How Transition Metals Affect Battery Acid Longevity

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Transition Metal Impact on Battery Acid Lifespan

The impact of transition metals on battery acid longevity is a critical factor in the performance and lifespan of various battery technologies. Transition metals, such as iron, cobalt, nickel, and manganese, play a significant role in the electrochemical processes within batteries, particularly in the electrolyte solution. These metals can affect the stability, conductivity, and overall efficiency of the battery acid, ultimately influencing the battery's longevity.

One of the primary ways transition metals impact battery acid lifespan is through their catalytic properties. These metals can catalyze the decomposition of the electrolyte, leading to the formation of unwanted byproducts and gas evolution. This process not only reduces the amount of available electrolyte but also increases internal pressure within the battery, potentially causing physical damage to the cell structure.

Furthermore, transition metals can participate in redox reactions within the battery, altering the acid-base balance of the electrolyte. This shift in pH can accelerate corrosion of battery components, including electrodes and separators, thereby shortening the overall lifespan of the battery. The presence of certain transition metals may also lead to the formation of complex ions, which can interfere with the normal charge-discharge cycles and reduce the battery's capacity over time.

The solubility of transition metals in battery acid is another crucial factor. As these metals dissolve, they can migrate through the electrolyte and deposit on electrode surfaces. This phenomenon, known as metal plating, can cause dendrite formation, leading to internal short circuits and premature battery failure. Additionally, the presence of dissolved metal ions can increase the self-discharge rate of the battery, resulting in reduced storage capacity and shorter shelf life.

The concentration of transition metals in battery acid is a delicate balance. While some metals are intentionally added to enhance specific battery properties, excessive amounts can be detrimental. For instance, trace amounts of cobalt or nickel in lithium-ion batteries can improve the stability of the cathode structure, but higher concentrations may lead to unwanted side reactions and accelerated degradation of the electrolyte.

To mitigate the negative effects of transition metals on battery acid longevity, researchers and manufacturers employ various strategies. These include the use of high-purity materials to minimize metal contamination, the development of advanced electrolyte formulations that are less susceptible to metal-induced degradation, and the implementation of protective coatings on electrode surfaces to prevent metal dissolution and migration.

Understanding the complex interactions between transition metals and battery acid is crucial for advancing battery technology. By carefully controlling the presence and behavior of these metals, it is possible to significantly extend battery lifespan, improve performance, and enhance the overall reliability of energy storage systems across various applications.

One of the primary ways transition metals impact battery acid lifespan is through their catalytic properties. These metals can catalyze the decomposition of the electrolyte, leading to the formation of unwanted byproducts and gas evolution. This process not only reduces the amount of available electrolyte but also increases internal pressure within the battery, potentially causing physical damage to the cell structure.

Furthermore, transition metals can participate in redox reactions within the battery, altering the acid-base balance of the electrolyte. This shift in pH can accelerate corrosion of battery components, including electrodes and separators, thereby shortening the overall lifespan of the battery. The presence of certain transition metals may also lead to the formation of complex ions, which can interfere with the normal charge-discharge cycles and reduce the battery's capacity over time.

The solubility of transition metals in battery acid is another crucial factor. As these metals dissolve, they can migrate through the electrolyte and deposit on electrode surfaces. This phenomenon, known as metal plating, can cause dendrite formation, leading to internal short circuits and premature battery failure. Additionally, the presence of dissolved metal ions can increase the self-discharge rate of the battery, resulting in reduced storage capacity and shorter shelf life.

The concentration of transition metals in battery acid is a delicate balance. While some metals are intentionally added to enhance specific battery properties, excessive amounts can be detrimental. For instance, trace amounts of cobalt or nickel in lithium-ion batteries can improve the stability of the cathode structure, but higher concentrations may lead to unwanted side reactions and accelerated degradation of the electrolyte.

To mitigate the negative effects of transition metals on battery acid longevity, researchers and manufacturers employ various strategies. These include the use of high-purity materials to minimize metal contamination, the development of advanced electrolyte formulations that are less susceptible to metal-induced degradation, and the implementation of protective coatings on electrode surfaces to prevent metal dissolution and migration.

Understanding the complex interactions between transition metals and battery acid is crucial for advancing battery technology. By carefully controlling the presence and behavior of these metals, it is possible to significantly extend battery lifespan, improve performance, and enhance the overall reliability of energy storage systems across various applications.

