Selecting Materials For Thermoelectric Generators In Low-Temperature Industrial Waste Heat Recovery Streams

AUG 26, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Materials Background and Objectives

Thermoelectric materials have evolved significantly since their discovery in the early 19th century, beginning with the Seebeck effect in 1821 and the Peltier effect in 1834. These phenomena established the fundamental principles of converting temperature differentials directly into electrical voltage and vice versa. The field remained largely theoretical until the mid-20th century when semiconductor research accelerated, leading to the development of practical thermoelectric materials with improved efficiency.

The evolution of thermoelectric technology has been marked by three distinct generations. First-generation materials, primarily based on bismuth telluride (Bi2Te3) alloys, dominated applications from the 1950s through the 1990s. Second-generation materials emerged in the early 2000s with complex crystal structures and nanostructuring techniques that reduced thermal conductivity while maintaining electrical conductivity. Currently, third-generation materials are being developed with advanced nano-engineering approaches to optimize the power factor and minimize thermal conductivity simultaneously.

Industrial waste heat represents an enormous untapped energy resource, with estimates suggesting that 20-50% of industrial energy consumption is ultimately discharged as waste heat. Low-temperature waste heat streams (typically below 250°C) are particularly abundant in industries such as food processing, textile manufacturing, and chemical production. Despite this abundance, these streams remain largely unexploited due to the technical challenges of efficient energy recovery at such temperature differentials.

The primary technical objective in this field is to develop thermoelectric materials that can efficiently operate in the temperature range of 30-250°C, which encompasses most industrial low-temperature waste heat sources. This requires materials with a dimensionless figure of merit (ZT) exceeding 2.0 at these temperatures, compared to current commercial materials that typically achieve ZT values of 0.8-1.2 in this range.

Secondary objectives include developing materials that are environmentally sustainable, avoiding toxic or rare elements like tellurium and lead that are common in current high-performance thermoelectrics. Cost-effectiveness is another critical goal, as materials must be economically viable for widespread industrial adoption. Current high-performance thermoelectric materials often cost $100-200 per kilogram, whereas industrial viability likely requires costs below $20 per kilogram.

Durability presents another significant challenge, as industrial environments often involve thermal cycling, vibration, and potential chemical exposure. Materials must maintain stable performance for at least 5-10 years of continuous operation to be commercially viable. Additionally, scalable manufacturing processes must be developed to produce these materials in the quantities needed for industrial-scale waste heat recovery systems.

The evolution of thermoelectric technology has been marked by three distinct generations. First-generation materials, primarily based on bismuth telluride (Bi2Te3) alloys, dominated applications from the 1950s through the 1990s. Second-generation materials emerged in the early 2000s with complex crystal structures and nanostructuring techniques that reduced thermal conductivity while maintaining electrical conductivity. Currently, third-generation materials are being developed with advanced nano-engineering approaches to optimize the power factor and minimize thermal conductivity simultaneously.

Industrial waste heat represents an enormous untapped energy resource, with estimates suggesting that 20-50% of industrial energy consumption is ultimately discharged as waste heat. Low-temperature waste heat streams (typically below 250°C) are particularly abundant in industries such as food processing, textile manufacturing, and chemical production. Despite this abundance, these streams remain largely unexploited due to the technical challenges of efficient energy recovery at such temperature differentials.

The primary technical objective in this field is to develop thermoelectric materials that can efficiently operate in the temperature range of 30-250°C, which encompasses most industrial low-temperature waste heat sources. This requires materials with a dimensionless figure of merit (ZT) exceeding 2.0 at these temperatures, compared to current commercial materials that typically achieve ZT values of 0.8-1.2 in this range.

Secondary objectives include developing materials that are environmentally sustainable, avoiding toxic or rare elements like tellurium and lead that are common in current high-performance thermoelectrics. Cost-effectiveness is another critical goal, as materials must be economically viable for widespread industrial adoption. Current high-performance thermoelectric materials often cost $100-200 per kilogram, whereas industrial viability likely requires costs below $20 per kilogram.

Durability presents another significant challenge, as industrial environments often involve thermal cycling, vibration, and potential chemical exposure. Materials must maintain stable performance for at least 5-10 years of continuous operation to be commercially viable. Additionally, scalable manufacturing processes must be developed to produce these materials in the quantities needed for industrial-scale waste heat recovery systems.

Market Analysis for Low-Temperature Waste Heat Recovery

The global market for low-temperature waste heat recovery systems is experiencing significant growth, driven by increasing energy costs and environmental regulations. Industrial sectors generate substantial amounts of waste heat below 200°C, which traditionally has been difficult to recover economically. Recent market research indicates that approximately 20-50% of industrial energy input is lost as waste heat, creating a substantial opportunity for thermoelectric generator (TEG) technologies.

