Developing Low-Cost Manufacturing Routes For Large-Area Thermoelectric Generator Modules In Waste Heat Recovery

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Generator Technology Evolution and Objectives

Thermoelectric generators (TEGs) have evolved significantly since their inception in the early 19th century with the discovery of the Seebeck effect by Thomas Johann Seebeck in 1821. This phenomenon, where a temperature difference between two dissimilar electrical conductors produces a voltage difference, forms the fundamental principle of thermoelectric generation. The technology remained largely theoretical until the mid-20th century when semiconductor materials revolutionized the field.

The 1950s marked a pivotal turning point with the development of bismuth telluride (Bi2Te3) based materials, which significantly improved conversion efficiency. By the 1960s, TEGs found their first practical applications in space missions, powering satellites and deep space probes like NASA's Voyager spacecraft, leveraging radioisotope thermoelectric generators (RTGs) to convert heat from radioactive decay into electricity.

Throughout the 1970s and 1980s, research focused primarily on improving material properties and understanding the physics of thermoelectric effects. The figure of merit ZT, which quantifies a material's thermoelectric performance, became the central metric driving innovation. Traditional TEGs during this period achieved ZT values of approximately 1, limiting their practical efficiency to around 5-7%.

A renaissance in thermoelectric research occurred in the 1990s with the introduction of nanostructured materials and quantum confinement effects. These approaches allowed for the decoupling of electrical and thermal properties, previously considered interdependent, pushing ZT values beyond 1.5 and approaching 2 in laboratory settings by the early 2000s.

The current technological trajectory aims to develop cost-effective, scalable manufacturing processes for large-area TEG modules specifically designed for waste heat recovery applications. This represents a significant shift from historical high-cost, small-scale production methods that limited widespread commercial adoption. The primary objective is to achieve a balance between performance and manufacturability, focusing on abundant, non-toxic materials that can be processed using conventional industrial techniques.

Key technical objectives include developing roll-to-roll or large-area printing processes for thermoelectric materials, reducing material usage through innovative device architectures, and designing modular systems that can be easily integrated into existing industrial infrastructure. Additionally, there is a strong emphasis on improving the durability and reliability of TEG systems under the harsh conditions typical of waste heat environments, including thermal cycling, oxidation, and mechanical stress.

The ultimate goal is to create economically viable TEG solutions that can achieve payback periods under five years when deployed in industrial waste heat recovery scenarios, making them competitive with alternative energy recovery technologies. This requires reducing manufacturing costs by at least 50% compared to current methods while maintaining or improving conversion efficiencies.

The 1950s marked a pivotal turning point with the development of bismuth telluride (Bi2Te3) based materials, which significantly improved conversion efficiency. By the 1960s, TEGs found their first practical applications in space missions, powering satellites and deep space probes like NASA's Voyager spacecraft, leveraging radioisotope thermoelectric generators (RTGs) to convert heat from radioactive decay into electricity.

Throughout the 1970s and 1980s, research focused primarily on improving material properties and understanding the physics of thermoelectric effects. The figure of merit ZT, which quantifies a material's thermoelectric performance, became the central metric driving innovation. Traditional TEGs during this period achieved ZT values of approximately 1, limiting their practical efficiency to around 5-7%.

A renaissance in thermoelectric research occurred in the 1990s with the introduction of nanostructured materials and quantum confinement effects. These approaches allowed for the decoupling of electrical and thermal properties, previously considered interdependent, pushing ZT values beyond 1.5 and approaching 2 in laboratory settings by the early 2000s.

The current technological trajectory aims to develop cost-effective, scalable manufacturing processes for large-area TEG modules specifically designed for waste heat recovery applications. This represents a significant shift from historical high-cost, small-scale production methods that limited widespread commercial adoption. The primary objective is to achieve a balance between performance and manufacturability, focusing on abundant, non-toxic materials that can be processed using conventional industrial techniques.

