Advances in Battery Acid Recycling Technologies

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Recycling Evolution and Objectives

Battery acid recycling has undergone significant evolution over the past few decades, driven by environmental concerns, regulatory pressures, and technological advancements. The journey began with rudimentary methods of neutralization and disposal, which were neither efficient nor environmentally friendly. As awareness grew about the hazardous nature of battery acid and its potential impact on ecosystems, the focus shifted towards more sustainable recycling practices.

In the 1970s and 1980s, the primary objective was to neutralize the acid and safely dispose of it. However, this approach failed to recover valuable materials and still posed environmental risks. The 1990s saw a paradigm shift with the introduction of hydrometallurgical processes, which aimed to recover lead and other metals from the acid. This marked the beginning of a more circular approach to battery acid management.

The turn of the millennium brought increased attention to resource conservation and environmental protection. Consequently, the objectives of battery acid recycling expanded beyond mere disposal to include material recovery, energy efficiency, and minimization of environmental impact. Advanced separation technologies and chemical processes were developed to extract not just lead, but also other valuable components like sulfur and plastic.

Recent years have witnessed a surge in research and development efforts focused on improving the efficiency and sustainability of battery acid recycling. The advent of lithium-ion batteries has further complicated the recycling landscape, necessitating new techniques and processes. Current objectives in the field include maximizing material recovery rates, reducing energy consumption in recycling processes, and developing closed-loop systems that can reintegrate recycled materials directly into new battery production.

Looking ahead, the future of battery acid recycling is likely to be shaped by several key objectives. These include the development of universal recycling processes capable of handling multiple battery chemistries, the integration of artificial intelligence and machine learning for optimized recycling operations, and the creation of more localized recycling facilities to reduce transportation-related emissions. Additionally, there is a growing emphasis on designing batteries with recycling in mind, a concept known as "Design for Recycling," which aims to simplify the end-of-life processing of batteries.

As the global demand for batteries continues to rise, driven by the electrification of transportation and the growth of renewable energy storage, the importance of efficient and sustainable battery acid recycling cannot be overstated. The evolution of this field reflects a broader shift towards circular economy principles, where waste is viewed as a resource rather than a problem to be disposed of. The ongoing technological advancements in this area are not just addressing environmental concerns but are also opening up new economic opportunities in the recycling and materials recovery sectors.

In the 1970s and 1980s, the primary objective was to neutralize the acid and safely dispose of it. However, this approach failed to recover valuable materials and still posed environmental risks. The 1990s saw a paradigm shift with the introduction of hydrometallurgical processes, which aimed to recover lead and other metals from the acid. This marked the beginning of a more circular approach to battery acid management.

The turn of the millennium brought increased attention to resource conservation and environmental protection. Consequently, the objectives of battery acid recycling expanded beyond mere disposal to include material recovery, energy efficiency, and minimization of environmental impact. Advanced separation technologies and chemical processes were developed to extract not just lead, but also other valuable components like sulfur and plastic.

Recent years have witnessed a surge in research and development efforts focused on improving the efficiency and sustainability of battery acid recycling. The advent of lithium-ion batteries has further complicated the recycling landscape, necessitating new techniques and processes. Current objectives in the field include maximizing material recovery rates, reducing energy consumption in recycling processes, and developing closed-loop systems that can reintegrate recycled materials directly into new battery production.

Looking ahead, the future of battery acid recycling is likely to be shaped by several key objectives. These include the development of universal recycling processes capable of handling multiple battery chemistries, the integration of artificial intelligence and machine learning for optimized recycling operations, and the creation of more localized recycling facilities to reduce transportation-related emissions. Additionally, there is a growing emphasis on designing batteries with recycling in mind, a concept known as "Design for Recycling," which aims to simplify the end-of-life processing of batteries.

As the global demand for batteries continues to rise, driven by the electrification of transportation and the growth of renewable energy storage, the importance of efficient and sustainable battery acid recycling cannot be overstated. The evolution of this field reflects a broader shift towards circular economy principles, where waste is viewed as a resource rather than a problem to be disposed of. The ongoing technological advancements in this area are not just addressing environmental concerns but are also opening up new economic opportunities in the recycling and materials recovery sectors.