The waste heat recovery market was valued at $54.3 billion in 2022 and is projected to reach $114.7 billion by 2030, growing at a CAGR of 9.8%. The low-temperature segment specifically is expanding more rapidly than medium and high-temperature applications due to its widespread availability across industries. Key sectors driving demand include manufacturing, power generation, oil and gas, chemical processing, and food and beverage industries.

Regional analysis shows Europe leading the market adoption due to stringent energy efficiency regulations and carbon reduction targets. North America follows closely, with significant growth potential in retrofitting aging industrial infrastructure. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid industrialization and increasing focus on sustainable manufacturing practices.

Customer demand is primarily driven by three factors: energy cost savings, regulatory compliance, and corporate sustainability goals. The payback period remains a critical decision factor, with most industrial customers expecting returns within 2-5 years. This creates a clear market requirement for thermoelectric materials that balance performance with cost-effectiveness.

Market barriers include high initial capital costs, lack of awareness about TEG technologies, and technical challenges in integrating these systems into existing industrial processes. The competitive landscape features established players like Alphabet Energy, Gentherm, and II-VI Marlow, alongside emerging startups developing novel material solutions.

Price sensitivity analysis reveals that material costs represent 30-40% of total system expenses for thermoelectric generators. Therefore, material selection significantly impacts market viability. Materials that can achieve conversion efficiencies above 5% at temperatures below 200°C while maintaining competitive production costs would capture substantial market share.

Future market trends indicate growing demand for modular, scalable TEG solutions that can be easily integrated into diverse industrial settings. Additionally, there is increasing interest in hybrid systems that combine thermoelectric generation with other waste heat recovery technologies to maximize overall efficiency and economic returns.

The waste heat recovery market was valued at $54.3 billion in 2022 and is projected to reach $114.7 billion by 2030, growing at a CAGR of 9.8%. The low-temperature segment specifically is expanding more rapidly than medium and high-temperature applications due to its widespread availability across industries. Key sectors driving demand include manufacturing, power generation, oil and gas, chemical processing, and food and beverage industries.

Regional analysis shows Europe leading the market adoption due to stringent energy efficiency regulations and carbon reduction targets. North America follows closely, with significant growth potential in retrofitting aging industrial infrastructure. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid industrialization and increasing focus on sustainable manufacturing practices.

Customer demand is primarily driven by three factors: energy cost savings, regulatory compliance, and corporate sustainability goals. The payback period remains a critical decision factor, with most industrial customers expecting returns within 2-5 years. This creates a clear market requirement for thermoelectric materials that balance performance with cost-effectiveness.

Market barriers include high initial capital costs, lack of awareness about TEG technologies, and technical challenges in integrating these systems into existing industrial processes. The competitive landscape features established players like Alphabet Energy, Gentherm, and II-VI Marlow, alongside emerging startups developing novel material solutions.

Price sensitivity analysis reveals that material costs represent 30-40% of total system expenses for thermoelectric generators. Therefore, material selection significantly impacts market viability. Materials that can achieve conversion efficiencies above 5% at temperatures below 200°C while maintaining competitive production costs would capture substantial market share.

Future market trends indicate growing demand for modular, scalable TEG solutions that can be easily integrated into diverse industrial settings. Additionally, there is increasing interest in hybrid systems that combine thermoelectric generation with other waste heat recovery technologies to maximize overall efficiency and economic returns.

Current Challenges in Thermoelectric Material Selection

The selection of appropriate materials for thermoelectric generators (TEGs) in low-temperature industrial waste heat recovery applications presents several significant challenges. Current thermoelectric materials struggle to achieve optimal performance in the temperature range of 100-300°C, which is typical for many industrial waste heat streams. This temperature range falls into a problematic gap where traditional high-temperature thermoelectric materials operate inefficiently, while low-temperature materials fail to provide adequate power output.

A primary challenge is the inherently low conversion efficiency of existing thermoelectric materials in this temperature range. Most commercially available materials exhibit a figure of merit (ZT) below 1 in low-temperature applications, resulting in conversion efficiencies typically under 5%. This low efficiency makes it difficult to justify the economic investment in TEG systems for industrial waste heat recovery.

Material stability presents another critical obstacle. Many promising thermoelectric compounds degrade when exposed to industrial environments containing moisture, oxidizing agents, or sulfur compounds. This degradation manifests as performance deterioration over time and significantly reduces the operational lifespan of TEG systems, making long-term deployment problematic.

Manufacturing scalability remains a substantial barrier. Advanced thermoelectric materials with improved performance often involve complex synthesis procedures, rare elements, or precise nanostructuring that are difficult to scale up for industrial production. This creates a disconnect between laboratory-demonstrated materials and commercially viable solutions for widespread implementation.

