Comparing Novel Thermoelectric Materials Skutterudites And Half-Heuslers For Waste Heat Recovery Applications

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Evolution and Recovery Goals

Thermoelectric materials have evolved significantly since their discovery in the early 19th century, with major advancements occurring in the late 20th and early 21st centuries. The field began with simple metallic thermocouples and has progressed to complex semiconductor-based materials with engineered nanostructures. This evolution has been driven by the increasing demand for sustainable energy solutions and the need to recover waste heat from industrial processes, automotive exhaust systems, and power generation facilities.

The development trajectory of thermoelectric materials has seen three distinct generations. First-generation materials, primarily based on bismuth telluride (Bi2Te3) and lead telluride (PbTe), dominated the market until the 1990s with modest efficiency values (ZT~1). Second-generation materials introduced quantum well structures and superlattices, pushing theoretical ZT values to 2-3. The current third generation, which includes skutterudites and half-Heusler compounds, focuses on nanostructuring and complex crystal structures to achieve higher performance while using more abundant and environmentally friendly elements.

Skutterudites, with their general formula MX3 (where M is typically Co, Rh, or Ir, and X is P, As, or Sb), feature a unique cage-like crystal structure that allows for "rattling" atoms to be inserted, disrupting phonon transport while maintaining good electrical conductivity. This phonon-glass electron-crystal (PGEC) concept has been instrumental in improving thermoelectric efficiency. The evolution of skutterudites has focused on optimizing the filling atoms and improving manufacturing techniques to enhance their stability at high temperatures.

Half-Heusler compounds, represented by the formula XYZ (where X and Y are transition metals and Z is a main group element), have emerged as promising candidates due to their thermal stability, mechanical robustness, and relatively high power factors. Research trends have moved toward band engineering and microstructural modifications to reduce thermal conductivity while preserving electrical properties.

The primary goal for waste heat recovery applications is to achieve a dimensionless figure of merit (ZT) exceeding 2 across a wide temperature range, particularly in the mid-to-high temperature spectrum (400-800°C) where industrial waste heat is abundant. Additional objectives include developing materials with mechanical durability for vibration-intensive environments, long-term stability under thermal cycling, and reduced manufacturing costs to enable widespread commercial adoption.

Current research aims to overcome the interdependence of thermoelectric properties (Seebeck coefficient, electrical conductivity, and thermal conductivity) through novel material design approaches. The ultimate target is to develop thermoelectric generators with conversion efficiencies above 15%, making waste heat recovery economically viable for broader industrial implementation.

The development trajectory of thermoelectric materials has seen three distinct generations. First-generation materials, primarily based on bismuth telluride (Bi2Te3) and lead telluride (PbTe), dominated the market until the 1990s with modest efficiency values (ZT~1). Second-generation materials introduced quantum well structures and superlattices, pushing theoretical ZT values to 2-3. The current third generation, which includes skutterudites and half-Heusler compounds, focuses on nanostructuring and complex crystal structures to achieve higher performance while using more abundant and environmentally friendly elements.

Skutterudites, with their general formula MX3 (where M is typically Co, Rh, or Ir, and X is P, As, or Sb), feature a unique cage-like crystal structure that allows for "rattling" atoms to be inserted, disrupting phonon transport while maintaining good electrical conductivity. This phonon-glass electron-crystal (PGEC) concept has been instrumental in improving thermoelectric efficiency. The evolution of skutterudites has focused on optimizing the filling atoms and improving manufacturing techniques to enhance their stability at high temperatures.

Half-Heusler compounds, represented by the formula XYZ (where X and Y are transition metals and Z is a main group element), have emerged as promising candidates due to their thermal stability, mechanical robustness, and relatively high power factors. Research trends have moved toward band engineering and microstructural modifications to reduce thermal conductivity while preserving electrical properties.