Key technical objectives include developing roll-to-roll or large-area printing processes for thermoelectric materials, reducing material usage through innovative device architectures, and designing modular systems that can be easily integrated into existing industrial infrastructure. Additionally, there is a strong emphasis on improving the durability and reliability of TEG systems under the harsh conditions typical of waste heat environments, including thermal cycling, oxidation, and mechanical stress.

The ultimate goal is to create economically viable TEG solutions that can achieve payback periods under five years when deployed in industrial waste heat recovery scenarios, making them competitive with alternative energy recovery technologies. This requires reducing manufacturing costs by at least 50% compared to current methods while maintaining or improving conversion efficiencies.

Market Analysis for Waste Heat Recovery Solutions

The global waste heat recovery market is experiencing significant growth, valued at approximately $54 billion in 2020 and projected to reach $80 billion by 2026, with a compound annual growth rate of 8.8%. This growth is primarily driven by increasing industrial energy costs, stringent environmental regulations, and corporate sustainability initiatives across various sectors.

Industrial processes represent the largest source of waste heat, with estimates suggesting that 20-50% of industrial energy consumption is ultimately discharged as waste heat. Key industries generating substantial waste heat include steel, cement, glass, chemical processing, and power generation, where temperatures can range from 100°C to over 1000°C. The automotive sector also presents significant opportunities, with 60-70% of fuel energy dissipated as heat through exhaust systems and engine cooling.

Thermoelectric generator (TEG) modules specifically occupy a growing niche within this market, currently valued at approximately $460 million and expected to grow at 14.5% annually through 2027. TEGs offer unique advantages in converting low to medium-grade waste heat (80-500°C) directly into electricity without moving parts, making them particularly suitable for distributed energy recovery applications.

Market adoption of large-area TEG solutions faces several barriers, including high initial capital costs, long payback periods (typically 3-7 years), and efficiency limitations. Current commercial TEG modules achieve only 5-8% conversion efficiency, significantly lower than competing technologies like Organic Rankine Cycle systems that can reach 15-20% efficiency for medium-temperature applications.

Regional analysis reveals that Asia-Pacific dominates the waste heat recovery market with 40% share, led by China's industrial expansion and Japan's energy efficiency policies. North America and Europe follow with approximately 25% each, driven by stringent emission regulations and sustainability targets. The Middle East and Africa represent emerging markets with growing industrial bases seeking energy optimization.

Customer segmentation shows distinct needs across different sectors. Heavy industries prioritize high-temperature, large-scale solutions with clear ROI metrics. Commercial buildings and data centers seek modular, maintenance-free systems. The transportation sector demands lightweight, compact solutions that can withstand vibration and variable operating conditions.

Pricing sensitivity remains a critical factor, with current TEG solutions costing $20-40 per watt of generating capacity. Market research indicates that price points below $10 per watt would significantly accelerate adoption across multiple sectors, highlighting the importance of developing cost-effective manufacturing routes for large-area TEG modules.

Industrial processes represent the largest source of waste heat, with estimates suggesting that 20-50% of industrial energy consumption is ultimately discharged as waste heat. Key industries generating substantial waste heat include steel, cement, glass, chemical processing, and power generation, where temperatures can range from 100°C to over 1000°C. The automotive sector also presents significant opportunities, with 60-70% of fuel energy dissipated as heat through exhaust systems and engine cooling.

Thermoelectric generator (TEG) modules specifically occupy a growing niche within this market, currently valued at approximately $460 million and expected to grow at 14.5% annually through 2027. TEGs offer unique advantages in converting low to medium-grade waste heat (80-500°C) directly into electricity without moving parts, making them particularly suitable for distributed energy recovery applications.

Market adoption of large-area TEG solutions faces several barriers, including high initial capital costs, long payback periods (typically 3-7 years), and efficiency limitations. Current commercial TEG modules achieve only 5-8% conversion efficiency, significantly lower than competing technologies like Organic Rankine Cycle systems that can reach 15-20% efficiency for medium-temperature applications.

