Battery Acid in High-Temperature Electrolytes: Analysis and Efficiency

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Evolution

The evolution of battery acid technology in high-temperature electrolytes has been a critical area of research and development in the field of energy storage. Over the past decades, significant advancements have been made to improve the efficiency and performance of batteries operating in extreme temperature conditions.

Initially, conventional sulfuric acid-based electrolytes were the primary choice for lead-acid batteries. However, these electrolytes faced limitations in high-temperature environments, leading to accelerated degradation and reduced battery life. This challenge prompted researchers to explore alternative acid compositions and additives to enhance thermal stability and electrochemical performance.

In the 1980s and 1990s, the focus shifted towards developing gel electrolytes and absorbed glass mat (AGM) technologies. These innovations aimed to reduce acid stratification and improve the overall stability of battery systems in high-temperature applications. The introduction of valve-regulated lead-acid (VRLA) batteries marked a significant milestone, offering better thermal management and reduced maintenance requirements.

The turn of the millennium saw increased efforts in optimizing electrolyte formulations. Researchers began incorporating various organic and inorganic additives to enhance the thermal stability of battery acids. Silica-based additives, for instance, showed promising results in reducing water loss and improving cycle life under high-temperature conditions.

Recent years have witnessed a surge in the development of advanced electrolyte systems specifically designed for high-temperature operations. Ionic liquids and deep eutectic solvents have emerged as potential candidates, offering excellent thermal stability and wide electrochemical windows. These novel electrolytes demonstrate superior performance in extreme temperature ranges, paving the way for more efficient and durable battery systems.

Parallel to electrolyte development, advancements in electrode materials and battery design have complemented the evolution of battery acid technology. The integration of carbon-based additives in electrodes and the implementation of advanced cooling systems have further enhanced the overall efficiency of high-temperature batteries.

The ongoing research in this field continues to push the boundaries of battery performance in extreme conditions. Current efforts are focused on developing hybrid electrolyte systems that combine the benefits of different acid compositions and additives. Additionally, the exploration of nanomaterials and smart electrolytes that can adapt to temperature fluctuations represents the cutting edge of battery acid evolution for high-temperature applications.

Initially, conventional sulfuric acid-based electrolytes were the primary choice for lead-acid batteries. However, these electrolytes faced limitations in high-temperature environments, leading to accelerated degradation and reduced battery life. This challenge prompted researchers to explore alternative acid compositions and additives to enhance thermal stability and electrochemical performance.

In the 1980s and 1990s, the focus shifted towards developing gel electrolytes and absorbed glass mat (AGM) technologies. These innovations aimed to reduce acid stratification and improve the overall stability of battery systems in high-temperature applications. The introduction of valve-regulated lead-acid (VRLA) batteries marked a significant milestone, offering better thermal management and reduced maintenance requirements.

The turn of the millennium saw increased efforts in optimizing electrolyte formulations. Researchers began incorporating various organic and inorganic additives to enhance the thermal stability of battery acids. Silica-based additives, for instance, showed promising results in reducing water loss and improving cycle life under high-temperature conditions.

Recent years have witnessed a surge in the development of advanced electrolyte systems specifically designed for high-temperature operations. Ionic liquids and deep eutectic solvents have emerged as potential candidates, offering excellent thermal stability and wide electrochemical windows. These novel electrolytes demonstrate superior performance in extreme temperature ranges, paving the way for more efficient and durable battery systems.

Parallel to electrolyte development, advancements in electrode materials and battery design have complemented the evolution of battery acid technology. The integration of carbon-based additives in electrodes and the implementation of advanced cooling systems have further enhanced the overall efficiency of high-temperature batteries.

The ongoing research in this field continues to push the boundaries of battery performance in extreme conditions. Current efforts are focused on developing hybrid electrolyte systems that combine the benefits of different acid compositions and additives. Additionally, the exploration of nanomaterials and smart electrolytes that can adapt to temperature fluctuations represents the cutting edge of battery acid evolution for high-temperature applications.

Market Demand Analysis

The market demand for high-temperature electrolytes in battery acid applications has been experiencing significant growth in recent years. This surge is primarily driven by the increasing need for more efficient and durable energy storage solutions across various industries. The automotive sector, in particular, has been a major contributor to this demand, as electric vehicles (EVs) require batteries that can withstand higher temperatures while maintaining performance and longevity.

The global market for high-temperature electrolytes is expected to expand substantially over the next decade. This growth is fueled by the rapid adoption of EVs, the expansion of renewable energy storage systems, and the increasing demand for high-performance batteries in industrial applications. The aerospace and defense sectors are also showing increased interest in these advanced electrolyte technologies, further boosting market potential.