Cost considerations further complicate material selection. High-performance thermoelectric materials frequently incorporate expensive elements like tellurium, germanium, or rare earth metals. The price volatility and supply chain uncertainties associated with these elements pose significant risks for large-scale industrial applications, particularly when competing against other waste heat recovery technologies.

Mechanical compatibility issues also present challenges. Industrial waste heat recovery systems must withstand thermal cycling, vibration, and mechanical stress. Many high-ZT thermoelectric materials exhibit brittle characteristics or thermal expansion mismatches with other system components, leading to mechanical failures during operation.

Environmental and regulatory concerns add another layer of complexity. Some effective thermoelectric materials contain toxic elements like lead or tellurium, facing increasing regulatory scrutiny and potential future restrictions. This drives the need for alternative materials that can maintain performance while meeting evolving environmental standards.

The interface between thermoelectric materials and heat sources/sinks represents a persistent technical challenge. Poor thermal contact reduces temperature differentials across the thermoelectric elements, significantly diminishing power output regardless of the intrinsic material properties. This highlights the need for integrated material and system design approaches.

A primary challenge is the inherently low conversion efficiency of existing thermoelectric materials in this temperature range. Most commercially available materials exhibit a figure of merit (ZT) below 1 in low-temperature applications, resulting in conversion efficiencies typically under 5%. This low efficiency makes it difficult to justify the economic investment in TEG systems for industrial waste heat recovery.

Material stability presents another critical obstacle. Many promising thermoelectric compounds degrade when exposed to industrial environments containing moisture, oxidizing agents, or sulfur compounds. This degradation manifests as performance deterioration over time and significantly reduces the operational lifespan of TEG systems, making long-term deployment problematic.

Manufacturing scalability remains a substantial barrier. Advanced thermoelectric materials with improved performance often involve complex synthesis procedures, rare elements, or precise nanostructuring that are difficult to scale up for industrial production. This creates a disconnect between laboratory-demonstrated materials and commercially viable solutions for widespread implementation.

Cost considerations further complicate material selection. High-performance thermoelectric materials frequently incorporate expensive elements like tellurium, germanium, or rare earth metals. The price volatility and supply chain uncertainties associated with these elements pose significant risks for large-scale industrial applications, particularly when competing against other waste heat recovery technologies.

Mechanical compatibility issues also present challenges. Industrial waste heat recovery systems must withstand thermal cycling, vibration, and mechanical stress. Many high-ZT thermoelectric materials exhibit brittle characteristics or thermal expansion mismatches with other system components, leading to mechanical failures during operation.

Environmental and regulatory concerns add another layer of complexity. Some effective thermoelectric materials contain toxic elements like lead or tellurium, facing increasing regulatory scrutiny and potential future restrictions. This drives the need for alternative materials that can maintain performance while meeting evolving environmental standards.

The interface between thermoelectric materials and heat sources/sinks represents a persistent technical challenge. Poor thermal contact reduces temperature differentials across the thermoelectric elements, significantly diminishing power output regardless of the intrinsic material properties. This highlights the need for integrated material and system design approaches.

Current Material Solutions for Low-Temperature TEGs

01 Semiconductor materials for thermoelectric generators

Semiconductor materials are widely used in thermoelectric generators due to their favorable electrical and thermal properties. These materials can efficiently convert temperature differences into electrical energy through the Seebeck effect. Various semiconductor compounds and alloys are developed to enhance the thermoelectric figure of merit (ZT), which determines the efficiency of energy conversion. These materials often include bismuth telluride, lead telluride, silicon-germanium alloys, and other semiconductor compounds optimized for specific temperature ranges.- Semiconductor-based thermoelectric materials: Semiconductor materials are widely used in thermoelectric generators due to their favorable electrical and thermal properties. These materials, including bismuth telluride, lead telluride, and silicon-germanium alloys, exhibit the Seebeck effect which allows them to convert temperature differences directly into electrical voltage. The performance of these semiconductor materials is often characterized by their figure of merit (ZT), which depends on electrical conductivity, thermal conductivity, and Seebeck coefficient. Advanced doping techniques and nanostructuring are employed to enhance the thermoelectric properties of these semiconductor materials.

- Nanostructured thermoelectric materials: Nanostructuring has emerged as a promising approach to enhance the performance of thermoelectric materials. By creating structures at the nanoscale, such as quantum dots, nanowires, or nanocomposites, the thermal conductivity can be reduced while maintaining good electrical conductivity. This approach helps to overcome the traditional trade-off between thermal and electrical properties in bulk materials. Nanostructured materials can achieve higher ZT values through phonon scattering at interfaces, quantum confinement effects, and energy filtering of charge carriers. These materials offer improved efficiency for thermoelectric power generation across various temperature ranges.