Regional analysis reveals that Asia-Pacific dominates the waste heat recovery market with 40% share, led by China's industrial expansion and Japan's energy efficiency policies. North America and Europe follow with approximately 25% each, driven by stringent emission regulations and sustainability targets. The Middle East and Africa represent emerging markets with growing industrial bases seeking energy optimization.

Customer segmentation shows distinct needs across different sectors. Heavy industries prioritize high-temperature, large-scale solutions with clear ROI metrics. Commercial buildings and data centers seek modular, maintenance-free systems. The transportation sector demands lightweight, compact solutions that can withstand vibration and variable operating conditions.

Pricing sensitivity remains a critical factor, with current TEG solutions costing $20-40 per watt of generating capacity. Market research indicates that price points below $10 per watt would significantly accelerate adoption across multiple sectors, highlighting the importance of developing cost-effective manufacturing routes for large-area TEG modules.

Current Challenges in Large-Area TEG Manufacturing

Despite significant advancements in thermoelectric generator (TEG) technology, large-area TEG manufacturing for waste heat recovery applications faces several critical challenges that impede widespread commercial adoption. The primary obstacle remains the high production costs associated with scaling traditional manufacturing processes to larger dimensions. Current manufacturing methods typically rely on labor-intensive batch processes that become exponentially more expensive as module size increases, creating a significant barrier to economic viability.

Material constraints present another substantial challenge. High-performance thermoelectric materials often contain rare or toxic elements such as tellurium, bismuth, and lead, which not only increase raw material costs but also introduce environmental and regulatory complications for mass production. The development of alternative material systems that maintain performance while using earth-abundant elements remains an ongoing research challenge.

Thermal management issues become increasingly complex with larger TEG modules. As module area expands, maintaining uniform temperature distribution across the entire device becomes problematic, leading to thermal stress, reduced conversion efficiency, and potential mechanical failures. Current manufacturing approaches struggle to incorporate effective thermal management solutions that can scale with increasing module dimensions.

Mechanical integrity represents a significant manufacturing hurdle for large-area TEGs. The inherent brittleness of many thermoelectric materials makes them susceptible to cracking during fabrication and operation, particularly when subjected to thermal cycling in waste heat recovery applications. Existing manufacturing techniques have not adequately addressed the need for mechanical robustness in scaled-up modules.

Interconnection and assembly challenges also intensify with increasing module size. The reliable electrical connection of numerous thermoelectric elements while maintaining low contact resistance becomes exponentially more difficult in large-area applications. Current automated assembly techniques developed for small-scale production often cannot be directly transferred to large-area manufacturing without significant modifications and cost increases.

Quality control and consistency present formidable obstacles in scaled production. Maintaining uniform material properties and performance across large areas requires sophisticated in-line monitoring and process control capabilities that are not yet fully developed for thermoelectric manufacturing. The lack of standardized testing protocols for large-area TEGs further complicates quality assurance efforts.

Integration challenges with existing industrial waste heat sources constitute another significant barrier. Large-area TEGs must be designed to conform to various industrial equipment geometries while maintaining optimal thermal contact, a requirement that complicates standardized manufacturing approaches and often necessitates customized solutions that increase production costs.

Material constraints present another substantial challenge. High-performance thermoelectric materials often contain rare or toxic elements such as tellurium, bismuth, and lead, which not only increase raw material costs but also introduce environmental and regulatory complications for mass production. The development of alternative material systems that maintain performance while using earth-abundant elements remains an ongoing research challenge.

Thermal management issues become increasingly complex with larger TEG modules. As module area expands, maintaining uniform temperature distribution across the entire device becomes problematic, leading to thermal stress, reduced conversion efficiency, and potential mechanical failures. Current manufacturing approaches struggle to incorporate effective thermal management solutions that can scale with increasing module dimensions.