One of the key drivers of market demand is the push for improved battery efficiency and energy density. High-temperature electrolytes offer the potential for batteries to operate at higher voltages, which can lead to increased energy storage capacity and faster charging times. This aligns with the industry-wide goal of developing batteries that can deliver more power while occupying less space and weight.

Safety concerns in battery technology have also contributed to the growing demand for high-temperature electrolytes. As incidents of battery fires and thermal runaway have gained public attention, there is a pressing need for electrolyte solutions that can enhance the overall safety profile of battery systems. High-temperature electrolytes that remain stable under extreme conditions are seen as a promising avenue for addressing these safety challenges.

The market is also being shaped by environmental regulations and sustainability goals. As governments worldwide implement stricter emissions standards and promote clean energy initiatives, the demand for advanced battery technologies, including those utilizing high-temperature electrolytes, is expected to rise. This regulatory landscape is encouraging both established companies and startups to invest in research and development of innovative electrolyte solutions.

In terms of regional market dynamics, Asia-Pacific is anticipated to be the fastest-growing market for high-temperature electrolytes, driven by the robust EV manufacturing sector in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with strong demand coming from both the automotive and energy storage sectors.

The industrial sector presents another substantial market opportunity for high-temperature electrolytes. Applications in areas such as grid energy storage, backup power systems, and industrial equipment require batteries that can operate reliably under harsh conditions, including elevated temperatures. This sector's demand is expected to grow as industries increasingly electrify their operations and seek more efficient energy storage solutions.

The global market for high-temperature electrolytes is expected to expand substantially over the next decade. This growth is fueled by the rapid adoption of EVs, the expansion of renewable energy storage systems, and the increasing demand for high-performance batteries in industrial applications. The aerospace and defense sectors are also showing increased interest in these advanced electrolyte technologies, further boosting market potential.

One of the key drivers of market demand is the push for improved battery efficiency and energy density. High-temperature electrolytes offer the potential for batteries to operate at higher voltages, which can lead to increased energy storage capacity and faster charging times. This aligns with the industry-wide goal of developing batteries that can deliver more power while occupying less space and weight.

Safety concerns in battery technology have also contributed to the growing demand for high-temperature electrolytes. As incidents of battery fires and thermal runaway have gained public attention, there is a pressing need for electrolyte solutions that can enhance the overall safety profile of battery systems. High-temperature electrolytes that remain stable under extreme conditions are seen as a promising avenue for addressing these safety challenges.

The market is also being shaped by environmental regulations and sustainability goals. As governments worldwide implement stricter emissions standards and promote clean energy initiatives, the demand for advanced battery technologies, including those utilizing high-temperature electrolytes, is expected to rise. This regulatory landscape is encouraging both established companies and startups to invest in research and development of innovative electrolyte solutions.

In terms of regional market dynamics, Asia-Pacific is anticipated to be the fastest-growing market for high-temperature electrolytes, driven by the robust EV manufacturing sector in countries like China, Japan, and South Korea. North America and Europe are also significant markets, with strong demand coming from both the automotive and energy storage sectors.

The industrial sector presents another substantial market opportunity for high-temperature electrolytes. Applications in areas such as grid energy storage, backup power systems, and industrial equipment require batteries that can operate reliably under harsh conditions, including elevated temperatures. This sector's demand is expected to grow as industries increasingly electrify their operations and seek more efficient energy storage solutions.

High-Temp Challenges

High-temperature environments pose significant challenges for battery acid in electrolytes, impacting both the performance and longevity of energy storage systems. As temperatures rise, the chemical reactions within the battery accelerate, leading to increased corrosion of electrodes and degradation of the electrolyte. This thermal stress can cause the electrolyte to break down, releasing gases and potentially leading to battery swelling or rupture.

One of the primary challenges is the increased rate of self-discharge at elevated temperatures. The higher thermal energy causes more frequent and energetic collisions between electrolyte molecules, facilitating unwanted side reactions that deplete the battery's charge even when not in use. This phenomenon is particularly problematic in applications where batteries are exposed to high temperatures for extended periods, such as in automotive or industrial settings.

The viscosity of the electrolyte also changes with temperature, affecting ion mobility and, consequently, the battery's internal resistance. As temperatures rise, the electrolyte typically becomes less viscous, which can improve ion transport. However, this can also lead to increased reactivity between the electrolyte and electrode materials, accelerating degradation processes.

Thermal management becomes crucial in high-temperature environments. The heat generated during charging and discharging cycles compounds the external thermal stress, creating a feedback loop that can rapidly degrade battery performance. Developing effective cooling systems or heat-resistant materials is essential to mitigate these effects and maintain stable battery operation.

