How Acid Catalysis Influences Battery Electrochemical Processes

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Acid Catalysis in Batteries: Background and Objectives

Acid catalysis plays a crucial role in battery electrochemical processes, influencing various aspects of battery performance and efficiency. The study of acid catalysis in batteries has evolved significantly over the past few decades, driven by the increasing demand for high-performance energy storage solutions. This field of research encompasses a wide range of battery technologies, from traditional lead-acid batteries to advanced lithium-ion systems and emerging next-generation chemistries.

The historical development of acid catalysis in batteries can be traced back to the early 20th century, with the invention of the lead-acid battery. Since then, researchers have continuously explored the potential of acid catalysis to enhance battery performance, focusing on improving energy density, cycle life, and charging efficiency. The evolution of this technology has been closely linked to advancements in materials science, electrochemistry, and nanotechnology.

In recent years, the focus has shifted towards understanding the fundamental mechanisms of acid catalysis at the molecular level. This has led to the development of novel catalytic materials and strategies that can significantly impact battery performance. The integration of advanced characterization techniques, such as in-situ spectroscopy and high-resolution microscopy, has provided unprecedented insights into the complex interactions between acid catalysts and battery components.

The primary objectives of studying acid catalysis in batteries are multifaceted. Firstly, researchers aim to enhance the overall energy efficiency of batteries by optimizing the catalytic processes occurring at the electrode-electrolyte interface. This includes improving the kinetics of charge transfer reactions and minimizing parasitic side reactions that can lead to capacity loss and degradation.

Secondly, there is a strong focus on developing sustainable and environmentally friendly battery technologies. Acid catalysis research plays a vital role in this aspect by enabling the use of earth-abundant materials and reducing the reliance on rare and expensive elements. Additionally, researchers are exploring ways to mitigate the environmental impact of battery production and disposal through innovative catalytic approaches.

Another key objective is to extend the operational lifespan of batteries by mitigating degradation mechanisms associated with acid-catalyzed reactions. This involves developing strategies to suppress unwanted side reactions, such as electrolyte decomposition and electrode corrosion, which can significantly impact battery longevity.

Furthermore, the field is moving towards the design of "smart" battery systems that can adapt to different operating conditions. Acid catalysis research is instrumental in developing responsive electrode materials and electrolytes that can optimize battery performance based on external factors such as temperature, charge/discharge rates, and state of charge.

As we look towards the future, the study of acid catalysis in batteries is expected to play a pivotal role in addressing global energy challenges. By unlocking new pathways for energy storage and conversion, this field has the potential to revolutionize various sectors, including electric vehicles, renewable energy integration, and portable electronics.

The historical development of acid catalysis in batteries can be traced back to the early 20th century, with the invention of the lead-acid battery. Since then, researchers have continuously explored the potential of acid catalysis to enhance battery performance, focusing on improving energy density, cycle life, and charging efficiency. The evolution of this technology has been closely linked to advancements in materials science, electrochemistry, and nanotechnology.

In recent years, the focus has shifted towards understanding the fundamental mechanisms of acid catalysis at the molecular level. This has led to the development of novel catalytic materials and strategies that can significantly impact battery performance. The integration of advanced characterization techniques, such as in-situ spectroscopy and high-resolution microscopy, has provided unprecedented insights into the complex interactions between acid catalysts and battery components.

The primary objectives of studying acid catalysis in batteries are multifaceted. Firstly, researchers aim to enhance the overall energy efficiency of batteries by optimizing the catalytic processes occurring at the electrode-electrolyte interface. This includes improving the kinetics of charge transfer reactions and minimizing parasitic side reactions that can lead to capacity loss and degradation.

Secondly, there is a strong focus on developing sustainable and environmentally friendly battery technologies. Acid catalysis research plays a vital role in this aspect by enabling the use of earth-abundant materials and reducing the reliance on rare and expensive elements. Additionally, researchers are exploring ways to mitigate the environmental impact of battery production and disposal through innovative catalytic approaches.

Another key objective is to extend the operational lifespan of batteries by mitigating degradation mechanisms associated with acid-catalyzed reactions. This involves developing strategies to suppress unwanted side reactions, such as electrolyte decomposition and electrode corrosion, which can significantly impact battery longevity.

