gradients across the device, diminishing power output and extending payback periods. The development of reliable, durable thermal interface materials that maintain performance over extended operational periods remains an ongoing research focus.

System durability and reliability issues further complicate economic calculations. TEGs deployed in industrial environments must withstand thermal cycling, mechanical vibration, and potentially corrosive conditions. Premature system failures or performance degradation over time can invalidate initial economic projections and extend payback periods beyond acceptable limits.

Heat exchanger design optimization presents complex engineering trade-offs between heat transfer effectiveness, pressure drop penalties, and manufacturing costs. Inadequate heat exchanger design can result in insufficient temperature differentials across the TEG modules, while overly complex designs may increase capital costs prohibitively.

Integration challenges with existing industrial processes also impact economic feasibility. Retrofitting TEG systems into operational facilities often requires production interruptions and modifications to existing equipment, adding significant indirect costs that must be factored into payback calculations but are frequently underestimated in preliminary analyses.

Finally, accurate measurement and verification of actual energy recovery performance in field conditions remains difficult. Laboratory performance metrics often fail to translate directly to real-world applications, creating uncertainty in economic projections and complicating investment decisions for potential adopters of TEG technology.

Current Economic Calculation Methodologies

01 Cost-benefit analysis of thermoelectric generators

Economic evaluations of thermoelectric generators (TEGs) focus on comparing initial investment costs against long-term energy savings. These analyses consider factors such as installation costs, maintenance requirements, and energy production efficiency. The cost-benefit ratio is calculated based on the energy output over time versus the initial capital expenditure, helping to determine the financial viability of TEG implementations in various applications.- Cost-benefit analysis of thermoelectric generators: Economic evaluations of thermoelectric generators focus on comparing initial investment costs against long-term energy savings. These analyses consider factors such as installation costs, maintenance requirements, and energy production efficiency. The payback period calculation typically accounts for the cost of materials, manufacturing processes, and the value of electricity generated over time. Various models have been developed to predict return on investment based on different operating conditions and applications.

- Waste heat recovery economics: Thermoelectric generators designed for waste heat recovery applications offer significant economic advantages by converting otherwise wasted thermal energy into usable electricity. The economic viability depends on the temperature differential available, the efficiency of the thermoelectric materials, and the consistency of the heat source. Industrial applications with continuous waste heat streams typically show shorter payback periods compared to intermittent heat sources. The economic assessment includes considerations of reduced primary energy consumption and associated cost savings.

- Renewable energy integration and economic impacts: Integrating thermoelectric generators with renewable energy systems creates hybrid solutions with improved economic performance. These integrated systems can enhance overall efficiency and provide more consistent power generation. The economic analysis considers the complementary nature of different energy sources, reduced reliance on grid electricity, and potential government incentives for renewable energy adoption. Payback periods are influenced by local energy prices, available subsidies, and the specific application context.

- Material advancements affecting economic viability: Recent advancements in thermoelectric materials have significantly improved the economic feasibility of thermoelectric generators. New materials with higher figure of merit (ZT) values increase conversion efficiency, directly impacting energy output and shortening payback periods. Economic analyses show that material innovations that reduce manufacturing costs while improving performance have the most substantial impact on commercial viability. The development of less expensive alternatives to rare or precious metals used in traditional thermoelectric devices has opened new market opportunities.

- Application-specific economic considerations: The economic viability of thermoelectric generators varies significantly across different applications. Automotive applications leverage existing heat sources but face space and weight constraints. Remote power applications may justify higher costs due to the absence of grid alternatives. Consumer applications typically require shorter payback periods to gain market acceptance. Industrial applications with continuous operation often demonstrate the most favorable economics. Each application requires specific economic modeling that accounts for unique operating conditions, regulatory environments, and market demands.

