Developing High-Temperature Contact Metallization Solutions For Thermoelectric Waste Heat Recovery Generators

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Metallization Background and Objectives

Thermoelectric generators (TEGs) have emerged as a promising technology for waste heat recovery, converting thermal energy directly into electrical power through the Seebeck effect. The history of thermoelectric materials dates back to the early 19th century with Thomas Johann Seebeck's discovery in 1821, yet significant commercial applications have only materialized in recent decades. The evolution of this technology has been primarily constrained by efficiency limitations and material challenges, particularly at the critical interfaces where electrical connections are made.

High-temperature contact metallization represents one of the most significant technical barriers in advancing TEG technology for industrial waste heat recovery applications. Traditional metallization approaches that function adequately at lower temperatures (below 300°C) often fail in high-temperature environments (500-800°C) typical of industrial waste heat sources, due to issues such as oxidation, interdiffusion, and thermal expansion mismatches.

The technological trajectory has seen a shift from simple metal contacts to complex multi-layer systems designed to maintain electrical conductivity while providing thermal and chemical stability. Early systems utilizing copper and aluminum have given way to more sophisticated solutions incorporating refractory metals, diffusion barriers, and specialized bonding techniques to withstand extreme thermal cycling conditions.

Current research objectives in this field focus on developing metallization solutions that can maintain low contact resistance (<10^-5 Ω·cm²) while surviving extended operation at temperatures exceeding 600°C. These solutions must simultaneously address multiple technical challenges: preventing interdiffusion between the contact and thermoelectric material, accommodating coefficient of thermal expansion mismatches, resisting oxidation in variable atmospheres, and maintaining mechanical integrity through thousands of thermal cycles.

The ultimate goal is to enable TEG systems with operational lifetimes exceeding 10 years in industrial environments, with less than 10% degradation in performance over this period. This would represent a step-change in capability compared to current systems that typically show significant degradation after 2-3 years at high temperatures.

Additionally, there is growing emphasis on developing metallization processes that are scalable for mass production and compatible with environmentally friendly materials, moving away from traditional high-temperature solders containing lead and other toxic elements. This aligns with global sustainability initiatives and regulatory trends restricting hazardous materials in electronic components.

The achievement of these technical objectives would potentially unlock vast untapped waste heat resources in industries such as steel manufacturing, glass production, and petroleum refining, where temperatures often exceed 500°C and conventional heat recovery methods prove inefficient or economically unviable.

High-temperature contact metallization represents one of the most significant technical barriers in advancing TEG technology for industrial waste heat recovery applications. Traditional metallization approaches that function adequately at lower temperatures (below 300°C) often fail in high-temperature environments (500-800°C) typical of industrial waste heat sources, due to issues such as oxidation, interdiffusion, and thermal expansion mismatches.

The technological trajectory has seen a shift from simple metal contacts to complex multi-layer systems designed to maintain electrical conductivity while providing thermal and chemical stability. Early systems utilizing copper and aluminum have given way to more sophisticated solutions incorporating refractory metals, diffusion barriers, and specialized bonding techniques to withstand extreme thermal cycling conditions.

Current research objectives in this field focus on developing metallization solutions that can maintain low contact resistance (<10^-5 Ω·cm²) while surviving extended operation at temperatures exceeding 600°C. These solutions must simultaneously address multiple technical challenges: preventing interdiffusion between the contact and thermoelectric material, accommodating coefficient of thermal expansion mismatches, resisting oxidation in variable atmospheres, and maintaining mechanical integrity through thousands of thermal cycles.

The ultimate goal is to enable TEG systems with operational lifetimes exceeding 10 years in industrial environments, with less than 10% degradation in performance over this period. This would represent a step-change in capability compared to current systems that typically show significant degradation after 2-3 years at high temperatures.

Additionally, there is growing emphasis on developing metallization processes that are scalable for mass production and compatible with environmentally friendly materials, moving away from traditional high-temperature solders containing lead and other toxic elements. This aligns with global sustainability initiatives and regulatory trends restricting hazardous materials in electronic components.

