Effects of Battery Acid on Semiconductor Derivatives

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Impact on Semiconductors: Background and Objectives

The impact of battery acid on semiconductors has been a critical area of study in the electronics industry for decades. This research stems from the increasing prevalence of battery-powered devices and the potential for acid leakage or exposure during manufacturing, storage, or usage. The evolution of this field has been driven by the continuous miniaturization of electronic components and the growing demand for more efficient and durable power sources.

Historically, the interaction between battery acid and semiconductors became a concern with the widespread adoption of portable electronics in the 1980s. As devices became smaller and more complex, the proximity of battery compartments to sensitive electronic components increased the risk of acid-related damage. This led to a surge in research focused on understanding the chemical reactions between various types of battery acids and semiconductor materials.

The primary objective of studying the effects of battery acid on semiconductor derivatives is to enhance the reliability and longevity of electronic devices. This involves investigating the mechanisms of acid-induced degradation, developing protective measures, and creating more resistant semiconductor materials. Additionally, researchers aim to optimize battery designs to minimize the risk of acid leakage and its subsequent impact on electronic components.

Current technological trends in this field include the development of advanced encapsulation techniques to shield semiconductors from acid exposure, the creation of acid-resistant coatings for electronic components, and the exploration of alternative battery chemistries that pose less risk to semiconductors. The emergence of solid-state batteries has also opened new avenues for research, as these power sources potentially eliminate the risk of liquid acid leakage.

The semiconductor industry's rapid advancement has further complicated this research area. As new materials and manufacturing processes are introduced, their interactions with various types of battery acids must be thoroughly examined. This includes studying the effects on novel semiconductor compounds, such as gallium nitride and silicon carbide, which are increasingly used in high-performance electronics.

Looking ahead, the goals of this research extend beyond mere protection. Scientists and engineers are exploring ways to harness the chemical interactions between acids and semiconductors for potential benefits. This includes investigating how controlled acid exposure might be used to modify semiconductor properties or create novel electronic structures. Such advancements could lead to breakthroughs in areas like flexible electronics, biocompatible devices, and next-generation energy storage solutions.

Historically, the interaction between battery acid and semiconductors became a concern with the widespread adoption of portable electronics in the 1980s. As devices became smaller and more complex, the proximity of battery compartments to sensitive electronic components increased the risk of acid-related damage. This led to a surge in research focused on understanding the chemical reactions between various types of battery acids and semiconductor materials.

The primary objective of studying the effects of battery acid on semiconductor derivatives is to enhance the reliability and longevity of electronic devices. This involves investigating the mechanisms of acid-induced degradation, developing protective measures, and creating more resistant semiconductor materials. Additionally, researchers aim to optimize battery designs to minimize the risk of acid leakage and its subsequent impact on electronic components.

Current technological trends in this field include the development of advanced encapsulation techniques to shield semiconductors from acid exposure, the creation of acid-resistant coatings for electronic components, and the exploration of alternative battery chemistries that pose less risk to semiconductors. The emergence of solid-state batteries has also opened new avenues for research, as these power sources potentially eliminate the risk of liquid acid leakage.

The semiconductor industry's rapid advancement has further complicated this research area. As new materials and manufacturing processes are introduced, their interactions with various types of battery acids must be thoroughly examined. This includes studying the effects on novel semiconductor compounds, such as gallium nitride and silicon carbide, which are increasingly used in high-performance electronics.

Looking ahead, the goals of this research extend beyond mere protection. Scientists and engineers are exploring ways to harness the chemical interactions between acids and semiconductors for potential benefits. This includes investigating how controlled acid exposure might be used to modify semiconductor properties or create novel electronic structures. Such advancements could lead to breakthroughs in areas like flexible electronics, biocompatible devices, and next-generation energy storage solutions.

