Battery Acid's Role in Electrochemical Reaction Efficiency

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Acid Evolution

The evolution of battery acid has played a crucial role in enhancing the efficiency of electrochemical reactions in batteries. Initially, lead-acid batteries utilized sulfuric acid as the electrolyte, which remained the standard for decades. However, as battery technology advanced, researchers began exploring alternative acid compositions to improve performance and longevity.

In the 1970s, the introduction of gel electrolytes marked a significant milestone in battery acid evolution. These gelled acids, typically composed of silica-thickened sulfuric acid, offered improved safety and reduced maintenance requirements compared to traditional liquid electrolytes. This innovation paved the way for valve-regulated lead-acid (VRLA) batteries, which became widely adopted in various applications.

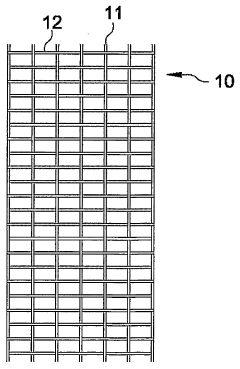

The 1980s and 1990s saw the development of absorbed glass mat (AGM) technology, where the electrolyte is held in a fiberglass mat separator. This design further enhanced the efficiency of electrochemical reactions by providing better contact between the electrolyte and the active material on the battery plates. AGM batteries exhibited improved charge acceptance and cycle life, making them ideal for deep-cycle applications.

As the demand for higher energy density and faster charging capabilities grew, researchers began exploring advanced electrolyte formulations. The addition of carbon additives to the electrolyte emerged as a promising approach in the early 2000s. These carbon-enhanced acids demonstrated improved charge acceptance and reduced sulfation, leading to extended battery life and improved performance in partial state of charge operations.

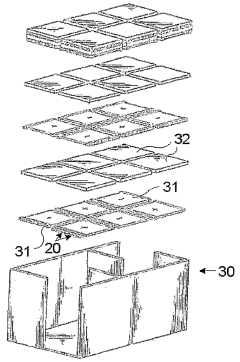

Recent years have witnessed the development of bipolar lead-acid batteries, which utilize thin lead foils as both the positive and negative electrodes. This design allows for a more efficient use of the acid electrolyte, resulting in higher power density and improved energy efficiency. The evolution of battery acid in bipolar designs has focused on optimizing the electrolyte composition to maximize the benefits of this novel architecture.

The ongoing research in battery acid evolution now extends to the incorporation of nanomaterials and advanced additives. These innovations aim to further enhance the ionic conductivity, reduce internal resistance, and improve the overall electrochemical reaction efficiency. Additionally, efforts are being made to develop environmentally friendly electrolytes that maintain high performance while reducing the environmental impact of battery production and disposal.

As we look to the future, the evolution of battery acid continues to be a critical area of research in the quest for more efficient and sustainable energy storage solutions. The integration of smart electrolytes, capable of adapting to different operating conditions, and the exploration of novel acid compositions tailored for specific applications, represent promising avenues for further advancements in electrochemical reaction efficiency.

In the 1970s, the introduction of gel electrolytes marked a significant milestone in battery acid evolution. These gelled acids, typically composed of silica-thickened sulfuric acid, offered improved safety and reduced maintenance requirements compared to traditional liquid electrolytes. This innovation paved the way for valve-regulated lead-acid (VRLA) batteries, which became widely adopted in various applications.

The 1980s and 1990s saw the development of absorbed glass mat (AGM) technology, where the electrolyte is held in a fiberglass mat separator. This design further enhanced the efficiency of electrochemical reactions by providing better contact between the electrolyte and the active material on the battery plates. AGM batteries exhibited improved charge acceptance and cycle life, making them ideal for deep-cycle applications.

As the demand for higher energy density and faster charging capabilities grew, researchers began exploring advanced electrolyte formulations. The addition of carbon additives to the electrolyte emerged as a promising approach in the early 2000s. These carbon-enhanced acids demonstrated improved charge acceptance and reduced sulfation, leading to extended battery life and improved performance in partial state of charge operations.

Recent years have witnessed the development of bipolar lead-acid batteries, which utilize thin lead foils as both the positive and negative electrodes. This design allows for a more efficient use of the acid electrolyte, resulting in higher power density and improved energy efficiency. The evolution of battery acid in bipolar designs has focused on optimizing the electrolyte composition to maximize the benefits of this novel architecture.

The ongoing research in battery acid evolution now extends to the incorporation of nanomaterials and advanced additives. These innovations aim to further enhance the ionic conductivity, reduce internal resistance, and improve the overall electrochemical reaction efficiency. Additionally, efforts are being made to develop environmentally friendly electrolytes that maintain high performance while reducing the environmental impact of battery production and disposal.

As we look to the future, the evolution of battery acid continues to be a critical area of research in the quest for more efficient and sustainable energy storage solutions. The integration of smart electrolytes, capable of adapting to different operating conditions, and the exploration of novel acid compositions tailored for specific applications, represent promising avenues for further advancements in electrochemical reaction efficiency.