- Organic and polymer-based thermoelectric materials: Organic and polymer-based materials represent an emerging class of thermoelectric materials that offer advantages such as flexibility, low cost, and environmental friendliness. These materials include conducting polymers, carbon nanotubes, and organic-inorganic hybrids. While their thermoelectric performance is generally lower than inorganic counterparts, they are attractive for applications where mechanical flexibility, large-area coverage, or biocompatibility is required. Recent advances in molecular design and doping strategies have significantly improved the thermoelectric properties of these materials, making them increasingly viable for low-temperature waste heat recovery applications.

- Oxide-based thermoelectric materials: Oxide-based thermoelectric materials offer advantages such as high thermal stability, oxidation resistance, and environmental friendliness. These materials, including strontium titanate, calcium cobaltite, and zinc oxide derivatives, are particularly suitable for high-temperature applications where conventional thermoelectric materials might degrade. While traditional oxide materials have suffered from relatively low electrical conductivity, recent developments in complex oxide structures, defect engineering, and interface design have led to significant improvements in their thermoelectric performance. Their abundance and stability make them promising candidates for sustainable large-scale thermoelectric applications.

- Skutterudite and half-Heusler alloys: Skutterudite and half-Heusler alloys represent two important classes of advanced thermoelectric materials with promising performance characteristics. Skutterudites, with their cage-like crystal structure, allow for the incorporation of rattling atoms that can effectively scatter phonons and reduce thermal conductivity while maintaining good electrical properties. Half-Heusler alloys, typically composed of transition metals and main group elements, offer a good balance of thermal stability, mechanical strength, and thermoelectric performance. Both material classes are particularly suitable for mid to high-temperature applications and can be further optimized through elemental substitution, nanostructuring, and compositional tuning.

02 Nanostructured thermoelectric materials

Nanostructured materials represent an advanced approach to improving thermoelectric performance. By engineering materials at the nanoscale, researchers can enhance phonon scattering while maintaining good electrical conductivity, thereby increasing the ZT value. Nanostructuring techniques include creating quantum dots, nanowires, superlattices, and nanocomposites. These structures effectively reduce thermal conductivity without significantly affecting electrical properties, leading to more efficient thermoelectric generators suitable for various applications.Expand Specific Solutions03 Organic and polymer-based thermoelectric materials

Organic and polymer-based materials offer advantages such as flexibility, low cost, and environmental friendliness for thermoelectric applications. These materials can be processed using solution-based techniques, enabling large-area and flexible thermoelectric generators. While traditionally having lower ZT values than inorganic counterparts, recent advances in conductive polymers, organic-inorganic hybrids, and carbon-based materials have significantly improved their thermoelectric performance, making them viable for low-temperature waste heat recovery and wearable energy harvesting devices.Expand Specific Solutions04 Oxide and ceramic thermoelectric materials

Oxide and ceramic materials are promising candidates for high-temperature thermoelectric applications due to their thermal stability and oxidation resistance. These materials include transition metal oxides, perovskites, and various ceramic compounds that can operate efficiently at temperatures above 700°C. While traditionally limited by lower electrical conductivity, recent developments have focused on enhancing their thermoelectric properties through doping, defect engineering, and compositional optimization, making them suitable for industrial waste heat recovery and high-temperature power generation.Expand Specific Solutions05 Advanced manufacturing and device integration techniques

Advanced manufacturing techniques play a crucial role in optimizing thermoelectric generator performance. These include precision deposition methods, additive manufacturing, thin-film technologies, and novel assembly processes that enhance material interfaces and reduce contact resistance. Innovative device architectures, such as segmented legs, cascaded structures, and integrated heat exchangers, maximize energy conversion efficiency across temperature gradients. These manufacturing approaches enable cost-effective production and integration of thermoelectric generators into various applications, from automotive waste heat recovery to portable power sources.Expand Specific Solutions

Key Industry Players in Thermoelectric Generation

The thermoelectric generator (TEG) market for low-temperature industrial waste heat recovery is in a growth phase, with increasing focus on energy efficiency and sustainability driving adoption. The market is expanding as industries seek cost-effective solutions for waste heat utilization, though still relatively modest compared to conventional energy technologies. Technical maturity varies significantly among key players, with established industrial giants like Siemens AG and 3M Innovative Properties offering commercial solutions, while research institutions such as National Institute for Materials Science, Shanghai Institute of Ceramics, and Fraunhofer-Gesellschaft are advancing material science breakthroughs. European Thermodynamics Limited and Silniva represent specialized TEG developers focusing specifically on low-temperature applications, while industrial conglomerates like NIPPON STEEL and Tata Steel are exploring implementation in energy-intensive manufacturing environments.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: The Shanghai Institute of Ceramics has developed advanced oxide-based thermoelectric materials specifically tailored for low-temperature industrial waste heat recovery. Their technology centers on heavily doped strontium titanate and calcium manganate systems that achieve surprisingly good performance in the 100-300°C range through precise control of oxygen vacancies and electronic band structure. The institute has pioneered innovative co-doping strategies that simultaneously optimize carrier concentration and mobility while introducing nanoscale features that scatter phonons effectively. Their manufacturing approach utilizes a modified sol-gel process followed by controlled sintering under specific atmospheric conditions, resulting in highly reproducible material properties at relatively low production costs. The institute has developed specialized module designs that address the traditionally poor mechanical properties of oxide ceramics, incorporating flexible interfaces that accommodate thermal expansion while maintaining electrical contact. Their systems have demonstrated remarkable stability in oxidizing environments and resistance to thermal cycling, with field tests showing less than 5% performance degradation after 8,000 hours of operation in actual industrial waste heat recovery applications.

