Battery Acid's Role in Enhanced Energy Management Systems

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Evolution

Battery acid, primarily composed of sulfuric acid and water, has played a crucial role in the evolution of energy management systems, particularly in lead-acid batteries. The journey of battery acid's development can be traced back to the late 18th century when Alessandro Volta invented the first electrical battery. However, it was not until 1859 that Gaston Planté developed the first rechargeable lead-acid battery, marking a significant milestone in battery technology.

The early lead-acid batteries used a dilute sulfuric acid solution as the electrolyte. As research progressed, scientists discovered that the concentration of the acid significantly impacted battery performance. This led to the optimization of acid concentration, typically ranging from 30% to 40% sulfuric acid by weight, to balance power output and battery life.

In the mid-20th century, the introduction of maintenance-free batteries revolutionized the industry. These batteries used calcium alloys in the lead plates, reducing water loss and minimizing the need for regular acid top-ups. This development greatly enhanced the practicality and reliability of lead-acid batteries in various applications, from automotive to backup power systems.

The 1970s saw the emergence of gel batteries, where silica was added to the electrolyte to create a gel-like substance. This innovation improved safety and allowed for more flexible battery positioning. Shortly after, Absorbed Glass Mat (AGM) technology was developed, where the electrolyte is held in glass fiber mats between the lead plates, further enhancing battery performance and safety.

Recent advancements in battery acid technology have focused on improving energy density, cycle life, and environmental sustainability. The development of high-purity acid and advanced additives has led to batteries with improved charge acceptance and longer service life. Additionally, research into alternative electrolytes, such as those based on ionic liquids, shows promise for next-generation energy storage systems.

The evolution of battery acid has also been driven by environmental concerns. Modern recycling techniques have been developed to recover and purify used battery acid, significantly reducing waste and environmental impact. Furthermore, ongoing research into safer and more environmentally friendly electrolytes continues to shape the future of energy storage technologies.

As we look towards the future, the role of battery acid in enhanced energy management systems is likely to evolve further. While lithium-ion batteries have gained prominence in many applications, advanced lead-acid batteries continue to play a vital role in various sectors due to their cost-effectiveness and reliability. The ongoing research in electrolyte composition and battery design promises to extend the capabilities of lead-acid batteries, ensuring their relevance in the ever-expanding field of energy storage and management.

The early lead-acid batteries used a dilute sulfuric acid solution as the electrolyte. As research progressed, scientists discovered that the concentration of the acid significantly impacted battery performance. This led to the optimization of acid concentration, typically ranging from 30% to 40% sulfuric acid by weight, to balance power output and battery life.

In the mid-20th century, the introduction of maintenance-free batteries revolutionized the industry. These batteries used calcium alloys in the lead plates, reducing water loss and minimizing the need for regular acid top-ups. This development greatly enhanced the practicality and reliability of lead-acid batteries in various applications, from automotive to backup power systems.

The 1970s saw the emergence of gel batteries, where silica was added to the electrolyte to create a gel-like substance. This innovation improved safety and allowed for more flexible battery positioning. Shortly after, Absorbed Glass Mat (AGM) technology was developed, where the electrolyte is held in glass fiber mats between the lead plates, further enhancing battery performance and safety.

Recent advancements in battery acid technology have focused on improving energy density, cycle life, and environmental sustainability. The development of high-purity acid and advanced additives has led to batteries with improved charge acceptance and longer service life. Additionally, research into alternative electrolytes, such as those based on ionic liquids, shows promise for next-generation energy storage systems.

The evolution of battery acid has also been driven by environmental concerns. Modern recycling techniques have been developed to recover and purify used battery acid, significantly reducing waste and environmental impact. Furthermore, ongoing research into safer and more environmentally friendly electrolytes continues to shape the future of energy storage technologies.