The primary goal for waste heat recovery applications is to achieve a dimensionless figure of merit (ZT) exceeding 2 across a wide temperature range, particularly in the mid-to-high temperature spectrum (400-800°C) where industrial waste heat is abundant. Additional objectives include developing materials with mechanical durability for vibration-intensive environments, long-term stability under thermal cycling, and reduced manufacturing costs to enable widespread commercial adoption.

Current research aims to overcome the interdependence of thermoelectric properties (Seebeck coefficient, electrical conductivity, and thermal conductivity) through novel material design approaches. The ultimate target is to develop thermoelectric generators with conversion efficiencies above 15%, making waste heat recovery economically viable for broader industrial implementation.

Market Analysis for Waste Heat Recovery Technologies

The global waste heat recovery (WHR) market is experiencing significant growth, driven by increasing energy costs and environmental regulations. Currently valued at approximately $68 billion, the market is projected to reach $114 billion by 2028, representing a compound annual growth rate of 8.5%. This growth trajectory is primarily fueled by industrial sectors including manufacturing, power generation, and transportation, where substantial thermal energy is routinely lost during operations.

Thermoelectric materials, which convert temperature differentials directly into electrical energy, represent a rapidly expanding segment within the WHR market. This segment is expected to grow at 9.7% annually through 2030, outpacing the broader market. The appeal of thermoelectric solutions lies in their solid-state operation, absence of moving parts, and scalability across various temperature ranges and applications.

Within the thermoelectric materials landscape, skutterudites and half-Heuslers are emerging as particularly promising candidates for commercial applications. The market for these advanced thermoelectric materials is currently estimated at $420 million and is projected to expand significantly as their performance characteristics improve and manufacturing costs decrease.

Regional analysis reveals that Asia-Pacific dominates the WHR market with 42% share, followed by Europe (28%) and North America (21%). China leads global production of thermoelectric materials, while Germany and Japan maintain technological leadership in high-performance applications. The United States is investing heavily in research and development, particularly through Department of Energy initiatives focused on industrial waste heat recovery.

End-user segmentation shows automotive applications currently represent the largest market for thermoelectric WHR technologies (38%), followed by industrial manufacturing (27%) and power generation (22%). The automotive sector's dominance is driven by stringent emissions regulations and the push for improved fuel efficiency in internal combustion engines.

Customer demand analysis indicates growing interest in modular, retrofit solutions that can be integrated into existing industrial infrastructure without significant process modifications. Performance metrics valued by customers include conversion efficiency, durability under thermal cycling, and total cost of ownership rather than initial capital expenditure alone.

Market barriers include high initial costs, with current thermoelectric systems averaging $8-12 per watt of recovered energy, and limited awareness of thermoelectric technologies among potential industrial adopters. However, these barriers are gradually eroding as material science advances drive improvements in both cost and performance metrics.

Thermoelectric materials, which convert temperature differentials directly into electrical energy, represent a rapidly expanding segment within the WHR market. This segment is expected to grow at 9.7% annually through 2030, outpacing the broader market. The appeal of thermoelectric solutions lies in their solid-state operation, absence of moving parts, and scalability across various temperature ranges and applications.

Within the thermoelectric materials landscape, skutterudites and half-Heuslers are emerging as particularly promising candidates for commercial applications. The market for these advanced thermoelectric materials is currently estimated at $420 million and is projected to expand significantly as their performance characteristics improve and manufacturing costs decrease.

Regional analysis reveals that Asia-Pacific dominates the WHR market with 42% share, followed by Europe (28%) and North America (21%). China leads global production of thermoelectric materials, while Germany and Japan maintain technological leadership in high-performance applications. The United States is investing heavily in research and development, particularly through Department of Energy initiatives focused on industrial waste heat recovery.

End-user segmentation shows automotive applications currently represent the largest market for thermoelectric WHR technologies (38%), followed by industrial manufacturing (27%) and power generation (22%). The automotive sector's dominance is driven by stringent emissions regulations and the push for improved fuel efficiency in internal combustion engines.

