Establishing Measurement Standards For Power Density Of Thermoelectric Generators Under Real-World Waste Heat Conditions

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Generator Standards Background and Objectives

Thermoelectric generators (TEGs) have emerged as a promising technology for waste heat recovery, converting thermal energy directly into electrical power without moving parts. The evolution of TEG technology dates back to the early 19th century with the discovery of the Seebeck effect, but significant commercial applications only materialized in the mid-20th century, primarily in specialized fields such as space exploration and remote power generation.

In recent decades, growing environmental concerns and energy efficiency imperatives have renewed interest in TEG technology across multiple industries. The global push toward sustainable energy solutions has positioned waste heat recovery as a critical strategy for improving overall energy efficiency in industrial processes, automotive applications, and power generation systems.

Current TEG technology faces substantial challenges in terms of efficiency, with typical conversion rates ranging from 5-8% under laboratory conditions. However, real-world applications often yield significantly lower performance due to variable heat sources, thermal cycling, and system integration issues. This discrepancy highlights a critical gap in the industry: the absence of standardized measurement protocols for TEG performance under actual operating conditions.

The primary objective of establishing measurement standards for power density of thermoelectric generators under real-world waste heat conditions is to create a unified framework that enables accurate comparison of different TEG technologies and systems. This standardization would facilitate meaningful benchmarking across various applications and accelerate the adoption of TEG technology in mainstream energy systems.

Additionally, these standards aim to bridge the gap between laboratory testing and field performance by accounting for the dynamic nature of waste heat sources in industrial settings. Factors such as temperature fluctuations, heat flux variations, and thermal interface resistances significantly impact real-world TEG performance but are often overlooked in controlled laboratory evaluations.

The development of comprehensive measurement standards would also support the advancement of TEG materials and system designs by providing clear performance metrics and testing methodologies. This would enable researchers and manufacturers to focus innovation efforts on addressing specific performance limitations under actual operating conditions rather than optimizing for idealized scenarios.

Furthermore, standardized measurement protocols would benefit end-users by providing reliable performance data for system sizing, economic feasibility assessments, and return-on-investment calculations. This transparency is essential for building market confidence and driving wider adoption of TEG technology across diverse applications from industrial waste heat recovery to vehicle exhaust systems and distributed power generation.

In recent decades, growing environmental concerns and energy efficiency imperatives have renewed interest in TEG technology across multiple industries. The global push toward sustainable energy solutions has positioned waste heat recovery as a critical strategy for improving overall energy efficiency in industrial processes, automotive applications, and power generation systems.

Current TEG technology faces substantial challenges in terms of efficiency, with typical conversion rates ranging from 5-8% under laboratory conditions. However, real-world applications often yield significantly lower performance due to variable heat sources, thermal cycling, and system integration issues. This discrepancy highlights a critical gap in the industry: the absence of standardized measurement protocols for TEG performance under actual operating conditions.

The primary objective of establishing measurement standards for power density of thermoelectric generators under real-world waste heat conditions is to create a unified framework that enables accurate comparison of different TEG technologies and systems. This standardization would facilitate meaningful benchmarking across various applications and accelerate the adoption of TEG technology in mainstream energy systems.

Additionally, these standards aim to bridge the gap between laboratory testing and field performance by accounting for the dynamic nature of waste heat sources in industrial settings. Factors such as temperature fluctuations, heat flux variations, and thermal interface resistances significantly impact real-world TEG performance but are often overlooked in controlled laboratory evaluations.

The development of comprehensive measurement standards would also support the advancement of TEG materials and system designs by providing clear performance metrics and testing methodologies. This would enable researchers and manufacturers to focus innovation efforts on addressing specific performance limitations under actual operating conditions rather than optimizing for idealized scenarios.

Furthermore, standardized measurement protocols would benefit end-users by providing reliable performance data for system sizing, economic feasibility assessments, and return-on-investment calculations. This transparency is essential for building market confidence and driving wider adoption of TEG technology across diverse applications from industrial waste heat recovery to vehicle exhaust systems and distributed power generation.