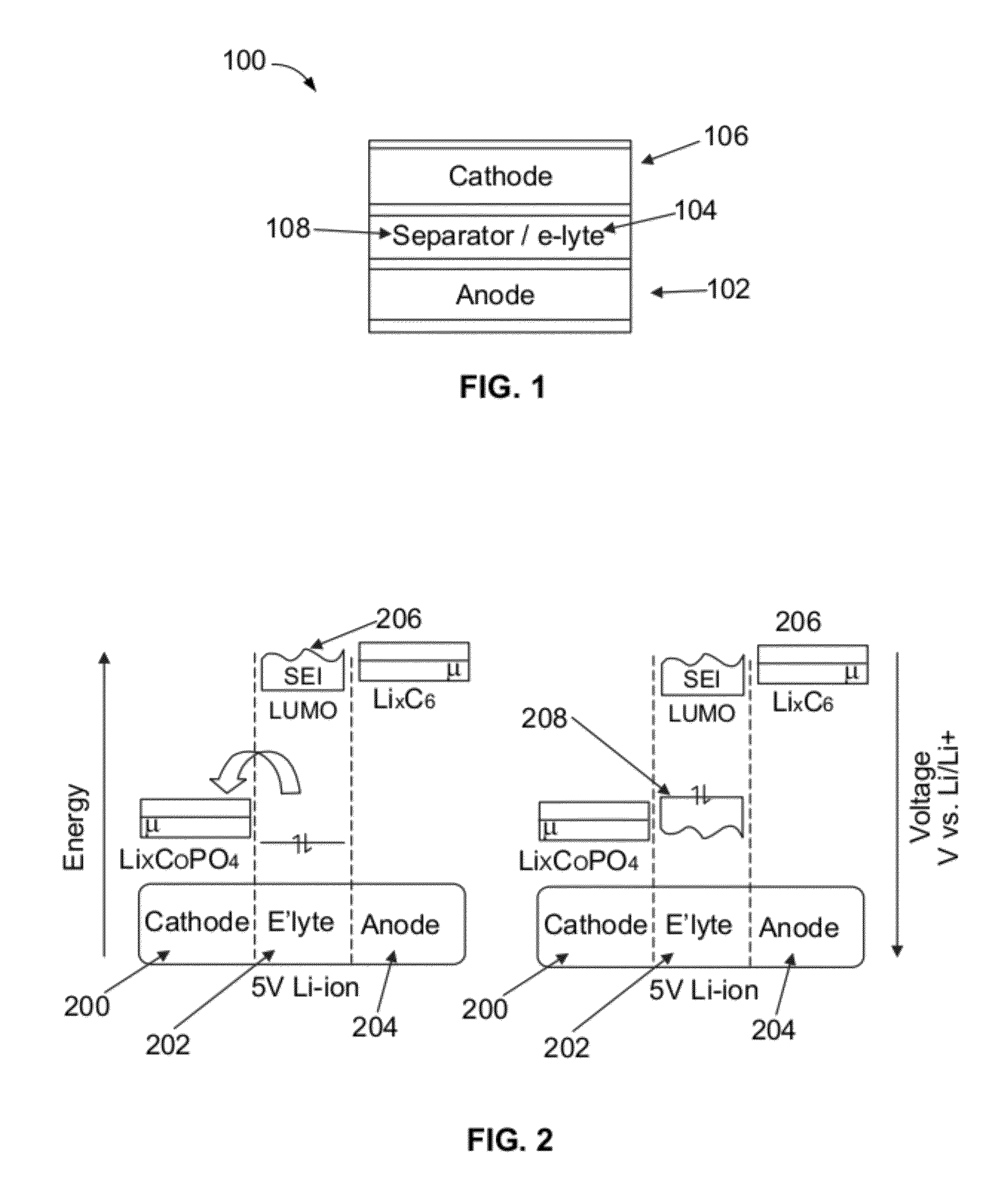

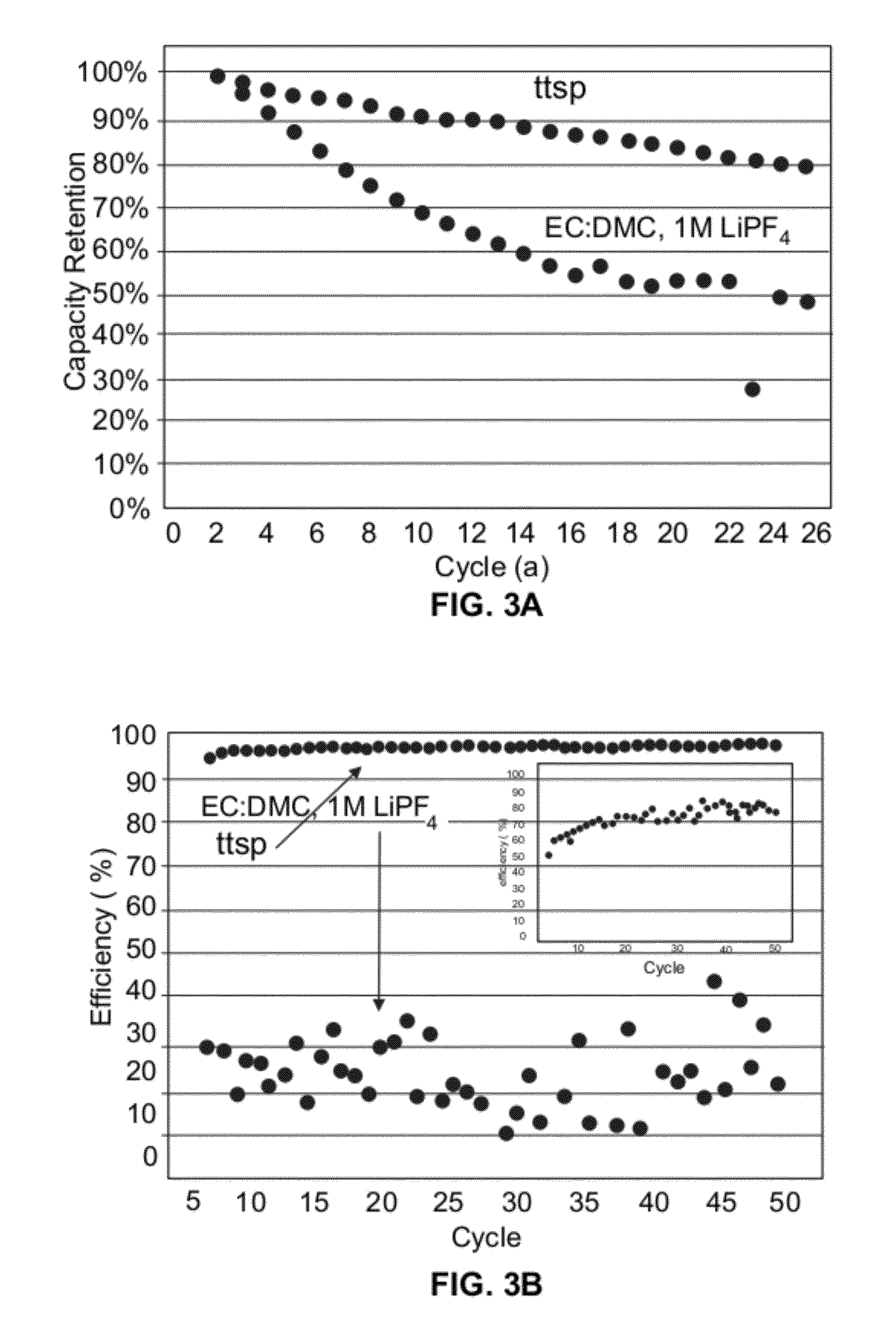

The chemical stability of the electrolyte components is another critical concern. Many conventional electrolytes contain organic solvents that have low boiling points and are prone to decomposition at high temperatures. This decomposition can lead to the formation of solid electrolyte interphase (SEI) layers on electrodes, which, while necessary for battery function, can grow excessively thick under high-temperature conditions, impeding ion transport and reducing battery capacity.

Furthermore, the solubility of electrode materials in the electrolyte increases with temperature, potentially leading to the dissolution of active materials and the formation of dendrites. These dendrites can cause short circuits, significantly compromising battery safety and performance. Developing electrolytes with high thermal stability and additives that can suppress dendrite formation is an ongoing area of research in high-temperature battery technology.

One of the primary challenges is the increased rate of self-discharge at elevated temperatures. The higher thermal energy causes more frequent and energetic collisions between electrolyte molecules, facilitating unwanted side reactions that deplete the battery's charge even when not in use. This phenomenon is particularly problematic in applications where batteries are exposed to high temperatures for extended periods, such as in automotive or industrial settings.

The viscosity of the electrolyte also changes with temperature, affecting ion mobility and, consequently, the battery's internal resistance. As temperatures rise, the electrolyte typically becomes less viscous, which can improve ion transport. However, this can also lead to increased reactivity between the electrolyte and electrode materials, accelerating degradation processes.