Mechanical integrity represents a significant manufacturing hurdle for large-area TEGs. The inherent brittleness of many thermoelectric materials makes them susceptible to cracking during fabrication and operation, particularly when subjected to thermal cycling in waste heat recovery applications. Existing manufacturing techniques have not adequately addressed the need for mechanical robustness in scaled-up modules.

Interconnection and assembly challenges also intensify with increasing module size. The reliable electrical connection of numerous thermoelectric elements while maintaining low contact resistance becomes exponentially more difficult in large-area applications. Current automated assembly techniques developed for small-scale production often cannot be directly transferred to large-area manufacturing without significant modifications and cost increases.

Quality control and consistency present formidable obstacles in scaled production. Maintaining uniform material properties and performance across large areas requires sophisticated in-line monitoring and process control capabilities that are not yet fully developed for thermoelectric manufacturing. The lack of standardized testing protocols for large-area TEGs further complicates quality assurance efforts.

Integration challenges with existing industrial waste heat sources constitute another significant barrier. Large-area TEGs must be designed to conform to various industrial equipment geometries while maintaining optimal thermal contact, a requirement that complicates standardized manufacturing approaches and often necessitates customized solutions that increase production costs.

Cost-Effective Manufacturing Approaches for Large-Area TEGs

01 Printing and deposition techniques for thermoelectric materials

Various printing and deposition techniques can be employed for low-cost manufacturing of thermoelectric generator modules. These include screen printing, inkjet printing, and other solution-based deposition methods that allow for precise patterning of thermoelectric materials on different substrates. These techniques reduce material waste, enable large-area fabrication, and can be integrated into roll-to-roll manufacturing processes, significantly lowering production costs compared to traditional methods.- Printing and deposition techniques for thermoelectric materials: Various printing and deposition techniques can be employed for low-cost manufacturing of thermoelectric generator modules. These include screen printing, inkjet printing, and other solution-based deposition methods that allow for precise patterning of thermoelectric materials on different substrates. These techniques reduce material waste, enable large-area fabrication, and can be integrated into roll-to-roll manufacturing processes, significantly lowering production costs compared to traditional methods.

- Bulk manufacturing methods for thermoelectric modules: Bulk manufacturing methods focus on producing thermoelectric materials in large quantities through processes such as powder metallurgy, hot pressing, and spark plasma sintering. These approaches enable the production of thermoelectric elements with controlled microstructures and improved performance characteristics. By optimizing process parameters and using automated assembly techniques, manufacturers can achieve economies of scale and reduce the overall cost of thermoelectric generator modules.

- Thin-film fabrication technologies: Thin-film fabrication technologies offer significant cost advantages for thermoelectric generator manufacturing. Methods such as physical vapor deposition, chemical vapor deposition, and electrodeposition can create thin layers of thermoelectric materials with precise thickness control. These approaches minimize material usage while maintaining performance, and can be integrated with semiconductor manufacturing processes. The reduced material consumption and compatibility with existing manufacturing infrastructure contribute to lower production costs.

- Novel material compositions for cost-effective thermoelectric modules: Developing novel material compositions is a key approach to reducing the manufacturing costs of thermoelectric generator modules. This includes using earth-abundant elements instead of rare or precious metals, creating nanostructured materials with enhanced properties, and developing composite materials that combine low-cost components while maintaining good thermoelectric performance. These material innovations can significantly reduce raw material costs while potentially improving conversion efficiency.

- Assembly and packaging innovations: Innovations in assembly and packaging techniques contribute to cost reduction in thermoelectric generator manufacturing. These include automated assembly processes, modular designs that simplify production, and novel interconnection methods that reduce thermal and electrical contact resistance. Advanced packaging approaches protect the thermoelectric elements while ensuring efficient heat transfer. These innovations streamline production workflows, reduce labor costs, and improve the reliability and durability of the final products.