Customer demand analysis indicates growing interest in modular, retrofit solutions that can be integrated into existing industrial infrastructure without significant process modifications. Performance metrics valued by customers include conversion efficiency, durability under thermal cycling, and total cost of ownership rather than initial capital expenditure alone.

Market barriers include high initial costs, with current thermoelectric systems averaging $8-12 per watt of recovered energy, and limited awareness of thermoelectric technologies among potential industrial adopters. However, these barriers are gradually eroding as material science advances drive improvements in both cost and performance metrics.

Skutterudites and Half-Heuslers: Current Status and Challenges

Skutterudites and Half-Heuslers represent two of the most promising thermoelectric material classes currently under intensive research for waste heat recovery applications. Globally, research institutions and companies have made significant advancements in both material systems, though several technical challenges remain before widespread commercial implementation becomes viable.

Skutterudites (CoSb3-based compounds) have demonstrated ZT values approaching 1.7 in laboratory settings, with their cage-like crystal structure allowing for effective phonon scattering through the "rattling" effect of guest atoms. This unique property enables skutterudites to achieve remarkably low thermal conductivity while maintaining good electrical properties. However, the high antimony content presents challenges related to cost, toxicity, and thermal stability at elevated temperatures exceeding 500°C.

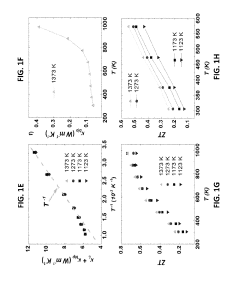

Half-Heusler compounds (typically XYZ compositions where X and Y are transition metals and Z is a main group element) have emerged as highly competitive alternatives, particularly for mid-to-high temperature applications (400-700°C). Their primary advantages include excellent mechanical properties, thermal stability, and relatively abundant constituent elements. Current state-of-the-art Half-Heusler materials have reached ZT values of approximately 1.5, with particularly promising results in n-type compositions.

The manufacturing scalability remains a significant challenge for both material systems. Skutterudites typically require complex multi-step synthesis processes including ball milling, hot pressing, and spark plasma sintering, which complicate mass production efforts. Half-Heuslers face similar processing challenges, though recent advancements in melt-spinning techniques have shown promise for streamlining production.

Mechanical robustness presents another critical challenge, particularly for automotive and industrial applications where thermal cycling and vibration are common. Skutterudites exhibit relatively poor mechanical properties and are prone to fracture, while Half-Heuslers demonstrate superior mechanical strength but can suffer from brittleness and thermal expansion mismatches when integrated into devices.

Contact resistance at material interfaces continues to limit overall device efficiency for both material systems. This challenge is particularly pronounced in segmented thermoelectric generators where different materials must be joined to optimize performance across temperature gradients.

Geographically, research leadership in these materials shows distinct patterns. Japan and China lead in skutterudite development, with Toyota and several Chinese universities publishing breakthrough research. Half-Heusler development is more concentrated in Europe and North America, with Germany's Fraunhofer Institute and Ohio State University in the US making notable contributions to the field.

Skutterudites (CoSb3-based compounds) have demonstrated ZT values approaching 1.7 in laboratory settings, with their cage-like crystal structure allowing for effective phonon scattering through the "rattling" effect of guest atoms. This unique property enables skutterudites to achieve remarkably low thermal conductivity while maintaining good electrical properties. However, the high antimony content presents challenges related to cost, toxicity, and thermal stability at elevated temperatures exceeding 500°C.

Half-Heusler compounds (typically XYZ compositions where X and Y are transition metals and Z is a main group element) have emerged as highly competitive alternatives, particularly for mid-to-high temperature applications (400-700°C). Their primary advantages include excellent mechanical properties, thermal stability, and relatively abundant constituent elements. Current state-of-the-art Half-Heusler materials have reached ZT values of approximately 1.5, with particularly promising results in n-type compositions.