Thermal management becomes crucial in high-temperature environments. The heat generated during charging and discharging cycles compounds the external thermal stress, creating a feedback loop that can rapidly degrade battery performance. Developing effective cooling systems or heat-resistant materials is essential to mitigate these effects and maintain stable battery operation.

The chemical stability of the electrolyte components is another critical concern. Many conventional electrolytes contain organic solvents that have low boiling points and are prone to decomposition at high temperatures. This decomposition can lead to the formation of solid electrolyte interphase (SEI) layers on electrodes, which, while necessary for battery function, can grow excessively thick under high-temperature conditions, impeding ion transport and reducing battery capacity.

Furthermore, the solubility of electrode materials in the electrolyte increases with temperature, potentially leading to the dissolution of active materials and the formation of dendrites. These dendrites can cause short circuits, significantly compromising battery safety and performance. Developing electrolytes with high thermal stability and additives that can suppress dendrite formation is an ongoing area of research in high-temperature battery technology.

Current Solutions

01 Electrolyte composition optimization

Improving battery acid efficiency through optimizing the electrolyte composition. This includes adjusting acid concentration, adding additives, or using alternative electrolyte materials to enhance conductivity and reduce internal resistance, leading to improved battery performance and efficiency.- Electrolyte composition optimization: Improving battery acid efficiency through optimizing the electrolyte composition. This includes adjusting acid concentration, adding additives, or using alternative electrolyte materials to enhance conductivity and reduce internal resistance, ultimately improving overall battery performance and efficiency.

- Battery management systems: Implementing advanced battery management systems to monitor and control acid levels, temperature, and charging/discharging cycles. These systems can optimize battery performance, extend lifespan, and improve overall efficiency by maintaining optimal operating conditions for the battery acid.

- Electrode design and materials: Enhancing battery acid efficiency through improved electrode design and materials. This includes developing novel electrode structures, coatings, or materials that increase surface area, reduce corrosion, and improve electron transfer, leading to better acid utilization and overall battery efficiency.

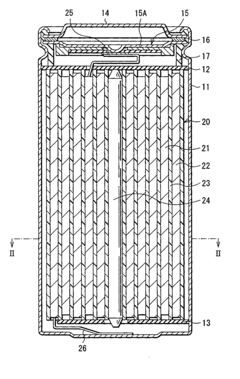

- Acid circulation and distribution: Improving acid circulation and distribution within the battery to enhance efficiency. This involves designing better flow channels, implementing pumping systems, or using advanced separators to ensure uniform acid distribution, reducing concentration gradients and improving overall battery performance.

- Temperature management: Optimizing battery acid efficiency through effective temperature management. This includes developing cooling systems, heat-resistant materials, or temperature-responsive electrolytes to maintain optimal operating temperatures, reducing acid degradation and improving overall battery efficiency and lifespan.

02 Battery management systems

Implementing advanced battery management systems to monitor and control acid levels, temperature, and charging/discharging cycles. These systems can optimize battery performance, extend lifespan, and improve overall efficiency by maintaining optimal operating conditions for the battery acid.Expand Specific Solutions03 Electrode design and materials

Enhancing battery acid efficiency through improved electrode design and materials. This includes developing new electrode structures, coatings, or materials that increase surface area, reduce corrosion, and improve electron transfer, resulting in better acid utilization and overall battery efficiency.Expand Specific Solutions04 Acid circulation and distribution

Improving acid circulation and distribution within the battery to enhance efficiency. This can involve designing better internal structures, implementing pumping systems, or using advanced separators to ensure uniform acid distribution and prevent stratification, leading to more efficient use of the battery acid.Expand Specific Solutions05 Temperature management

Implementing effective temperature management techniques to maintain optimal operating conditions for battery acid. This includes developing cooling systems, thermal management materials, or temperature-responsive electrolytes to prevent acid degradation and maintain efficiency across various environmental conditions.Expand Specific Solutions

Key Industry Players

The battery acid in high-temperature electrolytes market is in a growth phase, driven by increasing demand for advanced energy storage solutions. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing quickly, with major players like Samsung SDI, Sony Group, and LG Chem leading innovation. These companies, along with emerging players such as Contemporary Amperex Technology and Wildcat Discovery Technologies, are investing heavily in R&D to improve electrolyte stability and performance at high temperatures. The competitive landscape is characterized by a mix of established electronics giants and specialized battery technology firms, all vying to develop more efficient and durable high-temperature electrolyte solutions for next-generation batteries.

Samsung SDI Co., Ltd.