02 Bulk manufacturing methods for thermoelectric modules

Bulk manufacturing methods focus on cost-effective production of thermoelectric modules through techniques such as powder metallurgy, hot pressing, and extrusion. These approaches enable the production of thermoelectric materials in large quantities with controlled composition and microstructure. By optimizing sintering conditions, material formulations, and assembly processes, manufacturers can achieve significant cost reductions while maintaining performance characteristics of the thermoelectric generator modules.Expand Specific Solutions03 Novel material compositions for low-cost thermoelectric modules

Development of novel material compositions represents a significant approach to reducing manufacturing costs of thermoelectric generator modules. By replacing expensive and rare elements with earth-abundant materials, or by creating composite materials with enhanced properties, manufacturers can reduce raw material costs while maintaining or improving performance. These compositions often involve nanostructuring, doping, or creating alloys that optimize the thermoelectric figure of merit while using more economical constituent materials.Expand Specific Solutions04 Assembly and packaging innovations for thermoelectric modules

Innovations in assembly and packaging techniques contribute significantly to cost reduction in thermoelectric generator module manufacturing. These include automated assembly processes, simplified interconnection methods, and novel packaging approaches that reduce the number of components and assembly steps. By optimizing the module architecture, improving thermal interfaces, and developing standardized assembly procedures, manufacturers can achieve substantial cost savings while ensuring reliable performance and durability of the thermoelectric generator modules.Expand Specific Solutions05 Substrate and electrode materials for cost-effective thermoelectric modules

Selection and processing of substrate and electrode materials play a crucial role in reducing manufacturing costs of thermoelectric generator modules. By utilizing low-cost substrates such as polymers or ceramics, and developing efficient electrode materials and deposition methods, manufacturers can significantly decrease production expenses. These approaches often involve flexible substrates, improved adhesion techniques, and optimized electrical contact designs that enhance performance while reducing material and processing costs.Expand Specific Solutions

Leading Companies and Research Institutions in TEG Development

The thermoelectric waste heat recovery market is currently in a growth phase, with increasing focus on energy efficiency driving adoption across industrial sectors. The global market size for thermoelectric generators is expanding at approximately 8-10% annually, reaching towards $750 million. Technologically, the field faces challenges in scaling cost-effective manufacturing for large-area modules. Companies like Siemens AG, Toyota Motor Corp., and Murata Manufacturing are leading commercial development with established manufacturing capabilities, while research institutions such as Industrial Technology Research Institute and CEA are advancing fundamental technologies. Specialized players like European Thermodynamics, Thermogentech, and Cixten are developing innovative manufacturing approaches to reduce production costs. The technology remains in mid-maturity, with significant improvements needed in manufacturing efficiency and material optimization to achieve widespread commercial viability for large-scale waste heat recovery applications.

Industrial Technology Research Institute

Technical Solution: Industrial Technology Research Institute (ITRI) has developed a flexible thermoelectric generator (TEG) module manufacturing process that significantly reduces production costs. Their approach utilizes screen printing technology to deposit thermoelectric materials onto flexible substrates, enabling roll-to-roll processing for large-area TEG modules. ITRI's solution incorporates bismuth telluride-based materials with optimized doping levels to achieve a ZT value exceeding 1.0 at room temperature. The manufacturing process includes precise control of material composition, particle size distribution, and sintering conditions to ensure consistent performance across large areas. ITRI has also developed specialized interconnection techniques that minimize contact resistance between thermoelectric elements, resulting in higher overall conversion efficiency. Their modules demonstrate power densities of approximately 10-15 mW/cm² at temperature differences of 100°C, making them suitable for industrial waste heat recovery applications.

Strengths: Cost-effective roll-to-roll manufacturing enables scalable production; flexible substrate allows conforming to irregular heat sources; low-temperature processing reduces energy consumption during manufacturing. Weaknesses: Performance still lower than rigid modules; long-term reliability in harsh industrial environments remains challenging; bismuth telluride resource constraints may limit large-scale deployment.

