Impact of Battery Acid on Electronic Waste Recycling

AUG 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Challenges in E-Waste Recycling

Battery acid, primarily composed of sulfuric acid, poses significant challenges in the electronic waste recycling process. The corrosive nature of this acid can lead to severe damage to recycling equipment, compromising the efficiency and safety of e-waste processing facilities. When batteries are improperly handled or damaged during collection and transportation, the acid can leak, creating hazardous conditions for workers and the environment.

The presence of battery acid in e-waste streams complicates the sorting and separation processes. Automated systems designed to identify and categorize different materials may malfunction or provide inaccurate results when exposed to acidic residues. This can lead to contamination of other recyclable materials, reducing their value and recyclability. Additionally, the acid can react with other components in the e-waste, potentially generating toxic fumes or causing unexpected chemical reactions.

Environmental concerns are paramount when dealing with battery acid in e-waste recycling. Improper disposal or leakage can result in soil and water contamination, posing risks to ecosystems and human health. The acidic nature of the substance can alter the pH balance of soil and water bodies, affecting plant growth and aquatic life. Moreover, the potential for heavy metal contamination from batteries further exacerbates the environmental impact.

Worker safety is another critical challenge in handling battery acid during e-waste recycling. Exposure to sulfuric acid can cause severe burns, respiratory issues, and long-term health problems. Implementing proper safety protocols, including personal protective equipment (PPE) and specialized handling procedures, is essential but can increase operational costs and complexity for recycling facilities.

The presence of battery acid also affects the economic viability of e-waste recycling operations. The need for specialized equipment, safety measures, and acid neutralization processes increases the overall cost of recycling. This can potentially reduce profit margins or necessitate higher fees for e-waste collection and processing, which may discourage proper disposal practices.

Regulatory compliance adds another layer of complexity to addressing battery acid challenges in e-waste recycling. Different regions have varying regulations regarding the handling, transportation, and disposal of hazardous materials like battery acid. Recycling facilities must navigate these regulatory landscapes, often requiring additional certifications, permits, and reporting procedures, which can be time-consuming and costly.

Developing effective neutralization and containment strategies for battery acid is crucial for improving e-waste recycling processes. This may involve innovative technologies for acid detection, safe extraction methods, and on-site neutralization systems. However, implementing these solutions across the diverse landscape of e-waste recycling facilities presents logistical and financial hurdles.

The presence of battery acid in e-waste streams complicates the sorting and separation processes. Automated systems designed to identify and categorize different materials may malfunction or provide inaccurate results when exposed to acidic residues. This can lead to contamination of other recyclable materials, reducing their value and recyclability. Additionally, the acid can react with other components in the e-waste, potentially generating toxic fumes or causing unexpected chemical reactions.

Environmental concerns are paramount when dealing with battery acid in e-waste recycling. Improper disposal or leakage can result in soil and water contamination, posing risks to ecosystems and human health. The acidic nature of the substance can alter the pH balance of soil and water bodies, affecting plant growth and aquatic life. Moreover, the potential for heavy metal contamination from batteries further exacerbates the environmental impact.

Worker safety is another critical challenge in handling battery acid during e-waste recycling. Exposure to sulfuric acid can cause severe burns, respiratory issues, and long-term health problems. Implementing proper safety protocols, including personal protective equipment (PPE) and specialized handling procedures, is essential but can increase operational costs and complexity for recycling facilities.

The presence of battery acid also affects the economic viability of e-waste recycling operations. The need for specialized equipment, safety measures, and acid neutralization processes increases the overall cost of recycling. This can potentially reduce profit margins or necessitate higher fees for e-waste collection and processing, which may discourage proper disposal practices.

Regulatory compliance adds another layer of complexity to addressing battery acid challenges in e-waste recycling. Different regions have varying regulations regarding the handling, transportation, and disposal of hazardous materials like battery acid. Recycling facilities must navigate these regulatory landscapes, often requiring additional certifications, permits, and reporting procedures, which can be time-consuming and costly.