Market Analysis for Recycled Battery Acid

The global market for recycled battery acid has been experiencing significant growth in recent years, driven by increasing environmental concerns and stringent regulations regarding battery disposal. The recycling of battery acid, primarily sulfuric acid from lead-acid batteries, presents a substantial opportunity for both economic and environmental benefits.

The market size for recycled battery acid is closely tied to the lead-acid battery industry, which continues to dominate the automotive and industrial battery sectors. As the demand for these batteries remains strong, particularly in emerging economies, the volume of spent batteries requiring recycling is expected to grow correspondingly. This trend is further amplified by the rising adoption of electric vehicles and renewable energy storage systems, which often rely on lead-acid batteries for backup power.

Key market drivers include the growing emphasis on circular economy principles, government initiatives promoting battery recycling, and the cost-effectiveness of using recycled acid compared to virgin materials. Additionally, the increasing awareness of the environmental impact of improper battery disposal has led to more stringent regulations, creating a favorable market environment for recycling technologies.

Geographically, the market for recycled battery acid shows varying levels of maturity. Developed regions such as North America and Europe have well-established recycling infrastructures and stringent environmental regulations, leading to higher recycling rates. In contrast, emerging economies in Asia-Pacific and Latin America are experiencing rapid growth in this market, driven by industrialization and increasing vehicle ownership.

The automotive sector remains the largest consumer of recycled battery acid, followed by industrial applications and the chemical industry. The agriculture sector is also emerging as a significant end-user, utilizing recycled sulfuric acid for fertilizer production.

Market challenges include the need for significant capital investment in recycling technologies, fluctuations in raw material prices, and competition from alternative battery technologies. However, ongoing technological advancements in recycling processes are expected to improve efficiency and reduce costs, potentially expanding market opportunities.

Looking ahead, the market for recycled battery acid is projected to continue its growth trajectory. Factors such as the increasing focus on sustainable practices, the expansion of electric vehicle markets, and the development of more efficient recycling technologies are expected to drive this growth. Moreover, the potential for new applications of recycled battery acid in various industries presents additional avenues for market expansion.

The market size for recycled battery acid is closely tied to the lead-acid battery industry, which continues to dominate the automotive and industrial battery sectors. As the demand for these batteries remains strong, particularly in emerging economies, the volume of spent batteries requiring recycling is expected to grow correspondingly. This trend is further amplified by the rising adoption of electric vehicles and renewable energy storage systems, which often rely on lead-acid batteries for backup power.

Key market drivers include the growing emphasis on circular economy principles, government initiatives promoting battery recycling, and the cost-effectiveness of using recycled acid compared to virgin materials. Additionally, the increasing awareness of the environmental impact of improper battery disposal has led to more stringent regulations, creating a favorable market environment for recycling technologies.

Geographically, the market for recycled battery acid shows varying levels of maturity. Developed regions such as North America and Europe have well-established recycling infrastructures and stringent environmental regulations, leading to higher recycling rates. In contrast, emerging economies in Asia-Pacific and Latin America are experiencing rapid growth in this market, driven by industrialization and increasing vehicle ownership.

The automotive sector remains the largest consumer of recycled battery acid, followed by industrial applications and the chemical industry. The agriculture sector is also emerging as a significant end-user, utilizing recycled sulfuric acid for fertilizer production.

Market challenges include the need for significant capital investment in recycling technologies, fluctuations in raw material prices, and competition from alternative battery technologies. However, ongoing technological advancements in recycling processes are expected to improve efficiency and reduce costs, potentially expanding market opportunities.

Looking ahead, the market for recycled battery acid is projected to continue its growth trajectory. Factors such as the increasing focus on sustainable practices, the expansion of electric vehicle markets, and the development of more efficient recycling technologies are expected to drive this growth. Moreover, the potential for new applications of recycled battery acid in various industries presents additional avenues for market expansion.

Current Challenges in Battery Acid Recycling

Battery acid recycling faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary issues is the complexity of the recycling process itself. Battery acid, primarily composed of sulfuric acid, requires specialized handling and treatment methods to ensure safe and effective recycling. The corrosive nature of the acid poses risks to both workers and equipment, necessitating robust safety measures and specialized infrastructure.

Environmental concerns also present a major challenge in battery acid recycling. Improper handling or disposal of battery acid can lead to soil and water contamination, causing severe ecological damage. Stringent regulations and compliance requirements have been implemented to mitigate these risks, but they also increase the complexity and cost of recycling operations.