Market Analysis for Waste Heat Recovery Technologies

The global waste heat recovery market is experiencing significant growth, valued at approximately $54 billion in 2020 and projected to reach $80 billion by 2026, with a compound annual growth rate of 8.8%. This growth is primarily driven by increasing industrial energy costs, stringent environmental regulations regarding emissions, and growing awareness of energy efficiency benefits across manufacturing sectors.

Thermoelectric generators (TEGs) represent a promising segment within this market, currently accounting for about 7% of the waste heat recovery solutions but expected to grow at a faster rate of 11.2% annually through 2028. This accelerated growth is attributed to their solid-state operation, lack of moving parts, and ability to function in harsh environments where other recovery technologies cannot operate effectively.

Key market sectors for TEG waste heat recovery include automotive, where they can recover exhaust heat; heavy industries such as steel, glass, and cement manufacturing; power generation facilities; and increasingly, data centers with their substantial cooling requirements. The automotive sector currently leads TEG applications, representing approximately 35% of the market share, followed by industrial processes at 28%.

Geographically, North America and Europe dominate the TEG market with combined control of 65% of global installations, primarily due to stricter environmental regulations and higher energy costs. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate at 13.5% annually, driven by rapid industrialization and government initiatives promoting energy efficiency.

A significant market challenge remains the power density limitations of current TEG technologies, with typical commercial systems achieving only 0.2-0.5 W/cm² under ideal conditions—far below theoretical maximums. This performance gap represents both a market barrier and opportunity, as improvements in power density directly correlate with return on investment timelines for potential adopters.

Customer adoption is heavily influenced by payback periods, with surveys indicating that industrial customers expect recovery systems to pay for themselves within 2-4 years. Current TEG systems typically require 4-7 years for payback, limiting widespread adoption despite their technical advantages in certain applications.

Market analysis reveals growing demand for standardized performance metrics that accurately reflect real-world operating conditions rather than laboratory ideals. This demand aligns directly with the need for establishing measurement standards for power density under actual waste heat conditions, as customers increasingly require reliable performance predictions before making investment decisions.

Thermoelectric generators (TEGs) represent a promising segment within this market, currently accounting for about 7% of the waste heat recovery solutions but expected to grow at a faster rate of 11.2% annually through 2028. This accelerated growth is attributed to their solid-state operation, lack of moving parts, and ability to function in harsh environments where other recovery technologies cannot operate effectively.

Key market sectors for TEG waste heat recovery include automotive, where they can recover exhaust heat; heavy industries such as steel, glass, and cement manufacturing; power generation facilities; and increasingly, data centers with their substantial cooling requirements. The automotive sector currently leads TEG applications, representing approximately 35% of the market share, followed by industrial processes at 28%.

Geographically, North America and Europe dominate the TEG market with combined control of 65% of global installations, primarily due to stricter environmental regulations and higher energy costs. However, the Asia-Pacific region, particularly China and India, is witnessing the fastest growth rate at 13.5% annually, driven by rapid industrialization and government initiatives promoting energy efficiency.

A significant market challenge remains the power density limitations of current TEG technologies, with typical commercial systems achieving only 0.2-0.5 W/cm² under ideal conditions—far below theoretical maximums. This performance gap represents both a market barrier and opportunity, as improvements in power density directly correlate with return on investment timelines for potential adopters.

Customer adoption is heavily influenced by payback periods, with surveys indicating that industrial customers expect recovery systems to pay for themselves within 2-4 years. Current TEG systems typically require 4-7 years for payback, limiting widespread adoption despite their technical advantages in certain applications.

Market analysis reveals growing demand for standardized performance metrics that accurately reflect real-world operating conditions rather than laboratory ideals. This demand aligns directly with the need for establishing measurement standards for power density under actual waste heat conditions, as customers increasingly require reliable performance predictions before making investment decisions.

Current Challenges in TEG Power Density Measurement

The measurement of power density in thermoelectric generators (TEGs) under real-world waste heat conditions presents significant challenges that impede standardization efforts across the industry. Laboratory testing environments often fail to replicate the complex thermal dynamics encountered in actual applications, leading to substantial discrepancies between theoretical performance metrics and real-world outcomes. These discrepancies undermine confidence in TEG technology and hinder its broader adoption.