Developing effective neutralization and containment strategies for battery acid is crucial for improving e-waste recycling processes. This may involve innovative technologies for acid detection, safe extraction methods, and on-site neutralization systems. However, implementing these solutions across the diverse landscape of e-waste recycling facilities presents logistical and financial hurdles.

E-Waste Recycling Market Analysis

The electronic waste (e-waste) recycling market has experienced significant growth in recent years, driven by increasing awareness of environmental issues and the rapid proliferation of electronic devices. This market is characterized by the collection, dismantling, and processing of discarded electronic equipment to recover valuable materials and dispose of hazardous components safely.

Global e-waste generation has been steadily rising, with estimates suggesting that over 50 million metric tons of e-waste are produced annually. This trend is expected to continue as consumer electronics become more prevalent and have shorter lifecycles. The e-waste recycling market is responding to this challenge, with projections indicating substantial growth in the coming years.

The market is segmented based on the type of e-waste, including large household appliances, small household appliances, IT and telecommunication equipment, and consumer electronics. Each segment presents unique recycling challenges and opportunities. The IT and telecommunication equipment segment, in particular, has shown robust growth due to the rapid turnover of smartphones and computers.

Geographically, developed regions such as North America and Europe have more mature e-waste recycling markets, with established regulatory frameworks and infrastructure. However, emerging economies in Asia-Pacific and Latin America are experiencing the fastest growth rates in e-waste recycling, driven by increasing electronic consumption and improving environmental regulations.

The impact of battery acid on e-waste recycling is a critical factor shaping market dynamics. Batteries, especially those containing lead-acid or lithium-ion chemistries, pose significant environmental and health risks if not properly handled during the recycling process. The presence of battery acid necessitates specialized handling procedures and equipment, influencing the overall cost structure and operational complexity of e-waste recycling facilities.

Market players are investing in advanced technologies to address the challenges posed by battery acid and other hazardous materials. These innovations include automated sorting systems, chemical treatment processes, and containment solutions designed to neutralize and safely dispose of acidic components. The development of these technologies is not only improving the efficiency of e-waste recycling but also opening new market opportunities for specialized equipment manufacturers and service providers.

The regulatory landscape plays a crucial role in shaping the e-waste recycling market. Many countries have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. These regulations are driving investment in recycling infrastructure and creating new business models within the industry.

Global e-waste generation has been steadily rising, with estimates suggesting that over 50 million metric tons of e-waste are produced annually. This trend is expected to continue as consumer electronics become more prevalent and have shorter lifecycles. The e-waste recycling market is responding to this challenge, with projections indicating substantial growth in the coming years.

The market is segmented based on the type of e-waste, including large household appliances, small household appliances, IT and telecommunication equipment, and consumer electronics. Each segment presents unique recycling challenges and opportunities. The IT and telecommunication equipment segment, in particular, has shown robust growth due to the rapid turnover of smartphones and computers.

Geographically, developed regions such as North America and Europe have more mature e-waste recycling markets, with established regulatory frameworks and infrastructure. However, emerging economies in Asia-Pacific and Latin America are experiencing the fastest growth rates in e-waste recycling, driven by increasing electronic consumption and improving environmental regulations.

The impact of battery acid on e-waste recycling is a critical factor shaping market dynamics. Batteries, especially those containing lead-acid or lithium-ion chemistries, pose significant environmental and health risks if not properly handled during the recycling process. The presence of battery acid necessitates specialized handling procedures and equipment, influencing the overall cost structure and operational complexity of e-waste recycling facilities.

Market players are investing in advanced technologies to address the challenges posed by battery acid and other hazardous materials. These innovations include automated sorting systems, chemical treatment processes, and containment solutions designed to neutralize and safely dispose of acidic components. The development of these technologies is not only improving the efficiency of e-waste recycling but also opening new market opportunities for specialized equipment manufacturers and service providers.

The regulatory landscape plays a crucial role in shaping the e-waste recycling market. Many countries have implemented extended producer responsibility (EPR) programs, which require manufacturers to take responsibility for the entire lifecycle of their products, including disposal and recycling. These regulations are driving investment in recycling infrastructure and creating new business models within the industry.