02 Payback period calculation methods for TEG systems

Various methodologies are employed to calculate the payback periods for thermoelectric generator investments. These calculations typically account for energy production rates, market energy prices, installation costs, and operational expenses. Advanced models incorporate variables such as degradation rates of components, fluctuating energy prices, and maintenance schedules to provide more accurate estimations of when the initial investment will be recovered through energy savings or generation.Expand Specific Solutions03 Efficiency improvements affecting economic viability

Technological advancements in thermoelectric materials and system designs have significantly improved the economic viability of TEGs. Enhanced conversion efficiency, reduced material costs, and optimized heat transfer mechanisms contribute to shorter payback periods. These improvements allow TEGs to generate more electricity from the same heat source, thereby increasing the return on investment and making them more competitive with conventional power generation technologies.Expand Specific Solutions04 Application-specific economic considerations

The economic feasibility of thermoelectric generators varies significantly across different applications. In remote locations where grid connection is expensive, TEGs may offer faster payback despite higher initial costs. Industrial waste heat recovery applications typically show better economics due to continuous operation and abundant heat sources. Consumer applications often face longer payback periods but may be justified by other benefits such as reliability or environmental considerations.Expand Specific Solutions05 Environmental and regulatory factors affecting economics

Environmental benefits and regulatory incentives significantly impact the economic assessment of thermoelectric generators. Carbon credits, renewable energy subsidies, and tax incentives can substantially reduce effective payback periods. Additionally, increasingly stringent emissions regulations may make waste heat recovery systems more attractive from a compliance perspective. These non-technical factors often play a decisive role in investment decisions regarding thermoelectric technology implementation.Expand Specific Solutions

Key Industry Players in TEG Development

The thermoelectric generator (TEG) waste heat recovery market is currently in its growth phase, characterized by increasing adoption across automotive, industrial, and power generation sectors. Market size is projected to expand significantly due to rising energy efficiency demands and sustainability initiatives, though still representing a niche segment within the broader energy recovery landscape. Technologically, the field shows varying maturity levels among key players. Companies like Toyota, Mitsubishi Heavy Industries, and Gentherm demonstrate advanced capabilities in automotive TEG applications, while Resonac Holdings and Samsung SDI lead in material development. State Grid Corporation of China and Boeing represent industrial-scale implementation potential. Research institutions like China Electric Power Research Institute and UT-Battelle are advancing fundamental technologies, while newer entrants like Budderfly and Novopower are developing innovative system-level economic models to improve commercial viability and accelerate market adoption.

Toyota Motor Corp.

Technical Solution: Toyota has developed a sophisticated thermoelectric waste heat recovery system as part of their broader vehicle efficiency strategy. Their approach focuses on holistic system integration that optimizes the economic viability of thermoelectric generators in automotive applications. Toyota's TEG technology utilizes advanced skutterudite and half-Heusler materials with ZT values exceeding 1.3, configured in a cascaded architecture to maximize power generation across varying temperature gradients. Their economic analysis framework incorporates manufacturing scale economies, with projections showing that at production volumes exceeding 100,000 units annually, system costs could decrease by approximately 40%. Toyota's models indicate that their TEG systems can generate 200-500W of electrical power under typical driving conditions, reducing alternator load and improving fuel economy by 2-3%. Their payback period calculations incorporate regional variations in fuel costs and driving patterns, with estimates ranging from 3-5 years for passenger vehicles and 2-3 years for commercial applications with higher utilization rates.

Strengths: Extensive experience with hybrid powertrain systems; established global manufacturing infrastructure; comprehensive vehicle integration capabilities. Weaknesses: Current TEG performance still below theoretical targets; system complexity adds weight that partially offsets efficiency gains; technology effectiveness varies significantly with driving conditions.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed an industrial-scale thermoelectric waste heat recovery system targeting large power plants and industrial facilities. Their approach focuses on maximizing economic returns through careful system sizing and integration with existing thermal processes. MHI's technology utilizes segmented thermoelectric modules optimized for different temperature ranges, enabling effective operation across the broad temperature profiles found in industrial waste heat streams (200-600°C). Their economic analysis framework incorporates detailed capital expenditure modeling, operational cost projections, and maintenance requirements over system lifetimes exceeding 15 years. MHI's calculations demonstrate that for industrial facilities with continuous operations exceeding 7,500 hours annually and waste heat sources above 350°C, their TEG systems can achieve payback periods of 4-6 years. Their technology includes proprietary heat exchanger designs that minimize thermal resistance while withstanding the harsh conditions of industrial environments. MHI's systems are modular and scalable, with power generation capacities ranging from 10kW to 1MW depending on the available waste heat resource.