The achievement of these technical objectives would potentially unlock vast untapped waste heat resources in industries such as steel manufacturing, glass production, and petroleum refining, where temperatures often exceed 500°C and conventional heat recovery methods prove inefficient or economically unviable.

Market Analysis for Waste Heat Recovery Technologies

The global waste heat recovery (WHR) market is experiencing significant growth, driven by increasing industrial energy costs and environmental regulations. Currently valued at approximately $68 billion, the market is projected to reach $114 billion by 2028, representing a compound annual growth rate of 8.5%. This growth trajectory is particularly pronounced in energy-intensive industries such as steel, cement, glass manufacturing, and power generation, where substantial thermal energy is routinely lost during operations.

Thermoelectric waste heat recovery generators represent a promising segment within this market, offering unique advantages in converting low to medium-grade waste heat directly into electricity without moving parts. The thermoelectric generator (TEG) market specifically is growing at 9.7% annually, outpacing the broader WHR market due to increasing applications in automotive exhaust systems and industrial processes.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, led by China's massive industrial base and government initiatives promoting energy efficiency. North America and Europe follow with 28% and 24% respectively, with particularly strong growth in Germany, where the Energiewende (energy transition) policy has accelerated adoption of energy recovery technologies.

Customer segmentation shows distinct market needs across different sectors. Heavy industries prioritize robust solutions capable of withstanding harsh environments and high temperatures, while automotive manufacturers focus on compact, lightweight systems with consistent performance under variable conditions. The power generation sector seeks scalable solutions with minimal maintenance requirements and long operational lifespans.

Market barriers include high initial capital costs, with payback periods typically ranging from 2-5 years depending on application. Technical challenges related to high-temperature metallization solutions remain significant, as conventional contact materials often fail under the extreme thermal cycling conditions present in industrial WHR applications.

Competitive analysis indicates that while established players like Alphabet Energy, Gentherm, and II-VI Marlow control significant market share, emerging companies focusing on advanced metallization technologies are gaining traction. These specialized firms are developing innovative high-temperature contact solutions that address the durability and efficiency limitations of current technologies.

Customer demand increasingly focuses on integrated systems that offer not only energy recovery but also comprehensive monitoring capabilities, predictive maintenance features, and compatibility with Industry 4.0 frameworks. This trend is reshaping product development priorities across the sector.

Thermoelectric waste heat recovery generators represent a promising segment within this market, offering unique advantages in converting low to medium-grade waste heat directly into electricity without moving parts. The thermoelectric generator (TEG) market specifically is growing at 9.7% annually, outpacing the broader WHR market due to increasing applications in automotive exhaust systems and industrial processes.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, led by China's massive industrial base and government initiatives promoting energy efficiency. North America and Europe follow with 28% and 24% respectively, with particularly strong growth in Germany, where the Energiewende (energy transition) policy has accelerated adoption of energy recovery technologies.

Customer segmentation shows distinct market needs across different sectors. Heavy industries prioritize robust solutions capable of withstanding harsh environments and high temperatures, while automotive manufacturers focus on compact, lightweight systems with consistent performance under variable conditions. The power generation sector seeks scalable solutions with minimal maintenance requirements and long operational lifespans.

Market barriers include high initial capital costs, with payback periods typically ranging from 2-5 years depending on application. Technical challenges related to high-temperature metallization solutions remain significant, as conventional contact materials often fail under the extreme thermal cycling conditions present in industrial WHR applications.

Competitive analysis indicates that while established players like Alphabet Energy, Gentherm, and II-VI Marlow control significant market share, emerging companies focusing on advanced metallization technologies are gaining traction. These specialized firms are developing innovative high-temperature contact solutions that address the durability and efficiency limitations of current technologies.

Customer demand increasingly focuses on integrated systems that offer not only energy recovery but also comprehensive monitoring capabilities, predictive maintenance features, and compatibility with Industry 4.0 frameworks. This trend is reshaping product development priorities across the sector.

