How Emission Standards Correlate with Battery Acid Types

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Emission Standards and Battery Acid Evolution

The evolution of emission standards and battery acid types has been closely intertwined over the past few decades, driven by the increasing global focus on environmental protection and sustainable transportation. As governments worldwide have implemented stricter emission regulations, the automotive industry has been compelled to develop more efficient and cleaner technologies, including advancements in battery systems.

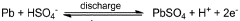

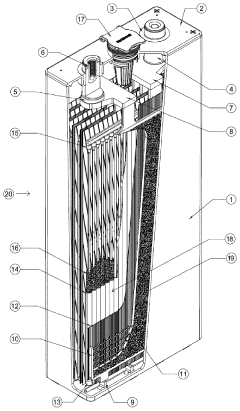

In the early stages of emission standards, lead-acid batteries were the predominant choice for vehicles. These batteries utilized sulfuric acid as the electrolyte, which was effective but posed environmental risks due to the presence of lead. As emission standards became more stringent, particularly with the introduction of Euro 1 standards in 1992 and subsequent iterations, the automotive industry began exploring alternative battery technologies.

The shift towards more environmentally friendly options led to the development of maintenance-free lead-acid batteries, which reduced acid spillage and emissions. This transition aligned with the tightening of emission standards, as manufacturers sought to minimize the environmental impact of their vehicles across all components.

The introduction of hybrid electric vehicles (HEVs) in the late 1990s marked a significant milestone in the correlation between emission standards and battery acid types. These vehicles utilized nickel-metal hydride (NiMH) batteries, which employed a potassium hydroxide electrolyte instead of sulfuric acid. This change was partly driven by the need to meet increasingly stringent emission standards, as HEVs offered reduced emissions compared to conventional internal combustion engine vehicles.

As emission standards continued to evolve, with the implementation of Euro 5 in 2009 and Euro 6 in 2014, the automotive industry saw a rapid shift towards lithium-ion batteries. These batteries, which use various lithium-based electrolytes, offered higher energy density and lower environmental impact compared to their predecessors. The adoption of lithium-ion technology was crucial in meeting the more demanding emission requirements, particularly for electric and plug-in hybrid vehicles.

The correlation between emission standards and battery acid types has also extended to the manufacturing and disposal processes. Stricter regulations on industrial emissions have led to improvements in battery production techniques, reducing the environmental impact of acid and chemical handling during manufacturing. Additionally, end-of-life battery recycling processes have been developed to comply with emission standards, ensuring proper disposal and minimizing the release of harmful substances into the environment.

Looking forward, the continued tightening of emission standards is likely to drive further innovations in battery technology. Solid-state batteries, which eliminate the need for liquid electrolytes altogether, are being developed as a potential solution to meet future ultra-low emission requirements. This ongoing evolution demonstrates the strong correlation between emission standards and the development of cleaner, more efficient battery technologies.

In the early stages of emission standards, lead-acid batteries were the predominant choice for vehicles. These batteries utilized sulfuric acid as the electrolyte, which was effective but posed environmental risks due to the presence of lead. As emission standards became more stringent, particularly with the introduction of Euro 1 standards in 1992 and subsequent iterations, the automotive industry began exploring alternative battery technologies.

The shift towards more environmentally friendly options led to the development of maintenance-free lead-acid batteries, which reduced acid spillage and emissions. This transition aligned with the tightening of emission standards, as manufacturers sought to minimize the environmental impact of their vehicles across all components.

The introduction of hybrid electric vehicles (HEVs) in the late 1990s marked a significant milestone in the correlation between emission standards and battery acid types. These vehicles utilized nickel-metal hydride (NiMH) batteries, which employed a potassium hydroxide electrolyte instead of sulfuric acid. This change was partly driven by the need to meet increasingly stringent emission standards, as HEVs offered reduced emissions compared to conventional internal combustion engine vehicles.

As emission standards continued to evolve, with the implementation of Euro 5 in 2009 and Euro 6 in 2014, the automotive industry saw a rapid shift towards lithium-ion batteries. These batteries, which use various lithium-based electrolytes, offered higher energy density and lower environmental impact compared to their predecessors. The adoption of lithium-ion technology was crucial in meeting the more demanding emission requirements, particularly for electric and plug-in hybrid vehicles.

