State-of-the-art Battery Acid Sequestration Methods

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Evolution

Battery acid, primarily composed of sulfuric acid and water, has undergone significant evolution since its inception in the early days of battery technology. The development of battery acid has been closely tied to the advancement of battery systems, particularly lead-acid batteries, which have been in use for over a century.

In the early stages of battery development, the concentration and purity of sulfuric acid used in batteries were relatively low, leading to reduced efficiency and shorter battery life. As understanding of electrochemistry improved, researchers began to optimize the acid composition to enhance battery performance.

The 1920s and 1930s saw a major breakthrough with the introduction of maintenance-free batteries, which utilized a more stable acid composition that reduced water loss and minimized the need for regular acid top-ups. This innovation significantly improved the practicality and reliability of batteries for automotive and industrial applications.

During the mid-20th century, advancements in manufacturing processes allowed for the production of higher purity sulfuric acid, resulting in improved battery performance and longevity. The introduction of additives to the acid, such as organic expanders and metal ions, further enhanced the electrochemical properties of batteries.

In recent decades, the focus has shifted towards developing safer and more environmentally friendly battery acid formulations. This has led to the exploration of gel electrolytes and absorbed glass mat (AGM) technologies, which immobilize the acid and reduce the risk of leaks and spills.

The advent of lithium-ion batteries in the 1990s brought about a paradigm shift in battery technology, moving away from traditional sulfuric acid-based electrolytes. However, research into improving lead-acid battery acid continues, driven by the need for more sustainable and cost-effective energy storage solutions.

Current research in battery acid evolution is centered on developing advanced electrolyte formulations that can enhance the charge acceptance, cycle life, and overall efficiency of batteries. This includes the exploration of novel additives, such as carbon nanotubes and graphene, which can modify the electrochemical properties of the acid and improve battery performance.

The evolution of battery acid has also been influenced by environmental concerns and regulations. Efforts to reduce the environmental impact of batteries have led to the development of acid recycling technologies and the exploration of alternative, less corrosive electrolytes.

As we look to the future, the evolution of battery acid is likely to continue, with a focus on developing more sustainable, efficient, and safe formulations. This ongoing research is crucial for addressing the growing demand for energy storage solutions in various applications, from renewable energy systems to electric vehicles.

In the early stages of battery development, the concentration and purity of sulfuric acid used in batteries were relatively low, leading to reduced efficiency and shorter battery life. As understanding of electrochemistry improved, researchers began to optimize the acid composition to enhance battery performance.

The 1920s and 1930s saw a major breakthrough with the introduction of maintenance-free batteries, which utilized a more stable acid composition that reduced water loss and minimized the need for regular acid top-ups. This innovation significantly improved the practicality and reliability of batteries for automotive and industrial applications.

During the mid-20th century, advancements in manufacturing processes allowed for the production of higher purity sulfuric acid, resulting in improved battery performance and longevity. The introduction of additives to the acid, such as organic expanders and metal ions, further enhanced the electrochemical properties of batteries.

In recent decades, the focus has shifted towards developing safer and more environmentally friendly battery acid formulations. This has led to the exploration of gel electrolytes and absorbed glass mat (AGM) technologies, which immobilize the acid and reduce the risk of leaks and spills.

The advent of lithium-ion batteries in the 1990s brought about a paradigm shift in battery technology, moving away from traditional sulfuric acid-based electrolytes. However, research into improving lead-acid battery acid continues, driven by the need for more sustainable and cost-effective energy storage solutions.

Current research in battery acid evolution is centered on developing advanced electrolyte formulations that can enhance the charge acceptance, cycle life, and overall efficiency of batteries. This includes the exploration of novel additives, such as carbon nanotubes and graphene, which can modify the electrochemical properties of the acid and improve battery performance.

The evolution of battery acid has also been influenced by environmental concerns and regulations. Efforts to reduce the environmental impact of batteries have led to the development of acid recycling technologies and the exploration of alternative, less corrosive electrolytes.

As we look to the future, the evolution of battery acid is likely to continue, with a focus on developing more sustainable, efficient, and safe formulations. This ongoing research is crucial for addressing the growing demand for energy storage solutions in various applications, from renewable energy systems to electric vehicles.

Market Demand Analysis

The market demand for advanced battery acid sequestration methods has been steadily increasing in recent years, driven by the rapid growth of the electric vehicle (EV) and renewable energy storage sectors. As these industries continue to expand, the need for safer, more efficient, and environmentally friendly battery technologies becomes paramount.