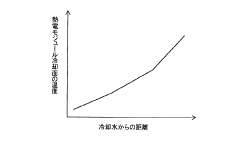

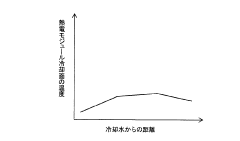

A primary challenge lies in the inherent variability of waste heat sources. Industrial processes, automotive exhaust systems, and geothermal sources exhibit fluctuating temperature profiles, heat flux distributions, and temporal variations that are difficult to characterize consistently. Current measurement protocols typically rely on steady-state conditions with controlled temperature differentials, which rarely occur in practical applications where thermal transients are the norm rather than the exception.

Interface management presents another critical obstacle. The thermal contact resistance between TEG modules and heat sources/sinks significantly impacts power density measurements but varies widely depending on surface roughness, pressure application, thermal interface materials, and mechanical clamping methods. The lack of standardized approaches for quantifying and accounting for these interface effects leads to inconsistent reporting across research groups and manufacturers.

System-level integration factors further complicate measurement standardization. Heat exchangers, thermal management components, and auxiliary systems introduce additional thermal resistances and flow dynamics that affect TEG performance. Current measurement methodologies often focus solely on the TEG module in isolation, neglecting these system-level interactions that ultimately determine real-world power generation capabilities.

Environmental conditions represent another variable that eludes standardization. Ambient temperature fluctuations, humidity levels, and air/fluid flow patterns around TEG systems influence heat dissipation characteristics and consequently affect power density measurements. The absence of protocols for normalizing these environmental factors makes cross-comparison between different studies and applications problematic.

Measurement instrumentation itself introduces challenges through varying accuracy levels, calibration procedures, and data acquisition methodologies. Temperature sensors, heat flux meters, and electrical measurement equipment each contribute uncertainty to power density calculations. Without standardized instrumentation requirements and measurement protocols, reported values may reflect equipment differences rather than actual TEG performance variations.

Temporal considerations add another layer of complexity, as TEG performance can degrade over time due to thermal cycling, oxidation, and material degradation. Current measurement approaches rarely account for these long-term reliability factors, focusing instead on initial performance metrics that may not represent sustained power density capabilities under extended operation.

A primary challenge lies in the inherent variability of waste heat sources. Industrial processes, automotive exhaust systems, and geothermal sources exhibit fluctuating temperature profiles, heat flux distributions, and temporal variations that are difficult to characterize consistently. Current measurement protocols typically rely on steady-state conditions with controlled temperature differentials, which rarely occur in practical applications where thermal transients are the norm rather than the exception.

Interface management presents another critical obstacle. The thermal contact resistance between TEG modules and heat sources/sinks significantly impacts power density measurements but varies widely depending on surface roughness, pressure application, thermal interface materials, and mechanical clamping methods. The lack of standardized approaches for quantifying and accounting for these interface effects leads to inconsistent reporting across research groups and manufacturers.

System-level integration factors further complicate measurement standardization. Heat exchangers, thermal management components, and auxiliary systems introduce additional thermal resistances and flow dynamics that affect TEG performance. Current measurement methodologies often focus solely on the TEG module in isolation, neglecting these system-level interactions that ultimately determine real-world power generation capabilities.

Environmental conditions represent another variable that eludes standardization. Ambient temperature fluctuations, humidity levels, and air/fluid flow patterns around TEG systems influence heat dissipation characteristics and consequently affect power density measurements. The absence of protocols for normalizing these environmental factors makes cross-comparison between different studies and applications problematic.

Measurement instrumentation itself introduces challenges through varying accuracy levels, calibration procedures, and data acquisition methodologies. Temperature sensors, heat flux meters, and electrical measurement equipment each contribute uncertainty to power density calculations. Without standardized instrumentation requirements and measurement protocols, reported values may reflect equipment differences rather than actual TEG performance variations.