Furthermore, the field is moving towards the design of "smart" battery systems that can adapt to different operating conditions. Acid catalysis research is instrumental in developing responsive electrode materials and electrolytes that can optimize battery performance based on external factors such as temperature, charge/discharge rates, and state of charge.

As we look towards the future, the study of acid catalysis in batteries is expected to play a pivotal role in addressing global energy challenges. By unlocking new pathways for energy storage and conversion, this field has the potential to revolutionize various sectors, including electric vehicles, renewable energy integration, and portable electronics.

Market Analysis for Advanced Battery Technologies

The advanced battery technology market is experiencing significant growth, driven by the increasing demand for electric vehicles, renewable energy storage, and portable electronic devices. This market segment is expected to continue its upward trajectory as governments worldwide implement stricter environmental regulations and consumers shift towards cleaner energy solutions.

In the context of acid catalysis influencing battery electrochemical processes, the market analysis reveals several key trends. Firstly, there is a growing interest in developing more efficient and sustainable battery technologies that can leverage acid catalysis to enhance performance. This is particularly evident in the research and development efforts focused on improving lithium-ion batteries and exploring alternative chemistries.

The automotive sector remains a primary driver of advanced battery technology adoption, with electric vehicle sales projected to increase substantially over the next decade. This growth is fueling investments in battery manufacturing capacity and spurring innovation in acid-catalyzed electrochemical processes to improve energy density, charging speeds, and overall battery lifespan.

Energy storage systems for grid applications represent another significant market opportunity. As renewable energy sources become more prevalent, the need for large-scale, efficient energy storage solutions grows. Advanced batteries utilizing acid catalysis are being explored to address the challenges of intermittent power generation from solar and wind sources.

The consumer electronics market continues to demand batteries with higher energy density and faster charging capabilities. This sector is driving research into novel acid-catalyzed electrode materials and electrolyte formulations to meet these requirements.

Geographically, Asia-Pacific leads the advanced battery technology market, with China, Japan, and South Korea being major players in both production and consumption. North America and Europe follow, with substantial investments in research and development, as well as manufacturing facilities.

Key market players include established battery manufacturers, automotive companies, and technology firms. These companies are actively pursuing partnerships and collaborations to accelerate innovation in acid-catalyzed battery technologies. Start-ups and research institutions are also contributing significantly to the market dynamics, often bringing disruptive technologies and novel approaches to battery design.

The market analysis indicates that while lithium-ion batteries currently dominate, there is growing interest in next-generation technologies such as solid-state batteries, lithium-sulfur, and metal-air batteries. Many of these emerging technologies rely on advanced acid catalysis to overcome current limitations in energy density, safety, and cycle life.

In the context of acid catalysis influencing battery electrochemical processes, the market analysis reveals several key trends. Firstly, there is a growing interest in developing more efficient and sustainable battery technologies that can leverage acid catalysis to enhance performance. This is particularly evident in the research and development efforts focused on improving lithium-ion batteries and exploring alternative chemistries.

The automotive sector remains a primary driver of advanced battery technology adoption, with electric vehicle sales projected to increase substantially over the next decade. This growth is fueling investments in battery manufacturing capacity and spurring innovation in acid-catalyzed electrochemical processes to improve energy density, charging speeds, and overall battery lifespan.

Energy storage systems for grid applications represent another significant market opportunity. As renewable energy sources become more prevalent, the need for large-scale, efficient energy storage solutions grows. Advanced batteries utilizing acid catalysis are being explored to address the challenges of intermittent power generation from solar and wind sources.

The consumer electronics market continues to demand batteries with higher energy density and faster charging capabilities. This sector is driving research into novel acid-catalyzed electrode materials and electrolyte formulations to meet these requirements.

Geographically, Asia-Pacific leads the advanced battery technology market, with China, Japan, and South Korea being major players in both production and consumption. North America and Europe follow, with substantial investments in research and development, as well as manufacturing facilities.

Key market players include established battery manufacturers, automotive companies, and technology firms. These companies are actively pursuing partnerships and collaborations to accelerate innovation in acid-catalyzed battery technologies. Start-ups and research institutions are also contributing significantly to the market dynamics, often bringing disruptive technologies and novel approaches to battery design.