The global lithium-ion battery market, which is closely tied to acid sequestration technologies, is projected to grow significantly in the coming years. This growth is primarily fueled by the increasing adoption of EVs, with major automotive manufacturers committing to electrifying their fleets. Additionally, the rising demand for grid-scale energy storage systems to support renewable energy integration is contributing to the market expansion.

Battery acid sequestration methods play a crucial role in addressing safety concerns associated with battery technologies. The potential for acid leakage or spills in conventional batteries poses risks to both users and the environment. As a result, there is a growing demand for innovative sequestration techniques that can effectively contain and neutralize battery acids, reducing the likelihood of accidents and environmental contamination.

The industrial sector, particularly manufacturing and telecommunications, is also driving demand for improved battery acid sequestration methods. These industries rely heavily on uninterruptible power supply (UPS) systems and backup power solutions, which often utilize lead-acid batteries. Enhanced sequestration technologies can extend battery life, improve safety, and reduce maintenance costs in these applications.

Environmental regulations and sustainability initiatives are further propelling the market for advanced acid sequestration methods. Governments worldwide are implementing stricter guidelines for battery disposal and recycling, creating a need for technologies that facilitate safer handling and processing of spent batteries. This regulatory landscape is encouraging battery manufacturers to invest in research and development of more environmentally friendly sequestration solutions.

The consumer electronics market, while not the primary driver, is also contributing to the demand for improved battery acid sequestration. As portable devices become more powerful and energy-intensive, there is a growing emphasis on battery safety and longevity. Consumers are increasingly aware of potential battery-related hazards, creating a market for devices with enhanced safety features, including better acid containment.

In the aerospace and defense sectors, there is a specialized demand for high-performance batteries with advanced sequestration capabilities. These industries require batteries that can withstand extreme conditions while maintaining the highest safety standards. The development of cutting-edge sequestration methods is essential to meet these stringent requirements and open up new applications in these high-value markets.

The global lithium-ion battery market, which is closely tied to acid sequestration technologies, is projected to grow significantly in the coming years. This growth is primarily fueled by the increasing adoption of EVs, with major automotive manufacturers committing to electrifying their fleets. Additionally, the rising demand for grid-scale energy storage systems to support renewable energy integration is contributing to the market expansion.

Battery acid sequestration methods play a crucial role in addressing safety concerns associated with battery technologies. The potential for acid leakage or spills in conventional batteries poses risks to both users and the environment. As a result, there is a growing demand for innovative sequestration techniques that can effectively contain and neutralize battery acids, reducing the likelihood of accidents and environmental contamination.

The industrial sector, particularly manufacturing and telecommunications, is also driving demand for improved battery acid sequestration methods. These industries rely heavily on uninterruptible power supply (UPS) systems and backup power solutions, which often utilize lead-acid batteries. Enhanced sequestration technologies can extend battery life, improve safety, and reduce maintenance costs in these applications.

Environmental regulations and sustainability initiatives are further propelling the market for advanced acid sequestration methods. Governments worldwide are implementing stricter guidelines for battery disposal and recycling, creating a need for technologies that facilitate safer handling and processing of spent batteries. This regulatory landscape is encouraging battery manufacturers to invest in research and development of more environmentally friendly sequestration solutions.

The consumer electronics market, while not the primary driver, is also contributing to the demand for improved battery acid sequestration. As portable devices become more powerful and energy-intensive, there is a growing emphasis on battery safety and longevity. Consumers are increasingly aware of potential battery-related hazards, creating a market for devices with enhanced safety features, including better acid containment.

In the aerospace and defense sectors, there is a specialized demand for high-performance batteries with advanced sequestration capabilities. These industries require batteries that can withstand extreme conditions while maintaining the highest safety standards. The development of cutting-edge sequestration methods is essential to meet these stringent requirements and open up new applications in these high-value markets.

Current Challenges

Battery acid sequestration methods face several significant challenges in the current technological landscape. One of the primary obstacles is the complexity of the chemical processes involved in effectively neutralizing and containing battery acid. The highly corrosive nature of these acids, typically sulfuric acid in lead-acid batteries, requires sophisticated handling and treatment techniques to ensure safety and environmental protection.