Temporal considerations add another layer of complexity, as TEG performance can degrade over time due to thermal cycling, oxidation, and material degradation. Current measurement approaches rarely account for these long-term reliability factors, focusing instead on initial performance metrics that may not represent sustained power density capabilities under extended operation.

Existing Measurement Protocols for TEG Performance

01 Material selection for high power density thermoelectric generators

The choice of thermoelectric materials significantly impacts the power density of thermoelectric generators. Advanced materials such as skutterudites, half-Heusler alloys, and nanostructured materials can enhance the figure of merit (ZT) and consequently improve power density. These materials are engineered to optimize the balance between thermal conductivity and electrical conductivity, leading to more efficient energy conversion and higher power output per unit volume.- Material selection for high power density thermoelectric generators: The choice of thermoelectric materials significantly impacts the power density of thermoelectric generators. Advanced materials with high figure of merit (ZT) values, such as bismuth telluride, lead telluride, and silicon-germanium alloys, can substantially improve conversion efficiency. Nanostructured materials and quantum well structures further enhance performance by reducing thermal conductivity while maintaining electrical conductivity. These material innovations are crucial for achieving higher power density in compact thermoelectric generator designs.

- Structural design optimization for thermoelectric generators: Innovative structural designs can significantly enhance the power density of thermoelectric generators. This includes optimized module configurations, improved heat exchanger designs, and novel geometrical arrangements of thermoelectric elements. Segmented and cascaded structures that operate efficiently across wider temperature gradients contribute to higher power output per unit volume. Miniaturization techniques and integration of multiple small-scale generators also play a crucial role in maximizing power density for various applications.

- Thermal management techniques for enhanced power density: Effective thermal management is essential for maximizing the power density of thermoelectric generators. This includes optimized heat transfer mechanisms, advanced heat sink designs, and efficient thermal interface materials. Techniques such as forced convection cooling, phase change materials for heat storage, and heat concentration methods help maintain optimal temperature gradients across thermoelectric elements. Proper thermal isolation between hot and cold sides prevents parasitic heat losses and ensures maximum conversion efficiency.

- Integration with waste heat recovery systems: Integrating thermoelectric generators with waste heat recovery systems significantly improves overall power density. These systems capture and utilize heat that would otherwise be lost from industrial processes, vehicle exhaust systems, or other heat-generating applications. The integration involves specialized heat exchangers, thermal coupling techniques, and optimized placement of thermoelectric modules. This approach not only increases power output but also improves the energy efficiency of the primary system by recovering waste energy.

- Circuit design and power conditioning for maximum power extraction: Advanced circuit designs and power conditioning techniques are crucial for extracting maximum power from thermoelectric generators. This includes maximum power point tracking (MPPT) systems, DC-DC converters optimized for thermoelectric characteristics, and intelligent load matching algorithms. Energy storage integration and hybrid power management systems help manage the variable output of thermoelectric generators. These electrical engineering approaches ensure that the theoretical power density capabilities of the thermoelectric materials and structures are effectively realized in practical applications.

02 Structural design optimization for thermoelectric generators

The structural design of thermoelectric generators plays a crucial role in maximizing power density. Innovative designs include segmented leg structures, cascaded architectures, and miniaturized modules that optimize heat flow paths and reduce thermal resistance. Advanced manufacturing techniques allow for precise control of geometry and interfaces, resulting in improved thermal management and higher power density outputs from compact generator designs.Expand Specific Solutions03 Thermal management techniques for enhanced power density

Effective thermal management is essential for maximizing the power density of thermoelectric generators. Techniques include the use of heat spreaders, phase change materials, and advanced heat sink designs to maintain optimal temperature gradients across thermoelectric elements. Proper thermal interface materials and connection methods reduce contact resistance and improve heat transfer efficiency, allowing for sustained high power density operation even under varying thermal conditions.Expand Specific Solutions04 Integration of thermoelectric generators with waste heat sources

Integrating thermoelectric generators with industrial waste heat sources, vehicle exhaust systems, or other heat-generating processes can significantly improve overall power density. Custom-designed thermoelectric systems that match the specific thermal characteristics of the heat source enable more efficient energy harvesting. These integrated systems often incorporate specialized heat exchangers and thermal coupling mechanisms to maximize temperature differentials and power output from otherwise wasted thermal energy.Expand Specific Solutions05 Circuit design and power conditioning for thermoelectric systems