Current E-Waste Recycling Techniques and Limitations

Electronic waste (e-waste) recycling has become increasingly important as the volume of discarded electronic devices continues to grow globally. Current e-waste recycling techniques primarily focus on the recovery of valuable metals and materials while minimizing environmental impact. However, these methods face significant limitations, particularly when dealing with battery acid contamination.

The most common e-waste recycling technique is manual disassembly, where trained workers carefully separate different components of electronic devices. This method allows for the efficient recovery of high-value materials but is labor-intensive and time-consuming. Additionally, manual disassembly exposes workers to potential health risks, especially when handling devices containing battery acid.

Mechanical shredding is another widely used technique, which involves crushing e-waste into small pieces for easier material separation. While this method is more efficient for processing large volumes of e-waste, it can lead to the mixing of different materials, making it challenging to isolate specific components. The presence of battery acid in this process can cause corrosion of equipment and contamination of other recyclable materials.

Chemical leaching is employed to extract precious metals from e-waste using various solvents. This method is effective for recovering gold, silver, and other valuable metals but can be environmentally hazardous if not properly managed. The presence of battery acid can interfere with the leaching process, potentially reducing the efficiency of metal recovery and increasing the complexity of waste treatment.

Pyrometallurgical processes, such as smelting, are used to recover metals from e-waste through high-temperature treatment. While effective for metal recovery, these processes consume significant energy and can release harmful emissions. Battery acid contamination in e-waste can lead to the formation of toxic gases during smelting, posing additional environmental and health risks.

A major limitation in current e-waste recycling techniques is the inadequate handling of battery acid. Many recycling facilities lack proper systems to neutralize or safely dispose of battery acid, leading to potential environmental contamination and reduced recycling efficiency. The corrosive nature of battery acid can damage recycling equipment, increasing maintenance costs and downtime.

Furthermore, the presence of battery acid complicates the sorting and classification of e-waste. Automated sorting systems may struggle to accurately identify and separate acid-contaminated components, leading to inefficiencies in the recycling process. This challenge is particularly acute for lithium-ion batteries, which are increasingly common in electronic devices and pose unique recycling challenges due to their chemical composition.

In conclusion, while current e-waste recycling techniques have made significant progress in material recovery, they face substantial limitations when dealing with battery acid contamination. Addressing these challenges will require innovative approaches to acid neutralization, improved sorting technologies, and the development of specialized recycling processes for battery-containing devices.

The most common e-waste recycling technique is manual disassembly, where trained workers carefully separate different components of electronic devices. This method allows for the efficient recovery of high-value materials but is labor-intensive and time-consuming. Additionally, manual disassembly exposes workers to potential health risks, especially when handling devices containing battery acid.

Mechanical shredding is another widely used technique, which involves crushing e-waste into small pieces for easier material separation. While this method is more efficient for processing large volumes of e-waste, it can lead to the mixing of different materials, making it challenging to isolate specific components. The presence of battery acid in this process can cause corrosion of equipment and contamination of other recyclable materials.

Chemical leaching is employed to extract precious metals from e-waste using various solvents. This method is effective for recovering gold, silver, and other valuable metals but can be environmentally hazardous if not properly managed. The presence of battery acid can interfere with the leaching process, potentially reducing the efficiency of metal recovery and increasing the complexity of waste treatment.

Pyrometallurgical processes, such as smelting, are used to recover metals from e-waste through high-temperature treatment. While effective for metal recovery, these processes consume significant energy and can release harmful emissions. Battery acid contamination in e-waste can lead to the formation of toxic gases during smelting, posing additional environmental and health risks.

A major limitation in current e-waste recycling techniques is the inadequate handling of battery acid. Many recycling facilities lack proper systems to neutralize or safely dispose of battery acid, leading to potential environmental contamination and reduced recycling efficiency. The corrosive nature of battery acid can damage recycling equipment, increasing maintenance costs and downtime.