The market analysis indicates that while lithium-ion batteries currently dominate, there is growing interest in next-generation technologies such as solid-state batteries, lithium-sulfur, and metal-air batteries. Many of these emerging technologies rely on advanced acid catalysis to overcome current limitations in energy density, safety, and cycle life.

Current Challenges in Acid Catalysis for Batteries

Acid catalysis in battery electrochemical processes presents several significant challenges that hinder the optimization of battery performance and longevity. One of the primary issues is the corrosive nature of acidic environments, which can lead to the degradation of electrode materials and other battery components. This corrosion not only reduces the overall efficiency of the battery but also shortens its lifespan, making it a critical concern for researchers and manufacturers alike.

Another challenge lies in controlling the acid-catalyzed side reactions that occur during battery operation. These unwanted reactions can consume active materials, produce gases, and form solid electrolyte interphase (SEI) layers that impede ion transport. Balancing the catalytic activity to promote desired reactions while suppressing detrimental side reactions remains a complex task that requires precise engineering of electrode surfaces and electrolyte compositions.

The stability of acid catalysts under varying operational conditions poses yet another hurdle. Temperature fluctuations, changes in pH, and the presence of impurities can all affect catalyst performance and longevity. Developing catalysts that maintain their activity and selectivity across a wide range of conditions is crucial for creating robust and reliable battery systems.

Furthermore, the integration of acid catalysis into existing battery technologies presents compatibility issues. Many current battery designs are not optimized for acidic environments, necessitating significant modifications to electrode materials, separators, and cell architectures. This integration challenge extends to the manufacturing processes, where new techniques may be required to incorporate acid catalysts effectively and safely.

The scalability of acid catalysis solutions also remains a concern. While certain acid-catalyzed processes show promise in laboratory settings, translating these results to large-scale production can be problematic. Issues such as uniform catalyst distribution, consistent performance across batches, and cost-effective production methods need to be addressed before widespread implementation can be achieved.

Lastly, the environmental impact of acid catalysis in batteries cannot be overlooked. The use of strong acids and potentially toxic catalysts raises concerns about the ecological footprint of battery production and disposal. Developing green catalytic processes that minimize environmental harm while maintaining high performance is a significant challenge that researchers must tackle to ensure the sustainability of future battery technologies.

Another challenge lies in controlling the acid-catalyzed side reactions that occur during battery operation. These unwanted reactions can consume active materials, produce gases, and form solid electrolyte interphase (SEI) layers that impede ion transport. Balancing the catalytic activity to promote desired reactions while suppressing detrimental side reactions remains a complex task that requires precise engineering of electrode surfaces and electrolyte compositions.

The stability of acid catalysts under varying operational conditions poses yet another hurdle. Temperature fluctuations, changes in pH, and the presence of impurities can all affect catalyst performance and longevity. Developing catalysts that maintain their activity and selectivity across a wide range of conditions is crucial for creating robust and reliable battery systems.

Furthermore, the integration of acid catalysis into existing battery technologies presents compatibility issues. Many current battery designs are not optimized for acidic environments, necessitating significant modifications to electrode materials, separators, and cell architectures. This integration challenge extends to the manufacturing processes, where new techniques may be required to incorporate acid catalysts effectively and safely.

The scalability of acid catalysis solutions also remains a concern. While certain acid-catalyzed processes show promise in laboratory settings, translating these results to large-scale production can be problematic. Issues such as uniform catalyst distribution, consistent performance across batches, and cost-effective production methods need to be addressed before widespread implementation can be achieved.

Lastly, the environmental impact of acid catalysis in batteries cannot be overlooked. The use of strong acids and potentially toxic catalysts raises concerns about the ecological footprint of battery production and disposal. Developing green catalytic processes that minimize environmental harm while maintaining high performance is a significant challenge that researchers must tackle to ensure the sustainability of future battery technologies.