As we look towards the future, the role of battery acid in enhanced energy management systems is likely to evolve further. While lithium-ion batteries have gained prominence in many applications, advanced lead-acid batteries continue to play a vital role in various sectors due to their cost-effectiveness and reliability. The ongoing research in electrolyte composition and battery design promises to extend the capabilities of lead-acid batteries, ensuring their relevance in the ever-expanding field of energy storage and management.

Energy Management Market

The energy management market has experienced significant growth in recent years, driven by increasing global energy consumption, rising electricity costs, and growing environmental concerns. This market encompasses a wide range of solutions and technologies designed to optimize energy usage, reduce waste, and improve overall efficiency across various sectors, including residential, commercial, and industrial applications.

The global energy management market size was valued at approximately $24 billion in 2020 and is projected to reach $62 billion by 2027, growing at a compound annual growth rate (CAGR) of around 14.6% during the forecast period. This robust growth is attributed to several factors, including government initiatives promoting energy efficiency, the adoption of smart grid technologies, and the increasing integration of renewable energy sources into existing power systems.

In the residential sector, the demand for energy management solutions is primarily driven by the growing adoption of smart home devices and the increasing awareness of energy conservation among homeowners. Smart thermostats, energy-efficient appliances, and home energy monitoring systems are gaining popularity as consumers seek to reduce their energy bills and carbon footprint.

The commercial and industrial sectors represent a significant portion of the energy management market, with large corporations and manufacturing facilities implementing sophisticated energy management systems to optimize their operations and reduce costs. These systems often incorporate advanced analytics, artificial intelligence, and machine learning algorithms to identify energy-saving opportunities and automate energy-intensive processes.

The integration of battery storage systems into energy management solutions has emerged as a key trend in recent years. As the cost of battery technology continues to decline and energy storage capacity improves, batteries are playing an increasingly important role in load balancing, peak shaving, and grid stabilization. This trend is particularly evident in regions with high renewable energy penetration, where energy storage is crucial for managing intermittent power generation from solar and wind sources.

The energy management market is characterized by intense competition, with both established players and innovative startups vying for market share. Key players in the market include Schneider Electric, Siemens, Honeywell, Johnson Controls, and ABB, among others. These companies offer a wide range of energy management solutions, from hardware components to software platforms and services.

Geographically, North America and Europe currently dominate the energy management market, owing to stringent energy efficiency regulations and high adoption rates of advanced technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and government initiatives to promote sustainable energy practices in countries like China and India.

The global energy management market size was valued at approximately $24 billion in 2020 and is projected to reach $62 billion by 2027, growing at a compound annual growth rate (CAGR) of around 14.6% during the forecast period. This robust growth is attributed to several factors, including government initiatives promoting energy efficiency, the adoption of smart grid technologies, and the increasing integration of renewable energy sources into existing power systems.

In the residential sector, the demand for energy management solutions is primarily driven by the growing adoption of smart home devices and the increasing awareness of energy conservation among homeowners. Smart thermostats, energy-efficient appliances, and home energy monitoring systems are gaining popularity as consumers seek to reduce their energy bills and carbon footprint.

The commercial and industrial sectors represent a significant portion of the energy management market, with large corporations and manufacturing facilities implementing sophisticated energy management systems to optimize their operations and reduce costs. These systems often incorporate advanced analytics, artificial intelligence, and machine learning algorithms to identify energy-saving opportunities and automate energy-intensive processes.

The integration of battery storage systems into energy management solutions has emerged as a key trend in recent years. As the cost of battery technology continues to decline and energy storage capacity improves, batteries are playing an increasingly important role in load balancing, peak shaving, and grid stabilization. This trend is particularly evident in regions with high renewable energy penetration, where energy storage is crucial for managing intermittent power generation from solar and wind sources.

The energy management market is characterized by intense competition, with both established players and innovative startups vying for market share. Key players in the market include Schneider Electric, Siemens, Honeywell, Johnson Controls, and ABB, among others. These companies offer a wide range of energy management solutions, from hardware components to software platforms and services.

Geographically, North America and Europe currently dominate the energy management market, owing to stringent energy efficiency regulations and high adoption rates of advanced technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, urbanization, and government initiatives to promote sustainable energy practices in countries like China and India.