Siemens AG

Technical Solution: Siemens AG has pioneered an integrated manufacturing approach for large-area thermoelectric generator modules specifically designed for industrial waste heat recovery. Their technology utilizes a modular design with standardized thermoelectric cells that can be assembled into larger arrays to match specific application requirements. Siemens' manufacturing route employs automated precision assembly techniques combined with advanced ceramic substrates that provide excellent thermal isolation between hot and cold sides while maintaining mechanical strength. The company has developed proprietary interconnection methods that reduce parasitic electrical resistance and improve overall system efficiency. Their manufacturing process incorporates in-line quality control systems that verify the performance of individual thermoelectric elements before final assembly, ensuring consistent module performance. Siemens' TEG modules achieve conversion efficiencies of 5-7% at temperature differences of 200-300°C, with a cost reduction of approximately 40% compared to traditional manufacturing methods through economies of scale and process optimization.

Strengths: Highly scalable manufacturing process suitable for industrial production volumes; robust design withstands thermal cycling and industrial environments; modular approach allows customization for different applications. Weaknesses: Higher initial capital investment required for manufacturing equipment; relatively heavy and rigid construction limits application in space-constrained areas; efficiency still moderate compared to theoretical limits.

Key Patents and Innovations in Low-Cost TEG Production

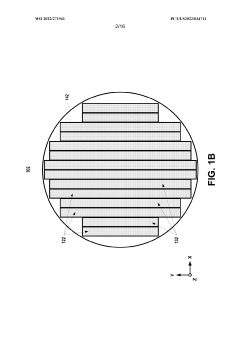

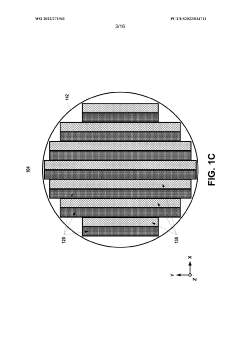

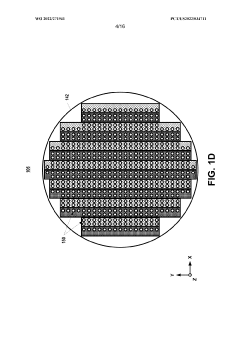

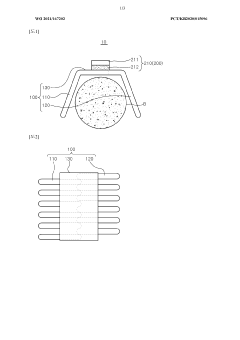

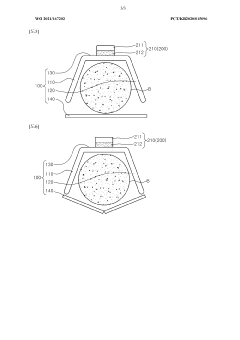

Large area scalable fabrication methodologies for versatile thermoelectric device modules

PatentWO2022271941A1

Innovation

- A method for large area scalable fabrication of thermoelectric device modules involves disposing thermoelectric structures on a substrate, removing the second substrate material, forming electrical contacts, and creating top headers, using a combination of photoresist coating and electroplating to overcome chemical incompatibility issues between p-type and n-type materials, enabling the production of versatile thin-film thermoelectric devices on a wafer scale.

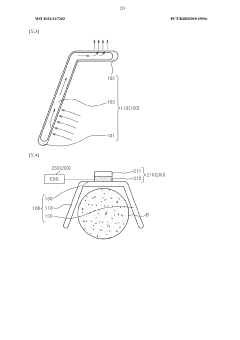

Thermoelectric power generation system for recovering casting waste heat

PatentWO2021167202A1

Innovation

- A thermoelectric power generation system using a waste heat recovery unit with heat pipes and a thermoelectric module that converts waste heat from continuous casting into electrical energy, eliminating the need for separate devices by leveraging heat pipes' ability to transfer heat independently and integrating a thermoelectric module for energy conversion.