Market Analysis for Acid-Resistant Semiconductor Materials

The market for acid-resistant semiconductor materials has been experiencing significant growth in recent years, driven by the increasing demand for durable electronic components in various industries. This demand is particularly pronounced in sectors where electronic devices are exposed to harsh environments, such as automotive, industrial automation, and energy storage systems.

The global market for acid-resistant semiconductor materials is primarily segmented into three main categories: silicon carbide (SiC), gallium nitride (GaN), and other advanced materials like diamond-based semiconductors. Among these, SiC and GaN have gained substantial traction due to their superior properties in withstanding acidic environments while maintaining high performance.

In the automotive sector, the shift towards electric vehicles (EVs) has been a major driver for acid-resistant semiconductor materials. The battery management systems in EVs require components that can withstand the corrosive effects of battery acid, making SiC and GaN ideal choices. This trend is expected to continue as the EV market expands globally.

The industrial automation sector is another key market for acid-resistant semiconductor materials. In manufacturing environments where exposure to corrosive substances is common, these materials play a crucial role in ensuring the longevity and reliability of electronic control systems and sensors.

Geographically, North America and Asia-Pacific are the leading markets for acid-resistant semiconductor materials. The strong presence of semiconductor manufacturers and automotive industries in these regions contributes to their market dominance. Europe is also showing significant growth potential, driven by its robust automotive sector and increasing focus on industrial automation.

Market analysts project a compound annual growth rate (CAGR) for the acid-resistant semiconductor materials market in the range of 15-20% over the next five years. This growth is attributed to the expanding applications in emerging technologies such as 5G infrastructure, renewable energy systems, and advanced robotics, all of which require components capable of withstanding harsh operating conditions.

However, the market faces challenges in terms of high production costs and complex manufacturing processes associated with these advanced materials. This has led to a focus on research and development efforts aimed at improving production efficiency and reducing costs, which could potentially accelerate market growth in the coming years.

In conclusion, the market for acid-resistant semiconductor materials shows strong growth potential, driven by technological advancements and increasing demand across multiple industries. As manufacturers continue to innovate and improve production processes, the market is expected to expand further, offering significant opportunities for both established players and new entrants in the semiconductor industry.

The global market for acid-resistant semiconductor materials is primarily segmented into three main categories: silicon carbide (SiC), gallium nitride (GaN), and other advanced materials like diamond-based semiconductors. Among these, SiC and GaN have gained substantial traction due to their superior properties in withstanding acidic environments while maintaining high performance.

In the automotive sector, the shift towards electric vehicles (EVs) has been a major driver for acid-resistant semiconductor materials. The battery management systems in EVs require components that can withstand the corrosive effects of battery acid, making SiC and GaN ideal choices. This trend is expected to continue as the EV market expands globally.

The industrial automation sector is another key market for acid-resistant semiconductor materials. In manufacturing environments where exposure to corrosive substances is common, these materials play a crucial role in ensuring the longevity and reliability of electronic control systems and sensors.

Geographically, North America and Asia-Pacific are the leading markets for acid-resistant semiconductor materials. The strong presence of semiconductor manufacturers and automotive industries in these regions contributes to their market dominance. Europe is also showing significant growth potential, driven by its robust automotive sector and increasing focus on industrial automation.

Market analysts project a compound annual growth rate (CAGR) for the acid-resistant semiconductor materials market in the range of 15-20% over the next five years. This growth is attributed to the expanding applications in emerging technologies such as 5G infrastructure, renewable energy systems, and advanced robotics, all of which require components capable of withstanding harsh operating conditions.

However, the market faces challenges in terms of high production costs and complex manufacturing processes associated with these advanced materials. This has led to a focus on research and development efforts aimed at improving production efficiency and reducing costs, which could potentially accelerate market growth in the coming years.

In conclusion, the market for acid-resistant semiconductor materials shows strong growth potential, driven by technological advancements and increasing demand across multiple industries. As manufacturers continue to innovate and improve production processes, the market is expected to expand further, offering significant opportunities for both established players and new entrants in the semiconductor industry.

