Battery Acid Containment Solutions for Environmental Safety

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Safety Background and Objectives

Battery acid containment has become a critical concern in the field of energy storage and environmental safety. As the global demand for batteries continues to surge, driven by the rapid adoption of electric vehicles and renewable energy systems, the need for effective acid containment solutions has never been more pressing. The primary objective of this research is to explore and evaluate cutting-edge technologies and methodologies for containing battery acid, with a focus on minimizing environmental impact and enhancing safety measures.

The evolution of battery technology has been marked by significant advancements in energy density and performance. However, these improvements have also brought about new challenges in terms of safety and environmental protection. Lead-acid batteries, despite being one of the oldest rechargeable battery technologies, still pose considerable risks due to their corrosive electrolyte. More recent lithium-ion batteries, while offering higher energy density, also present unique containment challenges, particularly in the event of thermal runaway or physical damage.

The environmental implications of battery acid leakage are severe and far-reaching. Soil contamination, water pollution, and potential harm to flora and fauna are just a few of the consequences of inadequate containment measures. Moreover, the health risks to humans exposed to battery acid are significant, ranging from skin burns to respiratory issues. These environmental and health concerns have prompted regulatory bodies worldwide to impose stricter guidelines on battery manufacturing, transportation, and disposal.

In light of these challenges, the battery industry has been actively pursuing innovative containment solutions. The technological trajectory in this field aims to develop materials and designs that can withstand extreme conditions, prevent leakage, and neutralize acid in the event of a breach. Advancements in polymer science, nanotechnology, and smart materials are opening up new possibilities for creating more robust and responsive containment systems.

This research seeks to comprehensively analyze the current state of battery acid containment technologies, identify key areas for improvement, and explore emerging solutions that promise enhanced safety and environmental protection. By examining both traditional and cutting-edge approaches, we aim to provide a roadmap for future developments in this critical area of battery technology. The ultimate goal is to contribute to the creation of safer, more environmentally friendly energy storage solutions that can support the growing global demand for sustainable power sources.

The evolution of battery technology has been marked by significant advancements in energy density and performance. However, these improvements have also brought about new challenges in terms of safety and environmental protection. Lead-acid batteries, despite being one of the oldest rechargeable battery technologies, still pose considerable risks due to their corrosive electrolyte. More recent lithium-ion batteries, while offering higher energy density, also present unique containment challenges, particularly in the event of thermal runaway or physical damage.

The environmental implications of battery acid leakage are severe and far-reaching. Soil contamination, water pollution, and potential harm to flora and fauna are just a few of the consequences of inadequate containment measures. Moreover, the health risks to humans exposed to battery acid are significant, ranging from skin burns to respiratory issues. These environmental and health concerns have prompted regulatory bodies worldwide to impose stricter guidelines on battery manufacturing, transportation, and disposal.

In light of these challenges, the battery industry has been actively pursuing innovative containment solutions. The technological trajectory in this field aims to develop materials and designs that can withstand extreme conditions, prevent leakage, and neutralize acid in the event of a breach. Advancements in polymer science, nanotechnology, and smart materials are opening up new possibilities for creating more robust and responsive containment systems.

This research seeks to comprehensively analyze the current state of battery acid containment technologies, identify key areas for improvement, and explore emerging solutions that promise enhanced safety and environmental protection. By examining both traditional and cutting-edge approaches, we aim to provide a roadmap for future developments in this critical area of battery technology. The ultimate goal is to contribute to the creation of safer, more environmentally friendly energy storage solutions that can support the growing global demand for sustainable power sources.

Market Analysis for Eco-friendly Battery Solutions

The market for eco-friendly battery solutions has experienced significant growth in recent years, driven by increasing environmental concerns and stringent regulations on hazardous waste management. The global market for sustainable battery technologies is projected to reach $110 billion by 2025, with a compound annual growth rate of 12.3% from 2020 to 2025. This growth is primarily fueled by the rising demand for electric vehicles, renewable energy storage systems, and portable electronic devices.

The automotive sector represents the largest market segment for eco-friendly battery solutions, accounting for approximately 40% of the total market share. As governments worldwide implement stricter emissions standards and offer incentives for electric vehicle adoption, the demand for environmentally safe battery technologies continues to surge. Major automakers are investing heavily in research and development of advanced battery systems with improved safety features and reduced environmental impact.