The correlation between emission standards and battery acid types has also extended to the manufacturing and disposal processes. Stricter regulations on industrial emissions have led to improvements in battery production techniques, reducing the environmental impact of acid and chemical handling during manufacturing. Additionally, end-of-life battery recycling processes have been developed to comply with emission standards, ensuring proper disposal and minimizing the release of harmful substances into the environment.

Looking forward, the continued tightening of emission standards is likely to drive further innovations in battery technology. Solid-state batteries, which eliminate the need for liquid electrolytes altogether, are being developed as a potential solution to meet future ultra-low emission requirements. This ongoing evolution demonstrates the strong correlation between emission standards and the development of cleaner, more efficient battery technologies.

Market Demand for Eco-Friendly Batteries

The market demand for eco-friendly batteries has been steadily increasing in recent years, driven by growing environmental concerns and stringent emission standards worldwide. As governments and regulatory bodies implement more rigorous regulations to reduce carbon emissions and combat climate change, the automotive industry has been compelled to shift towards cleaner energy solutions. This shift has created a significant surge in demand for eco-friendly batteries, particularly in the electric vehicle (EV) sector.

The correlation between emission standards and battery acid types has become a crucial factor in shaping market trends. Traditional lead-acid batteries, while cost-effective, have faced challenges in meeting increasingly strict environmental regulations due to their potential for lead contamination and greenhouse gas emissions during production and disposal. This has led to a growing preference for alternative battery technologies that offer improved environmental performance.

Lithium-ion batteries have emerged as the frontrunner in the eco-friendly battery market, particularly for EVs and renewable energy storage systems. Their higher energy density, longer lifespan, and lower environmental impact compared to lead-acid batteries have made them the preferred choice for manufacturers seeking to comply with stringent emission standards. The market for lithium-ion batteries in the automotive sector alone is projected to experience substantial growth in the coming years.

Other eco-friendly battery technologies, such as nickel-metal hydride (NiMH) and sodium-ion batteries, are also gaining traction in niche markets. These alternatives offer varying degrees of environmental benefits and performance characteristics, catering to specific industry needs while aligning with emission reduction goals.

The demand for eco-friendly batteries extends beyond the automotive sector. Industries such as renewable energy, consumer electronics, and grid storage are increasingly adopting cleaner battery technologies to reduce their carbon footprint and meet sustainability targets. This diversification of applications has further expanded the market potential for eco-friendly batteries.

As emission standards continue to tighten globally, the market demand for eco-friendly batteries is expected to accelerate. Manufacturers are investing heavily in research and development to improve battery performance, reduce production costs, and enhance recyclability. This innovation drive is likely to result in new battery chemistries and technologies that offer even greater environmental benefits and performance improvements.

The correlation between emission standards and battery acid types has become a crucial factor in shaping market trends. Traditional lead-acid batteries, while cost-effective, have faced challenges in meeting increasingly strict environmental regulations due to their potential for lead contamination and greenhouse gas emissions during production and disposal. This has led to a growing preference for alternative battery technologies that offer improved environmental performance.

Lithium-ion batteries have emerged as the frontrunner in the eco-friendly battery market, particularly for EVs and renewable energy storage systems. Their higher energy density, longer lifespan, and lower environmental impact compared to lead-acid batteries have made them the preferred choice for manufacturers seeking to comply with stringent emission standards. The market for lithium-ion batteries in the automotive sector alone is projected to experience substantial growth in the coming years.

Other eco-friendly battery technologies, such as nickel-metal hydride (NiMH) and sodium-ion batteries, are also gaining traction in niche markets. These alternatives offer varying degrees of environmental benefits and performance characteristics, catering to specific industry needs while aligning with emission reduction goals.

The demand for eco-friendly batteries extends beyond the automotive sector. Industries such as renewable energy, consumer electronics, and grid storage are increasingly adopting cleaner battery technologies to reduce their carbon footprint and meet sustainability targets. This diversification of applications has further expanded the market potential for eco-friendly batteries.

As emission standards continue to tighten globally, the market demand for eco-friendly batteries is expected to accelerate. Manufacturers are investing heavily in research and development to improve battery performance, reduce production costs, and enhance recyclability. This innovation drive is likely to result in new battery chemistries and technologies that offer even greater environmental benefits and performance improvements.

Current Challenges in Battery Acid Technology

The battery acid technology sector faces several significant challenges in the context of evolving emission standards. One of the primary issues is the need for improved energy density in battery systems to meet the increasing demands of electric vehicles (EVs) and renewable energy storage. Current battery acid formulations struggle to provide the necessary power-to-weight ratio required for long-range EVs, limiting their widespread adoption.