Acid Tech Challenges

The development of enhanced energy management systems faces several significant challenges related to battery acid technology. One of the primary obstacles is the corrosive nature of battery acid, which can lead to degradation of battery components and reduced lifespan. This corrosion issue not only affects the battery's performance but also poses safety risks and environmental concerns.

Another major challenge is the optimization of acid concentration and composition to maximize energy density and charge-discharge efficiency. Achieving the right balance between acid strength and battery longevity remains a complex task, requiring extensive research and testing. The acid's role in facilitating ion transfer during charge and discharge cycles is critical, yet maintaining optimal conditions throughout the battery's life cycle is difficult.

Temperature management presents another significant hurdle in acid-based battery systems. Extreme temperatures can affect acid viscosity and reactivity, leading to reduced performance and potential safety hazards. Developing effective thermal management solutions that work in conjunction with the acid electrolyte is crucial for enhancing overall system efficiency and reliability.

The scalability of acid-based energy storage systems for large-scale applications, such as grid-level storage, poses additional challenges. Issues related to acid handling, containment, and maintenance at scale need to be addressed to make these systems viable for widespread adoption in enhanced energy management scenarios.

Environmental and safety concerns associated with battery acid also present significant challenges. Proper disposal and recycling of acid electrolytes are essential to minimize environmental impact. Additionally, ensuring safe handling and containment of acid during manufacturing, operation, and maintenance processes is critical to prevent accidents and protect workers and end-users.

The integration of advanced monitoring and control systems to manage acid levels, concentration, and overall battery health in real-time is another technological challenge. Developing accurate sensors and algorithms capable of detecting subtle changes in acid properties and predicting potential issues before they occur is crucial for optimizing battery performance and longevity.

Lastly, the pursuit of alternative or modified acid formulations that can enhance energy density, cycle life, and safety while reducing environmental impact remains an ongoing challenge. This includes research into gel electrolytes, solid-state electrolytes, and other novel materials that could potentially replace traditional liquid acid electrolytes while maintaining or improving energy management capabilities.

Another major challenge is the optimization of acid concentration and composition to maximize energy density and charge-discharge efficiency. Achieving the right balance between acid strength and battery longevity remains a complex task, requiring extensive research and testing. The acid's role in facilitating ion transfer during charge and discharge cycles is critical, yet maintaining optimal conditions throughout the battery's life cycle is difficult.

Temperature management presents another significant hurdle in acid-based battery systems. Extreme temperatures can affect acid viscosity and reactivity, leading to reduced performance and potential safety hazards. Developing effective thermal management solutions that work in conjunction with the acid electrolyte is crucial for enhancing overall system efficiency and reliability.

The scalability of acid-based energy storage systems for large-scale applications, such as grid-level storage, poses additional challenges. Issues related to acid handling, containment, and maintenance at scale need to be addressed to make these systems viable for widespread adoption in enhanced energy management scenarios.

Environmental and safety concerns associated with battery acid also present significant challenges. Proper disposal and recycling of acid electrolytes are essential to minimize environmental impact. Additionally, ensuring safe handling and containment of acid during manufacturing, operation, and maintenance processes is critical to prevent accidents and protect workers and end-users.

The integration of advanced monitoring and control systems to manage acid levels, concentration, and overall battery health in real-time is another technological challenge. Developing accurate sensors and algorithms capable of detecting subtle changes in acid properties and predicting potential issues before they occur is crucial for optimizing battery performance and longevity.

Lastly, the pursuit of alternative or modified acid formulations that can enhance energy density, cycle life, and safety while reducing environmental impact remains an ongoing challenge. This includes research into gel electrolytes, solid-state electrolytes, and other novel materials that could potentially replace traditional liquid acid electrolytes while maintaining or improving energy management capabilities.