Furthermore, the presence of battery acid complicates the sorting and classification of e-waste. Automated sorting systems may struggle to accurately identify and separate acid-contaminated components, leading to inefficiencies in the recycling process. This challenge is particularly acute for lithium-ion batteries, which are increasingly common in electronic devices and pose unique recycling challenges due to their chemical composition.

In conclusion, while current e-waste recycling techniques have made significant progress in material recovery, they face substantial limitations when dealing with battery acid contamination. Addressing these challenges will require innovative approaches to acid neutralization, improved sorting technologies, and the development of specialized recycling processes for battery-containing devices.

Existing Solutions for Battery Acid Neutralization

01 Battery acid containment and management

Various designs and systems are implemented to contain and manage battery acid, preventing leakage and ensuring safe operation. These include specialized containers, sealing mechanisms, and drainage systems to control acid flow and minimize environmental impact.- Battery acid containment and management: Various designs and systems are implemented to contain and manage battery acid, preventing leakage and environmental contamination. These solutions include specialized containers, trays, and absorption materials to safely handle and store battery acid, minimizing potential hazards and improving overall battery safety.

- Battery acid impact on performance and lifespan: The impact of battery acid on battery performance and lifespan is addressed through innovative designs and materials. These improvements focus on reducing acid stratification, enhancing electrolyte circulation, and optimizing electrode structures to mitigate the negative effects of acid on battery components, thereby extending battery life and maintaining efficiency.

- Acid-resistant materials and coatings: Development of acid-resistant materials and coatings to protect battery components and surrounding structures from corrosion. These innovations include specialized polymers, composite materials, and protective layers that can withstand prolonged exposure to battery acid, enhancing the durability and safety of battery systems.

- Battery acid monitoring and management systems: Advanced monitoring and management systems are designed to track battery acid levels, composition, and temperature. These systems employ sensors, data analysis, and control mechanisms to maintain optimal acid conditions, detect potential issues early, and prevent acid-related failures or accidents in battery operations.

- Environmental and safety considerations: Addressing the environmental impact and safety concerns related to battery acid through improved disposal methods, neutralization techniques, and spill response protocols. These innovations aim to minimize the ecological footprint of battery acid and enhance workplace safety in battery manufacturing, maintenance, and recycling processes.

02 Battery acid impact on performance and lifespan

The impact of battery acid on battery performance and lifespan is addressed through innovative electrode designs, electrolyte compositions, and charging strategies. These advancements aim to minimize acid-induced degradation and extend battery life.Expand Specific Solutions03 Safety measures for battery acid handling

Safety measures are developed to protect against battery acid-related hazards. These include protective coatings, neutralization techniques, and emergency response systems to mitigate risks associated with acid exposure or spills.Expand Specific Solutions04 Battery acid monitoring and detection systems

Advanced monitoring and detection systems are designed to track battery acid levels, composition, and potential leaks. These systems employ sensors, data analysis, and alert mechanisms to ensure timely maintenance and prevent acid-related failures.Expand Specific Solutions05 Environmental impact mitigation of battery acid

Strategies are developed to minimize the environmental impact of battery acid. These include recycling processes, neutralization methods, and eco-friendly battery designs that reduce acid usage or implement safer alternatives.Expand Specific Solutions

Key Players in E-Waste Recycling Industry

The electronic waste recycling industry, particularly in relation to battery acid impact, is in a growth phase with increasing market size due to rising environmental concerns and regulatory pressures. The global e-waste recycling market is projected to expand significantly in the coming years. Technologically, the field is advancing rapidly, with companies like LG Energy Solution, Guangdong Bangpu Recycling Technology, and Aqua Metals leading innovations in battery recycling processes. These firms are developing more efficient and environmentally friendly methods to handle battery acid and other hazardous materials. The competitive landscape is diverse, including both established players and emerging startups, with a focus on developing sustainable solutions and circular economy models for electronic waste management.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a closed-loop battery recycling system that addresses the impact of battery acid on electronic waste recycling. Their process begins with a safe discharge and disassembly stage, followed by a crushing and sorting phase that separates battery components. For acid management, they employ a neutralization process using alkaline materials, which converts the acid into less harmful salts[10]. The company has also implemented an advanced hydrometallurgical process that uses controlled leaching to extract valuable metals from battery materials while minimizing acid-related environmental impacts. Additionally, LG has invested in the development of new battery chemistries that are inherently easier to recycle and pose less risk from acid contamination[11].