In the energy storage sector, the market for eco-friendly battery solutions is expected to grow at the fastest rate, with a projected CAGR of 15.7% from 2020 to 2025. This growth is driven by the increasing integration of renewable energy sources into power grids and the need for reliable energy storage systems. Utility companies and renewable energy providers are actively seeking battery solutions that offer enhanced safety and reduced environmental risks.

Consumer electronics represent another significant market segment for eco-friendly battery solutions, with a focus on developing safer and more sustainable power sources for smartphones, laptops, and other portable devices. The consumer electronics market for eco-friendly batteries is expected to reach $18 billion by 2025, growing at a CAGR of 9.8% from 2020 to 2025.

Geographically, Asia-Pacific dominates the market for eco-friendly battery solutions, accounting for 45% of the global market share. This is primarily due to the region's strong presence in the electric vehicle and consumer electronics industries. North America and Europe follow closely, with market shares of 30% and 20% respectively, driven by stringent environmental regulations and growing investments in renewable energy infrastructure.

Key market trends include the development of solid-state batteries, which offer improved safety and reduced environmental risks compared to traditional lithium-ion batteries. Additionally, there is a growing focus on battery recycling and second-life applications, aimed at minimizing the environmental impact of battery disposal and maximizing resource utilization.

The competitive landscape of the eco-friendly battery solutions market is characterized by intense research and development activities, strategic partnerships, and mergers and acquisitions. Leading players in the market include Tesla, Panasonic, LG Chem, and Samsung SDI, who are continuously innovating to develop safer and more environmentally friendly battery technologies.

The automotive sector represents the largest market segment for eco-friendly battery solutions, accounting for approximately 40% of the total market share. As governments worldwide implement stricter emissions standards and offer incentives for electric vehicle adoption, the demand for environmentally safe battery technologies continues to surge. Major automakers are investing heavily in research and development of advanced battery systems with improved safety features and reduced environmental impact.

In the energy storage sector, the market for eco-friendly battery solutions is expected to grow at the fastest rate, with a projected CAGR of 15.7% from 2020 to 2025. This growth is driven by the increasing integration of renewable energy sources into power grids and the need for reliable energy storage systems. Utility companies and renewable energy providers are actively seeking battery solutions that offer enhanced safety and reduced environmental risks.

Consumer electronics represent another significant market segment for eco-friendly battery solutions, with a focus on developing safer and more sustainable power sources for smartphones, laptops, and other portable devices. The consumer electronics market for eco-friendly batteries is expected to reach $18 billion by 2025, growing at a CAGR of 9.8% from 2020 to 2025.

Geographically, Asia-Pacific dominates the market for eco-friendly battery solutions, accounting for 45% of the global market share. This is primarily due to the region's strong presence in the electric vehicle and consumer electronics industries. North America and Europe follow closely, with market shares of 30% and 20% respectively, driven by stringent environmental regulations and growing investments in renewable energy infrastructure.

Key market trends include the development of solid-state batteries, which offer improved safety and reduced environmental risks compared to traditional lithium-ion batteries. Additionally, there is a growing focus on battery recycling and second-life applications, aimed at minimizing the environmental impact of battery disposal and maximizing resource utilization.

The competitive landscape of the eco-friendly battery solutions market is characterized by intense research and development activities, strategic partnerships, and mergers and acquisitions. Leading players in the market include Tesla, Panasonic, LG Chem, and Samsung SDI, who are continuously innovating to develop safer and more environmentally friendly battery technologies.

Current Challenges in Battery Acid Containment

Battery acid containment presents significant challenges in the realm of environmental safety, particularly as the demand for batteries continues to grow across various industries. One of the primary concerns is the potential for acid leakage, which can occur due to physical damage, manufacturing defects, or improper handling and storage. Such leaks pose serious risks to both human health and the environment, necessitating robust containment solutions.

The corrosive nature of battery acid compounds the challenge, as it can rapidly degrade traditional containment materials. This necessitates the development and use of specialized acid-resistant materials that can withstand prolonged exposure without compromising their structural integrity. However, finding materials that are both highly resistant to acid and cost-effective for large-scale implementation remains a significant hurdle.

Another critical challenge lies in the design of containment systems that can effectively manage thermal fluctuations. Batteries, especially when in use or during charging cycles, can generate substantial heat. This thermal stress can lead to expansion and contraction of containment materials, potentially creating weak points or gaps that could result in acid seepage. Designing containment solutions that maintain their efficacy across a wide temperature range is crucial for ensuring long-term safety.