The economic viability of battery acid recycling remains a significant hurdle. The process often requires substantial investments in equipment, facilities, and trained personnel. Moreover, the fluctuating market prices of recycled materials can impact the profitability of recycling operations, making it challenging for companies to maintain consistent financial returns.

Technical limitations in current recycling technologies also pose challenges. Many existing methods struggle to achieve high purity levels in recovered materials, limiting their potential applications and value. Additionally, the energy-intensive nature of some recycling processes contributes to higher operational costs and carbon footprints, contradicting the sustainability goals of recycling initiatives.

The diversity of battery chemistries in the market further complicates recycling efforts. Different types of batteries require varying recycling approaches, making it difficult to establish standardized processes. This diversity also impacts the efficiency of sorting and separation techniques, which are crucial steps in the recycling process.

Logistical challenges in collecting and transporting used batteries and their components, including acid, present another obstacle. Establishing efficient collection networks and ensuring proper handling during transportation are essential but often complex and costly endeavors.

Lastly, public awareness and participation in battery recycling programs remain inconsistent. Many consumers are unaware of the importance of proper battery disposal or lack convenient access to recycling facilities. This gap in awareness and accessibility leads to a significant portion of batteries ending up in landfills, where their acid content can pose long-term environmental risks.

Environmental concerns also present a major challenge in battery acid recycling. Improper handling or disposal of battery acid can lead to soil and water contamination, causing severe ecological damage. Stringent regulations and compliance requirements have been implemented to mitigate these risks, but they also increase the complexity and cost of recycling operations.

The economic viability of battery acid recycling remains a significant hurdle. The process often requires substantial investments in equipment, facilities, and trained personnel. Moreover, the fluctuating market prices of recycled materials can impact the profitability of recycling operations, making it challenging for companies to maintain consistent financial returns.

Technical limitations in current recycling technologies also pose challenges. Many existing methods struggle to achieve high purity levels in recovered materials, limiting their potential applications and value. Additionally, the energy-intensive nature of some recycling processes contributes to higher operational costs and carbon footprints, contradicting the sustainability goals of recycling initiatives.

The diversity of battery chemistries in the market further complicates recycling efforts. Different types of batteries require varying recycling approaches, making it difficult to establish standardized processes. This diversity also impacts the efficiency of sorting and separation techniques, which are crucial steps in the recycling process.

Logistical challenges in collecting and transporting used batteries and their components, including acid, present another obstacle. Establishing efficient collection networks and ensuring proper handling during transportation are essential but often complex and costly endeavors.

Lastly, public awareness and participation in battery recycling programs remain inconsistent. Many consumers are unaware of the importance of proper battery disposal or lack convenient access to recycling facilities. This gap in awareness and accessibility leads to a significant portion of batteries ending up in landfills, where their acid content can pose long-term environmental risks.

Existing Battery Acid Recycling Methods

01 Acid recovery and purification methods

Various techniques are employed to recover and purify battery acid, including filtration, distillation, and chemical treatment processes. These methods aim to remove impurities and contaminants from the acid, allowing it to be reused in new batteries or other industrial applications. Advanced separation technologies may be used to achieve high purity levels.- Acid recovery and purification methods: Various techniques are employed to recover and purify battery acid, including filtration, distillation, and chemical treatment processes. These methods aim to remove impurities and contaminants from the acid, allowing it to be reused in new batteries or other industrial applications. The purification process often involves multiple stages to ensure high-quality acid recovery.

- Lead recovery from battery components: Recycling processes focus on recovering lead from battery components, such as plates and grids. This involves separating lead-containing materials, smelting, and refining to produce pure lead that can be used in new battery production. Advanced techniques are employed to maximize lead recovery while minimizing environmental impact.

- Electrolyte treatment and reuse: Battery acid, primarily sulfuric acid electrolyte, is treated to remove impurities and adjust its concentration. The treated electrolyte can be reused in new batteries or converted into other useful chemicals. This process often involves neutralization, filtration, and concentration adjustment steps to meet the required specifications for reuse.

- Automated recycling systems: Automated systems are developed to streamline the battery acid recycling process. These systems incorporate various technologies such as robotics, sensors, and control systems to efficiently handle, separate, and process battery components. Automated recycling systems improve safety, increase efficiency, and reduce labor costs in battery recycling facilities.