Strengths: Integrated approach from battery production to recycling, large-scale implementation capability. Weaknesses: Primary focus on their own battery products may limit applicability to diverse e-waste streams.

Hunan Bangpu Recycling Technology Co., Ltd.

Technical Solution: Hunan Bangpu has developed an integrated recycling system for electronic waste, including batteries. Their approach focuses on the entire lifecycle of electronic products, from collection to material recovery. For battery acid management, they employ a neutralization and precipitation process, followed by advanced filtration techniques[4]. This method effectively removes heavy metals and other contaminants from the acid, allowing for safe disposal or potential reuse in industrial processes. The company has also implemented a closed-loop system that captures and treats acid vapors, significantly reducing environmental impact and worker exposure[5].

Strengths: Comprehensive e-waste management, efficient acid treatment process. Weaknesses: May be less specialized in battery-specific recycling compared to dedicated battery recyclers.

Innovations in Acid-Resistant Recycling Technologies

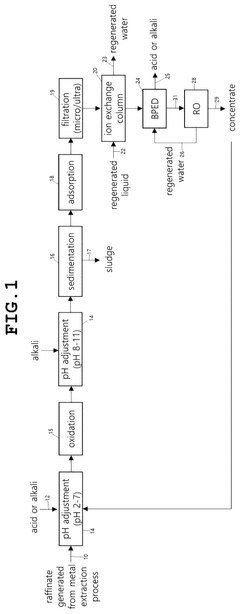

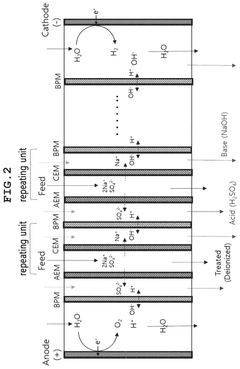

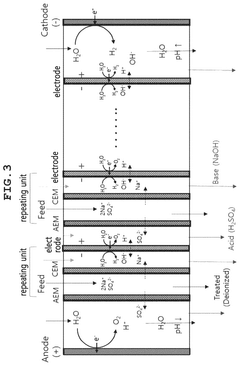

Method of recovering acid and alkali from raffinate generated from metal extraction process

PatentPendingUS20250003100A1

Innovation

- A method involving pretreatment of raffinates through processes like flocculation/sedimentation, adsorption, ion exchange, and oxidation, followed by electrodialysis using bipolar, cationic, or anionic membranes, to recover acids and alkalis, with the option of electrochemical-advanced oxidation and microfiltration for purification.

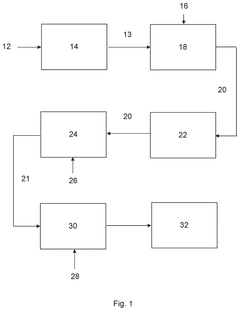

Apparatus and method for removing minerals from a mineral containing substance

PatentPendingUS20250011895A1

Innovation

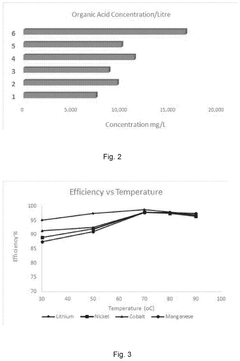

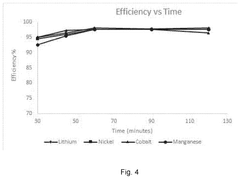

- A method involving freeze separation of a primary organic acid solution to concentrate and decrease its pH, creating a leachant that is applied to a mineral-containing substance, allowing for the extraction of metals like Lithium, Nickel, and Cobalt, followed by filtration and pH adjustment with sodium hydroxide, and treatment with carbon dioxide to precipitate lithium carbonate.