Strengths: Extensive experience with large-scale industrial energy systems; robust engineering for harsh industrial environments; comprehensive system integration capabilities. Weaknesses: Higher capital costs compared to some competing waste heat recovery technologies; requires significant space for installation; performance degrades over time in high-temperature industrial applications.

Critical Patents in TEG System Economics

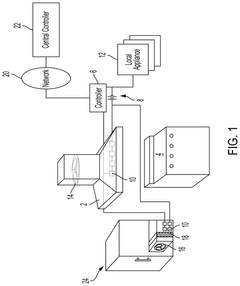

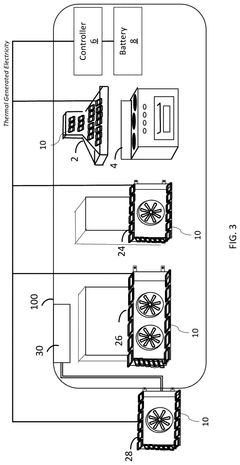

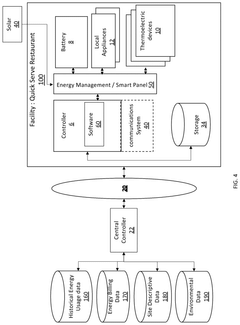

ThermoElectric Recharging Using Waste-Heat For Demand Charge Reduction

PatentPendingUS20250158542A1

Innovation

- A thermoelectric electricity generation system is implemented in QSR environments, utilizing multiple thermoelectric devices connected to heat sources such as kitchen vents, air conditioning coils, and refrigeration condenser coils. These devices generate electricity from temperature differentials and are connected to an electrical load, including batteries, to store energy for offsetting peak demand and reducing energy costs.

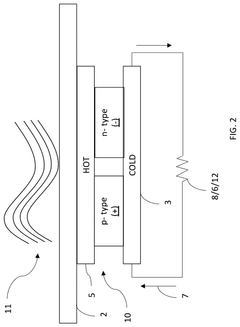

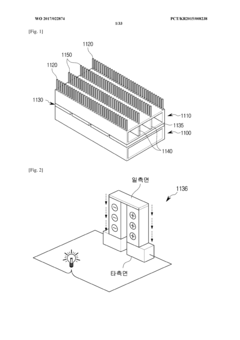

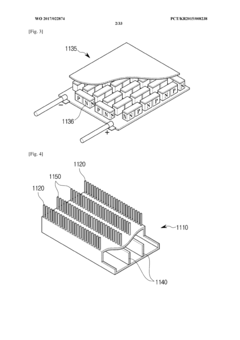

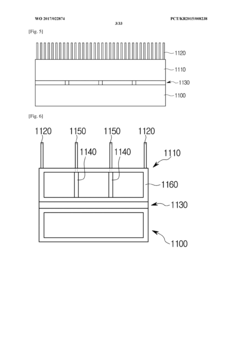

Thermoelectric power-generating apparatus, heating apparatus for fuel storage tank, and waste heat recovery system

PatentWO2017022874A1

Innovation

- A thermoelectric power generation device, fuel storage tank heating device, and waste heat recovery system that utilize temperature differences or waste heat to generate electrical energy through a thermoelectric power generation module, including a first pipe for fluid flow, a second pipe for cooling medium flow, and heat dissipation fins to reduce temperature differences and enhance energy efficiency.