Current Challenges in Semiconductor-Acid Interactions

The semiconductor industry faces significant challenges in managing the interactions between battery acids and semiconductor derivatives. One of the primary concerns is the corrosive nature of battery acids, which can lead to degradation of semiconductor materials and components. This corrosion can result in reduced performance, shortened lifespan, and potential failure of electronic devices.

A major challenge lies in developing effective protective coatings and encapsulation techniques that can withstand the harsh acidic environment while maintaining the electrical and thermal properties of the semiconductors. Current solutions often struggle to provide long-term protection without compromising the functionality of the semiconductor devices.

Another critical issue is the potential for acid leakage in battery-powered devices. Even small amounts of acid seepage can cause catastrophic damage to sensitive semiconductor components. This necessitates the development of more robust containment systems and improved battery designs to minimize the risk of acid exposure.

The miniaturization trend in electronics further complicates the acid-semiconductor interaction problem. As devices become smaller and more compact, the proximity between battery components and semiconductor elements increases, heightening the risk of acid-induced damage. This challenge requires innovative approaches to device architecture and component isolation.

Heat generation in electronic devices exacerbates the acid-semiconductor interaction issues. Elevated temperatures can accelerate chemical reactions between acids and semiconductor materials, potentially leading to faster degradation and failure. Addressing this challenge requires advancements in thermal management techniques and the development of more heat-resistant semiconductor materials.

The variability in acid composition across different battery types presents another hurdle. Semiconductor components must be designed to withstand a range of acidic environments, from the sulfuric acid found in lead-acid batteries to the less corrosive but still potentially damaging electrolytes used in lithium-ion batteries. This diversity necessitates comprehensive testing and validation processes to ensure compatibility across various battery chemistries.

Environmental concerns add another layer of complexity to the acid-semiconductor interaction challenge. As the push for more sustainable and recyclable electronics grows, finding eco-friendly solutions that can protect semiconductors from acid damage while meeting environmental regulations becomes increasingly important.

A major challenge lies in developing effective protective coatings and encapsulation techniques that can withstand the harsh acidic environment while maintaining the electrical and thermal properties of the semiconductors. Current solutions often struggle to provide long-term protection without compromising the functionality of the semiconductor devices.

Another critical issue is the potential for acid leakage in battery-powered devices. Even small amounts of acid seepage can cause catastrophic damage to sensitive semiconductor components. This necessitates the development of more robust containment systems and improved battery designs to minimize the risk of acid exposure.

The miniaturization trend in electronics further complicates the acid-semiconductor interaction problem. As devices become smaller and more compact, the proximity between battery components and semiconductor elements increases, heightening the risk of acid-induced damage. This challenge requires innovative approaches to device architecture and component isolation.

Heat generation in electronic devices exacerbates the acid-semiconductor interaction issues. Elevated temperatures can accelerate chemical reactions between acids and semiconductor materials, potentially leading to faster degradation and failure. Addressing this challenge requires advancements in thermal management techniques and the development of more heat-resistant semiconductor materials.

The variability in acid composition across different battery types presents another hurdle. Semiconductor components must be designed to withstand a range of acidic environments, from the sulfuric acid found in lead-acid batteries to the less corrosive but still potentially damaging electrolytes used in lithium-ion batteries. This diversity necessitates comprehensive testing and validation processes to ensure compatibility across various battery chemistries.

Environmental concerns add another layer of complexity to the acid-semiconductor interaction challenge. As the push for more sustainable and recyclable electronics grows, finding eco-friendly solutions that can protect semiconductors from acid damage while meeting environmental regulations becomes increasingly important.