Market Demand for Long-Lasting Batteries

The demand for long-lasting batteries has been steadily increasing across various sectors, driven by the growing reliance on portable electronic devices, electric vehicles, and renewable energy storage systems. In the consumer electronics market, smartphones, laptops, and wearable devices require batteries that can sustain longer periods of use between charges. This demand is further amplified by the increasing functionality and power requirements of these devices.

The automotive industry, particularly the electric vehicle (EV) sector, represents a significant driver for advanced battery technology. As more countries implement stringent emissions regulations and set targets for phasing out internal combustion engines, the demand for high-performance, long-lasting EV batteries continues to surge. Consumers and manufacturers alike are seeking batteries that can provide extended driving ranges and maintain capacity over many charging cycles.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and durable energy storage solutions. Grid-scale battery systems are becoming increasingly important for balancing supply and demand, as well as for providing backup power during peak usage periods or outages. The ability of batteries to maintain their capacity over extended periods is crucial for the economic viability of these large-scale energy storage projects.

Industrial applications, including robotics, aerospace, and marine technologies, also contribute to the growing demand for long-lasting batteries. These sectors require power sources that can operate reliably in challenging environments and maintain performance over extended periods without frequent replacement or maintenance.

The healthcare industry presents another significant market for durable battery technology. Medical devices, from portable diagnostic equipment to implantable devices, require batteries that can provide consistent power over long periods, often in critical situations where reliability is paramount.

As the Internet of Things (IoT) continues to expand, the need for long-lasting batteries in sensors and connected devices becomes increasingly important. These applications often require power sources that can operate autonomously for years without replacement, driving innovation in low-power, high-longevity battery technologies.

The market demand for long-lasting batteries is also influenced by environmental concerns and sustainability initiatives. Longer-lasting batteries reduce the frequency of replacement, thereby decreasing electronic waste and the environmental impact associated with battery production and disposal. This aligns with growing consumer awareness and corporate sustainability goals, further driving the demand for more durable and efficient battery technologies.

The automotive industry, particularly the electric vehicle (EV) sector, represents a significant driver for advanced battery technology. As more countries implement stringent emissions regulations and set targets for phasing out internal combustion engines, the demand for high-performance, long-lasting EV batteries continues to surge. Consumers and manufacturers alike are seeking batteries that can provide extended driving ranges and maintain capacity over many charging cycles.

In the renewable energy sector, the intermittent nature of solar and wind power generation necessitates efficient and durable energy storage solutions. Grid-scale battery systems are becoming increasingly important for balancing supply and demand, as well as for providing backup power during peak usage periods or outages. The ability of batteries to maintain their capacity over extended periods is crucial for the economic viability of these large-scale energy storage projects.

Industrial applications, including robotics, aerospace, and marine technologies, also contribute to the growing demand for long-lasting batteries. These sectors require power sources that can operate reliably in challenging environments and maintain performance over extended periods without frequent replacement or maintenance.

The healthcare industry presents another significant market for durable battery technology. Medical devices, from portable diagnostic equipment to implantable devices, require batteries that can provide consistent power over long periods, often in critical situations where reliability is paramount.

As the Internet of Things (IoT) continues to expand, the need for long-lasting batteries in sensors and connected devices becomes increasingly important. These applications often require power sources that can operate autonomously for years without replacement, driving innovation in low-power, high-longevity battery technologies.

The market demand for long-lasting batteries is also influenced by environmental concerns and sustainability initiatives. Longer-lasting batteries reduce the frequency of replacement, thereby decreasing electronic waste and the environmental impact associated with battery production and disposal. This aligns with growing consumer awareness and corporate sustainability goals, further driving the demand for more durable and efficient battery technologies.

Current Challenges in Battery Acid Stability

The stability of battery acid, particularly in the context of transition metal effects, presents several significant challenges in the field of battery technology. One of the primary issues is the gradual degradation of the electrolyte solution due to the presence of transition metal ions. These ions, often introduced as impurities or through electrode dissolution, can catalyze unwanted side reactions, leading to a decrease in the acid's longevity and overall battery performance.

A major challenge lies in mitigating the corrosive effects of transition metals on battery components. As these metals interact with the acidic environment, they can accelerate the corrosion of electrodes and other internal structures. This not only reduces the lifespan of the battery but also poses safety risks due to potential leakage or structural failure. The development of corrosion-resistant materials and protective coatings that can withstand both acidic conditions and transition metal presence remains an ongoing area of research.