Strengths: Exceptional chemical stability in oxidizing environments; utilizes abundant, non-toxic materials; excellent resistance to thermal shock and cycling; very competitive manufacturing costs. Weaknesses: Lower ZT values compared to telluride-based materials; higher electrical contact resistance requiring specialized interface engineering; limited flexibility in module design due to inherent brittleness of ceramic materials.

Siemens AG

Technical Solution: Siemens AG has developed an innovative hybrid thermoelectric material system specifically designed for low-temperature industrial waste heat recovery. Their approach combines modified half-Heusler compounds with advanced silicide materials to create a gradient structure that optimizes performance across varying temperature ranges. Siemens' technology incorporates nanoscale inclusions that effectively scatter phonons while minimizing impact on electron transport, achieving ZT values of approximately 1.1 in the critical 100-200°C range. Their manufacturing process utilizes advanced powder metallurgy techniques followed by spark plasma sintering to create highly dense materials with precisely controlled microstructures. Siemens has integrated these materials into a comprehensive waste heat recovery system that includes specialized heat exchangers, power conditioning electronics, and monitoring systems. Their modular design allows for flexible deployment across various industrial settings, with demonstrated energy recovery efficiencies of up to 7-8% in real-world industrial applications, representing a significant improvement over conventional technologies operating in similar temperature ranges.

Strengths: Comprehensive system approach that addresses all aspects of waste heat recovery; excellent durability and reliability in industrial environments; sophisticated power management systems that optimize output under varying conditions. Weaknesses: Higher initial capital investment compared to simpler systems; requires specialized maintenance expertise; performance optimization requires detailed site-specific engineering.