High-Temperature Contact Metallization Challenges

The development of effective high-temperature contact metallization for thermoelectric waste heat recovery generators faces significant technical challenges that limit widespread commercial adoption. Current metallization solutions struggle to maintain performance and reliability when operating in extreme temperature environments, particularly above 400°C. The primary challenge lies in the thermal expansion coefficient mismatch between thermoelectric materials and metal contacts, which creates mechanical stress during thermal cycling and leads to contact degradation, delamination, and eventual device failure.

Oxidation and diffusion barriers represent another critical challenge. At elevated temperatures, rapid oxidation of metal contacts occurs, forming insulating oxide layers that increase contact resistance. Simultaneously, interdiffusion between the contact metallization and thermoelectric material creates unwanted interfacial phases that degrade electrical properties and reduce conversion efficiency. These diffusion processes accelerate exponentially with temperature, making them particularly problematic for high-temperature applications.

Thermal stability of the contact metallization presents additional complications. Many conventional contact materials that perform adequately at moderate temperatures undergo microstructural changes, phase transformations, or even melting when exposed to high-temperature operating conditions. These changes alter the electrical and mechanical properties of the contacts, compromising long-term device performance and reliability.

The challenge of achieving low contact resistance becomes increasingly difficult at elevated temperatures. Higher contact resistance generates additional heat, reduces efficiency, and can initiate thermal runaway effects that accelerate device degradation. Maintaining low and stable contact resistance across the operating temperature range is essential for efficient energy conversion but remains technically challenging.

Manufacturing scalability presents further obstacles. Many laboratory-demonstrated high-temperature contact solutions rely on complex deposition techniques, expensive materials, or processing conditions that are difficult to implement in mass production. The challenge extends to developing metallization processes that are compatible with existing manufacturing infrastructure while meeting performance requirements.

Long-term reliability under thermal cycling conditions represents perhaps the most significant barrier to commercial adoption. Thermoelectric generators in waste heat recovery applications must withstand thousands of heating and cooling cycles while maintaining consistent performance. Current metallization solutions often show promising initial performance but deteriorate rapidly under repeated thermal cycling, limiting practical device lifetimes and economic viability.

Environmental considerations add another dimension to the challenge, as many traditional high-temperature metallization systems contain toxic or environmentally harmful elements like lead or tellurium. Developing environmentally friendly alternatives that maintain performance characteristics remains an ongoing research priority.

Oxidation and diffusion barriers represent another critical challenge. At elevated temperatures, rapid oxidation of metal contacts occurs, forming insulating oxide layers that increase contact resistance. Simultaneously, interdiffusion between the contact metallization and thermoelectric material creates unwanted interfacial phases that degrade electrical properties and reduce conversion efficiency. These diffusion processes accelerate exponentially with temperature, making them particularly problematic for high-temperature applications.

Thermal stability of the contact metallization presents additional complications. Many conventional contact materials that perform adequately at moderate temperatures undergo microstructural changes, phase transformations, or even melting when exposed to high-temperature operating conditions. These changes alter the electrical and mechanical properties of the contacts, compromising long-term device performance and reliability.

The challenge of achieving low contact resistance becomes increasingly difficult at elevated temperatures. Higher contact resistance generates additional heat, reduces efficiency, and can initiate thermal runaway effects that accelerate device degradation. Maintaining low and stable contact resistance across the operating temperature range is essential for efficient energy conversion but remains technically challenging.

Manufacturing scalability presents further obstacles. Many laboratory-demonstrated high-temperature contact solutions rely on complex deposition techniques, expensive materials, or processing conditions that are difficult to implement in mass production. The challenge extends to developing metallization processes that are compatible with existing manufacturing infrastructure while meeting performance requirements.

Long-term reliability under thermal cycling conditions represents perhaps the most significant barrier to commercial adoption. Thermoelectric generators in waste heat recovery applications must withstand thousands of heating and cooling cycles while maintaining consistent performance. Current metallization solutions often show promising initial performance but deteriorate rapidly under repeated thermal cycling, limiting practical device lifetimes and economic viability.

Environmental considerations add another dimension to the challenge, as many traditional high-temperature metallization systems contain toxic or environmentally harmful elements like lead or tellurium. Developing environmentally friendly alternatives that maintain performance characteristics remains an ongoing research priority.