The diversity of battery types and sizes further complicates the development of universal containment solutions. From small consumer electronics batteries to large-scale industrial and automotive applications, each category presents unique containment requirements. This variability necessitates a range of tailored solutions, making it challenging to standardize containment practices across the industry.

Environmental regulations and safety standards regarding battery acid containment are becoming increasingly stringent. Compliance with these evolving regulations requires continuous innovation and adaptation of containment technologies. This regulatory landscape, while necessary for environmental protection, adds layers of complexity and cost to the development and implementation of containment solutions.

The end-of-life management of batteries presents another significant challenge in acid containment. As batteries reach the end of their operational life, the risk of acid leakage increases. Developing safe and efficient methods for decommissioning, transporting, and recycling spent batteries while maintaining acid containment integrity is a critical area that requires ongoing research and development.

Lastly, the scalability of effective containment solutions poses a substantial challenge. As battery production and usage continue to grow exponentially, particularly in sectors like electric vehicles and renewable energy storage, scaling up containment technologies to match this growth while maintaining cost-effectiveness and reliability is a formidable task facing the industry.

The corrosive nature of battery acid compounds the challenge, as it can rapidly degrade traditional containment materials. This necessitates the development and use of specialized acid-resistant materials that can withstand prolonged exposure without compromising their structural integrity. However, finding materials that are both highly resistant to acid and cost-effective for large-scale implementation remains a significant hurdle.

Another critical challenge lies in the design of containment systems that can effectively manage thermal fluctuations. Batteries, especially when in use or during charging cycles, can generate substantial heat. This thermal stress can lead to expansion and contraction of containment materials, potentially creating weak points or gaps that could result in acid seepage. Designing containment solutions that maintain their efficacy across a wide temperature range is crucial for ensuring long-term safety.

The diversity of battery types and sizes further complicates the development of universal containment solutions. From small consumer electronics batteries to large-scale industrial and automotive applications, each category presents unique containment requirements. This variability necessitates a range of tailored solutions, making it challenging to standardize containment practices across the industry.

Environmental regulations and safety standards regarding battery acid containment are becoming increasingly stringent. Compliance with these evolving regulations requires continuous innovation and adaptation of containment technologies. This regulatory landscape, while necessary for environmental protection, adds layers of complexity and cost to the development and implementation of containment solutions.

The end-of-life management of batteries presents another significant challenge in acid containment. As batteries reach the end of their operational life, the risk of acid leakage increases. Developing safe and efficient methods for decommissioning, transporting, and recycling spent batteries while maintaining acid containment integrity is a critical area that requires ongoing research and development.

Lastly, the scalability of effective containment solutions poses a substantial challenge. As battery production and usage continue to grow exponentially, particularly in sectors like electric vehicles and renewable energy storage, scaling up containment technologies to match this growth while maintaining cost-effectiveness and reliability is a formidable task facing the industry.

Existing Acid Containment Strategies

01 Containment systems for battery acid spills

Specialized containment systems are designed to prevent and manage battery acid spills. These systems include leak-proof trays, barriers, and absorbent materials that can quickly neutralize and contain acid leaks. Such solutions help minimize environmental contamination and protect workers from exposure to hazardous substances.- Containment systems for battery acid spills: Specialized containment systems are designed to prevent and manage battery acid spills. These systems include leak-proof trays, secondary containment units, and spill pallets that can safely contain acid leaks from batteries. Such solutions help prevent environmental contamination and protect workers from exposure to hazardous materials.

- Acid-resistant materials for battery enclosures: The use of acid-resistant materials in battery enclosures and containment systems enhances safety and longevity. These materials, such as certain plastics, coated metals, or composite materials, can withstand prolonged exposure to battery acid without degradation, reducing the risk of leaks and environmental contamination.

- Ventilation and gas management systems: Proper ventilation and gas management systems are crucial for battery safety. These systems help prevent the buildup of potentially explosive gases produced during battery charging and discharging processes. Effective ventilation reduces the risk of fire, explosion, and exposure to harmful fumes, contributing to overall environmental safety.

- Neutralization and disposal methods for battery acid: Environmentally safe methods for neutralizing and disposing of battery acid are essential. These include using neutralizing agents to render the acid less harmful, proper collection and containment of waste acid, and specialized disposal procedures that comply with environmental regulations. Such methods minimize the impact of battery acid on the environment and human health.