Another significant hurdle is the management of gas evolution within the battery. Transition metals can catalyze the decomposition of water in the electrolyte, leading to increased hydrogen and oxygen production. This gas generation not only affects the internal pressure of the battery but also contributes to the drying out of the electrolyte, further compromising acid stability and battery performance. Designing effective gas recombination systems and optimizing electrolyte compositions to minimize these reactions are critical challenges facing battery engineers.

The formation of complex ions and precipitates due to transition metal interactions with the acid electrolyte poses additional complications. These formations can alter the electrolyte's conductivity, pH, and overall chemical balance, leading to reduced efficiency and shortened battery life. Developing strategies to prevent or control these chemical interactions without compromising the battery's core functionality remains a complex challenge.

Furthermore, the dynamic nature of transition metal effects on acid stability presents difficulties in predicting and modeling long-term battery performance. The gradual accumulation of metal ions and their evolving interactions with the electrolyte over time make it challenging to accurately forecast battery degradation rates and lifespans. This uncertainty complicates battery design and management strategies, particularly for applications requiring long-term reliability.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, electrochemistry, and chemical engineering. Innovations in electrolyte additives, electrode materials, and battery design are crucial for enhancing acid stability in the presence of transition metals. Additionally, the development of advanced monitoring and diagnostic tools to detect and mitigate the effects of transition metals in real-time could significantly improve battery management and longevity.

A major challenge lies in mitigating the corrosive effects of transition metals on battery components. As these metals interact with the acidic environment, they can accelerate the corrosion of electrodes and other internal structures. This not only reduces the lifespan of the battery but also poses safety risks due to potential leakage or structural failure. The development of corrosion-resistant materials and protective coatings that can withstand both acidic conditions and transition metal presence remains an ongoing area of research.

Another significant hurdle is the management of gas evolution within the battery. Transition metals can catalyze the decomposition of water in the electrolyte, leading to increased hydrogen and oxygen production. This gas generation not only affects the internal pressure of the battery but also contributes to the drying out of the electrolyte, further compromising acid stability and battery performance. Designing effective gas recombination systems and optimizing electrolyte compositions to minimize these reactions are critical challenges facing battery engineers.

The formation of complex ions and precipitates due to transition metal interactions with the acid electrolyte poses additional complications. These formations can alter the electrolyte's conductivity, pH, and overall chemical balance, leading to reduced efficiency and shortened battery life. Developing strategies to prevent or control these chemical interactions without compromising the battery's core functionality remains a complex challenge.

Furthermore, the dynamic nature of transition metal effects on acid stability presents difficulties in predicting and modeling long-term battery performance. The gradual accumulation of metal ions and their evolving interactions with the electrolyte over time make it challenging to accurately forecast battery degradation rates and lifespans. This uncertainty complicates battery design and management strategies, particularly for applications requiring long-term reliability.

Addressing these challenges requires a multidisciplinary approach, combining advances in materials science, electrochemistry, and chemical engineering. Innovations in electrolyte additives, electrode materials, and battery design are crucial for enhancing acid stability in the presence of transition metals. Additionally, the development of advanced monitoring and diagnostic tools to detect and mitigate the effects of transition metals in real-time could significantly improve battery management and longevity.

Existing Solutions for Acid Longevity

01 Battery management systems for improved longevity

Advanced battery management systems are employed to optimize charging, discharging, and overall battery performance. These systems monitor various parameters such as temperature, voltage, and current to extend battery life and maintain acid quality. By implementing intelligent control algorithms, the systems can prevent overcharging, deep discharging, and other detrimental conditions that could reduce battery acid longevity.- Battery management systems for improved longevity: Advanced battery management systems are employed to optimize charging, discharging, and overall battery performance. These systems monitor various parameters such as temperature, voltage, and current to extend battery life and maintain acid health. By implementing intelligent control algorithms, the systems can prevent overcharging, deep discharging, and other detrimental conditions that could reduce battery acid longevity.

- Electrolyte composition optimization: Improving the composition of battery electrolytes can significantly enhance acid longevity. This includes developing new additives, adjusting acid concentrations, and incorporating stabilizing compounds. These modifications aim to reduce acid degradation, minimize sulfation, and maintain optimal ionic conductivity throughout the battery's lifespan.

- Predictive maintenance and diagnostics: Implementing predictive maintenance techniques and advanced diagnostic tools can help identify potential issues before they impact battery acid longevity. Machine learning algorithms and data analytics are used to analyze battery performance data, predict failure modes, and recommend timely interventions to preserve acid health and extend overall battery life.