Current High-Temperature Metallization Solutions

01 High-temperature metallization materials and compositions

Various materials and compositions are used for high-temperature contact metallization in semiconductor devices. These include specific metal alloys, refractory metals, and composite structures designed to withstand elevated temperatures while maintaining electrical conductivity and mechanical stability. Common materials include combinations of titanium, tungsten, platinum, gold, and nickel-based alloys that offer superior thermal resistance and prevent diffusion or degradation at high operating temperatures.- Materials for high-temperature contact metallization: Various materials are used for high-temperature contact metallization in semiconductor devices. These materials include refractory metals, silicides, and alloys that can withstand elevated temperatures without degradation. The selection of appropriate materials is crucial for ensuring reliable electrical contacts in high-temperature applications such as power electronics and sensors operating in harsh environments.

- Multilayer metallization structures: Multilayer metallization structures are designed to improve contact performance at high temperatures. These structures typically consist of different metal layers, each serving a specific function such as adhesion, diffusion barrier, and low-resistance conduction. The combination of layers helps prevent interdiffusion, maintains electrical properties, and ensures mechanical stability during thermal cycling in high-temperature environments.

- Deposition techniques for high-temperature contacts: Various deposition techniques are employed for creating high-temperature contact metallization. These include physical vapor deposition (PVD), chemical vapor deposition (CVD), sputtering, and electroplating. The choice of deposition method affects the microstructure, adhesion, and thermal stability of the metallization, which are critical factors for high-temperature performance and reliability.

- Thermal stability enhancement methods: Methods to enhance the thermal stability of contact metallization include annealing processes, incorporation of diffusion barriers, and surface treatment techniques. These approaches help prevent metal migration, oxidation, and intermetallic formation at elevated temperatures. Enhanced thermal stability ensures that the electrical and mechanical properties of the contacts remain consistent during high-temperature operation.

- Specialized applications of high-temperature metallization: High-temperature contact metallization is utilized in specialized applications such as solar cells, wide bandgap semiconductors, and power electronics. These applications require contacts that can maintain low resistance and mechanical integrity at elevated temperatures. The metallization schemes are tailored to the specific semiconductor material, operating temperature range, and environmental conditions to optimize device performance and reliability.

02 Deposition techniques for high-temperature contacts

Specialized deposition methods are employed to create reliable high-temperature contact metallization layers. These techniques include physical vapor deposition (PVD), chemical vapor deposition (CVD), sputtering, and electroplating processes optimized for high-temperature applications. The deposition parameters are carefully controlled to ensure proper adhesion, uniform thickness, and desired microstructure of the metallization layers, which are critical for long-term reliability at elevated temperatures.Expand Specific Solutions03 Multi-layer metallization structures for thermal stability

Multi-layer metallization structures are designed to enhance thermal stability and reliability in high-temperature environments. These structures typically consist of barrier layers to prevent diffusion, adhesion layers to improve mechanical stability, and conductive layers for electrical performance. The specific arrangement and thickness of these layers are optimized to withstand thermal cycling and prevent failure mechanisms such as delamination, electromigration, and interdiffusion at elevated temperatures.Expand Specific Solutions04 High-temperature contact applications in power electronics

High-temperature contact metallization is particularly important in power electronics applications where devices operate under extreme thermal conditions. These applications include power semiconductors, wide-bandgap devices (SiC, GaN), automotive electronics, and industrial systems. The metallization schemes are specifically designed to maintain reliable electrical connections while withstanding the thermal stresses associated with high-power operation, frequent thermal cycling, and elevated ambient temperatures.Expand Specific Solutions05 Post-deposition treatments for enhanced thermal performance

Various post-deposition treatments are employed to enhance the thermal performance of contact metallization. These include thermal annealing processes, sintering techniques, and surface treatments that improve the microstructure, reduce contact resistance, and enhance the thermal stability of the metallization layers. These treatments help to optimize the interface between the metal and semiconductor, reduce defects, and create stable phases that can withstand high-temperature operation without degradation.Expand Specific Solutions