- Environmental protection measures: Recycling processes incorporate environmental protection measures to minimize pollution and ensure safe handling of hazardous materials. This includes containment systems, air filtration, wastewater treatment, and proper disposal of residual waste. Advanced technologies are employed to reduce emissions and ensure compliance with environmental regulations in battery acid recycling operations.

02 Electrolyte regeneration systems

Specialized systems are developed to regenerate spent battery electrolytes. These systems often involve a combination of chemical and physical processes to restore the electrolyte's original properties. The regeneration process may include steps such as neutralization, concentration adjustment, and removal of dissolved metals, enabling the electrolyte to be reused in new batteries.Expand Specific Solutions03 Lead recovery from battery acid

Techniques are developed to extract and recover lead from spent battery acid. These methods often involve precipitation, electrowinning, or other separation processes to isolate lead compounds. The recovered lead can be further processed and used in the production of new batteries or other lead-based products, reducing the need for raw material extraction.Expand Specific Solutions04 Integrated battery recycling systems

Comprehensive recycling systems are designed to handle various components of spent batteries, including the acid. These integrated systems often incorporate multiple stages of processing, such as acid drainage, neutralization, metal recovery, and plastic recycling. The goal is to maximize resource recovery while minimizing environmental impact.Expand Specific Solutions05 Environmentally friendly acid treatment processes

Innovative methods are developed to treat battery acid in an environmentally friendly manner. These processes may involve the use of bio-based materials, green chemistry principles, or closed-loop systems to minimize waste and emissions. The focus is on reducing the environmental footprint of acid recycling while maintaining high efficiency and cost-effectiveness.Expand Specific Solutions

Key Players in Battery Recycling Industry

The battery acid recycling technology sector is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The market size is expanding rapidly, with projections indicating significant growth in the coming years. Technologically, the field is advancing, with companies like Johnson Controls, Aqua Metals, and Clarios leading innovation. These firms are developing more efficient and environmentally friendly recycling processes, such as electroplating and hydrometallurgical techniques. Emerging players like Guangdong Bangpu and GEM Co. are also making strides in recycling technologies, particularly in the Asian market. Academic institutions, including Tsinghua University and the University of Birmingham, are contributing to research and development, further accelerating technological maturity in this sector.

Johnson Controls, Inc.

Technical Solution: Johnson Controls has developed advanced battery acid recycling technologies focusing on closed-loop recycling processes. Their approach involves a combination of hydrometallurgical and pyrometallurgical techniques to recover lead and other valuable materials from spent lead-acid batteries. The company has implemented a patented process that can recover up to 99% of the lead content from used batteries[1]. This process also includes innovative acid recovery methods, where the sulfuric acid is neutralized and converted into sodium sulfate, a common ingredient in detergents[2]. Johnson Controls has also invested in research to improve the energy efficiency of their recycling processes, reducing the overall carbon footprint of battery recycling operations[3].

Strengths: High recovery rate of lead, efficient acid neutralization, and reduced environmental impact. Weaknesses: High initial investment costs and potential complexity in scaling up operations.

Aqua Metals, Inc.

Technical Solution: Aqua Metals has pioneered a groundbreaking lead recycling technology called AquaRefining. This process uses a water-based, room-temperature electrochemical process to recover lead from used batteries, eliminating the traditional smelting method. The AquaRefining technology can produce 99.99+% pure lead without generating hazardous emissions[4]. The process is modular and scalable, allowing for flexible deployment in various locations. Aqua Metals has also developed methods to recycle the electrolyte solution, further reducing waste and improving overall efficiency[5]. Recent advancements include the ability to process both hard lead and lead compounds simultaneously, increasing the range of materials that can be recycled[6].

Strengths: Environmentally friendly process, high purity lead output, and modular design. Weaknesses: Relatively new technology with limited large-scale implementation history.

Innovative Acid Recycling Techniques

Battery recycling process

PatentWO2024178482A1

Innovation

- A hydrometallurgical process that mechanically processes lithium-ion batteries without heat treatment, using ozonization followed by electrodialysis for metal separation, and employs acid leaching without reducing agents to recover metals like lithium, cobalt, nickel, and manganese, with specific steps for precipitation and filtration to achieve high purity.