The manufacturing scalability remains a significant challenge for both material systems. Skutterudites typically require complex multi-step synthesis processes including ball milling, hot pressing, and spark plasma sintering, which complicate mass production efforts. Half-Heuslers face similar processing challenges, though recent advancements in melt-spinning techniques have shown promise for streamlining production.

Mechanical robustness presents another critical challenge, particularly for automotive and industrial applications where thermal cycling and vibration are common. Skutterudites exhibit relatively poor mechanical properties and are prone to fracture, while Half-Heuslers demonstrate superior mechanical strength but can suffer from brittleness and thermal expansion mismatches when integrated into devices.

Contact resistance at material interfaces continues to limit overall device efficiency for both material systems. This challenge is particularly pronounced in segmented thermoelectric generators where different materials must be joined to optimize performance across temperature gradients.

Geographically, research leadership in these materials shows distinct patterns. Japan and China lead in skutterudite development, with Toyota and several Chinese universities publishing breakthrough research. Half-Heusler development is more concentrated in Europe and North America, with Germany's Fraunhofer Institute and Ohio State University in the US making notable contributions to the field.

Comparative Analysis of Skutterudites vs Half-Heuslers

01 Composition and structure of skutterudite thermoelectric materials

Skutterudites are a class of thermoelectric materials with a cubic crystal structure and the general formula MX3 (where M is typically Co, Rh, or Ir, and X is P, As, or Sb). These materials can be modified through filling the voids in their crystal structure with guest atoms (filled skutterudites) to reduce thermal conductivity while maintaining good electrical properties. The composition can be optimized by adjusting the ratio of elements and introducing dopants to enhance the thermoelectric figure of merit (ZT).- Composition and structure of skutterudite thermoelectric materials: Skutterudites are a class of thermoelectric materials with a cubic crystal structure and the general formula MX3 (where M is typically Co, Rh, or Ir, and X is P, As, or Sb). These materials can be modified through filling the voids in their crystal structure with guest atoms (filled skutterudites) to reduce thermal conductivity while maintaining good electrical properties. The composition can be optimized by partial substitution of elements to achieve higher thermoelectric performance. Skutterudites are particularly effective for mid-to-high temperature applications due to their thermal stability and favorable thermoelectric properties.

- Composition and structure of Half-Heusler thermoelectric materials: Half-Heusler compounds are intermetallic materials with the general formula XYZ, where X and Y are transition metals and Z is a main group element. They possess a face-centered cubic crystal structure with one vacant sublattice compared to full Heusler compounds. These materials exhibit good electrical conductivity and Seebeck coefficient, making them promising for thermoelectric applications. Their performance can be enhanced through doping, alloying, and nanostructuring approaches. Half-Heuslers are particularly suitable for high-temperature applications due to their thermal stability and mechanical robustness.

- Nanostructuring and composite approaches for enhanced thermoelectric performance: Nanostructuring techniques are employed to enhance the thermoelectric performance of skutterudites and Half-Heusler materials. These approaches include creating nanocomposites, introducing nanoinclusions, and developing hierarchical structures at multiple length scales. Such nanostructuring creates additional phonon scattering interfaces that reduce thermal conductivity while preserving electrical conductivity. Methods include ball milling, melt spinning, precipitation techniques, and controlled solidification processes. These approaches can significantly improve the figure of merit (ZT) by optimizing the power factor and reducing thermal conductivity simultaneously.

- Doping and element substitution strategies: Doping and element substitution are critical strategies for optimizing the thermoelectric properties of skutterudites and Half-Heusler materials. For skutterudites, filling the structural voids with rare earth or alkaline earth elements (like La, Ce, Yb, Ba) can significantly reduce thermal conductivity through rattling effects. In Half-Heuslers, partial substitution of constituent elements can tune the carrier concentration and band structure. These approaches allow for independent optimization of electrical conductivity, Seebeck coefficient, and thermal conductivity to maximize the thermoelectric figure of merit (ZT).