The scalability of existing sequestration methods presents another major challenge. As the demand for batteries continues to grow across various industries, from automotive to renewable energy storage, the volume of acid waste generated has increased substantially. Current methods often struggle to keep pace with this rising demand, particularly in terms of processing capacity and cost-effectiveness at larger scales.

Environmental concerns pose a significant hurdle in the development and implementation of acid sequestration technologies. The potential for soil and water contamination from improper acid disposal necessitates stringent regulatory compliance. This challenge is compounded by the need to develop methods that not only neutralize the acid but also allow for the recovery and recycling of valuable materials, aligning with circular economy principles.

The energy intensity of some sequestration processes is another critical issue. Many current methods require substantial energy inputs, which can offset the environmental benefits of battery recycling and acid neutralization. This energy requirement not only increases operational costs but also contributes to the overall carbon footprint of the sequestration process, creating a paradox in environmental sustainability efforts.

Material limitations also present significant challenges. The development of acid-resistant materials for containment and processing equipment is crucial for long-term effectiveness and safety. However, finding materials that can withstand prolonged exposure to highly corrosive acids while remaining cost-effective and durable is an ongoing challenge for researchers and engineers in this field.

The variability in battery acid composition across different battery types and manufacturers adds another layer of complexity. Sequestration methods must be adaptable to handle acids with varying concentrations, impurities, and chemical properties. This variability necessitates the development of flexible and robust sequestration technologies capable of efficiently processing a wide range of acid waste streams.

Lastly, the economic viability of advanced sequestration methods remains a significant challenge. While there is a clear environmental imperative for improved acid management, the high costs associated with developing and implementing new technologies can be prohibitive. Balancing the need for effective acid sequestration with economic feasibility is crucial for widespread adoption and industry support.

The scalability of existing sequestration methods presents another major challenge. As the demand for batteries continues to grow across various industries, from automotive to renewable energy storage, the volume of acid waste generated has increased substantially. Current methods often struggle to keep pace with this rising demand, particularly in terms of processing capacity and cost-effectiveness at larger scales.

Environmental concerns pose a significant hurdle in the development and implementation of acid sequestration technologies. The potential for soil and water contamination from improper acid disposal necessitates stringent regulatory compliance. This challenge is compounded by the need to develop methods that not only neutralize the acid but also allow for the recovery and recycling of valuable materials, aligning with circular economy principles.

The energy intensity of some sequestration processes is another critical issue. Many current methods require substantial energy inputs, which can offset the environmental benefits of battery recycling and acid neutralization. This energy requirement not only increases operational costs but also contributes to the overall carbon footprint of the sequestration process, creating a paradox in environmental sustainability efforts.

Material limitations also present significant challenges. The development of acid-resistant materials for containment and processing equipment is crucial for long-term effectiveness and safety. However, finding materials that can withstand prolonged exposure to highly corrosive acids while remaining cost-effective and durable is an ongoing challenge for researchers and engineers in this field.

The variability in battery acid composition across different battery types and manufacturers adds another layer of complexity. Sequestration methods must be adaptable to handle acids with varying concentrations, impurities, and chemical properties. This variability necessitates the development of flexible and robust sequestration technologies capable of efficiently processing a wide range of acid waste streams.

Lastly, the economic viability of advanced sequestration methods remains a significant challenge. While there is a clear environmental imperative for improved acid management, the high costs associated with developing and implementing new technologies can be prohibitive. Balancing the need for effective acid sequestration with economic feasibility is crucial for widespread adoption and industry support.

Existing Solutions

01 Chemical neutralization of battery acid

This method involves using chemical compounds to neutralize the acidic components in battery electrolytes. Common neutralizing agents include alkaline substances such as sodium bicarbonate or calcium carbonate. The process helps to reduce the corrosive nature of the acid and make it safer for disposal or recycling.- Chemical neutralization of battery acid: This method involves using alkaline substances to neutralize the acidic components in battery acid. Common neutralizing agents include sodium bicarbonate, calcium carbonate, or specialized chemical compounds. The process helps to raise the pH of the acid, making it less corrosive and easier to handle for disposal or recycling.

- Adsorption-based acid sequestration: Adsorption techniques utilize materials with high surface area and affinity for acidic components to remove them from battery acid. Activated carbon, zeolites, or specialized polymeric adsorbents can be employed. This method is effective for capturing and immobilizing acid molecules, allowing for safer handling and disposal of battery waste.