Existing Acid Catalysis Solutions for Batteries

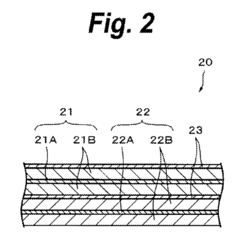

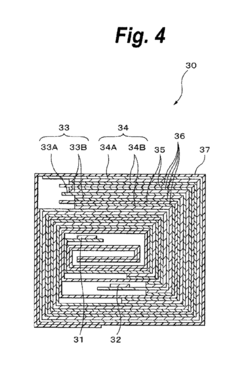

01 Electrode material composition and structure

The composition and structure of electrode materials play a crucial role in battery performance. This includes the development of novel materials, nanostructured electrodes, and composite materials to enhance capacity, conductivity, and stability. Innovations in this area focus on improving energy density, cycle life, and charge/discharge rates.- Electrode material composition and structure: The composition and structure of electrode materials play a crucial role in battery performance. This includes the development of novel materials, nanostructured electrodes, and composite materials to enhance energy density, power output, and cycling stability. Innovations in this area focus on improving the electrochemical properties of both cathodes and anodes.

- Electrolyte formulations and additives: Advancements in electrolyte formulations and additives are essential for improving battery performance and safety. This includes developing new electrolyte compositions, incorporating functional additives, and exploring solid-state electrolytes to enhance ionic conductivity, reduce side reactions, and improve the overall electrochemical stability of the battery system.

- Battery management and control systems: Sophisticated battery management and control systems are crucial for optimizing battery performance, safety, and longevity. This involves developing advanced algorithms for state-of-charge estimation, thermal management, and charge-discharge control. These systems help monitor and regulate the electrochemical processes within the battery to prevent degradation and ensure efficient operation.

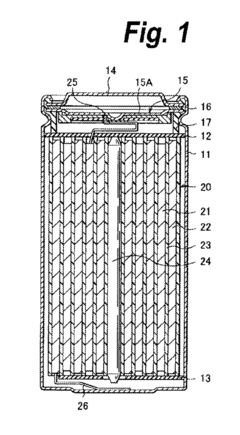

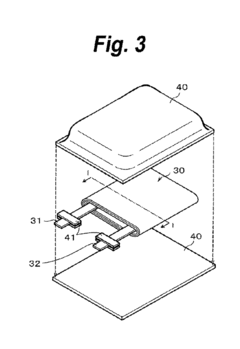

- Novel cell designs and architectures: Innovative cell designs and architectures are being explored to improve energy density, power output, and manufacturing efficiency. This includes the development of new form factors, such as flexible and thin-film batteries, as well as advanced packaging techniques to optimize space utilization and enhance overall battery performance.

- Recycling and sustainable battery technologies: Developing sustainable battery technologies and efficient recycling processes is becoming increasingly important. This involves designing batteries with recyclable materials, improving the recovery of valuable components from spent batteries, and exploring eco-friendly manufacturing processes to reduce the environmental impact of battery production and disposal.

02 Electrolyte formulations and additives

Advancements in electrolyte formulations and additives are essential for improving battery performance and safety. This includes developing new electrolyte compositions, ionic liquids, and solid electrolytes to enhance ionic conductivity, reduce side reactions, and improve the stability of the electrode-electrolyte interface.Expand Specific Solutions03 Battery management and control systems

Sophisticated battery management and control systems are crucial for optimizing battery performance, safety, and longevity. This includes advanced algorithms for state-of-charge estimation, thermal management, and charge/discharge control to prevent overcharging, overheating, and other detrimental conditions.Expand Specific Solutions04 Novel cell designs and architectures

Innovative cell designs and architectures are being developed to improve energy density, power output, and manufacturing efficiency. This includes advancements in electrode stacking, cell packaging, and the integration of new materials and components to create more compact and efficient battery systems.Expand Specific Solutions05 Recycling and sustainable battery technologies

Developing sustainable battery technologies and efficient recycling processes is becoming increasingly important. This includes methods for recovering and reusing valuable materials from spent batteries, as well as designing batteries with improved recyclability and reduced environmental impact.Expand Specific Solutions

Key Players in Battery Catalysis Research

The field of acid catalysis in battery electrochemical processes is in a growth phase, with increasing market size driven by the demand for more efficient and sustainable energy storage solutions. The global battery market is projected to reach significant value in the coming years, with acid catalysis playing a crucial role in enhancing battery performance. Technologically, the field is advancing rapidly, with companies like Form Energy, LG Chem, and Toyota Motor Corp leading innovation. These firms are developing novel catalytic materials and processes to improve battery efficiency, longevity, and environmental sustainability. Research institutions such as Tsinghua University and the Dalian Institute of Chemical Physics are also contributing to technological advancements, bridging the gap between fundamental research and industrial applications.