Current Acid Solutions

01 Battery acid level monitoring and management

Systems and methods for monitoring and managing battery acid levels to optimize battery performance and lifespan. This includes sensors for detecting acid levels, automated refilling systems, and algorithms for predicting maintenance needs based on usage patterns and environmental factors.- Battery acid level monitoring and management: Systems and methods for monitoring and managing battery acid levels to optimize battery performance and lifespan. This includes sensors for detecting acid levels, automated refilling systems, and algorithms for predicting maintenance needs based on usage patterns and environmental factors.

- Energy management systems for battery-powered devices: Advanced energy management systems designed to efficiently distribute and conserve power in battery-operated devices. These systems incorporate intelligent power allocation, load balancing, and adaptive charging techniques to extend battery life and improve overall device performance.

- Battery acid composition optimization: Innovative approaches to optimizing battery acid composition for enhanced energy storage and management. This includes developing new electrolyte formulations, additives to reduce corrosion, and materials that improve conductivity and charge retention.

- Thermal management of battery acid systems: Techniques for managing temperature in battery acid systems to prevent overheating and maintain optimal operating conditions. This encompasses cooling systems, heat dissipation methods, and temperature-responsive charging protocols to enhance battery efficiency and longevity.

- Smart charging and discharging strategies: Intelligent charging and discharging strategies that take into account battery acid characteristics, usage patterns, and environmental factors. These strategies aim to maximize battery life, improve charging efficiency, and optimize overall energy management in various applications.

02 Energy management systems for battery-powered devices

Advanced energy management systems designed to efficiently distribute and conserve power in battery-operated devices. These systems incorporate intelligent power allocation, load balancing, and adaptive charging techniques to extend battery life and improve overall device performance.Expand Specific Solutions03 Battery acid composition optimization

Innovative approaches to optimizing battery acid composition for enhanced energy storage and management. This includes developing new electrolyte formulations, additives to reduce corrosion, and materials that improve conductivity and charge retention.Expand Specific Solutions04 Thermal management of battery acid systems

Techniques for managing temperature in battery acid systems to prevent overheating and maintain optimal operating conditions. This encompasses cooling systems, heat dissipation methods, and temperature-responsive charging protocols to ensure battery safety and longevity.Expand Specific Solutions05 Smart charging and discharging algorithms

Development of intelligent algorithms for charging and discharging batteries to maximize efficiency and lifespan. These algorithms consider factors such as battery chemistry, usage patterns, and environmental conditions to optimize charging cycles and prevent acid degradation.Expand Specific Solutions

Key Industry Players

The battery acid technology market for enhanced energy management systems is in a growth phase, with increasing demand driven by the shift towards renewable energy and electric vehicles. The market size is expanding rapidly, with projections indicating substantial growth in the coming years. Technologically, while established players like GS Yuasa, LG Energy Solution, and Panasonic lead in mature lead-acid and lithium-ion technologies, innovative companies such as ArcActive and Mesha Energy Solutions are pushing boundaries with advanced lead-carbon and hybrid solutions. Emerging players like Turntide Technologies are also introducing novel approaches to energy management, indicating a dynamic and competitive landscape with varying levels of technological maturity across different battery chemistries and management systems.

GS Yuasa International Ltd.

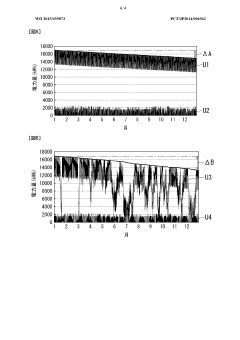

Technical Solution: GS Yuasa has developed advanced lead-acid battery technology for enhanced energy management systems. Their UltraBattery combines lead-acid chemistry with ultracapacitor technology, resulting in improved charge acceptance and cycle life[1]. This hybrid battery system utilizes a carbon-based electrode to manage partial state of charge operation more effectively. GS Yuasa's batteries incorporate advanced grid designs and active material formulations to enhance power density and reduce acid stratification[2]. The company has also implemented intelligent battery management systems that optimize charging algorithms and monitor individual cell performance in real-time[3].