- Membrane-based acid separation: This approach uses selective membranes to separate acidic components from the battery electrolyte. Ion exchange membranes or nanofiltration membranes can be employed to isolate and concentrate the acid, facilitating its removal or recovery. This method is particularly useful for recycling battery components and reducing environmental impact.

- Electrochemical acid removal: Electrochemical techniques can be used to remove or neutralize acid in battery systems. This may involve electrodialysis, capacitive deionization, or other electrode-based processes to selectively extract acidic ions from the electrolyte. These methods can be energy-efficient and allow for potential recovery of valuable materials.

- Encapsulation and solidification of acid: This method involves encapsulating or solidifying the battery acid to prevent its release into the environment. Techniques may include using polymer-based materials to form a protective barrier around the acid or converting it into a solid form through chemical reactions. This approach is particularly useful for long-term storage or disposal of battery waste.

02 Acid absorption using specialized materials

Specialized absorbent materials are used to sequester battery acid. These materials can include activated carbon, zeolites, or synthetic polymers designed to trap and contain acidic substances. The absorbents effectively immobilize the acid, preventing its spread and facilitating safe handling and disposal.Expand Specific Solutions03 Encapsulation techniques for acid containment

This approach involves encapsulating the battery acid within a protective barrier or matrix. The encapsulation material can be a polymer, ceramic, or other inert substance that prevents the acid from leaching out. This method is particularly useful for long-term storage or transportation of batteries or battery waste.Expand Specific Solutions04 Electrochemical acid recovery and treatment

Electrochemical methods are employed to recover and treat battery acid. This can involve processes such as electrodialysis or electrocoagulation, which use electrical current to separate acid components or convert them into less harmful substances. These techniques are often used in industrial-scale battery recycling operations.Expand Specific Solutions05 Biological acid sequestration methods

Biological approaches utilize microorganisms or plant-based systems to sequester or neutralize battery acid. This can include the use of specific bacteria strains that can metabolize acidic compounds or phytoremediation techniques using plants that can absorb and process the acid. These methods are often considered more environmentally friendly but may be slower than chemical or physical approaches.Expand Specific Solutions

Key Industry Players

The research on state-of-the-art battery acid sequestration methods is in a rapidly evolving phase, with significant market growth potential. The industry is transitioning from early-stage development to more mature applications, driven by increasing demand for sustainable energy storage solutions. Major players like LG Energy Solution, Tesla, and Contemporary Amperex Technology are investing heavily in R&D, pushing the technological boundaries. The market is characterized by a mix of established automotive giants such as Audi and Toyota, alongside specialized battery manufacturers like GS Yuasa and Tianneng Battery Group. This diverse competitive landscape indicates a technology that is progressing towards commercialization but still has room for innovation and market expansion.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a novel approach to battery acid sequestration using nanotechnology. Their method employs specially engineered nanoparticles that can selectively bind to and neutralize excess acid within the battery. These nanoparticles are designed to be stable in the harsh battery environment and can be regenerated through a proprietary process, allowing for continuous acid management throughout the battery's lifespan[2]. Additionally, LG has integrated this technology with their advanced battery management systems, enabling precise control over acid levels and optimizing overall battery performance[4].

Strengths: Highly efficient acid neutralization, regenerative capability, and integration with existing battery management systems. Weaknesses: Potential concerns about nanoparticle safety and long-term stability.

Tesla, Inc.

Technical Solution: Tesla has developed a cutting-edge battery acid sequestration system that utilizes a combination of advanced materials and intelligent control algorithms. Their approach involves a multi-layer sequestration matrix that can dynamically adjust its properties based on the battery's state of charge and operating conditions. This adaptive system allows for optimal acid management across a wide range of temperatures and usage patterns, significantly enhancing battery performance and longevity[5]. Tesla's method also incorporates machine learning algorithms that continuously optimize the sequestration process based on historical data and real-time measurements[6].

Strengths: Adaptive and intelligent acid management, improved performance across various conditions, and continuous optimization. Weaknesses: High complexity and potential reliance on proprietary algorithms and materials.

Core Innovations

Method for detecting acid stratification in a battery

PatentActiveUS20070065713A1

Innovation

- A method to detect acid stratification by comparing load and rest period state of charge values using estimated and measured open-circuit voltages, and neutralizing it by increasing charging voltage to create gas bubbles that mix the electrolyte, thereby correcting the state of charge and preventing stratification.