Environmental Regulations on E-Waste Recycling

Environmental regulations play a crucial role in shaping the landscape of electronic waste (e-waste) recycling, particularly concerning the impact of battery acid. These regulations aim to mitigate the environmental and health risks associated with improper handling and disposal of e-waste, including the hazardous materials found in batteries.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a framework for managing e-waste. This convention classifies certain types of e-waste, including those containing battery acid, as hazardous materials, requiring special handling and disposal procedures.

In the European Union, the Waste Electrical and Electronic Equipment (WEEE) Directive sets collection, recycling, and recovery targets for all types of electrical goods. The directive specifically addresses the treatment of batteries and accumulators, mandating their removal from e-waste before processing. Additionally, the EU's Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous substances in electrical and electronic equipment, indirectly affecting the composition of batteries and their impact on recycling processes.

The United States Environmental Protection Agency (EPA) regulates e-waste under the Resource Conservation and Recovery Act (RCRA). This act classifies certain e-waste components, including some types of batteries, as hazardous waste. The EPA has also implemented the Universal Waste Rule, which streamlines the management of widely generated hazardous wastes, including batteries, making it easier for organizations to collect and properly dispose of these materials.

Many countries have implemented Extended Producer Responsibility (EPR) programs, which hold manufacturers responsible for the entire lifecycle of their products, including end-of-life management. These programs often include specific provisions for battery collection and recycling, aiming to reduce the environmental impact of battery acid and other hazardous materials.

In response to the growing concern over lithium-ion batteries in e-waste, some jurisdictions have introduced specific regulations. For instance, California has implemented the Rechargeable Battery Recycling Act, which requires retailers to have battery collection and recycling programs in place.

As the volume of e-waste continues to grow globally, regulatory bodies are continuously updating and refining their approaches. There is an increasing focus on promoting circular economy principles, encouraging the design of electronics that are easier to recycle and recover valuable materials from, including batteries. This shift is reflected in emerging regulations that emphasize product design for recyclability and the use of less hazardous materials in battery production.

At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a framework for managing e-waste. This convention classifies certain types of e-waste, including those containing battery acid, as hazardous materials, requiring special handling and disposal procedures.

In the European Union, the Waste Electrical and Electronic Equipment (WEEE) Directive sets collection, recycling, and recovery targets for all types of electrical goods. The directive specifically addresses the treatment of batteries and accumulators, mandating their removal from e-waste before processing. Additionally, the EU's Restriction of Hazardous Substances (RoHS) Directive limits the use of certain hazardous substances in electrical and electronic equipment, indirectly affecting the composition of batteries and their impact on recycling processes.

The United States Environmental Protection Agency (EPA) regulates e-waste under the Resource Conservation and Recovery Act (RCRA). This act classifies certain e-waste components, including some types of batteries, as hazardous waste. The EPA has also implemented the Universal Waste Rule, which streamlines the management of widely generated hazardous wastes, including batteries, making it easier for organizations to collect and properly dispose of these materials.

Many countries have implemented Extended Producer Responsibility (EPR) programs, which hold manufacturers responsible for the entire lifecycle of their products, including end-of-life management. These programs often include specific provisions for battery collection and recycling, aiming to reduce the environmental impact of battery acid and other hazardous materials.

In response to the growing concern over lithium-ion batteries in e-waste, some jurisdictions have introduced specific regulations. For instance, California has implemented the Rechargeable Battery Recycling Act, which requires retailers to have battery collection and recycling programs in place.

As the volume of e-waste continues to grow globally, regulatory bodies are continuously updating and refining their approaches. There is an increasing focus on promoting circular economy principles, encouraging the design of electronics that are easier to recycle and recover valuable materials from, including batteries. This shift is reflected in emerging regulations that emphasize product design for recyclability and the use of less hazardous materials in battery production.