Strengths: Improved cycle life, higher charge acceptance, and better performance in partial state of charge applications. Weaknesses: Higher initial cost compared to traditional lead-acid batteries, and potential complexity in manufacturing and maintenance.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed innovative battery acid management techniques for their advanced energy storage systems. Their approach includes the use of gel electrolytes and absorbent glass mat (AGM) separators to immobilize the acid, reducing stratification and improving cycle life[4]. LG has also implemented advanced battery management systems (BMS) that continuously monitor acid concentration and adjust charging parameters to optimize performance and longevity[5]. The company's batteries feature enhanced grid designs and active material formulations that resist acid-induced corrosion and sulfation, leading to improved energy density and longer service life[6].

Strengths: Reduced acid stratification, improved cycle life, and advanced monitoring capabilities. Weaknesses: Potentially higher manufacturing costs and the need for specialized maintenance procedures.

Acid Innovation Patents

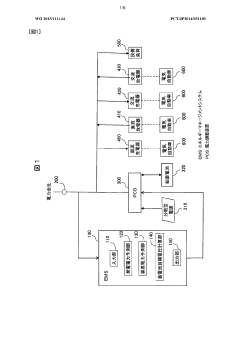

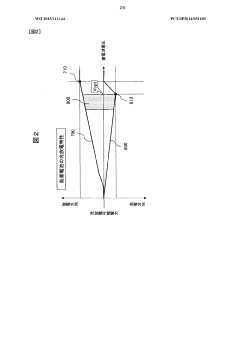

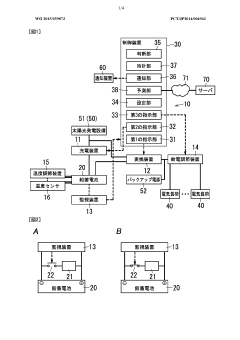

Power supply system and energy management system used in same

PatentWO2015111144A1

Innovation

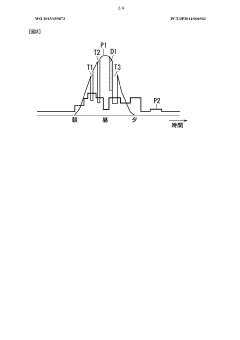

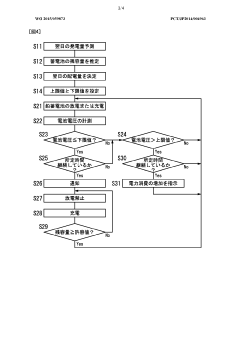

- A power supply system incorporating an Energy Management System (EMS) that predicts power generation and demand, calculates a target voltage for lead-acid batteries, and controls power input/output to maximize charge-discharge capacity by optimizing the operating voltage, considering the unique properties of lead-acid batteries, ensuring efficient and stable power management.

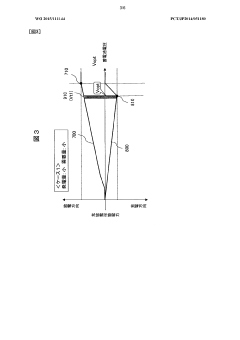

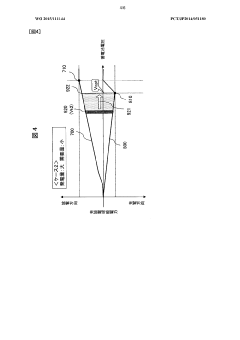

Power management apparatus

PatentWO2015059873A1

Innovation

- A power management device that includes a charging unit, conversion unit, monitoring unit, and control unit to manage the remaining capacity of lead-acid batteries, controlling charging and discharging to prevent sulfation without increasing device size or cost, by setting lower and upper limit values for capacity and adjusting power supply based on predicted energy generation.

Environmental Impact

The environmental impact of battery acid in enhanced energy management systems is a critical consideration as these technologies become more prevalent. The production, use, and disposal of battery acid, primarily sulfuric acid in lead-acid batteries, can have significant environmental implications if not properly managed.