- Device fabrication and applications of thermoelectric materials: Skutterudites and Half-Heusler materials are incorporated into thermoelectric devices for power generation and cooling applications. The fabrication process involves creating p-type and n-type legs, connecting them electrically in series and thermally in parallel to form modules. These materials are particularly suitable for waste heat recovery in automotive exhaust systems, industrial processes, and power plants due to their stability at high temperatures. Recent developments include flexible thermoelectric generators, wearable devices, and integration with other energy harvesting technologies to improve overall system efficiency.

02 Composition and structure of half-Heusler thermoelectric materials

Half-Heusler compounds are intermetallic materials with the general formula XYZ (where X and Y are transition metals and Z is a main group element). These materials possess a face-centered cubic structure and exhibit promising thermoelectric properties due to their narrow band gap semiconducting behavior. The thermoelectric performance of half-Heusler compounds can be enhanced through elemental substitution, nanostructuring, and band engineering to optimize electrical conductivity and reduce thermal conductivity.Expand Specific Solutions03 Fabrication methods for skutterudite and half-Heusler thermoelectric materials

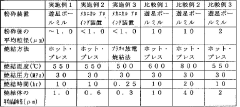

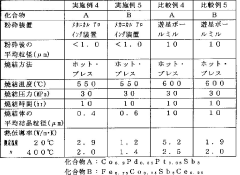

Various fabrication techniques are employed to synthesize skutterudite and half-Heusler thermoelectric materials, including solid-state reaction, mechanical alloying, melt spinning, and spark plasma sintering. These methods allow for precise control over composition, microstructure, and density, which significantly influence the thermoelectric properties. Advanced processing techniques such as hot pressing and rapid solidification can further enhance the thermoelectric performance by creating nanostructured materials with reduced thermal conductivity.Expand Specific Solutions04 Doping and nanostructuring strategies for enhanced thermoelectric performance

Doping and nanostructuring are effective strategies to enhance the thermoelectric performance of skutterudites and half-Heusler materials. Introducing dopants can optimize carrier concentration and mobility, while nanostructuring creates interfaces that scatter phonons without significantly affecting electron transport. These approaches help achieve the phonon-glass electron-crystal concept, where thermal conductivity is minimized while electrical conductivity remains high. Techniques include incorporating nanoinclusions, creating hierarchical structures, and forming composite materials.Expand Specific Solutions05 Applications and device integration of skutterudite and half-Heusler thermoelectric materials

Skutterudite and half-Heusler thermoelectric materials are integrated into various devices for power generation and cooling applications. These include waste heat recovery systems in automotive and industrial settings, space power generation using radioisotope thermoelectric generators, and solid-state cooling devices. The integration process involves addressing challenges such as thermal and mechanical stability, contact resistance, and module design to maximize efficiency and reliability under operating conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectrics

The thermoelectric materials market for waste heat recovery applications is currently in a growth phase, with skutterudites and half-Heuslers emerging as promising alternatives to traditional materials. The global thermoelectric market is projected to reach $1.5 billion by 2027, driven by increasing focus on energy efficiency across industries. Technologically, research institutions like Massachusetts Institute of Technology, California Institute of Technology, and Zhejiang University are advancing fundamental science, while companies including Toshiba Materials, GMZ Energy, and Resonac Holdings are commercializing applications. Major industrial players such as Toyota Central R&D Labs, General Motors, and Robert Bosch are integrating these materials into automotive waste heat recovery systems. The competitive landscape shows a collaborative ecosystem between academic research and industrial implementation, with Asian institutions and companies demonstrating particular strength in patent activity and commercial development.

Toshiba Corp.