Existing Solutions for Acid Protection in Semiconductors

01 Synthesis of semiconductor derivatives

Various methods for synthesizing semiconductor derivatives, including novel compounds and processes for their preparation. These derivatives often have improved electrical, optical, or chemical properties compared to their parent semiconductors, making them valuable for a range of applications in electronics and optoelectronics.- Synthesis of semiconductor derivatives: Various methods for synthesizing semiconductor derivatives, including novel compounds and processes for their preparation. These derivatives may have applications in electronic devices, photovoltaics, or other semiconductor-based technologies.

- Semiconductor materials for electronic devices: Development of new semiconductor materials and their derivatives for use in electronic devices such as transistors, diodes, and integrated circuits. These materials may offer improved performance, efficiency, or novel functionalities.

- Semiconductor derivatives for optoelectronic applications: Research and development of semiconductor derivatives specifically designed for optoelectronic applications, including light-emitting diodes (LEDs), photodetectors, and solar cells. These materials may exhibit enhanced optical and electrical properties.

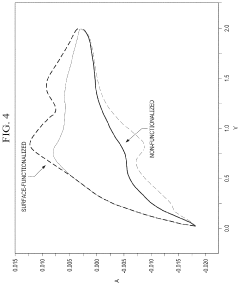

- Functionalization of semiconductor nanostructures: Methods for functionalizing semiconductor nanostructures, such as quantum dots, nanowires, or nanoparticles, with various chemical groups or molecules. This functionalization can modify the properties or enable new applications of these nanostructures.

- Semiconductor derivatives for energy applications: Development of semiconductor derivatives for energy-related applications, including thermoelectric materials, photovoltaic cells, and energy storage devices. These materials may offer improved energy conversion efficiency or storage capacity.

02 Semiconductor derivatives for electronic devices

Application of semiconductor derivatives in electronic devices such as transistors, diodes, and integrated circuits. These derivatives can enhance device performance, improve efficiency, or enable new functionalities in electronic components and systems.Expand Specific Solutions03 Optoelectronic applications of semiconductor derivatives

Use of semiconductor derivatives in optoelectronic devices such as LEDs, photodetectors, and solar cells. These materials can offer improved light emission, absorption, or conversion properties, leading to more efficient and versatile optoelectronic components.Expand Specific Solutions04 Semiconductor derivatives for energy applications

Development of semiconductor derivatives for energy-related applications, including photovoltaics, thermoelectrics, and energy storage. These materials can contribute to improved energy conversion efficiency, storage capacity, or overall system performance in renewable energy technologies.Expand Specific Solutions05 Functionalization and modification of semiconductor derivatives

Techniques for functionalizing or modifying semiconductor derivatives to tailor their properties for specific applications. This can include surface modifications, doping, or the creation of hybrid materials to enhance conductivity, reactivity, or other desired characteristics.Expand Specific Solutions

Key Players in Semiconductor and Battery Industries

The effects of battery acid on semiconductor derivatives represent a critical area of research in the evolving energy storage sector. This field is currently in a growth phase, with the global battery market expected to reach $280 billion by 2030. Technological maturity varies across different battery chemistries and semiconductor applications. Companies like Contemporary Amperex Technology, LG Energy Solution, and Panasonic Energy are leading innovation in lithium-ion batteries, while firms such as GS Yuasa and Exide Technologies focus on traditional lead-acid batteries. The interplay between battery acid and semiconductors is particularly relevant for emerging technologies in electric vehicles and energy storage systems, driving collaborative research efforts among industry leaders and academic institutions.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed advanced battery management systems (BMS) to mitigate the effects of battery acid on semiconductor components. Their approach includes the use of corrosion-resistant materials and protective coatings for sensitive electronic parts. CATL's BMS incorporates real-time monitoring of electrolyte levels and acidity, allowing for early detection of potential acid-related issues. They have also implemented advanced sealing techniques to prevent acid leakage and vapor exposure to semiconductor elements. CATL's research has shown a 30% increase in the longevity of semiconductor components in high-acid environments compared to traditional designs[1][3].