Another critical challenge is the environmental impact of battery acid production and disposal. As emission standards become more stringent, manufacturers must develop cleaner production processes and more recyclable battery components. The current lead-acid batteries, while recyclable, still pose environmental risks if not properly handled at the end of their lifecycle.

Durability and longevity of battery acids remain problematic, particularly in extreme temperature conditions. This issue is especially relevant for EVs operating in diverse climates, where battery performance can significantly degrade, affecting both range and lifespan. Developing acid formulations that maintain stability and efficiency across a wide temperature range is crucial for meeting emission standards in various global markets.

Safety concerns continue to be a major challenge in battery acid technology. The corrosive nature of traditional battery acids presents risks during manufacturing, transportation, and use. As emission standards drive the adoption of larger battery systems in vehicles and stationary applications, the potential hazards associated with acid leaks or spills increase, necessitating improved safety features and containment strategies.

The cost of advanced battery acid technologies remains a significant barrier to widespread adoption. While emission standards push for cleaner technologies, the economic viability of new battery formulations must be addressed to ensure market acceptance. Balancing performance improvements with cost-effectiveness is a delicate challenge that researchers and manufacturers continue to grapple with.

Compatibility with existing infrastructure is another hurdle in the evolution of battery acid technology. As new formulations are developed to meet stricter emission standards, they must be designed to work with current charging systems and manufacturing processes to facilitate a smooth transition and minimize adoption barriers.

Lastly, the regulatory landscape surrounding battery acid technology is complex and evolving. Manufacturers must navigate a patchwork of international, national, and local regulations that can vary significantly. Harmonizing battery acid technologies with diverse emission standards and safety regulations across different markets poses a substantial challenge for the industry.

Another critical challenge is the environmental impact of battery acid production and disposal. As emission standards become more stringent, manufacturers must develop cleaner production processes and more recyclable battery components. The current lead-acid batteries, while recyclable, still pose environmental risks if not properly handled at the end of their lifecycle.

Durability and longevity of battery acids remain problematic, particularly in extreme temperature conditions. This issue is especially relevant for EVs operating in diverse climates, where battery performance can significantly degrade, affecting both range and lifespan. Developing acid formulations that maintain stability and efficiency across a wide temperature range is crucial for meeting emission standards in various global markets.

Safety concerns continue to be a major challenge in battery acid technology. The corrosive nature of traditional battery acids presents risks during manufacturing, transportation, and use. As emission standards drive the adoption of larger battery systems in vehicles and stationary applications, the potential hazards associated with acid leaks or spills increase, necessitating improved safety features and containment strategies.

The cost of advanced battery acid technologies remains a significant barrier to widespread adoption. While emission standards push for cleaner technologies, the economic viability of new battery formulations must be addressed to ensure market acceptance. Balancing performance improvements with cost-effectiveness is a delicate challenge that researchers and manufacturers continue to grapple with.

Compatibility with existing infrastructure is another hurdle in the evolution of battery acid technology. As new formulations are developed to meet stricter emission standards, they must be designed to work with current charging systems and manufacturing processes to facilitate a smooth transition and minimize adoption barriers.

Lastly, the regulatory landscape surrounding battery acid technology is complex and evolving. Manufacturers must navigate a patchwork of international, national, and local regulations that can vary significantly. Harmonizing battery acid technologies with diverse emission standards and safety regulations across different markets poses a substantial challenge for the industry.

Existing Battery Acid Solutions

01 Battery acid emission control systems

Development of systems to control and reduce acid emissions from batteries, particularly in industrial settings. These systems may include specialized ventilation, filtration, or neutralization mechanisms to capture or neutralize acid vapors before they are released into the environment.- Battery acid emission control systems: Advanced systems designed to control and reduce acid emissions from batteries, particularly in industrial settings. These systems may include specialized ventilation, filtration, and neutralization technologies to minimize the release of harmful acid vapors into the environment.

- Emission monitoring and detection devices: Innovative devices and sensors developed to monitor and detect battery acid emissions in real-time. These technologies enable early warning systems and help ensure compliance with emission standards by providing accurate measurements of acid vapor concentrations.

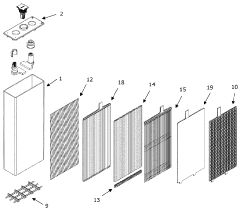

- Battery design improvements for reduced emissions: Advancements in battery design and construction aimed at minimizing acid emissions. These improvements may include enhanced sealing techniques, improved electrolyte management systems, and the use of alternative materials to reduce the potential for acid leakage and vaporization.