Critical Patents in Low-Temperature Thermoelectric Materials

Use of thermoelectric materials for low temperature thermoelectric purposes

PatentInactiveUS20100139730A1

Innovation

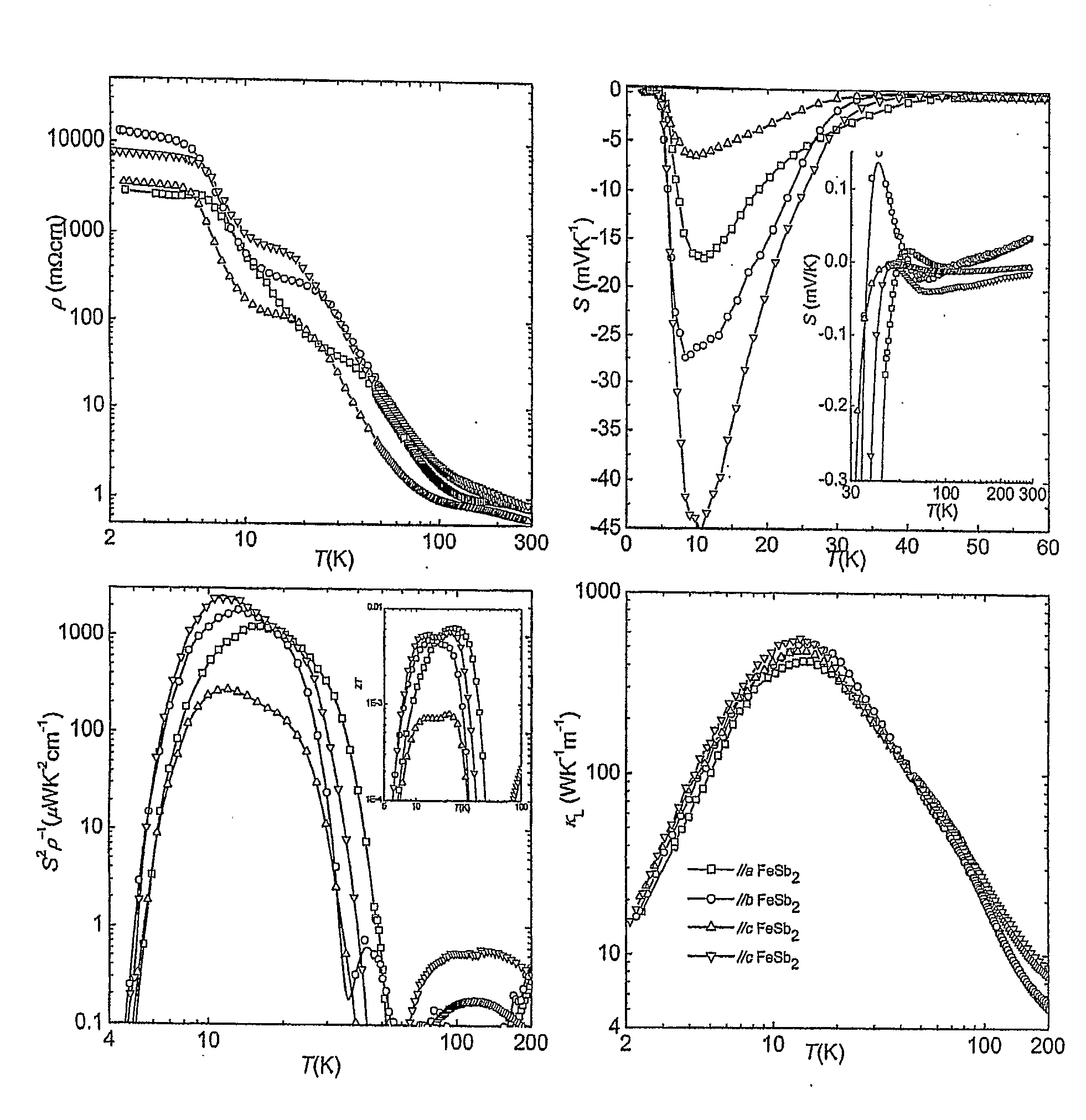

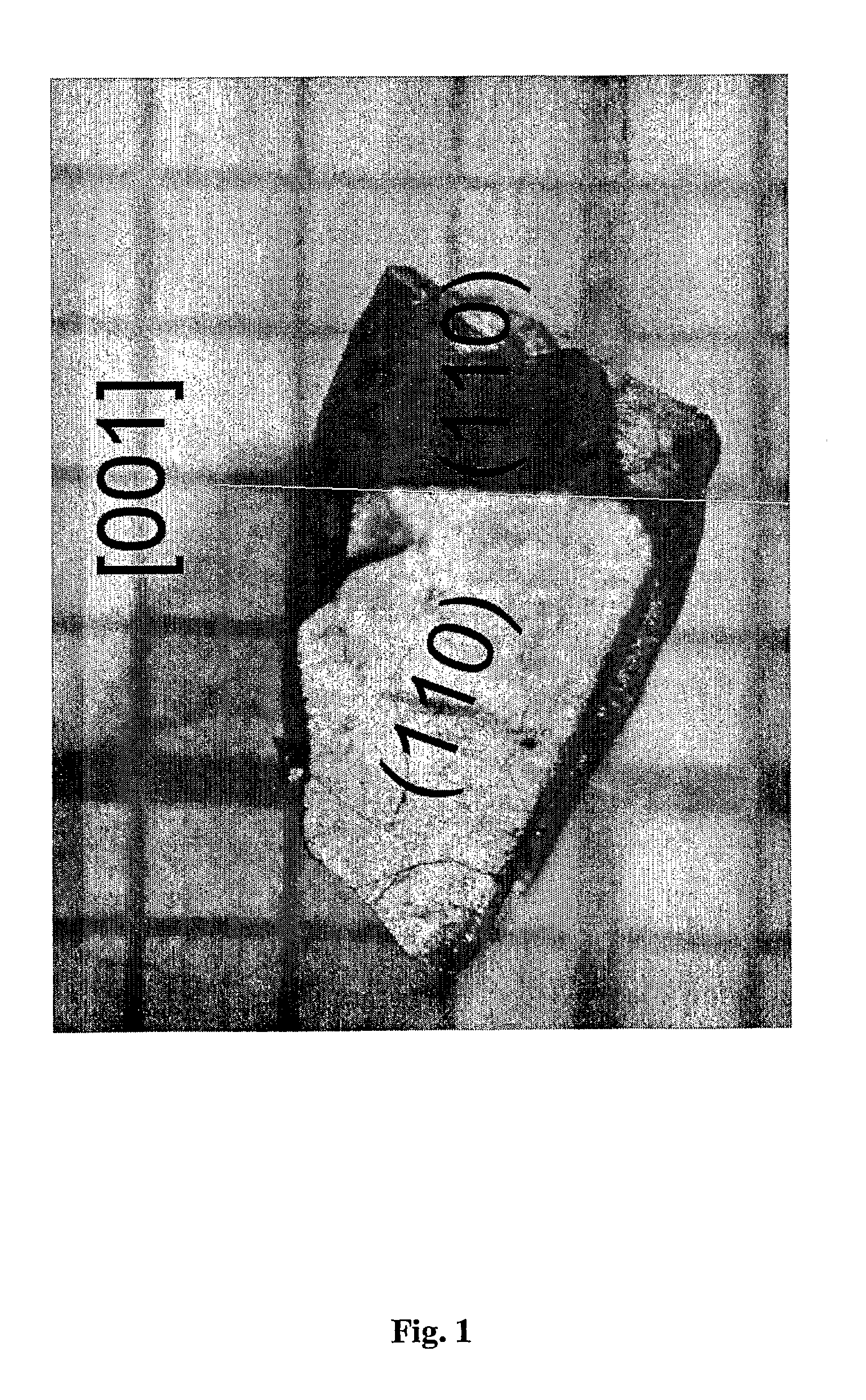

- A thermoelectric material with a stoichiometry corresponding to FeSb2, where Fe and Sb atoms are optionally substituted with various elements, exhibiting a power factor of 25 pW/cmK2 or more at 150 K or less, is developed. This material is manufactured through a process involving weighing and heating the constituent elements in an ampoule to form a melt, which is then cooled to obtain the thermoelectric material.

Thermoelectric generator

PatentWO2012045536A2

Innovation

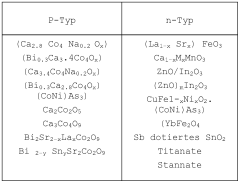

- A thermoelectric generator design featuring horizontally arranged layers with vertically running channels, utilizing a carrier matrix with platelet-shaped semiconductive particles and insulating layers to facilitate current flow along a temperature gradient, with oxidic semiconductor materials that offer improved conductivity and reduced thermal conductivity.

Environmental Impact and Sustainability Considerations

The integration of thermoelectric generators (TEGs) in low-temperature industrial waste heat recovery systems presents significant environmental and sustainability implications that extend beyond mere energy efficiency considerations. When selecting materials for TEGs, lifecycle assessment becomes a critical evaluation framework, encompassing raw material extraction, manufacturing processes, operational lifespan, and end-of-life management.

Material sourcing for thermoelectric components raises important environmental concerns, particularly regarding rare earth elements and heavy metals commonly used in high-performance TEGs. Elements such as tellurium, bismuth, and antimony face supply constraints and often involve environmentally damaging extraction processes. The mining operations associated with these materials can lead to habitat destruction, water pollution, and significant carbon emissions, necessitating careful consideration of material alternatives with lower environmental footprints.

Manufacturing processes for thermoelectric materials typically require high temperatures and energy-intensive procedures, contributing to the embodied energy of the final TEG systems. Advanced manufacturing techniques such as additive manufacturing and precision deposition methods offer potential pathways to reduce material waste and energy consumption during production. Additionally, the development of non-toxic, abundant material alternatives represents a promising direction for enhancing the sustainability profile of thermoelectric technologies.