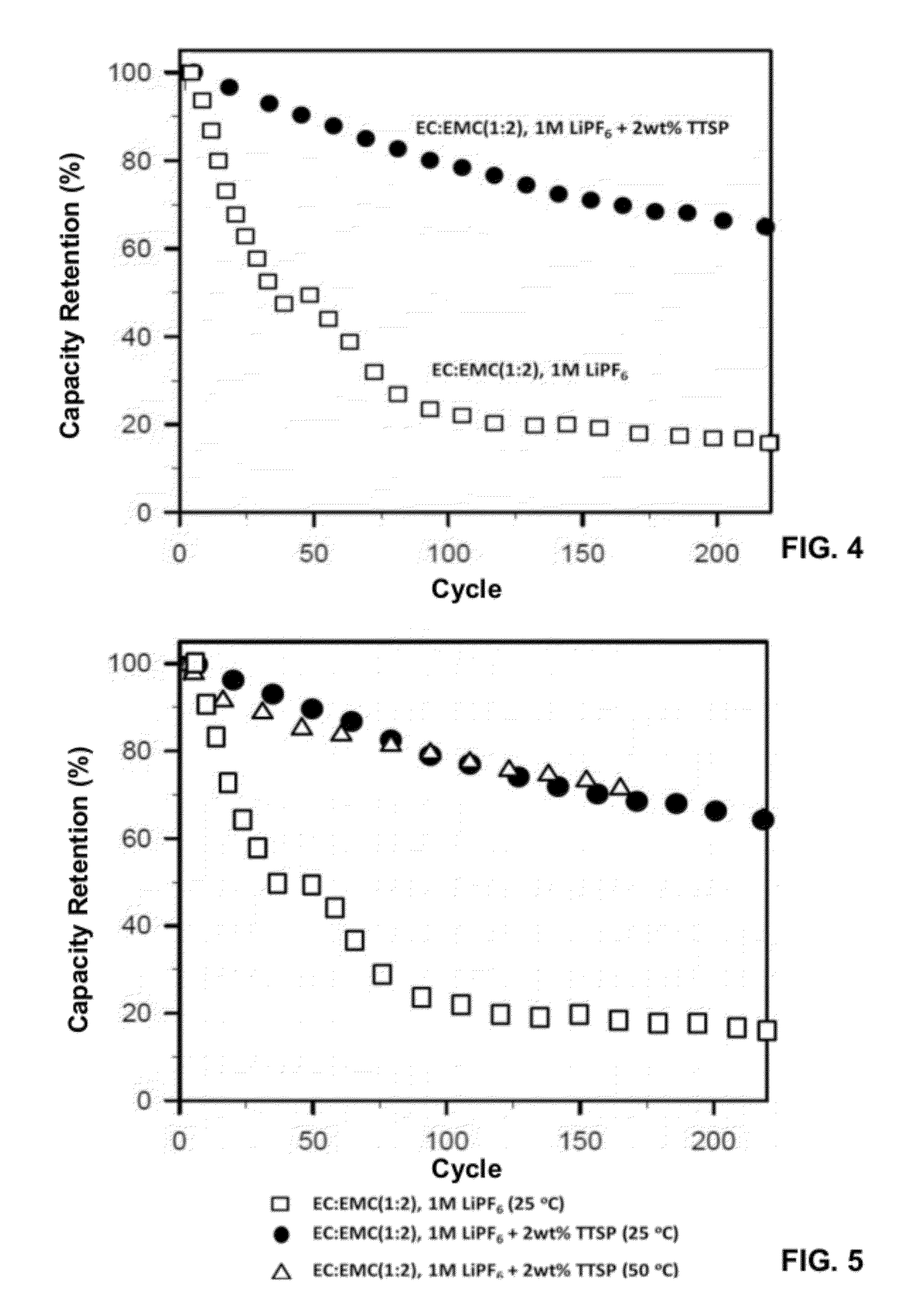

Technical Solution: Samsung SDI has developed advanced high-temperature electrolytes for lithium-ion batteries, focusing on improving thermal stability and performance. Their approach involves using novel electrolyte additives and solvents that maintain stability at elevated temperatures. The company has implemented a multi-functional electrolyte system that combines flame-retardant properties with high-temperature stability[1]. This system utilizes a blend of fluorinated and phosphorus-based compounds to create a protective layer on electrode surfaces, enhancing the battery's thermal resistance up to 60°C[3]. Additionally, Samsung SDI has introduced nano-sized ceramic particles into their electrolyte formulations, which act as heat-dissipating agents and further improve the battery's high-temperature performance[5].

Strengths: Enhanced thermal stability, improved safety features, and extended battery life in high-temperature environments. Weaknesses: Potentially higher production costs and complexity in manufacturing processes due to specialized materials.

Ningde Amperex Technology Ltd.