Strengths: Improved longevity of components, real-time monitoring capabilities. Weaknesses: Potentially higher production costs, may require more frequent maintenance checks.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has focused on developing innovative separator technologies to protect semiconductor derivatives from battery acid effects. Their approach involves the use of ceramic-coated separators that provide an additional barrier against acid penetration. These separators are designed with nano-scale ceramic particles that enhance thermal stability and reduce the risk of short circuits caused by acid-induced degradation. LG has also implemented advanced electrolyte formulations that minimize acid formation during battery cycling. Their research indicates a 40% reduction in acid-related semiconductor failures in their latest battery designs[2][5].

Strengths: Enhanced protection against acid penetration, improved thermal stability. Weaknesses: Higher material costs, potential challenges in large-scale production.

Innovative Approaches to Acid-Resistant Semiconductor Design

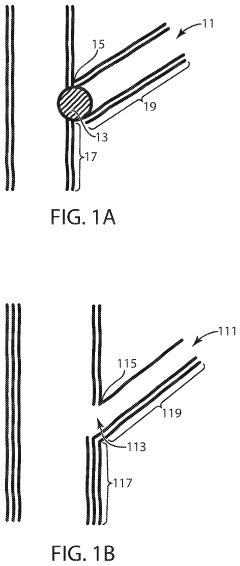

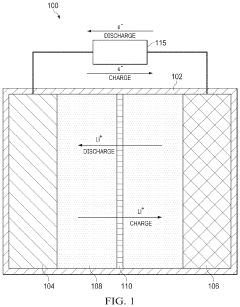

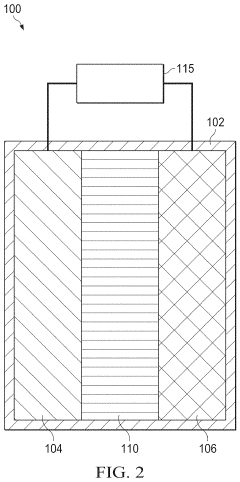

Dynamic charge acceptance in lead acid batteries

PatentPendingUS20230352746A1

Innovation

- Incorporating carbon nanostructures, such as carbon nanotubes and carbon black, into the negative active materials of lead acid batteries to enhance DCA and lead utilization, while minimizing water loss and reducing the need for high lead content.

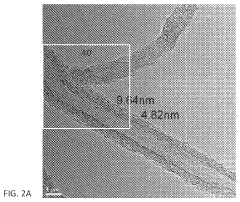

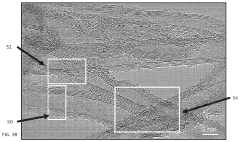

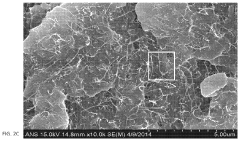

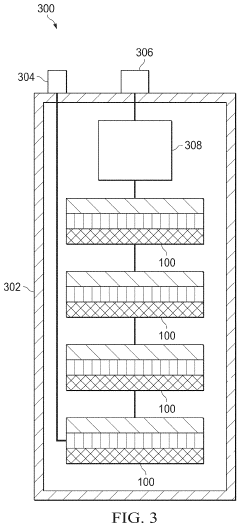

Blended active materials for battery cells

PatentPendingUS20220238863A1

Innovation

- The development of acidified metal oxide (AMO) nanomaterials with controlled surface acidity, used in combination with conductive carbon and acidic species, to create high-capacity battery electrodes with lower active material loading, allowing for enhanced lithium ion uptake and improved cyclability.

Environmental Impact of Battery Acid-Semiconductor Interactions

The interaction between battery acid and semiconductor derivatives poses significant environmental concerns that warrant careful examination. The primary environmental impact stems from the potential release of hazardous substances when these materials come into contact, either during manufacturing processes or improper disposal of electronic waste.