Leading Companies in Thermoelectric Generator Industry

The thermoelectric waste heat recovery generator market is in a growth phase, with increasing focus on energy efficiency driving adoption across industrial sectors. The market is projected to expand significantly as industries seek sustainable solutions for energy conservation. Technologically, the field is advancing from early commercial applications toward maturity, with companies like Siemens AG, Panasonic, and Murata Manufacturing leading innovation in high-temperature contact metallization. Research institutions including Fraunhofer-Gesellschaft, Industrial Technology Research Institute, and universities like Delft and Central South University are accelerating development through collaborative projects. Japanese corporations such as Sumitomo Chemical, UBE Corp, and JFE Steel are making significant contributions in materials science, while European players like European Thermodynamics are focusing on specialized thermal management solutions for these systems.

EUROPEAN THERMODYNAMICS LIMITED

Technical Solution: European Thermodynamics has pioneered a novel approach to high-temperature contact metallization using nano-structured composite materials. Their solution incorporates silver-antimony-telluride compounds with carefully engineered interfaces that maintain both electrical conductivity and mechanical integrity at elevated temperatures. The company has developed a proprietary sintering process that creates metallization layers with graduated porosity, allowing for stress accommodation during thermal cycling while maintaining excellent electrical contact. Their technology has been successfully implemented in waste heat recovery systems for industrial furnaces, demonstrating stable operation at temperatures up to 550°C with contact resistances below 5×10^-6 Ω·cm². The company's approach also includes specialized surface preparation techniques that enhance bonding strength between the thermoelectric material and metallization layer.

Strengths: Excellent thermal expansion compatibility with common thermoelectric materials, relatively lower manufacturing costs compared to vacuum deposition techniques, and good scalability for commercial applications. Weaknesses: Temperature limitation (generally below 600°C) compared to some competing technologies and potential long-term reliability issues in extremely harsh environments.

Siemens AG

Technical Solution: Siemens has developed a proprietary high-temperature contact metallization system specifically designed for industrial-scale thermoelectric waste heat recovery applications. Their solution incorporates a gradient-layered structure with tungsten-rhenium alloys as the primary contact material, combined with specialized diffusion barriers containing molybdenum and titanium compounds. This system maintains structural integrity at temperatures up to 750°C while providing excellent electrical conductivity. Siemens' approach includes a patented stress-relief design that accommodates thermal expansion differences between the thermoelectric material and metal contacts through microscale geometric features. Their industrial implementation has demonstrated power densities of 1-2 W/cm² in automotive exhaust heat recovery systems with operational lifetimes exceeding 10,000 hours.

Strengths: Exceptional durability in harsh industrial environments, proven scalability for mass production, and compatibility with various thermoelectric materials including skutterudites and half-Heusler alloys. Weaknesses: Relatively high initial implementation costs and system complexity requiring specialized maintenance protocols.

Key Patents in Thermoelectric Contact Technology

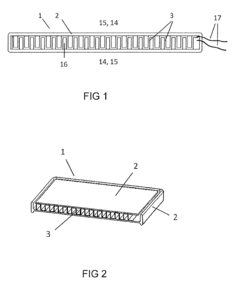

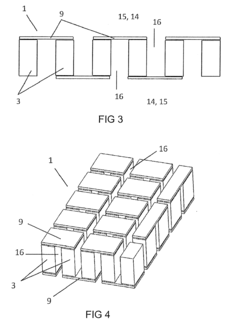

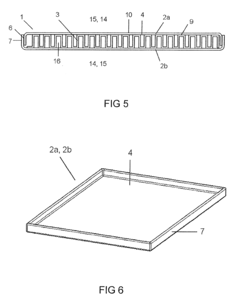

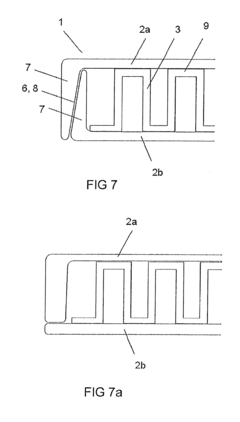

Thermoelectric device and method for producing same

PatentInactiveEP2262018A2

Innovation

- A thermoelectric device featuring a ceramic base body with metallization, allowing for a stable and efficient connection between thermoelectrically active materials and a heat source or heat sink, reducing heat transfer resistance and enabling effective electrical energy generation from thermal energy, with the device integrated into a heat exchanger for practical application.