GM Global Technology Operations LLC

Technical Solution: GM has been investigating the role of acid catalysis in the context of next-generation battery technologies, particularly for electric vehicles. Their research focuses on understanding and controlling the acid-base interactions at the electrode-electrolyte interface to optimize battery performance and longevity. GM has developed proprietary electrolyte formulations that incorporate carefully selected acidic additives to promote the formation of a stable cathode electrolyte interphase (CEI) in high-voltage lithium-ion batteries[7]. This approach aims to mitigate cathode degradation and enhance the battery's thermal stability. Additionally, GM has explored the use of acid-functionalized separators to improve lithium-ion transport and suppress dendrite growth in lithium metal batteries[8]. The company has also investigated the application of acid catalysis principles in solid-state electrolytes to enhance interfacial stability and ionic conductivity[9].

Strengths: Comprehensive approach to integrating acid catalysis across multiple battery components, focus on high-performance EV applications. Weaknesses: Potential trade-offs between performance enhancements and long-term durability, complexity in scaling up advanced electrolyte formulations for mass production.

Toyota Motor Corp.

Technical Solution: Toyota has been at the forefront of researching acid catalysis effects in advanced battery systems, particularly for hybrid and electric vehicle applications. Their approach focuses on understanding the intricate balance between acid-catalyzed reactions and overall battery performance. Toyota has developed novel electrolyte systems that utilize controlled acid catalysis to enhance the formation of protective surface films on both the anode and cathode[10]. This strategy aims to improve the battery's cycle life and safety characteristics. The company has also investigated the use of acid-treated carbon materials as conductive additives in electrode formulations to enhance electron transfer and active material utilization[11]. Additionally, Toyota has explored the application of acid catalysis principles in the recycling of spent lithium-ion batteries, developing efficient processes for metal recovery and electrode material regeneration[12]. Their research extends to next-generation technologies, including solid-state batteries, where acid-base interactions play a crucial role in interfacial stability and ion transport.

Strengths: Holistic approach to acid catalysis across battery lifecycle, from performance enhancement to recycling; strong focus on practical applications for vehicle electrification. Weaknesses: Balancing performance improvements with cost considerations for mass-market adoption; potential challenges in implementing complex catalytic systems in large-scale manufacturing.

Innovative Acid Catalysts for Electrochemical Processes

Battery having a charge voltage between 4.25 V and 6.00 V

PatentInactiveUS8101296B2

Innovation

- Incorporating an electrolytic solution with additives such as acid anhydrides and cyclic carbonic ester derivatives with halogen atoms, which form a protective coating on the anode and suppress decomposition, maintaining a stable open circuit voltage between 4.25V and 6.00V, thereby enhancing energy density and cycle life.

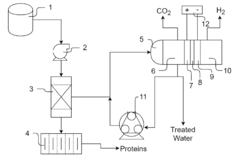

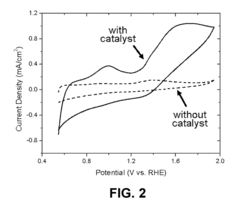

Electrochemical processes for acid whey treatment and reuse

PatentInactiveUS20170096742A1

Innovation

- The use of electrochemical cells with an anode and cathode, potentially separated by a membrane, to oxidize lactose, lactic acid, and proteins in acid whey, generating gases and purifying water, with optional catalysts and pre-filtration to enhance efficiency.

Environmental Impact of Acid Catalysis in Batteries

The environmental impact of acid catalysis in batteries is a critical consideration as the demand for energy storage solutions continues to grow. The use of acid catalysts in battery electrochemical processes can have both positive and negative effects on the environment, necessitating a comprehensive assessment of their overall impact.