- Temperature control and thermal management: Effective temperature control and thermal management strategies are crucial for maintaining battery acid longevity. This includes developing cooling systems, heat dissipation techniques, and insulation methods to keep batteries within optimal temperature ranges. By preventing overheating and extreme temperature fluctuations, these approaches help preserve the chemical stability of the battery acid.

- Novel electrode materials and designs: Developing innovative electrode materials and designs can contribute to improved battery acid longevity. This includes exploring new alloys, nanostructured materials, and surface treatments that enhance electrochemical stability and reduce corrosion. Advanced electrode designs also aim to optimize current distribution and minimize localized acid degradation, thereby extending overall battery life.

02 Electrolyte composition optimization

Improving the composition of battery electrolytes can significantly enhance acid longevity. This involves developing new formulations or additives that reduce acid degradation, minimize sulfation, and improve overall electrolyte stability. Advanced electrolyte compositions may include organic or inorganic compounds that protect the electrodes and maintain optimal acid concentration over extended periods.Expand Specific Solutions03 Predictive maintenance and diagnostics

Implementing predictive maintenance techniques and advanced diagnostic tools can help identify potential issues before they impact battery acid longevity. These methods may involve machine learning algorithms, data analytics, and real-time monitoring to assess battery health, predict acid degradation, and recommend timely interventions to extend battery life.Expand Specific Solutions04 Thermal management for acid stability

Effective thermal management systems are crucial for maintaining optimal battery acid temperature, which directly impacts longevity. These systems may include advanced cooling mechanisms, heat dissipation techniques, or thermal insulation to prevent excessive heat buildup. By maintaining stable temperature conditions, the rate of acid degradation and other temperature-dependent deterioration processes can be significantly reduced.Expand Specific Solutions05 Novel electrode materials and designs

Developing innovative electrode materials and designs can contribute to improved battery acid longevity. This may involve using advanced nanomaterials, composite electrodes, or novel surface treatments that reduce acid consumption, minimize corrosion, and enhance overall electrochemical stability. These advancements can lead to more efficient energy storage and reduced stress on the battery acid over time.Expand Specific Solutions

Key Players in Battery Industry

The transition metal impact on battery acid longevity is a critical area of research in the evolving energy storage sector. The industry is in a growth phase, with the global lithium-ion battery market expected to reach $129.3 billion by 2027. Technological maturity varies, with established players like Panasonic, LG Chem, and CATL leading in commercialization, while newer entrants like A123 Systems and BYD are advancing innovative solutions. Companies such as Toyota, Nissan, and Tesla are driving demand through electric vehicle production. Academic institutions like South China University of Technology and Zhejiang University are contributing fundamental research, fostering industry-academia collaborations to address challenges in battery chemistry and longevity.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has pioneered the development of LFP (Lithium Iron Phosphate) batteries, which inherently offer better resistance to acid-induced degradation due to the stable olivine structure of the cathode material. Their cell-to-pack (CTP) technology integrates LFP cells directly into the battery pack, improving energy density while maintaining the acid resistance benefits[2]. CATL has also made significant strides in gradient cathode materials, where the concentration of transition metals varies from the particle surface to the core, creating a protective shell against acid attack. Their recent advancements include doping strategies for cathode materials, introducing small amounts of elements like aluminum or zirconium to enhance structural stability and reduce transition metal dissolution in acidic environments[4].

Strengths: Excellent thermal stability, long cycle life, and inherent resistance to acid-induced degradation. Weaknesses: Lower energy density compared to nickel-rich cathodes, which may limit application in high-energy-density scenarios.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced transition metal-based cathode materials for lithium-ion batteries, focusing on nickel-rich formulations to enhance energy density and longevity. Their NMC (Nickel Manganese Cobalt) cathodes, particularly the high-nickel variants like NMC811, demonstrate improved cycle life and capacity retention[1]. The company employs precise control of particle morphology and surface coatings to mitigate acid-induced degradation. LG Chem's research also extends to novel electrolyte additives that form stable passivation layers on electrode surfaces, reducing transition metal dissolution and subsequent capacity fade[3]. Their holistic approach includes optimizing the interplay between cathode composition, electrolyte formulation, and battery management systems to maximize acid resistance and overall battery lifespan.