Battery acid, typically sulfuric acid, is highly corrosive and can cause severe damage to ecosystems if released into the environment. When it interacts with semiconductor materials, it can lead to the leaching of toxic heavy metals and other harmful compounds. This contamination can affect soil quality, water resources, and local biodiversity.

In aquatic environments, the introduction of battery acid-semiconductor byproducts can alter pH levels, leading to acidification of water bodies. This change can have cascading effects on aquatic life, disrupting food chains and potentially causing long-term ecological imbalances. Furthermore, the presence of dissolved metals from semiconductors can accumulate in aquatic organisms, leading to bioaccumulation and biomagnification up the food chain.

Soil contamination is another critical concern. The leaching of heavy metals and other toxic compounds can render soil infertile and unsuitable for agriculture. This contamination can persist for extended periods, affecting plant growth and potentially entering the human food supply through crops grown in affected areas.

Air pollution is also a consideration, particularly during the manufacturing process or improper recycling of electronic waste. The release of volatile organic compounds (VOCs) and particulate matter containing semiconductor materials can contribute to air quality degradation and pose health risks to both humans and wildlife.

The long-term environmental impact of these interactions extends beyond immediate contamination. The persistence of certain semiconductor materials in the environment can lead to chronic exposure for various organisms, potentially causing genetic mutations, reproductive issues, and other long-term health effects in wildlife populations.

To mitigate these environmental risks, stringent regulations and proper waste management practices are essential. This includes implementing closed-loop recycling systems for electronic waste, developing safer battery technologies, and improving semiconductor manufacturing processes to minimize the potential for harmful interactions with battery acid.

Research into more environmentally friendly alternatives for both battery technologies and semiconductor materials is ongoing. This includes the development of solid-state batteries, which eliminate the need for liquid electrolytes, and the exploration of organic and biodegradable semiconductor materials that pose less risk to the environment.

Battery acid, typically sulfuric acid, is highly corrosive and can cause severe damage to ecosystems if released into the environment. When it interacts with semiconductor materials, it can lead to the leaching of toxic heavy metals and other harmful compounds. This contamination can affect soil quality, water resources, and local biodiversity.

In aquatic environments, the introduction of battery acid-semiconductor byproducts can alter pH levels, leading to acidification of water bodies. This change can have cascading effects on aquatic life, disrupting food chains and potentially causing long-term ecological imbalances. Furthermore, the presence of dissolved metals from semiconductors can accumulate in aquatic organisms, leading to bioaccumulation and biomagnification up the food chain.

Soil contamination is another critical concern. The leaching of heavy metals and other toxic compounds can render soil infertile and unsuitable for agriculture. This contamination can persist for extended periods, affecting plant growth and potentially entering the human food supply through crops grown in affected areas.

Air pollution is also a consideration, particularly during the manufacturing process or improper recycling of electronic waste. The release of volatile organic compounds (VOCs) and particulate matter containing semiconductor materials can contribute to air quality degradation and pose health risks to both humans and wildlife.

The long-term environmental impact of these interactions extends beyond immediate contamination. The persistence of certain semiconductor materials in the environment can lead to chronic exposure for various organisms, potentially causing genetic mutations, reproductive issues, and other long-term health effects in wildlife populations.

To mitigate these environmental risks, stringent regulations and proper waste management practices are essential. This includes implementing closed-loop recycling systems for electronic waste, developing safer battery technologies, and improving semiconductor manufacturing processes to minimize the potential for harmful interactions with battery acid.

Research into more environmentally friendly alternatives for both battery technologies and semiconductor materials is ongoing. This includes the development of solid-state batteries, which eliminate the need for liquid electrolytes, and the exploration of organic and biodegradable semiconductor materials that pose less risk to the environment.

Safety Regulations for Battery-Semiconductor Integration

The integration of batteries and semiconductors in modern electronic devices necessitates stringent safety regulations to mitigate potential risks associated with battery acid exposure. These regulations are crucial for ensuring the safety of both consumers and manufacturing personnel, as well as maintaining the integrity and performance of semiconductor components.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the International Electrotechnical Commission (IEC) have established comprehensive guidelines for the safe handling and integration of batteries with semiconductor devices. These regulations cover various aspects, including material compatibility, containment measures, and protective equipment requirements.