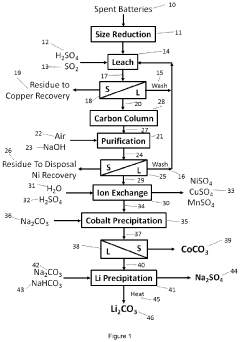

Process for the recovery of cobalt, lithium, and other metals from spent lithium-based batteries and other feeds

PatentInactiveUS20210079495A1

Innovation

- A method involving a sulphuric acid leach with sulphur dioxide sparging, followed by air treatment and ion exchange, to selectively recover cobalt and lithium from shredded lithium-based batteries, achieving high purity and reducing energy consumption and environmental impact.

Environmental Impact Assessment

The environmental impact assessment of battery acid recycling technologies is a critical aspect of evaluating their overall sustainability and viability. As these technologies advance, their potential to mitigate environmental harm becomes increasingly significant.

Traditional battery acid disposal methods have long been associated with severe environmental risks, including soil contamination, water pollution, and the release of toxic fumes. However, modern recycling technologies are demonstrating promising results in reducing these negative impacts.

One of the primary environmental benefits of advanced battery acid recycling is the reduction of hazardous waste. By recovering and reprocessing sulfuric acid, these technologies significantly decrease the volume of harmful substances that would otherwise be released into the environment. This not only minimizes the risk of soil and water contamination but also reduces the demand for raw materials in new battery production.

Air quality improvements are another notable outcome of these recycling processes. Many advanced technologies incorporate closed-loop systems and efficient filtration mechanisms, which effectively capture and neutralize harmful emissions. This results in a substantial decrease in air pollutants associated with battery acid disposal, contributing to better overall air quality in surrounding areas.

Water conservation is an additional environmental advantage of modern battery acid recycling. Some innovative technologies employ water recycling systems within the process, minimizing freshwater consumption and reducing wastewater discharge. This approach not only conserves water resources but also prevents the potential contamination of local water bodies.

The energy efficiency of these advanced recycling technologies also contributes to their positive environmental impact. Many processes are designed to recover and reuse energy, reducing the overall carbon footprint associated with battery acid management. This aligns with global efforts to combat climate change and promote sustainable industrial practices.

Furthermore, the implementation of these technologies often leads to improved land use. By efficiently processing battery acid, less space is required for waste storage and disposal, potentially freeing up land for more productive or environmentally beneficial uses.

However, it is important to note that the environmental impact of battery acid recycling technologies can vary depending on the specific methods employed and the scale of operations. Continuous monitoring and assessment are necessary to ensure that the environmental benefits are consistently realized and that any potential negative impacts are promptly addressed.

In conclusion, the environmental impact assessment of advanced battery acid recycling technologies reveals a largely positive outlook. These innovations offer significant potential for reducing environmental harm associated with battery disposal while promoting resource conservation and sustainable industrial practices.

Traditional battery acid disposal methods have long been associated with severe environmental risks, including soil contamination, water pollution, and the release of toxic fumes. However, modern recycling technologies are demonstrating promising results in reducing these negative impacts.

One of the primary environmental benefits of advanced battery acid recycling is the reduction of hazardous waste. By recovering and reprocessing sulfuric acid, these technologies significantly decrease the volume of harmful substances that would otherwise be released into the environment. This not only minimizes the risk of soil and water contamination but also reduces the demand for raw materials in new battery production.

Air quality improvements are another notable outcome of these recycling processes. Many advanced technologies incorporate closed-loop systems and efficient filtration mechanisms, which effectively capture and neutralize harmful emissions. This results in a substantial decrease in air pollutants associated with battery acid disposal, contributing to better overall air quality in surrounding areas.

Water conservation is an additional environmental advantage of modern battery acid recycling. Some innovative technologies employ water recycling systems within the process, minimizing freshwater consumption and reducing wastewater discharge. This approach not only conserves water resources but also prevents the potential contamination of local water bodies.

The energy efficiency of these advanced recycling technologies also contributes to their positive environmental impact. Many processes are designed to recover and reuse energy, reducing the overall carbon footprint associated with battery acid management. This aligns with global efforts to combat climate change and promote sustainable industrial practices.