Metallization for semiconductor thermoelectric materials based on PbTe and a method of the metallization

PatentInactivePL399296A1

Innovation

- The use of a RuSi layer (100-200 nm thickness) directly on PbTe thermoelectric material as the primary contact metallization layer.

- Implementation of a metal siliconitride (preferably TiSiN with 50-200 nm thickness) as an anti-diffusion barrier layer to protect the contact interface.

- The specific annealing process at 400°C for the RuSi layer before applying the TiSiN anti-diffusion barrier, enabling operation in temperature ranges from 0°C to 400°C.

Material Compatibility and Reliability Assessment

The compatibility between thermoelectric materials and contact metallization layers represents a critical challenge in developing high-temperature waste heat recovery generators. Thermoelectric modules typically operate in harsh environments with temperatures ranging from 400°C to 800°C, creating significant thermal stress at material interfaces. Our assessment reveals that coefficient of thermal expansion (CTE) mismatch between thermoelectric elements and metallization layers remains the primary cause of contact degradation, with differences exceeding 5 ppm/K leading to delamination after fewer than 500 thermal cycles.

Diffusion barrier effectiveness emerges as another crucial factor affecting long-term reliability. Noble metals like platinum and palladium demonstrate superior performance as diffusion barriers, maintaining integrity at temperatures up to 650°C for over 5,000 hours of operation. In contrast, conventional nickel barriers begin showing significant interdiffusion with both n-type and p-type thermoelectric materials at temperatures above 450°C, compromising electrical properties within 2,000 hours.

Oxidation resistance testing under accelerated aging conditions indicates that multi-layer metallization systems incorporating oxidation-resistant outer layers (such as Cr/Ni/Au) outperform single-layer solutions by a factor of 3-5x in lifetime performance. The formation of intermetallic compounds at the interface, particularly between antimony-based thermoelectrics and silver contacts, contributes to increasing contact resistance over time, with rates of approximately 5-8% increase per 1,000 hours at operating temperatures.

Mechanical adhesion strength measurements using standardized pull tests demonstrate that surface preparation techniques significantly impact bond durability. Plasma-activated surfaces prior to metallization deposition show 40-60% higher adhesion strength compared to conventional cleaning methods. Additionally, the incorporation of nano-textured interface layers has shown promise in accommodating thermal expansion differences while maintaining electrical conductivity.

Chemical compatibility analysis reveals that sulfur-containing environments accelerate degradation of copper-based contact systems, while platinum group metals maintain stability. For bismuth telluride systems operating at moderate temperatures (250-400°C), silver-based contacts with appropriate diffusion barriers demonstrate optimal performance-to-cost ratios. However, for higher temperature applications with skutterudite or half-Heusler materials, more expensive refractory metal contacts become necessary despite their higher electrical resistance.

Diffusion barrier effectiveness emerges as another crucial factor affecting long-term reliability. Noble metals like platinum and palladium demonstrate superior performance as diffusion barriers, maintaining integrity at temperatures up to 650°C for over 5,000 hours of operation. In contrast, conventional nickel barriers begin showing significant interdiffusion with both n-type and p-type thermoelectric materials at temperatures above 450°C, compromising electrical properties within 2,000 hours.

Oxidation resistance testing under accelerated aging conditions indicates that multi-layer metallization systems incorporating oxidation-resistant outer layers (such as Cr/Ni/Au) outperform single-layer solutions by a factor of 3-5x in lifetime performance. The formation of intermetallic compounds at the interface, particularly between antimony-based thermoelectrics and silver contacts, contributes to increasing contact resistance over time, with rates of approximately 5-8% increase per 1,000 hours at operating temperatures.

Mechanical adhesion strength measurements using standardized pull tests demonstrate that surface preparation techniques significantly impact bond durability. Plasma-activated surfaces prior to metallization deposition show 40-60% higher adhesion strength compared to conventional cleaning methods. Additionally, the incorporation of nano-textured interface layers has shown promise in accommodating thermal expansion differences while maintaining electrical conductivity.