One of the primary safety concerns addressed by these regulations is the prevention of battery acid leakage. Manufacturers are required to implement robust sealing mechanisms and use corrosion-resistant materials in battery casings to minimize the risk of acid exposure. Additionally, regulations mandate the use of acid-resistant coatings on semiconductor components that may come into contact with battery acid in the event of a leak.

Safety regulations also emphasize the importance of proper ventilation in manufacturing and storage facilities where batteries and semiconductors are handled. This is crucial for dissipating potentially harmful fumes and preventing the accumulation of explosive gases that may result from battery acid reactions.

Personal protective equipment (PPE) requirements are another critical aspect of safety regulations. Workers involved in the production and assembly of battery-semiconductor integrated devices must be provided with appropriate PPE, including acid-resistant gloves, goggles, and protective clothing. Regular training on the proper use of PPE and handling procedures is also mandated to ensure compliance with safety protocols.

Disposal and recycling of battery-semiconductor integrated devices are subject to strict regulations to prevent environmental contamination. Manufacturers are required to implement proper disposal methods and establish recycling programs to safely handle end-of-life products containing potentially hazardous materials.

Furthermore, safety regulations mandate the implementation of quality control measures throughout the manufacturing process. This includes regular testing of battery integrity, acid containment systems, and the resilience of semiconductor components to potential acid exposure. Manufacturers are required to maintain detailed records of these tests and implement traceability systems to facilitate rapid response in case of safety incidents.

Emergency response protocols are also a crucial component of safety regulations. Manufacturers must establish clear procedures for handling acid spills, battery failures, and other potential hazards. This includes the provision of appropriate neutralizing agents, spill containment equipment, and emergency shower and eyewash stations in production areas.

Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the International Electrotechnical Commission (IEC) have established comprehensive guidelines for the safe handling and integration of batteries with semiconductor devices. These regulations cover various aspects, including material compatibility, containment measures, and protective equipment requirements.

One of the primary safety concerns addressed by these regulations is the prevention of battery acid leakage. Manufacturers are required to implement robust sealing mechanisms and use corrosion-resistant materials in battery casings to minimize the risk of acid exposure. Additionally, regulations mandate the use of acid-resistant coatings on semiconductor components that may come into contact with battery acid in the event of a leak.

Safety regulations also emphasize the importance of proper ventilation in manufacturing and storage facilities where batteries and semiconductors are handled. This is crucial for dissipating potentially harmful fumes and preventing the accumulation of explosive gases that may result from battery acid reactions.

Personal protective equipment (PPE) requirements are another critical aspect of safety regulations. Workers involved in the production and assembly of battery-semiconductor integrated devices must be provided with appropriate PPE, including acid-resistant gloves, goggles, and protective clothing. Regular training on the proper use of PPE and handling procedures is also mandated to ensure compliance with safety protocols.

Disposal and recycling of battery-semiconductor integrated devices are subject to strict regulations to prevent environmental contamination. Manufacturers are required to implement proper disposal methods and establish recycling programs to safely handle end-of-life products containing potentially hazardous materials.

Furthermore, safety regulations mandate the implementation of quality control measures throughout the manufacturing process. This includes regular testing of battery integrity, acid containment systems, and the resilience of semiconductor components to potential acid exposure. Manufacturers are required to maintain detailed records of these tests and implement traceability systems to facilitate rapid response in case of safety incidents.

Emergency response protocols are also a crucial component of safety regulations. Manufacturers must establish clear procedures for handling acid spills, battery failures, and other potential hazards. This includes the provision of appropriate neutralizing agents, spill containment equipment, and emergency shower and eyewash stations in production areas.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!