Technical Solution: Toshiba Corporation has developed advanced thermoelectric waste heat recovery systems utilizing both skutterudite and half-Heusler materials for industrial and automotive applications. Their technology focuses on high-temperature operation (400-600°C) where these materials demonstrate peak performance. Toshiba's skutterudite materials employ a multi-filling strategy with rare earth elements in the CoSb3 structure, achieving ZT values of approximately 1.3 at operating temperatures. Their proprietary manufacturing process includes controlled solidification techniques and precise doping control to optimize electrical and thermal properties. For half-Heusler compounds, Toshiba has developed MNiSn-based materials (where M = Ti, Zr, Hf) with nanostructured inclusions that effectively scatter phonons while maintaining good electrical conductivity. Their module design incorporates specialized electrode structures and interface materials to minimize contact resistance and thermal stress during operation. Toshiba has demonstrated these technologies in pilot installations at industrial facilities, achieving power generation of 10-15 kW from waste heat sources with payback periods estimated at 3-5 years depending on installation conditions.

Strengths: Extensive experience in power generation systems integration; established manufacturing infrastructure capable of scaling production; comprehensive reliability testing protocols for industrial applications. Weaknesses: Material costs remain relatively high, particularly for skutterudites containing rare earth elements; thermal cycling performance needs further improvement for applications with frequent start-stop cycles; module efficiency decreases significantly at lower temperature differentials.

Robert Bosch GmbH

Technical Solution: Robert Bosch has developed a comprehensive thermoelectric waste heat recovery system focusing on both skutterudite and half-Heusler materials for automotive applications. Their technology integrates specially designed heat exchangers with optimized thermoelectric modules to capture exhaust gas heat efficiently. Bosch's approach includes advanced material engineering techniques such as elemental substitution and nanostructuring to enhance the ZT values of their materials. For skutterudites, they've achieved filled structures (RxCo4Sb12, where R represents rare earth elements) with reduced thermal conductivity while maintaining electrical performance. Their half-Heusler compounds (primarily based on TiNiSn and ZrNiSn systems) demonstrate excellent mechanical stability at high temperatures and power densities of up to 2.5 W/cm². Bosch has implemented these materials in prototype systems that demonstrated fuel efficiency improvements of 3-5% in heavy-duty diesel engines under highway driving conditions.

Strengths: Extensive automotive integration expertise; robust manufacturing capabilities for scaling production; comprehensive system approach including heat exchangers, power electronics, and thermal management. Weaknesses: Relatively high system complexity increases implementation costs; dependence on some rare earth elements for skutterudite fillers raises supply chain concerns; thermal cycling performance needs further improvement for meeting automotive durability requirements.

Key Patents and Breakthroughs in Novel Thermoelectric Materials

Skutterudite thermoelectric material and manufacture thereof

PatentInactiveJP1999040860A

Innovation

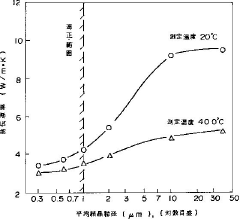

- A polycrystalline skutterudite thermoelectric material with an average crystal grain size of 1 μm or less is produced by pulverizing raw materials into a powder, pressure-sintering at specific temperatures and pressures, and using mechanical alloying and plasma discharge sintering to reduce thermal conductivity.

Systems and methods of fabrication and use of NbFeSb P-type half-heusler thermoelectric materials

PatentActiveUS10243127B2

Innovation

- A method involving the fabrication of a thermoelectric component using a Nb1-xTixFeSb alloy through arc melting, ball-milling, and hot-pressing at elevated temperatures (up to 1373 K) to achieve a high power factor and output power density, with the resulting component exhibiting enhanced carrier mobility and grain size effects that improve thermal and electrical conductivity.

Environmental Impact and Sustainability Assessment

The environmental impact assessment of thermoelectric materials, particularly skutterudites and half-Heuslers, reveals significant sustainability implications for waste heat recovery applications. These novel materials offer promising alternatives to conventional thermoelectric systems, potentially reducing the environmental footprint associated with energy generation and industrial processes.