Environmental Impact and Sustainability Assessment

The development of large-area thermoelectric generator (TEG) modules for waste heat recovery presents significant environmental implications that warrant comprehensive assessment. When evaluating the environmental impact of these technologies, lifecycle analysis reveals that TEGs offer substantial potential for reducing greenhouse gas emissions by converting otherwise wasted thermal energy into usable electricity without additional fuel consumption.

Manufacturing processes for TEG modules traditionally involve energy-intensive methods and potentially hazardous materials. However, emerging low-cost manufacturing routes are increasingly focusing on environmentally benign materials and energy-efficient production techniques. The substitution of rare or toxic elements like tellurium with more abundant and less harmful alternatives such as silicides, skutterudites, or organic thermoelectric materials represents a critical advancement toward sustainability.

Water consumption during manufacturing presents another environmental consideration. Conventional semiconductor fabrication techniques often require substantial water resources for cleaning and processing. Low-cost manufacturing innovations utilizing dry processing methods, reduced cleaning cycles, and water recycling systems can significantly decrease the water footprint of TEG production facilities.

The waste stream management associated with large-area TEG manufacturing deserves particular attention. Implementation of circular economy principles through material recovery systems can minimize landfill contributions. Advanced manufacturing approaches incorporating design-for-disassembly principles facilitate end-of-life recycling, potentially recovering up to 90% of valuable materials from decommissioned modules.

Carbon footprint analysis of the entire TEG lifecycle demonstrates that despite initial manufacturing emissions, the net environmental benefit becomes positive within 1-3 years of operation in waste heat recovery applications. This favorable environmental payback period shortens as manufacturing processes become more efficient and module lifespans extend beyond the current 10-15 year average.

Regulatory compliance represents an increasingly important aspect of environmental sustainability for TEG technologies. Emerging manufacturing routes must address evolving standards such as the Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations, particularly as TEG deployment scales to industrial levels.

The sustainability advantages of waste heat recovery using TEGs extend beyond direct environmental metrics. By improving overall energy efficiency in industrial processes, transportation systems, and power generation, these technologies contribute to broader sustainability goals including reduced primary energy consumption and enhanced resource utilization efficiency.

Manufacturing processes for TEG modules traditionally involve energy-intensive methods and potentially hazardous materials. However, emerging low-cost manufacturing routes are increasingly focusing on environmentally benign materials and energy-efficient production techniques. The substitution of rare or toxic elements like tellurium with more abundant and less harmful alternatives such as silicides, skutterudites, or organic thermoelectric materials represents a critical advancement toward sustainability.

Water consumption during manufacturing presents another environmental consideration. Conventional semiconductor fabrication techniques often require substantial water resources for cleaning and processing. Low-cost manufacturing innovations utilizing dry processing methods, reduced cleaning cycles, and water recycling systems can significantly decrease the water footprint of TEG production facilities.

The waste stream management associated with large-area TEG manufacturing deserves particular attention. Implementation of circular economy principles through material recovery systems can minimize landfill contributions. Advanced manufacturing approaches incorporating design-for-disassembly principles facilitate end-of-life recycling, potentially recovering up to 90% of valuable materials from decommissioned modules.

Carbon footprint analysis of the entire TEG lifecycle demonstrates that despite initial manufacturing emissions, the net environmental benefit becomes positive within 1-3 years of operation in waste heat recovery applications. This favorable environmental payback period shortens as manufacturing processes become more efficient and module lifespans extend beyond the current 10-15 year average.

Regulatory compliance represents an increasingly important aspect of environmental sustainability for TEG technologies. Emerging manufacturing routes must address evolving standards such as the Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations, particularly as TEG deployment scales to industrial levels.