- Monitoring and early detection systems: Advanced monitoring and early detection systems play a crucial role in battery acid containment. These systems can detect leaks, changes in acidity levels, or other potential hazards before they become significant problems. Early detection allows for prompt response, reducing the risk of environmental contamination and improving overall safety in battery storage and usage areas.

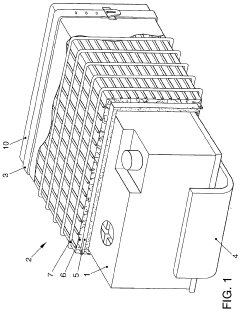

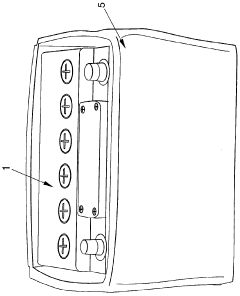

02 Battery enclosures with integrated safety features

Advanced battery enclosures are developed with built-in safety features to prevent acid leakage and contain potential spills. These enclosures may include corrosion-resistant materials, double-wall construction, and integrated spill containment systems. Such designs enhance overall battery safety and reduce the risk of environmental contamination.Expand Specific Solutions03 Acid-resistant flooring and coatings

Specialized acid-resistant flooring and coatings are used in battery storage and handling areas. These materials provide an additional layer of protection against acid spills, preventing seepage into the ground and facilitating easier cleanup. Such solutions contribute to improved environmental safety in battery-related facilities.Expand Specific Solutions04 Neutralization and treatment systems for battery acid

Advanced systems are developed for neutralizing and treating battery acid in case of spills or during battery disposal. These systems may include automated neutralization processes, filtration methods, and safe disposal techniques. Such solutions ensure that battery acid is properly handled and does not pose a threat to the environment.Expand Specific Solutions05 Monitoring and early detection systems

Sophisticated monitoring and early detection systems are implemented to identify potential battery acid leaks or spills before they become significant environmental hazards. These systems may include sensors, alarms, and real-time monitoring technologies that allow for rapid response and containment of acid-related incidents.Expand Specific Solutions

Key Players in Battery Safety Industry

The battery acid containment solutions market is in a growth phase, driven by increasing environmental concerns and stringent safety regulations. The market size is expanding as more industries adopt these solutions to mitigate environmental risks. Technologically, the field is advancing rapidly, with companies like Contemporary Amperex Technology Co., Ltd. and Panasonic Holdings Corp. leading innovation in battery design and safety features. China Petroleum & Chemical Corp. and Sinopec Safety Engineering Research Institute Co., Ltd. are contributing to the development of containment materials and systems. Universities such as Carnegie Mellon and California Institute of Technology are conducting research to improve containment technologies, indicating a collaborative effort between industry and academia to enhance environmental safety in battery applications.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed advanced battery acid containment solutions focusing on multi-layer protection systems. Their approach includes a combination of high-performance separator materials, enhanced electrolyte formulations, and intelligent battery management systems (BMS). The company utilizes nano-coated separators that improve acid resistance and thermal stability[1]. CATL's electrolyte additives help form a stable solid electrolyte interphase (SEI) layer, reducing acid-induced corrosion[3]. Additionally, their BMS incorporates real-time monitoring and predictive algorithms to detect potential acid leakage risks early[5].

Strengths: Comprehensive multi-layer protection, advanced materials science, and intelligent monitoring systems. Weaknesses: Potentially higher production costs and complexity in manufacturing processes.

China Petroleum & Chemical Corp.

Technical Solution: Sinopec has leveraged its expertise in chemical engineering to develop innovative acid containment solutions for battery applications. The company has created advanced polymer-based linings for battery casings that offer superior acid resistance and durability[8]. Sinopec's research has also yielded new composite materials that can effectively neutralize acid spills while maintaining structural integrity[10]. Additionally, they have developed smart sensors integrated into battery systems to detect minute changes in acidity levels and trigger containment protocols[12].

Strengths: Strong background in chemical engineering, diverse range of containment solutions. Weaknesses: Relatively new entrant in the battery technology field, may lack specific battery design expertise.