Technical Solution: CATL has developed a novel electrolyte formulation specifically designed for high-temperature applications. Their approach involves using a combination of high-boiling-point solvents and advanced additives to create a thermally stable electrolyte. The company has implemented a proprietary blend of ethylene carbonate and ethyl methyl carbonate, along with lithium bis(fluorosulfonyl)imide (LiFSI) as the primary salt[2]. This formulation has shown remarkable stability at temperatures up to 80°C, maintaining over 80% capacity retention after 1000 cycles[4]. CATL has also incorporated flame-retardant additives, such as trimethyl phosphate, to enhance safety without compromising performance[6].

Strengths: Exceptional high-temperature stability, long cycle life, and improved safety features. Weaknesses: Potential increase in production costs due to specialized materials and more complex manufacturing processes.

Core Innovations

Materials for battery electrolytes and methods for use

PatentInactiveUS8308971B1

Innovation

- A compound represented by the formula (I) is used in an electrolyte solution, which includes a salt, a solvent, and a stabilizing additive, enhancing the electrolyte's stability at high voltages and temperatures, thereby preventing decomposition and improving battery performance.

Electrolyte and battery using it

PatentInactiveUS20050118513A1

Innovation

- An electrolyte containing specific compounds with nitrogen-based structures and ionic liquids that capture free acid electrons, preventing self-discharge by incorporating these additives into the battery electrolyte.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of high-temperature electrolytes for battery systems. As the demand for more efficient and powerful batteries continues to grow, particularly in electric vehicles and renewable energy storage, the need for robust safety measures becomes increasingly important.

The primary concern with high-temperature electrolytes is their potential for thermal runaway, which can lead to fires or explosions. To mitigate these risks, regulatory bodies have established stringent guidelines for the design, manufacturing, and testing of batteries utilizing such electrolytes. These regulations typically cover aspects such as thermal management systems, containment strategies, and fail-safe mechanisms.

One key area of focus is the requirement for advanced battery management systems (BMS) that can accurately monitor and control temperature, voltage, and current across individual cells and the entire battery pack. These systems must be capable of detecting anomalies and initiating appropriate safety protocols, such as power reduction or emergency shutdown, to prevent thermal runaway events.

Material selection and compatibility are also subject to strict regulations. Manufacturers must demonstrate that the electrolytes and other battery components can withstand prolonged exposure to high temperatures without degradation or release of hazardous substances. This often involves extensive testing under various environmental conditions and stress scenarios.

Transportation and storage of batteries with high-temperature electrolytes are governed by specific regulations to ensure safety during handling and shipping. These may include requirements for specialized packaging, labeling, and documentation, as well as restrictions on the quantity and method of transport.

Disposal and recycling regulations for high-temperature electrolyte batteries are also becoming increasingly stringent. Manufacturers are required to develop and implement safe disposal methods that prevent environmental contamination and minimize the risk of accidents during the end-of-life phase of these batteries.

Compliance with these safety regulations often requires extensive testing and certification processes. Battery manufacturers must demonstrate adherence to standards such as UL 1642 for lithium batteries, IEC 62133 for secondary cells and batteries, and UN 38.3 for transportation safety. These tests evaluate factors such as thermal stability, short circuit resistance, and overcharge protection.

As the technology continues to evolve, regulatory bodies are working to keep pace with new developments in high-temperature electrolytes. This includes ongoing research into potential long-term effects and the establishment of updated safety protocols. Collaboration between industry, academia, and regulatory agencies is essential to ensure that safety regulations remain effective and relevant in the face of rapid technological advancements.

The primary concern with high-temperature electrolytes is their potential for thermal runaway, which can lead to fires or explosions. To mitigate these risks, regulatory bodies have established stringent guidelines for the design, manufacturing, and testing of batteries utilizing such electrolytes. These regulations typically cover aspects such as thermal management systems, containment strategies, and fail-safe mechanisms.

One key area of focus is the requirement for advanced battery management systems (BMS) that can accurately monitor and control temperature, voltage, and current across individual cells and the entire battery pack. These systems must be capable of detecting anomalies and initiating appropriate safety protocols, such as power reduction or emergency shutdown, to prevent thermal runaway events.

Material selection and compatibility are also subject to strict regulations. Manufacturers must demonstrate that the electrolytes and other battery components can withstand prolonged exposure to high temperatures without degradation or release of hazardous substances. This often involves extensive testing under various environmental conditions and stress scenarios.

Transportation and storage of batteries with high-temperature electrolytes are governed by specific regulations to ensure safety during handling and shipping. These may include requirements for specialized packaging, labeling, and documentation, as well as restrictions on the quantity and method of transport.