Advanced circuit designs and power conditioning systems are crucial for extracting maximum power density from thermoelectric generators. Maximum power point tracking (MPPT) algorithms, DC-DC converters with high efficiency, and specialized load matching circuits help optimize electrical output under varying temperature conditions. These electronic subsystems ensure that thermoelectric generators operate at their optimal electrical load point, maximizing power density regardless of fluctuations in thermal input or electrical demand.Expand Specific Solutions

Leading Organizations in Thermoelectric Standards Development

The thermoelectric generator (TEG) power density measurement standards market is currently in an early growth phase, characterized by increasing demand for waste heat recovery solutions but lacking unified measurement protocols. The global TEG market is projected to expand significantly as industries seek energy efficiency improvements, though standardization remains a challenge. From a technical maturity perspective, established players like Robert Bosch, Siemens, and Toyota Motor Corp are advancing commercial applications, while research institutions such as Tianjin University and Delft University of Technology focus on fundamental improvements. Specialized companies including Phononic and KELK Ltd are developing niche applications, with collaborative efforts between industry and academia driving innovation in measurement methodologies for real-world waste heat conditions.

Robert Bosch GmbH

Technical Solution: Robert Bosch has developed a comprehensive measurement framework for thermoelectric generators (TEGs) that simulates real-world waste heat conditions in automotive applications. Their approach incorporates dynamic temperature profiles and variable heat flux conditions to accurately assess power density metrics. Bosch's testing methodology includes specialized test benches that can replicate engine exhaust conditions with temperatures ranging from 100°C to 600°C and flow rates up to 500 kg/h[1]. Their standardized protocol accounts for thermal cycling, mechanical vibration, and thermal shock to evaluate long-term performance degradation. Bosch has also pioneered the use of dimensionless figures of merit that normalize power density measurements across different operating conditions, enabling fair comparisons between various TEG designs regardless of the specific waste heat source characteristics[3].

Strengths: Industry-leading automotive validation processes with real-world driving cycle integration; comprehensive test facilities that can accurately simulate vehicle operating conditions. Weaknesses: Standards primarily optimized for automotive applications may not translate well to other industrial waste heat recovery scenarios; proprietary nature of some testing methodologies limits broader adoption across the industry.

Phononic, Inc.

Technical Solution: Phononic has developed a solid-state heat pump technology platform that incorporates advanced measurement standards for thermoelectric power density evaluation. Their approach focuses on standardizing performance metrics under variable thermal loads and ambient conditions. Phononic's measurement methodology employs a controlled thermal interface management system that precisely quantifies the thermal resistance between the TEG and heat source/sink, which significantly impacts real-world power density[2]. Their testing protocol incorporates multiple temperature sensors distributed across the thermal pathway to create detailed thermal gradient maps, allowing for precise power density calculations based on active material volume rather than just device footprint. Phononic has also pioneered the use of transient measurement techniques that capture the dynamic response of TEGs under fluctuating waste heat conditions, providing more realistic performance data than steady-state measurements alone[4]. Their standardized testing includes accelerated life testing under thermal cycling to predict long-term power density degradation.

Strengths: Highly accurate thermal interface characterization methodology; sophisticated transient measurement capabilities that better reflect real-world conditions; focus on commercial viability metrics. Weaknesses: Testing standards primarily optimized for consumer and medical cooling applications rather than high-temperature industrial waste heat; relatively limited experience with extremely high-temperature waste heat sources (>400°C).

Critical Technologies for Real-World TEG Assessment

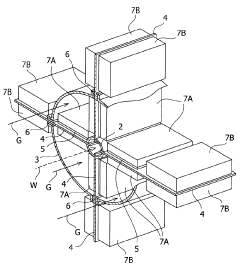

Compact high power density thermoelectric generator

PatentWO2015130827A3

Innovation

- Modular design approach using basic building TEG blocks that can be combined to form basic TEG sections, which can further be combined to create scalable HPD TEG systems with a wide range of power outputs.