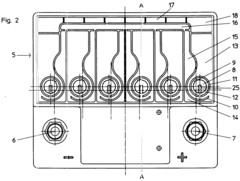

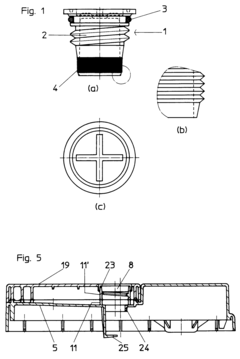

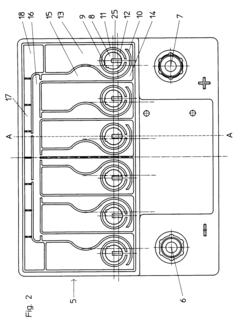

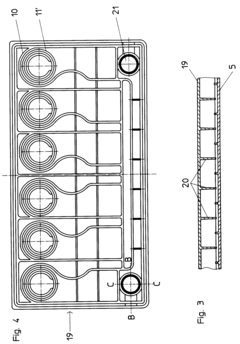

Accumulateur with a bas-venting system incorporated in the cover

PatentInactiveEP0570703A1

Innovation

- A lead-acid battery design featuring a thermoplastic block cover composed of a base cover and cover plate, with a sealing plug that seals at two levels and a labyrinthine gas collection space to prevent acid escape, allowing for efficient acid separation and return, and enabling leak testing of individual cells.

Environmental Impact

Battery acid sequestration methods have significant environmental implications that extend beyond the immediate containment of hazardous materials. The environmental impact of these methods encompasses various aspects, including soil and water contamination, air pollution, and long-term ecological effects.

One of the primary environmental concerns associated with battery acid sequestration is the potential for soil contamination. Improper handling or disposal of battery acid can lead to soil acidification, altering the pH balance and negatively affecting plant growth and soil microorganisms. This can result in reduced soil fertility and ecosystem disruption in affected areas.

Water pollution is another critical environmental issue related to battery acid management. Leakage or improper disposal of battery acid can contaminate groundwater and surface water sources, posing risks to aquatic ecosystems and potentially entering the human water supply. The acidic nature of the waste can cause severe damage to aquatic life and disrupt the delicate balance of water ecosystems.

Air pollution is a less obvious but still significant environmental impact of battery acid sequestration methods. Some sequestration processes may involve the release of volatile organic compounds (VOCs) or other harmful gases, contributing to air quality degradation and potentially affecting human health in surrounding areas.

The long-term ecological effects of battery acid sequestration are also a concern. Even when properly contained, the presence of large quantities of sequestered acid can pose risks to local flora and fauna. The potential for accidental releases or gradual leakage over time necessitates ongoing monitoring and maintenance of sequestration sites.

However, advancements in sequestration technologies have led to more environmentally friendly approaches. Modern methods often incorporate neutralization processes that reduce the acidity of the waste, minimizing its potential environmental impact. Additionally, some innovative techniques focus on recycling and repurposing battery acid components, reducing the overall waste volume and associated environmental risks.

The development of closed-loop systems for battery acid management represents a significant step towards minimizing environmental impact. These systems aim to contain and treat acid waste within the battery production or recycling facility, reducing the need for external sequestration and lowering the risk of environmental contamination.

In conclusion, while battery acid sequestration methods have historically posed significant environmental challenges, ongoing research and technological advancements are continually improving their environmental performance. The focus on sustainable practices, recycling, and closed-loop systems is crucial in mitigating the environmental impact of battery acid management, aligning with broader goals of environmental protection and sustainable industrial practices.

One of the primary environmental concerns associated with battery acid sequestration is the potential for soil contamination. Improper handling or disposal of battery acid can lead to soil acidification, altering the pH balance and negatively affecting plant growth and soil microorganisms. This can result in reduced soil fertility and ecosystem disruption in affected areas.

Water pollution is another critical environmental issue related to battery acid management. Leakage or improper disposal of battery acid can contaminate groundwater and surface water sources, posing risks to aquatic ecosystems and potentially entering the human water supply. The acidic nature of the waste can cause severe damage to aquatic life and disrupt the delicate balance of water ecosystems.

Air pollution is a less obvious but still significant environmental impact of battery acid sequestration methods. Some sequestration processes may involve the release of volatile organic compounds (VOCs) or other harmful gases, contributing to air quality degradation and potentially affecting human health in surrounding areas.