The operational environmental benefits of TEGs in waste heat recovery applications must be quantified through comprehensive energy payback period calculations. For low-temperature applications, this analysis becomes particularly crucial as the lower conversion efficiencies may extend the time required for the system to offset its embodied environmental impact. Studies indicate that well-designed TEG systems in industrial settings can achieve energy payback periods of 1-3 years, depending on material selection and operational parameters.

End-of-life considerations present both challenges and opportunities for TEG sustainability. The recyclability of thermoelectric materials varies significantly, with some containing hazardous substances that require specialized disposal procedures. Designing for disassembly and material recovery can substantially improve the circular economy potential of these systems. Recent research into modular TEG designs facilitates easier component replacement and material reclamation, extending system lifespans and reducing waste.

Carbon footprint reduction represents a primary environmental benefit of implementing TEGs in industrial waste heat recovery. By converting otherwise wasted thermal energy into useful electricity, these systems can displace grid electricity generation, potentially reducing greenhouse gas emissions. Quantitative assessments indicate that industrial-scale TEG implementations can achieve carbon emission reductions of 0.5-2 tons CO2 equivalent per kW of installed capacity annually, depending on the regional electricity generation mix and operational parameters.

Material sourcing for thermoelectric components raises important environmental concerns, particularly regarding rare earth elements and heavy metals commonly used in high-performance TEGs. Elements such as tellurium, bismuth, and antimony face supply constraints and often involve environmentally damaging extraction processes. The mining operations associated with these materials can lead to habitat destruction, water pollution, and significant carbon emissions, necessitating careful consideration of material alternatives with lower environmental footprints.

Manufacturing processes for thermoelectric materials typically require high temperatures and energy-intensive procedures, contributing to the embodied energy of the final TEG systems. Advanced manufacturing techniques such as additive manufacturing and precision deposition methods offer potential pathways to reduce material waste and energy consumption during production. Additionally, the development of non-toxic, abundant material alternatives represents a promising direction for enhancing the sustainability profile of thermoelectric technologies.