One of the primary environmental concerns associated with acid catalysis in batteries is the potential for acid leakage or spillage. If not properly contained, these acidic substances can contaminate soil and water sources, leading to ecosystem disruption and potential harm to flora and fauna. This risk is particularly pronounced in the case of lead-acid batteries, which have been widely used in automotive applications for decades.

However, the implementation of advanced containment systems and improved battery designs has significantly reduced the risk of acid leakage in modern batteries. Additionally, the development of more environmentally friendly acid catalysts, such as those derived from organic compounds, has further mitigated the potential negative impacts on ecosystems.

On the positive side, acid catalysis can enhance the efficiency and performance of batteries, potentially leading to reduced energy consumption and lower greenhouse gas emissions. By improving the electrochemical processes within batteries, acid catalysts can contribute to longer battery life cycles, reducing the need for frequent replacements and minimizing electronic waste.

The production and disposal of batteries utilizing acid catalysis also warrant environmental consideration. The manufacturing process of these batteries may involve the use of hazardous materials and energy-intensive processes, contributing to carbon emissions and resource depletion. However, advancements in green chemistry and sustainable manufacturing practices are gradually addressing these concerns, with a focus on reducing the environmental footprint of battery production.

End-of-life management of batteries containing acid catalysts is another crucial aspect of their environmental impact. Proper recycling and disposal methods are essential to prevent the release of harmful substances into the environment. Many countries have implemented regulations and recycling programs to ensure the safe handling and recycling of batteries, recovering valuable materials and minimizing environmental contamination.

As research in this field progresses, there is a growing emphasis on developing more sustainable acid catalysts and battery technologies. This includes exploring bio-based acids, ionic liquids, and other environmentally benign alternatives that can maintain or improve battery performance while reducing potential ecological risks.

In conclusion, while acid catalysis in batteries presents certain environmental challenges, ongoing technological advancements and stringent regulations are continuously improving their overall environmental profile. The balance between enhanced battery performance and minimized ecological impact remains a key focus in the development of next-generation energy storage solutions.

One of the primary environmental concerns associated with acid catalysis in batteries is the potential for acid leakage or spillage. If not properly contained, these acidic substances can contaminate soil and water sources, leading to ecosystem disruption and potential harm to flora and fauna. This risk is particularly pronounced in the case of lead-acid batteries, which have been widely used in automotive applications for decades.

However, the implementation of advanced containment systems and improved battery designs has significantly reduced the risk of acid leakage in modern batteries. Additionally, the development of more environmentally friendly acid catalysts, such as those derived from organic compounds, has further mitigated the potential negative impacts on ecosystems.

On the positive side, acid catalysis can enhance the efficiency and performance of batteries, potentially leading to reduced energy consumption and lower greenhouse gas emissions. By improving the electrochemical processes within batteries, acid catalysts can contribute to longer battery life cycles, reducing the need for frequent replacements and minimizing electronic waste.

The production and disposal of batteries utilizing acid catalysis also warrant environmental consideration. The manufacturing process of these batteries may involve the use of hazardous materials and energy-intensive processes, contributing to carbon emissions and resource depletion. However, advancements in green chemistry and sustainable manufacturing practices are gradually addressing these concerns, with a focus on reducing the environmental footprint of battery production.

End-of-life management of batteries containing acid catalysts is another crucial aspect of their environmental impact. Proper recycling and disposal methods are essential to prevent the release of harmful substances into the environment. Many countries have implemented regulations and recycling programs to ensure the safe handling and recycling of batteries, recovering valuable materials and minimizing environmental contamination.

As research in this field progresses, there is a growing emphasis on developing more sustainable acid catalysts and battery technologies. This includes exploring bio-based acids, ionic liquids, and other environmentally benign alternatives that can maintain or improve battery performance while reducing potential ecological risks.

In conclusion, while acid catalysis in batteries presents certain environmental challenges, ongoing technological advancements and stringent regulations are continuously improving their overall environmental profile. The balance between enhanced battery performance and minimized ecological impact remains a key focus in the development of next-generation energy storage solutions.

Safety Considerations for Acid-Catalyzed Battery Systems

The implementation of acid catalysis in battery systems introduces significant safety considerations that must be carefully addressed. The corrosive nature of acids poses potential risks to both the battery components and the surrounding environment. Proper containment and sealing mechanisms are crucial to prevent acid leakage, which could lead to equipment damage, environmental contamination, and potential harm to users.