Life cycle analysis of skutterudites and half-Heuslers indicates lower environmental impacts compared to traditional thermoelectric materials. The production processes for these materials require less energy and generate fewer greenhouse gas emissions, particularly when manufacturing techniques are optimized. Additionally, both material classes demonstrate extended operational lifespans, reducing replacement frequency and associated resource consumption.

Raw material considerations present contrasting profiles between the two material classes. Skutterudites typically contain cobalt, antimony, and rare earth elements as fillers, raising concerns about resource scarcity and extraction impacts. Half-Heuslers, composed primarily of nickel, titanium, and zirconium, generally utilize more abundant elements, though zirconium mining can have significant land disturbance impacts.

The waste heat recovery capabilities of these materials deliver substantial environmental benefits through improved energy efficiency. Industrial implementations of skutterudite and half-Heusler systems can reduce primary energy consumption by 5-15%, depending on the application. This translates to proportional reductions in greenhouse gas emissions and air pollutants associated with conventional power generation.

End-of-life management presents both challenges and opportunities. The valuable elements in both material classes create economic incentives for recycling, though current recovery infrastructure remains underdeveloped. Research indicates that over 80% of the constituent elements could theoretically be recovered through appropriate recycling processes, significantly reducing the need for virgin material extraction.

Comparative analysis between skutterudites and half-Heuslers reveals trade-offs in environmental performance. Skutterudites generally demonstrate higher conversion efficiencies in mid-temperature ranges (400-600°C), potentially offering greater emission reduction benefits. However, half-Heuslers typically contain fewer critical raw materials and demonstrate superior mechanical stability, potentially resulting in longer service lives and reduced material replacement requirements.

Regulatory compliance considerations are increasingly relevant as global environmental standards evolve. Both material classes generally align with RoHS and REACH regulations, though the antimony content in skutterudites may face increasing scrutiny under future regulatory frameworks. Half-Heuslers, with their generally less problematic elemental composition, may present fewer regulatory hurdles for widespread commercial adoption.

Life cycle analysis of skutterudites and half-Heuslers indicates lower environmental impacts compared to traditional thermoelectric materials. The production processes for these materials require less energy and generate fewer greenhouse gas emissions, particularly when manufacturing techniques are optimized. Additionally, both material classes demonstrate extended operational lifespans, reducing replacement frequency and associated resource consumption.

Raw material considerations present contrasting profiles between the two material classes. Skutterudites typically contain cobalt, antimony, and rare earth elements as fillers, raising concerns about resource scarcity and extraction impacts. Half-Heuslers, composed primarily of nickel, titanium, and zirconium, generally utilize more abundant elements, though zirconium mining can have significant land disturbance impacts.

The waste heat recovery capabilities of these materials deliver substantial environmental benefits through improved energy efficiency. Industrial implementations of skutterudite and half-Heusler systems can reduce primary energy consumption by 5-15%, depending on the application. This translates to proportional reductions in greenhouse gas emissions and air pollutants associated with conventional power generation.

End-of-life management presents both challenges and opportunities. The valuable elements in both material classes create economic incentives for recycling, though current recovery infrastructure remains underdeveloped. Research indicates that over 80% of the constituent elements could theoretically be recovered through appropriate recycling processes, significantly reducing the need for virgin material extraction.

Comparative analysis between skutterudites and half-Heuslers reveals trade-offs in environmental performance. Skutterudites generally demonstrate higher conversion efficiencies in mid-temperature ranges (400-600°C), potentially offering greater emission reduction benefits. However, half-Heuslers typically contain fewer critical raw materials and demonstrate superior mechanical stability, potentially resulting in longer service lives and reduced material replacement requirements.

Regulatory compliance considerations are increasingly relevant as global environmental standards evolve. Both material classes generally align with RoHS and REACH regulations, though the antimony content in skutterudites may face increasing scrutiny under future regulatory frameworks. Half-Heuslers, with their generally less problematic elemental composition, may present fewer regulatory hurdles for widespread commercial adoption.