Economic Viability of Advanced Acid Treatment Methods

The economic viability of advanced acid treatment methods in electronic waste recycling is a critical factor in determining the feasibility and sustainability of these processes. As the volume of electronic waste continues to grow globally, the need for efficient and cost-effective recycling methods becomes increasingly important. Advanced acid treatment methods offer promising solutions for recovering valuable materials from e-waste, particularly in the extraction of precious metals and rare earth elements.

One of the primary considerations in assessing the economic viability of these methods is the initial capital investment required for equipment and infrastructure. While advanced acid treatment systems may have higher upfront costs compared to traditional recycling methods, they often offer improved recovery rates and higher purity of extracted materials. This increased efficiency can lead to higher revenue streams from the sale of recovered metals and other valuable components.

Operating costs are another crucial factor in determining economic viability. Advanced acid treatment methods typically require specialized chemicals and energy inputs, which can contribute significantly to ongoing expenses. However, these costs may be offset by the reduced labor requirements and increased automation capabilities of modern systems. Additionally, as the technology matures and becomes more widespread, economies of scale are likely to drive down both capital and operating costs.

The market value of recovered materials plays a pivotal role in the economic equation. Fluctuations in commodity prices can significantly impact the profitability of e-waste recycling operations. Advanced acid treatment methods that can extract a wider range of valuable materials or achieve higher purity levels may be better positioned to weather market volatility and maintain profitability.

Environmental regulations and compliance costs must also be factored into the economic assessment. While advanced acid treatment methods may require more stringent safety measures and waste management protocols, they often result in reduced environmental impact compared to traditional recycling methods. This can lead to lower compliance costs and potential incentives from regulatory bodies, improving the overall economic viability.

The scalability of advanced acid treatment methods is another important consideration. As the volume of e-waste continues to grow, the ability to scale up operations efficiently can significantly impact long-term economic viability. Methods that can be easily adapted to handle increasing volumes without proportional increases in costs are likely to be more economically attractive.

In conclusion, while advanced acid treatment methods for electronic waste recycling may require higher initial investments, their potential for improved recovery rates, higher-value outputs, and reduced environmental impact make them economically viable options for many recycling operations. As technology continues to advance and regulatory pressures increase, these methods are likely to become increasingly competitive and essential in the e-waste recycling industry.

One of the primary considerations in assessing the economic viability of these methods is the initial capital investment required for equipment and infrastructure. While advanced acid treatment systems may have higher upfront costs compared to traditional recycling methods, they often offer improved recovery rates and higher purity of extracted materials. This increased efficiency can lead to higher revenue streams from the sale of recovered metals and other valuable components.

Operating costs are another crucial factor in determining economic viability. Advanced acid treatment methods typically require specialized chemicals and energy inputs, which can contribute significantly to ongoing expenses. However, these costs may be offset by the reduced labor requirements and increased automation capabilities of modern systems. Additionally, as the technology matures and becomes more widespread, economies of scale are likely to drive down both capital and operating costs.

The market value of recovered materials plays a pivotal role in the economic equation. Fluctuations in commodity prices can significantly impact the profitability of e-waste recycling operations. Advanced acid treatment methods that can extract a wider range of valuable materials or achieve higher purity levels may be better positioned to weather market volatility and maintain profitability.

Environmental regulations and compliance costs must also be factored into the economic assessment. While advanced acid treatment methods may require more stringent safety measures and waste management protocols, they often result in reduced environmental impact compared to traditional recycling methods. This can lead to lower compliance costs and potential incentives from regulatory bodies, improving the overall economic viability.

The scalability of advanced acid treatment methods is another important consideration. As the volume of e-waste continues to grow, the ability to scale up operations efficiently can significantly impact long-term economic viability. Methods that can be easily adapted to handle increasing volumes without proportional increases in costs are likely to be more economically attractive.

In conclusion, while advanced acid treatment methods for electronic waste recycling may require higher initial investments, their potential for improved recovery rates, higher-value outputs, and reduced environmental impact make them economically viable options for many recycling operations. As technology continues to advance and regulatory pressures increase, these methods are likely to become increasingly competitive and essential in the e-waste recycling industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!