- Compact design with high power density specifically engineered to harness energy from hot fluid heat sources such as vehicle exhaust systems.

- Versatile application capability across multiple platforms including trucks, cars, boats, and other engine-based systems.

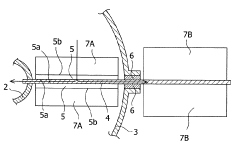

Thermoelectric power generator

PatentActiveJP2015164391A

Innovation

- A thermoelectric generator design featuring a first cylindrical portion for a cooling medium flow path and a second cylindrical portion for a heating medium flow path, with thermoelectric conversion modules arranged between heat transfer members, utilizing hybrid cooling with both cooling water and outside air, and incorporating heat sinks and heat insulating materials to enhance heat transfer and cooling efficiency.

Environmental Impact of Waste Heat Recovery Systems

The implementation of thermoelectric generators (TEGs) for waste heat recovery represents a significant opportunity for reducing environmental impacts across multiple industrial sectors. By converting waste heat into usable electricity, TEGs offer a pathway to improve energy efficiency and reduce greenhouse gas emissions that would otherwise result from additional power generation.

Waste heat recovery systems utilizing TEGs can significantly reduce carbon dioxide emissions by decreasing the demand for primary energy sources. Quantitative assessments indicate that industrial waste heat recovery could potentially reduce global CO2 emissions by 1-2% annually, with TEGs playing an increasingly important role in this reduction as their power density improves.

The environmental benefits extend beyond emissions reduction. By establishing standardized measurements for TEG power density under real-world conditions, industries can more accurately assess the lifecycle environmental impacts of these systems. Current lifecycle analyses suggest that modern TEG systems can achieve carbon payback periods of 1-3 years depending on application, with total lifecycle emission reductions of 10-15 times their embodied carbon.

Material considerations present both challenges and opportunities for environmental sustainability. While traditional thermoelectric materials like bismuth telluride contain rare or toxic elements, recent advances in measurement standards are driving development of more environmentally benign alternatives. Standardized testing under real-world conditions helps identify materials that maintain performance while reducing environmental footprint.

Water conservation represents another significant environmental benefit of TEG-based waste heat recovery. Unlike traditional heat-to-power conversion systems that often require water cooling, TEGs operate without water consumption, potentially saving millions of gallons annually in water-stressed regions where industrial operations are prevalent.

The circular economy potential of TEG systems depends heavily on accurate power density measurements. With proper standards in place, manufacturers can design for disassembly and material recovery, extending the environmental benefits through multiple product lifecycles. Current research indicates that up to 85% of materials in modern TEGs could be recovered and reused with appropriate end-of-life processing.

Land use impacts of waste heat recovery systems are minimal compared to other renewable energy technologies, requiring no additional land beyond existing industrial footprints. This advantage becomes particularly significant when considering the cumulative environmental benefits of widespread TEG deployment across global industrial sectors.

Waste heat recovery systems utilizing TEGs can significantly reduce carbon dioxide emissions by decreasing the demand for primary energy sources. Quantitative assessments indicate that industrial waste heat recovery could potentially reduce global CO2 emissions by 1-2% annually, with TEGs playing an increasingly important role in this reduction as their power density improves.

The environmental benefits extend beyond emissions reduction. By establishing standardized measurements for TEG power density under real-world conditions, industries can more accurately assess the lifecycle environmental impacts of these systems. Current lifecycle analyses suggest that modern TEG systems can achieve carbon payback periods of 1-3 years depending on application, with total lifecycle emission reductions of 10-15 times their embodied carbon.

Material considerations present both challenges and opportunities for environmental sustainability. While traditional thermoelectric materials like bismuth telluride contain rare or toxic elements, recent advances in measurement standards are driving development of more environmentally benign alternatives. Standardized testing under real-world conditions helps identify materials that maintain performance while reducing environmental footprint.

Water conservation represents another significant environmental benefit of TEG-based waste heat recovery. Unlike traditional heat-to-power conversion systems that often require water cooling, TEGs operate without water consumption, potentially saving millions of gallons annually in water-stressed regions where industrial operations are prevalent.