Innovative Containment Materials and Designs

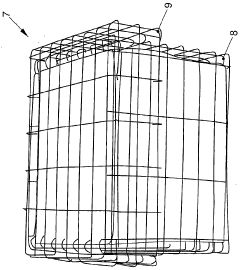

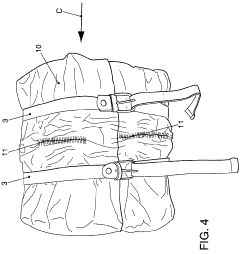

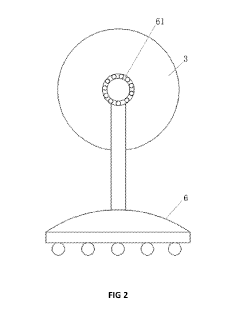

Battery arrangement

PatentWO2003092088A2

Innovation

- A battery arrangement featuring an absorbent cover with multiple layers, including an open-pored sponge layer for rapid absorption and a highly absorbent non-woven fabric for permanent storage, surrounded by mechanical protection and a flexible, acid-resistant outer cover to minimize fluid escape during crashes or leaks.

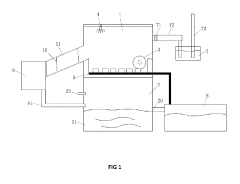

Lead-acid battery storage container

PatentActiveUS20190280351A1

Innovation

- A lead-acid battery storage container with a double-layer structure, featuring a pressure roller mechanism for compacting batteries, an air duct for gas filtration, and a water pool for acid liquid dilution and collection, preventing acid leakage and pollution.

Environmental Regulations on Battery Disposal

Environmental regulations on battery disposal have become increasingly stringent in recent years, reflecting growing concerns about the potential environmental and health hazards associated with improper battery disposal. These regulations aim to minimize the release of toxic substances, such as lead, cadmium, and mercury, into the environment and protect human health.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a framework for managing hazardous waste, including batteries. This convention requires signatories to implement measures to reduce the generation of hazardous waste and promote environmentally sound management practices.

In the United States, the Environmental Protection Agency (EPA) regulates battery disposal under the Resource Conservation and Recovery Act (RCRA). The Mercury-Containing and Rechargeable Battery Management Act of 1996 further mandates the proper disposal of certain types of batteries, including lead-acid, nickel-cadmium, and small sealed lead-acid batteries.

The European Union has implemented the Batteries Directive (2006/66/EC), which sets collection and recycling targets for all types of batteries. This directive also prohibits the marketing of batteries containing certain hazardous substances and requires manufacturers to design appliances in a way that allows for easy battery removal.

Many countries have adopted extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal. These programs often involve collection and recycling schemes funded by producers.

Specific regulations for lead-acid batteries, commonly used in vehicles, require special handling due to their corrosive and toxic nature. In many jurisdictions, it is illegal to dispose of lead-acid batteries in landfills or through regular waste streams. Instead, they must be recycled through authorized facilities.

Compliance with these regulations often involves implementing proper storage, labeling, and transportation procedures for used batteries. Many countries require businesses that handle batteries to obtain permits and maintain detailed records of their disposal activities.

As technology advances and new battery chemistries emerge, regulatory frameworks are continually evolving to address novel environmental challenges. For instance, the growing use of lithium-ion batteries in electric vehicles and energy storage systems has prompted the development of new guidelines for their safe disposal and recycling.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a framework for managing hazardous waste, including batteries. This convention requires signatories to implement measures to reduce the generation of hazardous waste and promote environmentally sound management practices.

In the United States, the Environmental Protection Agency (EPA) regulates battery disposal under the Resource Conservation and Recovery Act (RCRA). The Mercury-Containing and Rechargeable Battery Management Act of 1996 further mandates the proper disposal of certain types of batteries, including lead-acid, nickel-cadmium, and small sealed lead-acid batteries.

The European Union has implemented the Batteries Directive (2006/66/EC), which sets collection and recycling targets for all types of batteries. This directive also prohibits the marketing of batteries containing certain hazardous substances and requires manufacturers to design appliances in a way that allows for easy battery removal.

Many countries have adopted extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal. These programs often involve collection and recycling schemes funded by producers.

Specific regulations for lead-acid batteries, commonly used in vehicles, require special handling due to their corrosive and toxic nature. In many jurisdictions, it is illegal to dispose of lead-acid batteries in landfills or through regular waste streams. Instead, they must be recycled through authorized facilities.

Compliance with these regulations often involves implementing proper storage, labeling, and transportation procedures for used batteries. Many countries require businesses that handle batteries to obtain permits and maintain detailed records of their disposal activities.