During the manufacturing process of batteries, the production of sulfuric acid can lead to air and water pollution if strict environmental controls are not in place. Emissions of sulfur dioxide and other sulfur compounds can contribute to acid rain and air quality degradation. Additionally, the mining and processing of raw materials for battery production, such as lead and other metals, can result in habitat destruction and soil contamination.

In the operational phase, enhanced energy management systems utilizing battery acid can indirectly contribute to reduced environmental impact by improving energy efficiency and enabling greater integration of renewable energy sources. However, the potential for acid leaks and spills during battery operation and maintenance poses risks to soil and water ecosystems. Proper containment and handling procedures are essential to mitigate these risks.

The end-of-life management of batteries containing acid is a significant environmental concern. Improper disposal can lead to soil and groundwater contamination, potentially affecting both human health and ecosystems. Recycling processes for lead-acid batteries, while well-established, still present environmental challenges, including the release of toxic fumes and the generation of hazardous waste.

However, advancements in battery technology and energy management systems are addressing some of these environmental concerns. The development of more efficient and longer-lasting batteries reduces the frequency of replacement and, consequently, the overall environmental footprint. Additionally, improved recycling technologies and circular economy approaches are enhancing the recovery of materials from spent batteries, reducing the demand for raw materials and minimizing waste.

The shift towards more environmentally friendly alternatives, such as lithium-ion batteries, is also influencing the landscape of energy management systems. While these alternatives present their own set of environmental challenges, they often have a lower overall environmental impact compared to traditional lead-acid batteries.

In conclusion, while battery acid plays a crucial role in enhanced energy management systems, its environmental impact necessitates careful consideration and management throughout the entire lifecycle of the battery. Continued research and development in battery technology, coupled with stringent environmental regulations and improved recycling processes, are essential to minimize the negative environmental effects while maximizing the benefits of these energy management solutions.

During the manufacturing process of batteries, the production of sulfuric acid can lead to air and water pollution if strict environmental controls are not in place. Emissions of sulfur dioxide and other sulfur compounds can contribute to acid rain and air quality degradation. Additionally, the mining and processing of raw materials for battery production, such as lead and other metals, can result in habitat destruction and soil contamination.

In the operational phase, enhanced energy management systems utilizing battery acid can indirectly contribute to reduced environmental impact by improving energy efficiency and enabling greater integration of renewable energy sources. However, the potential for acid leaks and spills during battery operation and maintenance poses risks to soil and water ecosystems. Proper containment and handling procedures are essential to mitigate these risks.

The end-of-life management of batteries containing acid is a significant environmental concern. Improper disposal can lead to soil and groundwater contamination, potentially affecting both human health and ecosystems. Recycling processes for lead-acid batteries, while well-established, still present environmental challenges, including the release of toxic fumes and the generation of hazardous waste.

However, advancements in battery technology and energy management systems are addressing some of these environmental concerns. The development of more efficient and longer-lasting batteries reduces the frequency of replacement and, consequently, the overall environmental footprint. Additionally, improved recycling technologies and circular economy approaches are enhancing the recovery of materials from spent batteries, reducing the demand for raw materials and minimizing waste.

The shift towards more environmentally friendly alternatives, such as lithium-ion batteries, is also influencing the landscape of energy management systems. While these alternatives present their own set of environmental challenges, they often have a lower overall environmental impact compared to traditional lead-acid batteries.

In conclusion, while battery acid plays a crucial role in enhanced energy management systems, its environmental impact necessitates careful consideration and management throughout the entire lifecycle of the battery. Continued research and development in battery technology, coupled with stringent environmental regulations and improved recycling processes, are essential to minimize the negative environmental effects while maximizing the benefits of these energy management solutions.

Safety Regulations

Safety regulations play a crucial role in the development and implementation of enhanced energy management systems that utilize battery acid. These regulations are designed to protect workers, consumers, and the environment from potential hazards associated with the use of battery acid in energy storage and management applications.