The sustainability advantages of waste heat recovery using TEGs extend beyond direct environmental metrics. By improving overall energy efficiency in industrial processes, transportation systems, and power generation, these technologies contribute to broader sustainability goals including reduced primary energy consumption and enhanced resource utilization efficiency.

Economic Viability and Return on Investment Analysis

The economic viability of large-area thermoelectric generator (TEG) modules for waste heat recovery hinges on several critical factors. Initial capital investment for manufacturing facilities represents a significant barrier, with specialized equipment costs ranging from $500,000 to $2 million depending on production scale and automation level. However, recent innovations in roll-to-roll processing and additive manufacturing techniques have demonstrated potential cost reductions of 30-45% compared to traditional batch processing methods.

Material costs constitute approximately 40-60% of total manufacturing expenses, with semiconductor materials being the most significant contributor. Alternative material strategies using earth-abundant elements like silicon-germanium alloys, magnesium silicide, and tetrahedrites show promising cost-performance ratios, potentially reducing material costs by 25-35% while maintaining acceptable conversion efficiencies.

Labor costs vary significantly by region, with fully automated production lines reducing labor requirements by up to 70% compared to semi-automated processes. This automation, while requiring higher initial investment, typically achieves ROI breakeven within 3-5 years for high-volume production facilities.

Energy consumption during manufacturing presents another economic consideration, with energy-efficient production methods potentially reducing operational costs by 15-20%. Implementation of lean manufacturing principles has demonstrated waste reduction of up to 25% in pilot production lines.

Market analysis indicates that TEG modules achieving manufacturing costs below $3/W can reach ROI within 4-7 years in industrial waste heat recovery applications, depending on energy prices and utilization rates. Commercial buildings and automotive applications typically require lower price points of $1-2/W for viable ROI timeframes of 3-5 years.

Sensitivity analysis reveals that manufacturing scale significantly impacts economic viability, with production volumes exceeding 100,000 units annually typically required to achieve competitive cost structures. Government incentives for clean energy technologies can further improve ROI metrics by 15-30% through tax credits, grants, or accelerated depreciation allowances.

Long-term economic benefits extend beyond direct energy savings to include reduced maintenance costs, increased system reliability, and potential carbon credit opportunities in regulated markets. These secondary benefits can improve lifetime ROI by an additional 10-20% when properly quantified in comprehensive economic assessments.

Material costs constitute approximately 40-60% of total manufacturing expenses, with semiconductor materials being the most significant contributor. Alternative material strategies using earth-abundant elements like silicon-germanium alloys, magnesium silicide, and tetrahedrites show promising cost-performance ratios, potentially reducing material costs by 25-35% while maintaining acceptable conversion efficiencies.

Labor costs vary significantly by region, with fully automated production lines reducing labor requirements by up to 70% compared to semi-automated processes. This automation, while requiring higher initial investment, typically achieves ROI breakeven within 3-5 years for high-volume production facilities.

Energy consumption during manufacturing presents another economic consideration, with energy-efficient production methods potentially reducing operational costs by 15-20%. Implementation of lean manufacturing principles has demonstrated waste reduction of up to 25% in pilot production lines.

Market analysis indicates that TEG modules achieving manufacturing costs below $3/W can reach ROI within 4-7 years in industrial waste heat recovery applications, depending on energy prices and utilization rates. Commercial buildings and automotive applications typically require lower price points of $1-2/W for viable ROI timeframes of 3-5 years.

Sensitivity analysis reveals that manufacturing scale significantly impacts economic viability, with production volumes exceeding 100,000 units annually typically required to achieve competitive cost structures. Government incentives for clean energy technologies can further improve ROI metrics by 15-30% through tax credits, grants, or accelerated depreciation allowances.

Long-term economic benefits extend beyond direct energy savings to include reduced maintenance costs, increased system reliability, and potential carbon credit opportunities in regulated markets. These secondary benefits can improve lifetime ROI by an additional 10-20% when properly quantified in comprehensive economic assessments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!