Chemical compatibility analysis reveals that sulfur-containing environments accelerate degradation of copper-based contact systems, while platinum group metals maintain stability. For bismuth telluride systems operating at moderate temperatures (250-400°C), silver-based contacts with appropriate diffusion barriers demonstrate optimal performance-to-cost ratios. However, for higher temperature applications with skutterudite or half-Heusler materials, more expensive refractory metal contacts become necessary despite their higher electrical resistance.

Environmental Impact and Sustainability Considerations

The development of high-temperature contact metallization solutions for thermoelectric waste heat recovery generators presents significant environmental implications that warrant careful consideration. These systems fundamentally contribute to sustainability by capturing waste heat that would otherwise be released into the environment, converting it into usable electricity. This energy recovery process can substantially reduce fossil fuel consumption and associated greenhouse gas emissions across industrial applications, power generation facilities, and transportation sectors.

Material selection for metallization contacts carries important environmental considerations. Traditional high-temperature metallization often relies on rare earth elements and precious metals with problematic supply chains. Mining these materials frequently results in habitat destruction, water pollution, and significant carbon emissions. Developing alternative metallization solutions using more abundant materials or recycled content could dramatically reduce the environmental footprint of thermoelectric generator manufacturing.

Life cycle assessment (LCA) studies indicate that the environmental benefits of thermoelectric waste heat recovery systems heavily depend on their operational lifespan. High-temperature metallization solutions that extend device durability directly enhance sustainability by improving the energy return on investment. Current research suggests that advanced metallization techniques could potentially double service life in extreme temperature environments, significantly improving the net environmental benefit of these systems.

Manufacturing processes for high-temperature metallization also present environmental challenges. Conventional techniques often involve energy-intensive processes and hazardous chemicals. Emerging green manufacturing approaches, including additive manufacturing and low-temperature deposition methods, offer promising alternatives that reduce energy consumption and minimize toxic waste generation during production.

End-of-life considerations represent another critical environmental dimension. Designing metallization solutions with recyclability in mind can create closed-loop material systems. Current thermoelectric devices often face recycling challenges due to complex material integration, but research into delamination techniques and selective material recovery shows promise for improving recoverability of valuable metals from spent devices.

Regulatory frameworks increasingly emphasize environmental performance, with policies like the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) directly impacting material selection for metallization. Future-proof solutions must anticipate stricter environmental regulations by prioritizing non-toxic, recyclable materials that comply with emerging sustainability standards.

Material selection for metallization contacts carries important environmental considerations. Traditional high-temperature metallization often relies on rare earth elements and precious metals with problematic supply chains. Mining these materials frequently results in habitat destruction, water pollution, and significant carbon emissions. Developing alternative metallization solutions using more abundant materials or recycled content could dramatically reduce the environmental footprint of thermoelectric generator manufacturing.

Life cycle assessment (LCA) studies indicate that the environmental benefits of thermoelectric waste heat recovery systems heavily depend on their operational lifespan. High-temperature metallization solutions that extend device durability directly enhance sustainability by improving the energy return on investment. Current research suggests that advanced metallization techniques could potentially double service life in extreme temperature environments, significantly improving the net environmental benefit of these systems.

Manufacturing processes for high-temperature metallization also present environmental challenges. Conventional techniques often involve energy-intensive processes and hazardous chemicals. Emerging green manufacturing approaches, including additive manufacturing and low-temperature deposition methods, offer promising alternatives that reduce energy consumption and minimize toxic waste generation during production.

End-of-life considerations represent another critical environmental dimension. Designing metallization solutions with recyclability in mind can create closed-loop material systems. Current thermoelectric devices often face recycling challenges due to complex material integration, but research into delamination techniques and selective material recovery shows promise for improving recoverability of valuable metals from spent devices.

Regulatory frameworks increasingly emphasize environmental performance, with policies like the European Union's Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) directly impacting material selection for metallization. Future-proof solutions must anticipate stricter environmental regulations by prioritizing non-toxic, recyclable materials that comply with emerging sustainability standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!