- Regulatory compliance and testing methods: Standardized testing procedures and compliance methods developed to ensure batteries meet emission standards. These may include specific protocols for measuring acid emissions, guidelines for proper handling and disposal, and certification processes for battery manufacturers.

- Acid neutralization and containment solutions: Innovative solutions for neutralizing and containing battery acid emissions. These may include specialized absorbent materials, chemical neutralizers, and containment systems designed to capture and treat acid vapors before they are released into the environment.

02 Acid-resistant battery casings and seals

Design and implementation of improved battery casings and sealing mechanisms that are resistant to acid corrosion and prevent leakage. These innovations aim to contain acid within the battery, reducing the risk of emissions and improving overall battery safety and longevity.Expand Specific Solutions03 Acid mist suppression techniques

Development of methods to suppress acid mist formation during battery charging and operation. This may include the use of chemical additives, specialized charging protocols, or physical barriers to minimize the generation and release of acid mist into the surrounding environment.Expand Specific Solutions04 Battery acid recycling and neutralization

Implementation of processes for recycling or neutralizing battery acid to reduce environmental impact. These methods may involve collecting and treating spent battery acid, converting it into less harmful substances, or repurposing it for other industrial applications.Expand Specific Solutions05 Monitoring and detection systems for acid emissions

Development of advanced sensors and monitoring systems to detect and measure acid emissions from batteries. These technologies enable real-time tracking of emission levels, allowing for prompt intervention and compliance with environmental regulations.Expand Specific Solutions

Key Players in Battery Manufacturing

The correlation between emission standards and battery acid types is a complex issue in an evolving industry. The market is in a growth phase, driven by increasing environmental regulations and the push for cleaner energy solutions. The global market size for advanced batteries is projected to expand significantly in the coming years. Technologically, the field is rapidly advancing, with companies like SolarEdge Technologies, Johnson Controls, and Exide Technologies leading innovation in battery technologies. Research institutions such as Jilin University and the University of Adelaide are contributing to advancements in battery chemistry and materials. The industry is seeing a shift towards more environmentally friendly and efficient battery acid formulations, with companies like GS Yuasa International and Daramic LLC developing new separator technologies to enhance battery performance and longevity.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced battery technologies that align with stringent emission standards. Their Ultium battery platform utilizes a unique chemistry with reduced cobalt content and increased nickel, which allows for higher energy density and lower costs[1]. This technology correlates with emission standards by enabling longer electric vehicle ranges, thus reducing overall vehicle emissions. GM's battery management system optimizes performance and longevity, adapting to various driving conditions and environmental factors[2]. The company has also invested in silicon anode technology, which could potentially increase energy density by 20-40% compared to current lithium-ion batteries[3].

Strengths: Innovative battery chemistry, scalable platform, reduced dependency on rare materials. Weaknesses: High initial investment costs, potential supply chain challenges for new materials.

Robert Bosch GmbH

Technical Solution: Bosch has developed a range of battery technologies that address emission standards through improved efficiency and performance. Their 48V battery system for mild hybrid vehicles significantly reduces CO2 emissions by up to 15%[4]. Bosch's advanced lead-acid batteries incorporate micro-hybrid technology, which enables start-stop functionality and regenerative braking, further reducing emissions in conventional vehicles[5]. The company has also invested in solid-state battery research, aiming to increase energy density and reduce charging times, which could lead to wider adoption of electric vehicles and lower overall emissions[6].

Strengths: Diverse battery portfolio catering to various vehicle types, strong focus on emissions reduction. Weaknesses: Reliance on traditional lead-acid technology in some products, which may face challenges in stricter emission environments.

Innovative Acid Formulations Analysis

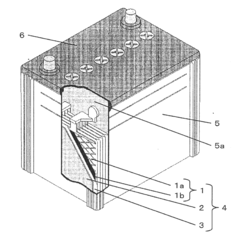

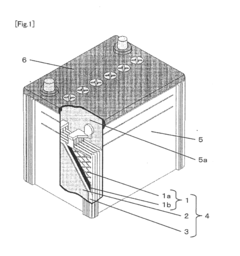

Lead acid battery

PatentActiveUS20180026310A1

Innovation

- A lead acid battery design with a positive to negative electrode active material mass ratio of 1.25 to 1.65, incorporating bismuth in the negative electrode grid and carbon in the negative electrode active material to prevent stratification and enhance charging efficiency, ensuring homogeneous charge/discharge reactions.

battery

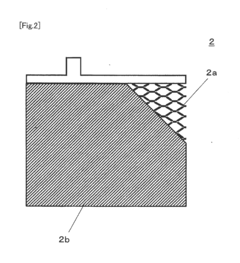

PatentWO2024074533A1

Innovation

- The use of a positive electrode with tube members and a negative electrode comprising carbon nanomaterial, specifically carbon nanotubes, enhances performance by reducing electrical resistance and improving the utilization and packing of active materials, allowing for higher capacity and faster charging.