The long-term ecological effects of battery acid sequestration are also a concern. Even when properly contained, the presence of large quantities of sequestered acid can pose risks to local flora and fauna. The potential for accidental releases or gradual leakage over time necessitates ongoing monitoring and maintenance of sequestration sites.

However, advancements in sequestration technologies have led to more environmentally friendly approaches. Modern methods often incorporate neutralization processes that reduce the acidity of the waste, minimizing its potential environmental impact. Additionally, some innovative techniques focus on recycling and repurposing battery acid components, reducing the overall waste volume and associated environmental risks.

The development of closed-loop systems for battery acid management represents a significant step towards minimizing environmental impact. These systems aim to contain and treat acid waste within the battery production or recycling facility, reducing the need for external sequestration and lowering the risk of environmental contamination.

In conclusion, while battery acid sequestration methods have historically posed significant environmental challenges, ongoing research and technological advancements are continually improving their environmental performance. The focus on sustainable practices, recycling, and closed-loop systems is crucial in mitigating the environmental impact of battery acid management, aligning with broader goals of environmental protection and sustainable industrial practices.

Regulatory Framework

The regulatory framework surrounding battery acid sequestration methods is complex and multifaceted, involving various governmental agencies and international bodies. At the forefront of these regulations is the Environmental Protection Agency (EPA) in the United States, which has established stringent guidelines for the handling, storage, and disposal of battery acid under the Resource Conservation and Recovery Act (RCRA).

The RCRA classifies spent battery acid as a hazardous waste due to its corrosive nature, mandating specific treatment and disposal procedures. Companies engaged in battery acid sequestration must obtain permits and adhere to strict reporting requirements, ensuring transparency and accountability in their operations. The Department of Transportation (DOT) also plays a crucial role, regulating the transportation of battery acid and related materials through its Hazardous Materials Regulations.

Internationally, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a global framework for managing hazardous wastes, including battery acid. Signatory countries are required to implement domestic legislation to enforce these international standards, creating a more unified approach to battery acid management across borders.

The European Union has implemented the Batteries Directive (2006/66/EC), which sets targets for the collection and recycling of batteries, including provisions for the proper handling of battery acid. This directive emphasizes producer responsibility and encourages the development of more environmentally friendly battery technologies.

In recent years, there has been a growing focus on circular economy principles within regulatory frameworks. This shift is encouraging the development of more advanced battery acid sequestration methods that not only neutralize the acid but also recover valuable materials for reuse. Regulatory bodies are increasingly incentivizing research and development in this area through grants and tax incentives.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, also play a significant role in shaping battery acid sequestration practices. These regulations mandate specific safety protocols, personal protective equipment, and training requirements for workers handling battery acid.

As the electric vehicle market expands and the demand for energy storage solutions grows, regulatory bodies are adapting their frameworks to address the increasing volume of battery waste. This includes updating existing regulations and developing new standards specifically tailored to emerging battery technologies and their associated acid management challenges.

The RCRA classifies spent battery acid as a hazardous waste due to its corrosive nature, mandating specific treatment and disposal procedures. Companies engaged in battery acid sequestration must obtain permits and adhere to strict reporting requirements, ensuring transparency and accountability in their operations. The Department of Transportation (DOT) also plays a crucial role, regulating the transportation of battery acid and related materials through its Hazardous Materials Regulations.

Internationally, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a global framework for managing hazardous wastes, including battery acid. Signatory countries are required to implement domestic legislation to enforce these international standards, creating a more unified approach to battery acid management across borders.

The European Union has implemented the Batteries Directive (2006/66/EC), which sets targets for the collection and recycling of batteries, including provisions for the proper handling of battery acid. This directive emphasizes producer responsibility and encourages the development of more environmentally friendly battery technologies.

In recent years, there has been a growing focus on circular economy principles within regulatory frameworks. This shift is encouraging the development of more advanced battery acid sequestration methods that not only neutralize the acid but also recover valuable materials for reuse. Regulatory bodies are increasingly incentivizing research and development in this area through grants and tax incentives.

Occupational safety regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the US, also play a significant role in shaping battery acid sequestration practices. These regulations mandate specific safety protocols, personal protective equipment, and training requirements for workers handling battery acid.

As the electric vehicle market expands and the demand for energy storage solutions grows, regulatory bodies are adapting their frameworks to address the increasing volume of battery waste. This includes updating existing regulations and developing new standards specifically tailored to emerging battery technologies and their associated acid management challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!