Cost-Benefit Analysis of Implementation Scenarios

Implementing thermoelectric waste heat recovery systems using skutterudites and half-Heuslers requires careful economic analysis across various application scenarios. Initial capital expenditure for skutterudite-based systems typically ranges from $2,500-4,000 per kW of generation capacity, while half-Heusler systems generally cost $3,000-5,000 per kW due to their more complex manufacturing processes and material requirements.

Operational expenses differ significantly between these materials. Skutterudites demonstrate longer operational lifespans (approximately 8-10 years) compared to half-Heuslers (6-8 years), resulting in different replacement cycle economics. However, half-Heuslers maintain higher efficiency at elevated temperatures, making them potentially more cost-effective in high-temperature industrial applications despite higher initial costs.

Return on investment calculations indicate that automotive applications using skutterudites can achieve payback periods of 3-5 years, while industrial waste heat recovery systems using half-Heuslers in high-temperature environments (>500°C) may reach payback within 2-4 years due to greater energy capture efficiency.

Scaling considerations reveal important economic thresholds. Small-scale implementations (<10kW) typically favor skutterudites due to lower initial investment requirements, while large industrial installations (>50kW) often justify half-Heusler implementation despite higher upfront costs, as their superior high-temperature performance delivers greater long-term value.

Environmental cost-benefit analysis demonstrates that both materials offer significant carbon reduction potential, with half-Heuslers providing approximately 15-20% greater CO2 reduction per dollar invested in high-temperature applications. However, skutterudites maintain advantage in moderate temperature ranges (250-400°C).

Maintenance economics also differ substantially. Skutterudite systems typically require maintenance intervals of 18-24 months at costs representing 2-3% of initial investment, while half-Heusler systems require more frequent maintenance (12-18 months) at slightly higher relative costs (3-4% of initial investment).

Risk assessment calculations indicate that skutterudites present lower technological implementation risk due to their more established manufacturing processes, while half-Heuslers offer potentially higher rewards but with greater performance variability across operating conditions. This risk-reward profile suggests portfolio approaches for large-scale industrial adopters, implementing both technologies across different temperature zones within complex systems.

Operational expenses differ significantly between these materials. Skutterudites demonstrate longer operational lifespans (approximately 8-10 years) compared to half-Heuslers (6-8 years), resulting in different replacement cycle economics. However, half-Heuslers maintain higher efficiency at elevated temperatures, making them potentially more cost-effective in high-temperature industrial applications despite higher initial costs.

Return on investment calculations indicate that automotive applications using skutterudites can achieve payback periods of 3-5 years, while industrial waste heat recovery systems using half-Heuslers in high-temperature environments (>500°C) may reach payback within 2-4 years due to greater energy capture efficiency.

Scaling considerations reveal important economic thresholds. Small-scale implementations (<10kW) typically favor skutterudites due to lower initial investment requirements, while large industrial installations (>50kW) often justify half-Heusler implementation despite higher upfront costs, as their superior high-temperature performance delivers greater long-term value.

Environmental cost-benefit analysis demonstrates that both materials offer significant carbon reduction potential, with half-Heuslers providing approximately 15-20% greater CO2 reduction per dollar invested in high-temperature applications. However, skutterudites maintain advantage in moderate temperature ranges (250-400°C).

Maintenance economics also differ substantially. Skutterudite systems typically require maintenance intervals of 18-24 months at costs representing 2-3% of initial investment, while half-Heusler systems require more frequent maintenance (12-18 months) at slightly higher relative costs (3-4% of initial investment).

Risk assessment calculations indicate that skutterudites present lower technological implementation risk due to their more established manufacturing processes, while half-Heuslers offer potentially higher rewards but with greater performance variability across operating conditions. This risk-reward profile suggests portfolio approaches for large-scale industrial adopters, implementing both technologies across different temperature zones within complex systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!