As technology advances and new battery chemistries emerge, regulatory frameworks are continually evolving to address novel environmental challenges. For instance, the growing use of lithium-ion batteries in electric vehicles and energy storage systems has prompted the development of new guidelines for their safe disposal and recycling.

Life Cycle Assessment of Battery Containment Solutions

Life Cycle Assessment (LCA) of battery containment solutions is a crucial aspect of evaluating the environmental impact and safety of battery acid management systems. This comprehensive analysis examines the entire lifecycle of containment solutions, from raw material extraction to end-of-life disposal, providing valuable insights into their overall sustainability and environmental performance.

The assessment begins with the production phase, where the environmental impacts of manufacturing containment materials are evaluated. This includes energy consumption, resource depletion, and emissions associated with producing materials such as high-density polyethylene (HDPE), polypropylene, or specialized acid-resistant coatings. The transportation of raw materials and finished products is also considered, accounting for fuel consumption and associated emissions.

During the use phase, the LCA focuses on the performance of containment solutions in preventing acid leakage and spills. Factors such as durability, chemical resistance, and maintenance requirements are analyzed to determine the long-term effectiveness of the containment systems. The assessment also considers the potential environmental risks associated with acid containment failures and the subsequent impact on soil, water, and ecosystems.

End-of-life considerations form a critical component of the LCA. This includes evaluating the recyclability of containment materials, the energy required for recycling processes, and the potential for material recovery. For non-recyclable components, the assessment examines disposal methods and their environmental implications, such as landfill space requirements and potential leaching of harmful substances.

The LCA also incorporates a comparative analysis of different containment solutions, enabling stakeholders to make informed decisions based on environmental performance. This may include comparing traditional containment methods with innovative solutions, such as advanced polymer composites or bio-based materials, to identify more sustainable alternatives.

Furthermore, the assessment considers the potential for improvement in containment solution design and manufacturing processes. This involves identifying hotspots in the lifecycle where environmental impacts are most significant and proposing strategies for mitigation. Such improvements may include optimizing material usage, enhancing recycling processes, or developing more environmentally friendly production techniques.

By conducting a comprehensive Life Cycle Assessment, stakeholders can gain a holistic understanding of the environmental implications of battery acid containment solutions. This information is invaluable for guiding product development, informing policy decisions, and promoting more sustainable practices in the battery industry. Ultimately, the LCA serves as a powerful tool for enhancing environmental safety and reducing the ecological footprint of battery systems throughout their lifecycle.

The assessment begins with the production phase, where the environmental impacts of manufacturing containment materials are evaluated. This includes energy consumption, resource depletion, and emissions associated with producing materials such as high-density polyethylene (HDPE), polypropylene, or specialized acid-resistant coatings. The transportation of raw materials and finished products is also considered, accounting for fuel consumption and associated emissions.

During the use phase, the LCA focuses on the performance of containment solutions in preventing acid leakage and spills. Factors such as durability, chemical resistance, and maintenance requirements are analyzed to determine the long-term effectiveness of the containment systems. The assessment also considers the potential environmental risks associated with acid containment failures and the subsequent impact on soil, water, and ecosystems.

End-of-life considerations form a critical component of the LCA. This includes evaluating the recyclability of containment materials, the energy required for recycling processes, and the potential for material recovery. For non-recyclable components, the assessment examines disposal methods and their environmental implications, such as landfill space requirements and potential leaching of harmful substances.

The LCA also incorporates a comparative analysis of different containment solutions, enabling stakeholders to make informed decisions based on environmental performance. This may include comparing traditional containment methods with innovative solutions, such as advanced polymer composites or bio-based materials, to identify more sustainable alternatives.

Furthermore, the assessment considers the potential for improvement in containment solution design and manufacturing processes. This involves identifying hotspots in the lifecycle where environmental impacts are most significant and proposing strategies for mitigation. Such improvements may include optimizing material usage, enhancing recycling processes, or developing more environmentally friendly production techniques.

By conducting a comprehensive Life Cycle Assessment, stakeholders can gain a holistic understanding of the environmental implications of battery acid containment solutions. This information is invaluable for guiding product development, informing policy decisions, and promoting more sustainable practices in the battery industry. Ultimately, the LCA serves as a powerful tool for enhancing environmental safety and reducing the ecological footprint of battery systems throughout their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!