Environmental Impact Assessment

The environmental impact of battery acid types and their correlation with emission standards is a critical aspect of sustainable energy storage and transportation systems. As emission standards become increasingly stringent, the choice of battery acid plays a significant role in determining the overall environmental footprint of battery-powered vehicles and energy storage solutions.

Lead-acid batteries, which have been widely used for decades, pose substantial environmental risks due to their high lead content and sulfuric acid electrolyte. The production, use, and disposal of these batteries can lead to soil and water contamination if not properly managed. In contrast, newer battery technologies, such as lithium-ion batteries, have a lower direct environmental impact in terms of toxic materials but present challenges in terms of resource extraction and end-of-life management.

The correlation between emission standards and battery acid types is evident in the shift towards more environmentally friendly battery chemistries. As regulations on vehicle emissions tighten, there is a growing demand for batteries that not only provide higher energy density but also have a reduced environmental impact throughout their lifecycle. This has led to the development of advanced lead-acid batteries with improved recycling capabilities and the adoption of alternative chemistries like nickel-metal hydride and lithium-ion.

Emission standards indirectly influence battery acid selection by driving the automotive industry towards electrification. As internal combustion engines face stricter emission limits, the transition to electric and hybrid vehicles accelerates. This shift necessitates batteries with higher performance and lower environmental impact, further pushing the development of advanced battery technologies and electrolytes.

The environmental assessment of battery acids must consider the entire lifecycle, from raw material extraction to disposal or recycling. Lithium-ion batteries, while offering superior performance, raise concerns about the environmental and social impacts of lithium mining. However, their longer lifespan and higher energy density can offset some of these concerns when compared to traditional lead-acid batteries over the long term.

Recycling infrastructure and regulations play a crucial role in mitigating the environmental impact of battery acids. As emission standards drive the adoption of new battery technologies, it becomes imperative to develop efficient recycling processes for these emerging chemistries. This includes the recovery of valuable materials and the safe disposal of potentially harmful components, ensuring a closed-loop system that minimizes environmental degradation.

In conclusion, the correlation between emission standards and battery acid types is characterized by a push towards more sustainable and efficient energy storage solutions. As regulations evolve, so too must battery technologies, balancing performance requirements with environmental considerations to create a more sustainable future for transportation and energy systems.

Lead-acid batteries, which have been widely used for decades, pose substantial environmental risks due to their high lead content and sulfuric acid electrolyte. The production, use, and disposal of these batteries can lead to soil and water contamination if not properly managed. In contrast, newer battery technologies, such as lithium-ion batteries, have a lower direct environmental impact in terms of toxic materials but present challenges in terms of resource extraction and end-of-life management.

The correlation between emission standards and battery acid types is evident in the shift towards more environmentally friendly battery chemistries. As regulations on vehicle emissions tighten, there is a growing demand for batteries that not only provide higher energy density but also have a reduced environmental impact throughout their lifecycle. This has led to the development of advanced lead-acid batteries with improved recycling capabilities and the adoption of alternative chemistries like nickel-metal hydride and lithium-ion.

Emission standards indirectly influence battery acid selection by driving the automotive industry towards electrification. As internal combustion engines face stricter emission limits, the transition to electric and hybrid vehicles accelerates. This shift necessitates batteries with higher performance and lower environmental impact, further pushing the development of advanced battery technologies and electrolytes.

The environmental assessment of battery acids must consider the entire lifecycle, from raw material extraction to disposal or recycling. Lithium-ion batteries, while offering superior performance, raise concerns about the environmental and social impacts of lithium mining. However, their longer lifespan and higher energy density can offset some of these concerns when compared to traditional lead-acid batteries over the long term.