The operational environmental benefits of TEGs in waste heat recovery applications must be quantified through comprehensive energy payback period calculations. For low-temperature applications, this analysis becomes particularly crucial as the lower conversion efficiencies may extend the time required for the system to offset its embodied environmental impact. Studies indicate that well-designed TEG systems in industrial settings can achieve energy payback periods of 1-3 years, depending on material selection and operational parameters.

End-of-life considerations present both challenges and opportunities for TEG sustainability. The recyclability of thermoelectric materials varies significantly, with some containing hazardous substances that require specialized disposal procedures. Designing for disassembly and material recovery can substantially improve the circular economy potential of these systems. Recent research into modular TEG designs facilitates easier component replacement and material reclamation, extending system lifespans and reducing waste.

Carbon footprint reduction represents a primary environmental benefit of implementing TEGs in industrial waste heat recovery. By converting otherwise wasted thermal energy into useful electricity, these systems can displace grid electricity generation, potentially reducing greenhouse gas emissions. Quantitative assessments indicate that industrial-scale TEG implementations can achieve carbon emission reductions of 0.5-2 tons CO2 equivalent per kW of installed capacity annually, depending on the regional electricity generation mix and operational parameters.

Cost-Benefit Analysis of TEG Implementation

Implementing thermoelectric generators (TEGs) for low-temperature industrial waste heat recovery requires careful cost-benefit analysis to determine economic viability. Initial capital expenditure for TEG systems includes material costs, manufacturing expenses, installation fees, and integration with existing industrial infrastructure. Material selection significantly impacts these costs, with higher-performance thermoelectric materials like bismuth telluride compounds commanding premium prices compared to silicon-germanium or lead telluride alternatives.

Operational expenses must be evaluated over the system's lifetime, including maintenance requirements, potential component replacements, and monitoring systems. TEG systems generally offer lower maintenance costs compared to traditional heat recovery methods due to their lack of moving parts, potentially reducing long-term operational expenditures by 15-30% depending on the industrial environment.

Energy savings represent the primary benefit stream, calculated by multiplying recovered electrical power by operational hours and electricity costs. For low-temperature waste heat streams (80-250°C), conversion efficiencies typically range from 2-8%, yielding payback periods between 3-7 years in most industrial applications. Secondary benefits include reduced cooling requirements for industrial processes and decreased carbon emissions, which may qualify for carbon credits or environmental incentives in certain jurisdictions.

Return on investment calculations must account for TEG degradation over time, with performance typically declining 0.5-2% annually depending on material selection and operating conditions. Sensitivity analysis reveals that electricity prices significantly impact economic viability—a 20% increase in electricity costs can reduce payback periods by approximately 15-18%.

Scale considerations demonstrate that larger implementations generally offer improved economics through economies of scale, with installation costs per kilowatt decreasing as system size increases. However, this advantage plateaus beyond certain implementation sizes due to limitations in waste heat availability and system complexity.

Comparative analysis against alternative waste heat recovery technologies shows that while organic Rankine cycle systems may offer higher efficiencies for larger applications, TEGs provide superior economics for distributed, smaller-scale recovery scenarios where maintenance simplicity and reliability are prioritized over maximum efficiency. This advantage becomes particularly pronounced in remote industrial settings where maintenance access is limited or costly.

Operational expenses must be evaluated over the system's lifetime, including maintenance requirements, potential component replacements, and monitoring systems. TEG systems generally offer lower maintenance costs compared to traditional heat recovery methods due to their lack of moving parts, potentially reducing long-term operational expenditures by 15-30% depending on the industrial environment.

Energy savings represent the primary benefit stream, calculated by multiplying recovered electrical power by operational hours and electricity costs. For low-temperature waste heat streams (80-250°C), conversion efficiencies typically range from 2-8%, yielding payback periods between 3-7 years in most industrial applications. Secondary benefits include reduced cooling requirements for industrial processes and decreased carbon emissions, which may qualify for carbon credits or environmental incentives in certain jurisdictions.

Return on investment calculations must account for TEG degradation over time, with performance typically declining 0.5-2% annually depending on material selection and operating conditions. Sensitivity analysis reveals that electricity prices significantly impact economic viability—a 20% increase in electricity costs can reduce payback periods by approximately 15-18%.

Scale considerations demonstrate that larger implementations generally offer improved economics through economies of scale, with installation costs per kilowatt decreasing as system size increases. However, this advantage plateaus beyond certain implementation sizes due to limitations in waste heat availability and system complexity.

Comparative analysis against alternative waste heat recovery technologies shows that while organic Rankine cycle systems may offer higher efficiencies for larger applications, TEGs provide superior economics for distributed, smaller-scale recovery scenarios where maintenance simplicity and reliability are prioritized over maximum efficiency. This advantage becomes particularly pronounced in remote industrial settings where maintenance access is limited or costly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!