Disposal and recycling regulations for high-temperature electrolyte batteries are also becoming increasingly stringent. Manufacturers are required to develop and implement safe disposal methods that prevent environmental contamination and minimize the risk of accidents during the end-of-life phase of these batteries.

Compliance with these safety regulations often requires extensive testing and certification processes. Battery manufacturers must demonstrate adherence to standards such as UL 1642 for lithium batteries, IEC 62133 for secondary cells and batteries, and UN 38.3 for transportation safety. These tests evaluate factors such as thermal stability, short circuit resistance, and overcharge protection.

As the technology continues to evolve, regulatory bodies are working to keep pace with new developments in high-temperature electrolytes. This includes ongoing research into potential long-term effects and the establishment of updated safety protocols. Collaboration between industry, academia, and regulatory agencies is essential to ensure that safety regulations remain effective and relevant in the face of rapid technological advancements.

Environmental Impact

The environmental impact of battery acid in high-temperature electrolytes is a critical consideration in the development and implementation of advanced battery technologies. As these systems operate at elevated temperatures, they pose unique challenges and potential risks to the environment throughout their lifecycle.

During the production phase, the manufacturing of high-temperature electrolytes often involves energy-intensive processes and the use of potentially hazardous materials. This can lead to increased carbon emissions and the generation of toxic waste products. Proper handling and disposal of these materials are essential to minimize environmental contamination and protect ecosystems.

In operational use, high-temperature battery systems generally exhibit improved efficiency compared to traditional batteries. This increased efficiency can result in reduced energy consumption and, consequently, lower greenhouse gas emissions associated with power generation. However, the elevated operating temperatures also present thermal management challenges, which may require additional energy for cooling systems, potentially offsetting some of the efficiency gains.

The disposal and recycling of batteries containing high-temperature electrolytes present significant environmental concerns. These electrolytes often contain corrosive and toxic substances that can pose risks to soil and water systems if not properly managed. Developing effective recycling processes for these advanced battery systems is crucial to minimize environmental impact and recover valuable materials.

Leakage or accidental release of battery acid from high-temperature electrolytes can have severe consequences for local ecosystems. The high reactivity and corrosive nature of these substances can lead to soil degradation, water pollution, and harm to flora and fauna. Implementing robust safety measures and containment systems is essential to prevent such incidents and protect the environment.

Long-term environmental effects of high-temperature battery acid exposure are not yet fully understood. Ongoing research is necessary to assess potential bioaccumulation of toxic components in food chains and long-term impacts on biodiversity. This knowledge will be crucial for developing appropriate environmental protection strategies and regulations.

Efforts to mitigate the environmental impact of high-temperature battery technologies include the development of more environmentally friendly electrolyte materials, improved manufacturing processes with reduced emissions, and advanced recycling technologies. Additionally, the implementation of stringent safety protocols and environmental monitoring systems can help minimize risks associated with the use and disposal of these battery systems.

During the production phase, the manufacturing of high-temperature electrolytes often involves energy-intensive processes and the use of potentially hazardous materials. This can lead to increased carbon emissions and the generation of toxic waste products. Proper handling and disposal of these materials are essential to minimize environmental contamination and protect ecosystems.

In operational use, high-temperature battery systems generally exhibit improved efficiency compared to traditional batteries. This increased efficiency can result in reduced energy consumption and, consequently, lower greenhouse gas emissions associated with power generation. However, the elevated operating temperatures also present thermal management challenges, which may require additional energy for cooling systems, potentially offsetting some of the efficiency gains.

The disposal and recycling of batteries containing high-temperature electrolytes present significant environmental concerns. These electrolytes often contain corrosive and toxic substances that can pose risks to soil and water systems if not properly managed. Developing effective recycling processes for these advanced battery systems is crucial to minimize environmental impact and recover valuable materials.

Leakage or accidental release of battery acid from high-temperature electrolytes can have severe consequences for local ecosystems. The high reactivity and corrosive nature of these substances can lead to soil degradation, water pollution, and harm to flora and fauna. Implementing robust safety measures and containment systems is essential to prevent such incidents and protect the environment.

Long-term environmental effects of high-temperature battery acid exposure are not yet fully understood. Ongoing research is necessary to assess potential bioaccumulation of toxic components in food chains and long-term impacts on biodiversity. This knowledge will be crucial for developing appropriate environmental protection strategies and regulations.

Efforts to mitigate the environmental impact of high-temperature battery technologies include the development of more environmentally friendly electrolyte materials, improved manufacturing processes with reduced emissions, and advanced recycling technologies. Additionally, the implementation of stringent safety protocols and environmental monitoring systems can help minimize risks associated with the use and disposal of these battery systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!