One of the primary safety concerns addressed by regulations is the proper handling and storage of battery acid. Strict guidelines are in place for the transportation, storage, and disposal of battery acid to prevent accidental spills or leaks. These regulations often require specialized containment systems, protective equipment, and training for personnel who work with battery acid.

In the context of energy management systems, safety regulations also focus on the design and construction of battery enclosures. These enclosures must be capable of withstanding corrosion, preventing electrolyte leakage, and maintaining structural integrity under various environmental conditions. Ventilation requirements are typically specified to prevent the accumulation of potentially explosive hydrogen gas produced during battery charging.

Electrical safety is another critical aspect covered by regulations. Standards are set for insulation, grounding, and circuit protection to prevent electrical hazards such as short circuits, overheating, and electrocution. These regulations often mandate the use of safety devices such as fuses, circuit breakers, and isolation switches in battery-based energy management systems.

Environmental protection is a key consideration in safety regulations for battery acid applications. Guidelines are established for the proper disposal of spent batteries and acid, as well as for the containment and cleanup of accidental spills. Many regulations also address the recycling of battery components to minimize environmental impact and conserve resources.

Worker safety is paramount in the regulatory framework. Occupational health and safety standards dictate the use of personal protective equipment, emergency response procedures, and regular safety training for employees working with battery acid and related energy management systems. These regulations often include requirements for eye wash stations, safety showers, and first aid facilities in areas where battery acid is handled or stored.

As the technology for enhanced energy management systems evolves, safety regulations are continually updated to address new challenges and risks. This includes considerations for emerging battery chemistries, advanced monitoring systems, and integration with smart grid technologies. Regulatory bodies work closely with industry experts and researchers to ensure that safety standards keep pace with technological advancements in the field.

Compliance with safety regulations is typically enforced through a combination of inspections, certifications, and reporting requirements. Many jurisdictions require regular audits and assessments of energy management systems to ensure ongoing compliance with safety standards. Penalties for non-compliance can be severe, including fines, operational shutdowns, and legal liabilities.

One of the primary safety concerns addressed by regulations is the proper handling and storage of battery acid. Strict guidelines are in place for the transportation, storage, and disposal of battery acid to prevent accidental spills or leaks. These regulations often require specialized containment systems, protective equipment, and training for personnel who work with battery acid.

In the context of energy management systems, safety regulations also focus on the design and construction of battery enclosures. These enclosures must be capable of withstanding corrosion, preventing electrolyte leakage, and maintaining structural integrity under various environmental conditions. Ventilation requirements are typically specified to prevent the accumulation of potentially explosive hydrogen gas produced during battery charging.

Electrical safety is another critical aspect covered by regulations. Standards are set for insulation, grounding, and circuit protection to prevent electrical hazards such as short circuits, overheating, and electrocution. These regulations often mandate the use of safety devices such as fuses, circuit breakers, and isolation switches in battery-based energy management systems.

Environmental protection is a key consideration in safety regulations for battery acid applications. Guidelines are established for the proper disposal of spent batteries and acid, as well as for the containment and cleanup of accidental spills. Many regulations also address the recycling of battery components to minimize environmental impact and conserve resources.

Worker safety is paramount in the regulatory framework. Occupational health and safety standards dictate the use of personal protective equipment, emergency response procedures, and regular safety training for employees working with battery acid and related energy management systems. These regulations often include requirements for eye wash stations, safety showers, and first aid facilities in areas where battery acid is handled or stored.

As the technology for enhanced energy management systems evolves, safety regulations are continually updated to address new challenges and risks. This includes considerations for emerging battery chemistries, advanced monitoring systems, and integration with smart grid technologies. Regulatory bodies work closely with industry experts and researchers to ensure that safety standards keep pace with technological advancements in the field.

Compliance with safety regulations is typically enforced through a combination of inspections, certifications, and reporting requirements. Many jurisdictions require regular audits and assessments of energy management systems to ensure ongoing compliance with safety standards. Penalties for non-compliance can be severe, including fines, operational shutdowns, and legal liabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!