The circular economy potential of TEG systems depends heavily on accurate power density measurements. With proper standards in place, manufacturers can design for disassembly and material recovery, extending the environmental benefits through multiple product lifecycles. Current research indicates that up to 85% of materials in modern TEGs could be recovered and reused with appropriate end-of-life processing.

Land use impacts of waste heat recovery systems are minimal compared to other renewable energy technologies, requiring no additional land beyond existing industrial footprints. This advantage becomes particularly significant when considering the cumulative environmental benefits of widespread TEG deployment across global industrial sectors.

International Harmonization of TEG Testing Standards

The global nature of thermoelectric generator (TEG) technology development necessitates standardized testing protocols that transcend national boundaries. Currently, significant disparities exist between testing methodologies employed across different regions, creating barriers to technology comparison, market development, and international collaboration. These inconsistencies primarily stem from varying definitions of performance metrics, testing conditions, and reporting requirements.

Major standards organizations including the International Electrotechnical Commission (IEC), International Organization for Standardization (ISO), and ASTM International have initiated efforts to develop harmonized TEG testing standards. The IEC Technical Committee 47 has been particularly active in this domain, working on standards specifically addressing thermoelectric power generation under variable heat conditions.

Key challenges in international harmonization include reconciling the different approaches to temperature gradient measurement, accounting for regional variations in waste heat characteristics, and establishing universally accepted definitions for power density calculations. The lack of consensus on how to simulate real-world operating conditions in laboratory settings further complicates standardization efforts.

Recent progress has been made through international working groups comprising representatives from major TEG manufacturing countries including Japan, Germany, USA, China, and South Korea. These collaborative initiatives have produced draft frameworks for unified testing protocols that accommodate various waste heat sources while maintaining measurement consistency.

The economic implications of harmonized standards are substantial, potentially reducing certification costs for manufacturers and accelerating global market access. A unified approach would enable direct performance comparisons between TEGs developed in different countries, fostering healthy competition and accelerating technological advancement.

Several bilateral agreements between standards bodies have emerged as stepping stones toward comprehensive harmonization. For instance, the German DIN and American ASTM have established mutual recognition protocols for certain aspects of TEG testing, creating a foundation for broader international consensus.

The roadmap toward full harmonization includes establishing international round-robin testing programs, developing reference materials for calibration, and creating open-access databases of standardized test results. These initiatives aim to build trust in the testing ecosystem while accommodating the diverse needs of stakeholders across the global TEG value chain.

Major standards organizations including the International Electrotechnical Commission (IEC), International Organization for Standardization (ISO), and ASTM International have initiated efforts to develop harmonized TEG testing standards. The IEC Technical Committee 47 has been particularly active in this domain, working on standards specifically addressing thermoelectric power generation under variable heat conditions.

Key challenges in international harmonization include reconciling the different approaches to temperature gradient measurement, accounting for regional variations in waste heat characteristics, and establishing universally accepted definitions for power density calculations. The lack of consensus on how to simulate real-world operating conditions in laboratory settings further complicates standardization efforts.

Recent progress has been made through international working groups comprising representatives from major TEG manufacturing countries including Japan, Germany, USA, China, and South Korea. These collaborative initiatives have produced draft frameworks for unified testing protocols that accommodate various waste heat sources while maintaining measurement consistency.

The economic implications of harmonized standards are substantial, potentially reducing certification costs for manufacturers and accelerating global market access. A unified approach would enable direct performance comparisons between TEGs developed in different countries, fostering healthy competition and accelerating technological advancement.

Several bilateral agreements between standards bodies have emerged as stepping stones toward comprehensive harmonization. For instance, the German DIN and American ASTM have established mutual recognition protocols for certain aspects of TEG testing, creating a foundation for broader international consensus.

The roadmap toward full harmonization includes establishing international round-robin testing programs, developing reference materials for calibration, and creating open-access databases of standardized test results. These initiatives aim to build trust in the testing ecosystem while accommodating the diverse needs of stakeholders across the global TEG value chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!