Strengths: High energy density, improved cycle life, and reduced acid-induced degradation. Weaknesses: Potential thermal instability at high nickel content, higher production costs for advanced materials and coatings.

Core Innovations in Electrolyte Chemistry

Lithium transition metal oxide, cathode additive for lithium secondary battery, and lithium secondary battery comprising same

PatentWO2022158670A1

Innovation

- A lithium transition metal oxide represented by the formula Li6Co1-xMxO4, where M is a heterogeneous element selected from group 2, 13, 14, 4-period, 5-period, or 6-period transition metals, is introduced as a positive electrode additive to minimize side reactions and stabilize the crystal phase, suppressing gas generation and improving safety and lifespan.

Lithium ion battery

PatentWO2018043431A1

Innovation

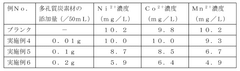

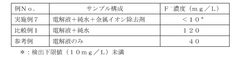

- Incorporating a metal ion remover, such as zeolite or a carbon-based material, within the battery case to adsorb transition metal ions and suppress the generation of hydrofluoric acid, thereby maintaining battery stability and extending lifespan.

Environmental Impact of Battery Acid

The environmental impact of battery acid is a critical concern in the context of how transition metals affect battery longevity. Battery acid, typically sulfuric acid in lead-acid batteries, can have severe consequences on ecosystems and human health if not properly managed throughout the battery lifecycle.

When batteries degrade or are improperly disposed of, the acid can leak into soil and water systems. This leakage can lead to soil acidification, altering the pH balance and potentially rendering areas inhospitable for plant growth. The acidic runoff can contaminate groundwater and surface water, affecting aquatic life and potentially entering the food chain.

Transition metals, which play a crucial role in battery performance, can exacerbate these environmental issues. As batteries deteriorate, these metals can leach into the environment along with the acid. Some transition metals, such as lead, cadmium, and nickel, are particularly toxic and can accumulate in living organisms, leading to long-term ecological damage.

The manufacturing process of batteries also contributes to environmental concerns. The extraction and processing of transition metals for battery production often involve energy-intensive and polluting activities. Mining operations can lead to habitat destruction, while refining processes may release harmful emissions and generate hazardous waste.

Recycling and proper disposal of batteries are essential in mitigating these environmental impacts. However, the presence of transition metals can complicate recycling processes, requiring specialized facilities and techniques to safely recover and reuse these materials. Improper recycling attempts can release toxic substances into the environment, potentially causing more harm than good.

The automotive industry's shift towards electric vehicles has intensified the focus on battery environmental impact. While this transition reduces direct emissions from vehicles, it increases the demand for batteries and, consequently, the potential for environmental damage from battery acid and associated metals if not managed properly.

Researchers and manufacturers are exploring ways to minimize the environmental footprint of batteries. This includes developing more environmentally friendly electrolytes, improving battery longevity to reduce waste, and enhancing recycling technologies. Some promising approaches involve using organic or water-based electrolytes instead of traditional acid-based solutions, potentially reducing the risk of harmful leakage.

In conclusion, the environmental impact of battery acid, particularly in relation to transition metals, is a multifaceted issue that spans the entire battery lifecycle. Addressing these challenges requires a comprehensive approach, involving improved battery design, responsible manufacturing practices, efficient recycling systems, and stringent regulations to ensure proper handling and disposal of batteries.

When batteries degrade or are improperly disposed of, the acid can leak into soil and water systems. This leakage can lead to soil acidification, altering the pH balance and potentially rendering areas inhospitable for plant growth. The acidic runoff can contaminate groundwater and surface water, affecting aquatic life and potentially entering the food chain.

Transition metals, which play a crucial role in battery performance, can exacerbate these environmental issues. As batteries deteriorate, these metals can leach into the environment along with the acid. Some transition metals, such as lead, cadmium, and nickel, are particularly toxic and can accumulate in living organisms, leading to long-term ecological damage.

The manufacturing process of batteries also contributes to environmental concerns. The extraction and processing of transition metals for battery production often involve energy-intensive and polluting activities. Mining operations can lead to habitat destruction, while refining processes may release harmful emissions and generate hazardous waste.

Recycling and proper disposal of batteries are essential in mitigating these environmental impacts. However, the presence of transition metals can complicate recycling processes, requiring specialized facilities and techniques to safely recover and reuse these materials. Improper recycling attempts can release toxic substances into the environment, potentially causing more harm than good.