Furthermore, the implementation of these technologies often leads to improved land use. By efficiently processing battery acid, less space is required for waste storage and disposal, potentially freeing up land for more productive or environmentally beneficial uses.

However, it is important to note that the environmental impact of battery acid recycling technologies can vary depending on the specific methods employed and the scale of operations. Continuous monitoring and assessment are necessary to ensure that the environmental benefits are consistently realized and that any potential negative impacts are promptly addressed.

In conclusion, the environmental impact assessment of advanced battery acid recycling technologies reveals a largely positive outlook. These innovations offer significant potential for reducing environmental harm associated with battery disposal while promoting resource conservation and sustainable industrial practices.

Regulatory Framework for Battery Recycling

The regulatory framework for battery recycling has become increasingly stringent in recent years, reflecting growing environmental concerns and the need for sustainable resource management. At the international level, the Basel Convention on the Control of Transboundary Movements of Hazardous Wastes and Their Disposal provides a global framework for the management of hazardous wastes, including spent batteries. This convention sets standards for the movement of such materials across borders and encourages the development of environmentally sound management practices.

In the European Union, the Batteries Directive (2006/66/EC) establishes specific rules for the collection, recycling, and disposal of batteries. This directive sets collection targets for member states and requires producers to finance the costs of collecting, treating, and recycling waste batteries. It also prohibits the disposal of automotive and industrial batteries in landfills or by incineration.

The United States has a more fragmented approach, with regulations varying by state. However, the federal Mercury-Containing and Rechargeable Battery Management Act of 1996 sets national standards for the proper management of certain types of batteries. Many states have implemented their own battery recycling laws, often more stringent than federal regulations.

In Asia, countries like Japan and South Korea have implemented comprehensive battery recycling regulations. Japan's Law for the Promotion of Effective Utilization of Resources mandates the collection and recycling of rechargeable batteries, while South Korea's Act on the Promotion of Saving and Recycling of Resources includes specific provisions for battery recycling.

Emerging economies are also developing regulatory frameworks for battery recycling. China, for instance, has introduced policies to promote the recycling of new energy vehicle batteries, including guidelines for the establishment of a traceability management system for the entire lifecycle of these batteries.

These regulatory frameworks typically include provisions for the proper handling, storage, and transportation of spent batteries, as well as requirements for recycling facilities to obtain permits and meet specific environmental and safety standards. Many jurisdictions also mandate extended producer responsibility, requiring manufacturers to take financial or physical responsibility for the end-of-life management of their products.

As the global shift towards electric vehicles accelerates, regulators are increasingly focusing on the recycling of lithium-ion batteries. This has led to the development of new standards and guidelines specific to this battery type, addressing challenges such as fire risk during transportation and the need for specialized recycling processes.

In the European Union, the Batteries Directive (2006/66/EC) establishes specific rules for the collection, recycling, and disposal of batteries. This directive sets collection targets for member states and requires producers to finance the costs of collecting, treating, and recycling waste batteries. It also prohibits the disposal of automotive and industrial batteries in landfills or by incineration.

The United States has a more fragmented approach, with regulations varying by state. However, the federal Mercury-Containing and Rechargeable Battery Management Act of 1996 sets national standards for the proper management of certain types of batteries. Many states have implemented their own battery recycling laws, often more stringent than federal regulations.

In Asia, countries like Japan and South Korea have implemented comprehensive battery recycling regulations. Japan's Law for the Promotion of Effective Utilization of Resources mandates the collection and recycling of rechargeable batteries, while South Korea's Act on the Promotion of Saving and Recycling of Resources includes specific provisions for battery recycling.

Emerging economies are also developing regulatory frameworks for battery recycling. China, for instance, has introduced policies to promote the recycling of new energy vehicle batteries, including guidelines for the establishment of a traceability management system for the entire lifecycle of these batteries.

These regulatory frameworks typically include provisions for the proper handling, storage, and transportation of spent batteries, as well as requirements for recycling facilities to obtain permits and meet specific environmental and safety standards. Many jurisdictions also mandate extended producer responsibility, requiring manufacturers to take financial or physical responsibility for the end-of-life management of their products.

As the global shift towards electric vehicles accelerates, regulators are increasingly focusing on the recycling of lithium-ion batteries. This has led to the development of new standards and guidelines specific to this battery type, addressing challenges such as fire risk during transportation and the need for specialized recycling processes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!