Environmental Impact and Sustainability Benefits

The implementation of thermoelectric generators (TEGs) for waste heat recovery represents a significant opportunity for environmental impact reduction and sustainability enhancement across multiple industrial sectors. By capturing and converting waste heat that would otherwise be released into the atmosphere, TEGs directly contribute to improved energy efficiency and reduced greenhouse gas emissions. Quantitative assessments indicate that industrial waste heat recovery systems utilizing TEGs can reduce carbon dioxide emissions by 10-15% in energy-intensive industries such as steel manufacturing, cement production, and glass making.

The environmental benefits extend beyond carbon reduction. TEGs operate without moving parts or working fluids, eliminating the risk of refrigerant leakage that plagues many traditional heat recovery systems. This characteristic makes them particularly valuable in environmentally sensitive applications where the release of harmful substances must be avoided. Additionally, the solid-state nature of TEGs means they generate no noise pollution, further enhancing their environmental profile.

From a sustainability perspective, TEGs contribute to circular economy principles by transforming waste energy streams into valuable electricity. This closed-loop approach aligns with sustainable development goals and corporate environmental responsibility initiatives. The materials used in modern TEG manufacturing are increasingly selected for their reduced environmental impact, with research focusing on replacing rare earth elements with more abundant and less environmentally damaging alternatives.

Life cycle assessment (LCA) studies of TEG systems reveal favorable environmental profiles when compared to alternative waste heat recovery technologies. While the manufacturing phase does involve energy-intensive processes, the operational benefits typically offset these impacts within 1-3 years, depending on the application intensity. The long operational lifetime of TEGs—often exceeding 15 years with minimal maintenance—further enhances their sustainability credentials.

Water conservation represents another significant environmental benefit of TEG implementation. Unlike many conventional power generation systems that require substantial water resources for cooling, TEGs operate without water consumption. In water-stressed regions, this characteristic provides an additional sustainability advantage that should be factored into economic calculations and payback period assessments.

The scalability of TEG systems allows for incremental implementation, enabling organizations to gradually reduce their environmental footprint while managing capital expenditure. This phased approach to sustainability improvement offers practical pathways for industries to meet increasingly stringent environmental regulations and voluntary carbon reduction commitments while maintaining economic viability.

The environmental benefits extend beyond carbon reduction. TEGs operate without moving parts or working fluids, eliminating the risk of refrigerant leakage that plagues many traditional heat recovery systems. This characteristic makes them particularly valuable in environmentally sensitive applications where the release of harmful substances must be avoided. Additionally, the solid-state nature of TEGs means they generate no noise pollution, further enhancing their environmental profile.

From a sustainability perspective, TEGs contribute to circular economy principles by transforming waste energy streams into valuable electricity. This closed-loop approach aligns with sustainable development goals and corporate environmental responsibility initiatives. The materials used in modern TEG manufacturing are increasingly selected for their reduced environmental impact, with research focusing on replacing rare earth elements with more abundant and less environmentally damaging alternatives.

Life cycle assessment (LCA) studies of TEG systems reveal favorable environmental profiles when compared to alternative waste heat recovery technologies. While the manufacturing phase does involve energy-intensive processes, the operational benefits typically offset these impacts within 1-3 years, depending on the application intensity. The long operational lifetime of TEGs—often exceeding 15 years with minimal maintenance—further enhances their sustainability credentials.

Water conservation represents another significant environmental benefit of TEG implementation. Unlike many conventional power generation systems that require substantial water resources for cooling, TEGs operate without water consumption. In water-stressed regions, this characteristic provides an additional sustainability advantage that should be factored into economic calculations and payback period assessments.

The scalability of TEG systems allows for incremental implementation, enabling organizations to gradually reduce their environmental footprint while managing capital expenditure. This phased approach to sustainability improvement offers practical pathways for industries to meet increasingly stringent environmental regulations and voluntary carbon reduction commitments while maintaining economic viability.

Policy Incentives for Waste Heat Recovery Systems

Policy incentives play a crucial role in accelerating the adoption of thermoelectric generator (TEG) systems for waste heat recovery applications. Governments worldwide have implemented various financial mechanisms to offset initial capital costs and improve the economic viability of these technologies.