The automotive industry's shift towards electric vehicles has intensified the focus on battery environmental impact. While this transition reduces direct emissions from vehicles, it increases the demand for batteries and, consequently, the potential for environmental damage from battery acid and associated metals if not managed properly.

Researchers and manufacturers are exploring ways to minimize the environmental footprint of batteries. This includes developing more environmentally friendly electrolytes, improving battery longevity to reduce waste, and enhancing recycling technologies. Some promising approaches involve using organic or water-based electrolytes instead of traditional acid-based solutions, potentially reducing the risk of harmful leakage.

In conclusion, the environmental impact of battery acid, particularly in relation to transition metals, is a multifaceted issue that spans the entire battery lifecycle. Addressing these challenges requires a comprehensive approach, involving improved battery design, responsible manufacturing practices, efficient recycling systems, and stringent regulations to ensure proper handling and disposal of batteries.

Recycling Technologies for Spent Battery Acid

Recycling technologies for spent battery acid have become increasingly important as the demand for batteries continues to grow. These technologies aim to recover valuable materials and reduce environmental impact. One of the primary methods involves neutralization, where the acid is treated with alkaline substances to adjust its pH level. This process renders the acid less hazardous and prepares it for further treatment or disposal.

Another widely used technique is electrodialysis, which employs ion-selective membranes to separate and concentrate the acid components. This method is particularly effective for recovering sulfuric acid from lead-acid batteries. The recovered acid can often be reused in battery manufacturing or other industrial processes, contributing to a circular economy approach.

Thermal decomposition is also utilized in some recycling processes. This method involves heating the spent acid to high temperatures, causing it to break down into its constituent components. The resulting gases can be captured and processed to recover valuable materials or converted into less harmful substances.

Membrane filtration technologies have shown promise in recent years. These systems use specialized membranes to separate contaminants from the acid, allowing for the recovery of purified acid solutions. This approach is particularly useful for removing metal ions and other impurities that accumulate in the acid during battery use.

Chemical precipitation is another important recycling technique. In this process, chemicals are added to the spent acid to cause certain components to precipitate out of solution. This allows for the selective recovery of valuable metals and other materials, which can then be further processed or reused.

Bioremediation approaches are also being explored for battery acid recycling. These methods utilize microorganisms to break down or neutralize the acid components. While still in the early stages of development, bioremediation could offer a more environmentally friendly alternative to traditional chemical treatments.

As research continues, new technologies are emerging that combine multiple approaches or utilize novel materials. For example, advanced adsorption materials are being developed to selectively remove specific contaminants from spent acid. Additionally, electrochemical processes are being refined to improve the efficiency of metal recovery and acid regeneration.

The choice of recycling technology often depends on factors such as the type of battery, the composition of the spent acid, and the desired end products. As the battery industry evolves, recycling technologies must adapt to handle new chemistries and meet increasingly stringent environmental regulations.

Another widely used technique is electrodialysis, which employs ion-selective membranes to separate and concentrate the acid components. This method is particularly effective for recovering sulfuric acid from lead-acid batteries. The recovered acid can often be reused in battery manufacturing or other industrial processes, contributing to a circular economy approach.

Thermal decomposition is also utilized in some recycling processes. This method involves heating the spent acid to high temperatures, causing it to break down into its constituent components. The resulting gases can be captured and processed to recover valuable materials or converted into less harmful substances.

Membrane filtration technologies have shown promise in recent years. These systems use specialized membranes to separate contaminants from the acid, allowing for the recovery of purified acid solutions. This approach is particularly useful for removing metal ions and other impurities that accumulate in the acid during battery use.

Chemical precipitation is another important recycling technique. In this process, chemicals are added to the spent acid to cause certain components to precipitate out of solution. This allows for the selective recovery of valuable metals and other materials, which can then be further processed or reused.

Bioremediation approaches are also being explored for battery acid recycling. These methods utilize microorganisms to break down or neutralize the acid components. While still in the early stages of development, bioremediation could offer a more environmentally friendly alternative to traditional chemical treatments.

As research continues, new technologies are emerging that combine multiple approaches or utilize novel materials. For example, advanced adsorption materials are being developed to selectively remove specific contaminants from spent acid. Additionally, electrochemical processes are being refined to improve the efficiency of metal recovery and acid regeneration.

The choice of recycling technology often depends on factors such as the type of battery, the composition of the spent acid, and the desired end products. As the battery industry evolves, recycling technologies must adapt to handle new chemistries and meet increasingly stringent environmental regulations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!