Recycling infrastructure and regulations play a crucial role in mitigating the environmental impact of battery acids. As emission standards drive the adoption of new battery technologies, it becomes imperative to develop efficient recycling processes for these emerging chemistries. This includes the recovery of valuable materials and the safe disposal of potentially harmful components, ensuring a closed-loop system that minimizes environmental degradation.

In conclusion, the correlation between emission standards and battery acid types is characterized by a push towards more sustainable and efficient energy storage solutions. As regulations evolve, so too must battery technologies, balancing performance requirements with environmental considerations to create a more sustainable future for transportation and energy systems.

Regulatory Compliance Strategies

Regulatory compliance strategies for emission standards and battery acid types require a comprehensive approach that addresses both environmental concerns and technological advancements. As emission standards become increasingly stringent, manufacturers must adapt their battery technologies to meet these requirements while maintaining performance and cost-effectiveness.

One key strategy is the development of advanced battery management systems (BMS) that optimize the performance of batteries in relation to emission standards. These systems can monitor and control various parameters such as temperature, charge/discharge rates, and overall battery health. By fine-tuning these aspects, BMS can help reduce emissions and extend battery life, thereby ensuring compliance with regulatory standards.

Another important approach is the implementation of closed-loop recycling programs for battery acids. This strategy not only helps in reducing the environmental impact of battery disposal but also ensures compliance with hazardous waste regulations. By establishing partnerships with recycling facilities, manufacturers can create a sustainable ecosystem that aligns with emission standards and promotes responsible resource management.

The adoption of alternative battery chemistries is also a crucial compliance strategy. As traditional lead-acid batteries face scrutiny due to their environmental impact, manufacturers are exploring options such as lithium-ion, nickel-metal hydride, and solid-state batteries. These alternatives often offer improved energy density and reduced emissions, making them more attractive in the context of stringent regulatory requirements.

Manufacturers are also investing in research and development to improve the efficiency of battery acid formulations. By optimizing the chemical composition of battery acids, it is possible to reduce harmful emissions during the battery's lifecycle. This approach often involves the use of additives that enhance performance while minimizing environmental impact.

Collaboration with regulatory bodies and industry associations is another essential strategy for ensuring compliance. By actively participating in the development of new standards and providing input on technological capabilities, manufacturers can help shape regulations that are both environmentally responsible and technologically feasible. This proactive engagement can lead to more realistic compliance timelines and standards that align with the current state of battery technology.

Lastly, the implementation of robust quality control and testing procedures is crucial for maintaining regulatory compliance. Regular audits, third-party certifications, and continuous monitoring of production processes help ensure that batteries consistently meet emission standards throughout their lifecycle. This approach not only aids in compliance but also builds trust with regulators and consumers alike.

One key strategy is the development of advanced battery management systems (BMS) that optimize the performance of batteries in relation to emission standards. These systems can monitor and control various parameters such as temperature, charge/discharge rates, and overall battery health. By fine-tuning these aspects, BMS can help reduce emissions and extend battery life, thereby ensuring compliance with regulatory standards.

Another important approach is the implementation of closed-loop recycling programs for battery acids. This strategy not only helps in reducing the environmental impact of battery disposal but also ensures compliance with hazardous waste regulations. By establishing partnerships with recycling facilities, manufacturers can create a sustainable ecosystem that aligns with emission standards and promotes responsible resource management.

The adoption of alternative battery chemistries is also a crucial compliance strategy. As traditional lead-acid batteries face scrutiny due to their environmental impact, manufacturers are exploring options such as lithium-ion, nickel-metal hydride, and solid-state batteries. These alternatives often offer improved energy density and reduced emissions, making them more attractive in the context of stringent regulatory requirements.

Manufacturers are also investing in research and development to improve the efficiency of battery acid formulations. By optimizing the chemical composition of battery acids, it is possible to reduce harmful emissions during the battery's lifecycle. This approach often involves the use of additives that enhance performance while minimizing environmental impact.

Collaboration with regulatory bodies and industry associations is another essential strategy for ensuring compliance. By actively participating in the development of new standards and providing input on technological capabilities, manufacturers can help shape regulations that are both environmentally responsible and technologically feasible. This proactive engagement can lead to more realistic compliance timelines and standards that align with the current state of battery technology.

Lastly, the implementation of robust quality control and testing procedures is crucial for maintaining regulatory compliance. Regular audits, third-party certifications, and continuous monitoring of production processes help ensure that batteries consistently meet emission standards throughout their lifecycle. This approach not only aids in compliance but also builds trust with regulators and consumers alike.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!