Material selection plays a vital role in ensuring the safety of acid-catalyzed battery systems. Components that come into direct contact with the acid must be highly resistant to corrosion and degradation. This includes electrodes, separators, and internal structural elements. The use of acid-resistant polymers, ceramics, or specially treated metals is essential to maintain the integrity of the battery system over its operational lifetime.

Thermal management is another critical aspect of safety in acid-catalyzed batteries. The catalytic reactions can generate heat, which, if not properly dissipated, may lead to thermal runaway and potentially catastrophic failure. Implementing effective cooling systems and incorporating thermal sensors for real-time monitoring are necessary precautions to maintain safe operating temperatures.

Gas evolution is a common occurrence in acid-catalyzed electrochemical processes. The production of hydrogen gas, in particular, presents explosion risks if allowed to accumulate. Proper venting mechanisms and pressure relief systems must be integrated into the battery design to safely release any gases produced during operation or charging.

Electrical safety is paramount in battery systems, and the presence of acid catalysts introduces additional complexities. The highly conductive nature of acidic electrolytes increases the risk of short circuits. Robust insulation and carefully designed electrical pathways are essential to prevent unintended current flow and potential electrical hazards.

Handling and transportation of acid-catalyzed batteries require specific safety protocols. Proper packaging, labeling, and storage conditions must be established to prevent accidental exposure or spills during transit or storage. Emergency response procedures should be developed and communicated to all personnel involved in the handling of these battery systems.

Environmental considerations extend beyond immediate safety concerns. The disposal or recycling of acid-catalyzed batteries must be carefully managed to prevent environmental contamination. Developing efficient recycling processes and establishing proper disposal guidelines are crucial for the sustainable implementation of this technology.

Human Resource Development:

1. Develop comprehensive training programs for personnel involved in the production, handling, and maintenance of acid-catalyzed battery systems.

2. Establish clear safety protocols and emergency response procedures specific to acid-related incidents.

3. Regularly update safety guidelines based on ongoing research and incident reports from the field.

Material selection plays a vital role in ensuring the safety of acid-catalyzed battery systems. Components that come into direct contact with the acid must be highly resistant to corrosion and degradation. This includes electrodes, separators, and internal structural elements. The use of acid-resistant polymers, ceramics, or specially treated metals is essential to maintain the integrity of the battery system over its operational lifetime.

Thermal management is another critical aspect of safety in acid-catalyzed batteries. The catalytic reactions can generate heat, which, if not properly dissipated, may lead to thermal runaway and potentially catastrophic failure. Implementing effective cooling systems and incorporating thermal sensors for real-time monitoring are necessary precautions to maintain safe operating temperatures.

Gas evolution is a common occurrence in acid-catalyzed electrochemical processes. The production of hydrogen gas, in particular, presents explosion risks if allowed to accumulate. Proper venting mechanisms and pressure relief systems must be integrated into the battery design to safely release any gases produced during operation or charging.

Electrical safety is paramount in battery systems, and the presence of acid catalysts introduces additional complexities. The highly conductive nature of acidic electrolytes increases the risk of short circuits. Robust insulation and carefully designed electrical pathways are essential to prevent unintended current flow and potential electrical hazards.

Handling and transportation of acid-catalyzed batteries require specific safety protocols. Proper packaging, labeling, and storage conditions must be established to prevent accidental exposure or spills during transit or storage. Emergency response procedures should be developed and communicated to all personnel involved in the handling of these battery systems.

Environmental considerations extend beyond immediate safety concerns. The disposal or recycling of acid-catalyzed batteries must be carefully managed to prevent environmental contamination. Developing efficient recycling processes and establishing proper disposal guidelines are crucial for the sustainable implementation of this technology.

Human Resource Development:

1. Develop comprehensive training programs for personnel involved in the production, handling, and maintenance of acid-catalyzed battery systems.

2. Establish clear safety protocols and emergency response procedures specific to acid-related incidents.

3. Regularly update safety guidelines based on ongoing research and incident reports from the field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!