Tax incentives represent one of the most direct policy tools, with many countries offering investment tax credits ranging from 10% to 30% for qualifying waste heat recovery installations. These credits effectively reduce the net system cost and can significantly improve payback periods, often shortening them by 1-3 years depending on project scale and regional tax structures.

Accelerated depreciation schedules provide another powerful fiscal incentive, allowing businesses to depreciate TEG systems over shorter timeframes (typically 3-5 years) rather than standard 15-20 year equipment lifespans. This front-loading of tax benefits improves cash flow during early project years when financial returns are most critical for investment decisions.

Direct grants and subsidies are available in several jurisdictions, particularly for demonstration projects and first-commercial deployments. The European Union's Horizon Europe program and the U.S. Department of Energy's Advanced Manufacturing Office have established funding mechanisms specifically targeting industrial waste heat recovery technologies, with grants covering 25-50% of eligible project costs.

Low-interest loan programs and loan guarantees reduce financing costs for TEG implementations. Green banks and sustainable finance initiatives in countries like Germany, Japan, and Singapore offer preferential lending rates that can be 2-4 percentage points below market rates, substantially improving project economics over system lifetimes.

Carbon pricing mechanisms indirectly benefit TEG economics by monetizing emissions reductions. In regions with carbon taxes or cap-and-trade systems, the avoided emissions from waste heat recovery create additional revenue streams or cost savings that can be incorporated into payback calculations, typically adding $5-30 per MWh of value depending on carbon prices.

Renewable portfolio standards and energy efficiency obligations in some markets create compliance certificate markets where waste heat recovery projects can generate tradable certificates. These provide supplementary revenue streams that can improve project economics by 5-15% depending on certificate values.

Performance-based incentives tied to actual energy production or savings have emerged as innovative policy tools. These mechanisms reduce investor risk by guaranteeing minimum returns while ensuring public funds support only operational systems, creating alignment between policy objectives and market outcomes.

Tax incentives represent one of the most direct policy tools, with many countries offering investment tax credits ranging from 10% to 30% for qualifying waste heat recovery installations. These credits effectively reduce the net system cost and can significantly improve payback periods, often shortening them by 1-3 years depending on project scale and regional tax structures.

Accelerated depreciation schedules provide another powerful fiscal incentive, allowing businesses to depreciate TEG systems over shorter timeframes (typically 3-5 years) rather than standard 15-20 year equipment lifespans. This front-loading of tax benefits improves cash flow during early project years when financial returns are most critical for investment decisions.

Direct grants and subsidies are available in several jurisdictions, particularly for demonstration projects and first-commercial deployments. The European Union's Horizon Europe program and the U.S. Department of Energy's Advanced Manufacturing Office have established funding mechanisms specifically targeting industrial waste heat recovery technologies, with grants covering 25-50% of eligible project costs.

Low-interest loan programs and loan guarantees reduce financing costs for TEG implementations. Green banks and sustainable finance initiatives in countries like Germany, Japan, and Singapore offer preferential lending rates that can be 2-4 percentage points below market rates, substantially improving project economics over system lifetimes.

Carbon pricing mechanisms indirectly benefit TEG economics by monetizing emissions reductions. In regions with carbon taxes or cap-and-trade systems, the avoided emissions from waste heat recovery create additional revenue streams or cost savings that can be incorporated into payback calculations, typically adding $5-30 per MWh of value depending on carbon prices.

Renewable portfolio standards and energy efficiency obligations in some markets create compliance certificate markets where waste heat recovery projects can generate tradable certificates. These provide supplementary revenue streams that can improve project economics by 5-15% depending on certificate values.

Performance-based incentives tied to actual energy production or savings have emerged as innovative policy tools. These mechanisms reduce investor risk by guaranteeing minimum returns while ensuring public funds support only operational systems, creating alignment between policy objectives and market outcomes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!