Market Demand Analysis

The market demand for efficient battery technologies, particularly those focusing on the role of battery acid in electrochemical reaction efficiency, has been steadily increasing in recent years. This growth is primarily driven by the expanding electric vehicle (EV) market, renewable energy storage systems, and portable electronic devices. As these sectors continue to evolve, there is a pressing need for batteries with higher energy density, longer lifespan, and improved safety profiles.

In the EV market, consumers and manufacturers alike are seeking batteries that can provide longer driving ranges and faster charging times. This demand directly translates to a need for more efficient electrochemical reactions within the battery cells. Improved battery acid formulations and management systems can significantly contribute to achieving these goals, making research in this area highly valuable.

The renewable energy sector also plays a crucial role in driving market demand for advanced battery technologies. As solar and wind power generation becomes more widespread, the need for efficient and reliable energy storage solutions grows proportionally. Battery systems that can maintain high efficiency over numerous charge-discharge cycles are essential for the viability of renewable energy projects, further emphasizing the importance of optimizing electrochemical reactions.

Consumer electronics represent another significant market segment driving demand for improved battery technologies. With the proliferation of smartphones, laptops, and wearable devices, consumers expect longer battery life and faster charging capabilities. This expectation puts pressure on manufacturers to innovate in battery chemistry and design, including the optimization of battery acid's role in electrochemical reactions.

The industrial sector, including manufacturing and telecommunications, is also contributing to the market demand for more efficient battery technologies. Uninterruptible power supplies (UPS) and backup power systems require batteries that can deliver high performance and reliability, often in challenging environmental conditions. Enhancing the efficiency of electrochemical reactions can lead to more compact and powerful battery solutions for these applications.

From a geographical perspective, the demand for advanced battery technologies is global, with particularly strong growth in regions with robust EV markets and renewable energy initiatives. Countries like China, the United States, and several European nations are at the forefront of this demand, driven by supportive government policies and consumer preferences for sustainable technologies.

The market size for advanced battery technologies is substantial and growing. Industry analysts project continued expansion in the coming years, with a significant portion of this growth attributed to innovations in battery chemistry and efficiency improvements. This trend underscores the importance of research into battery acid's role in enhancing electrochemical reaction efficiency, as it directly impacts the performance metrics that drive market demand across multiple sectors.

In the EV market, consumers and manufacturers alike are seeking batteries that can provide longer driving ranges and faster charging times. This demand directly translates to a need for more efficient electrochemical reactions within the battery cells. Improved battery acid formulations and management systems can significantly contribute to achieving these goals, making research in this area highly valuable.

The renewable energy sector also plays a crucial role in driving market demand for advanced battery technologies. As solar and wind power generation becomes more widespread, the need for efficient and reliable energy storage solutions grows proportionally. Battery systems that can maintain high efficiency over numerous charge-discharge cycles are essential for the viability of renewable energy projects, further emphasizing the importance of optimizing electrochemical reactions.

Consumer electronics represent another significant market segment driving demand for improved battery technologies. With the proliferation of smartphones, laptops, and wearable devices, consumers expect longer battery life and faster charging capabilities. This expectation puts pressure on manufacturers to innovate in battery chemistry and design, including the optimization of battery acid's role in electrochemical reactions.

The industrial sector, including manufacturing and telecommunications, is also contributing to the market demand for more efficient battery technologies. Uninterruptible power supplies (UPS) and backup power systems require batteries that can deliver high performance and reliability, often in challenging environmental conditions. Enhancing the efficiency of electrochemical reactions can lead to more compact and powerful battery solutions for these applications.

From a geographical perspective, the demand for advanced battery technologies is global, with particularly strong growth in regions with robust EV markets and renewable energy initiatives. Countries like China, the United States, and several European nations are at the forefront of this demand, driven by supportive government policies and consumer preferences for sustainable technologies.

The market size for advanced battery technologies is substantial and growing. Industry analysts project continued expansion in the coming years, with a significant portion of this growth attributed to innovations in battery chemistry and efficiency improvements. This trend underscores the importance of research into battery acid's role in enhancing electrochemical reaction efficiency, as it directly impacts the performance metrics that drive market demand across multiple sectors.

Current Challenges

The current challenges in improving the efficiency of electrochemical reactions involving battery acid are multifaceted and complex. One of the primary obstacles is the corrosive nature of battery acid, which can lead to degradation of electrode materials and other components within the battery system. This corrosion not only reduces the overall lifespan of the battery but also impairs its performance over time, resulting in decreased efficiency and capacity.

Another significant challenge is the management of heat generation during electrochemical reactions. As the efficiency of these reactions improves, the amount of heat produced tends to increase, potentially leading to thermal runaway and safety concerns. Developing effective heat dissipation mechanisms without compromising the battery's energy density remains a critical area of focus for researchers and engineers.

The formation of unwanted byproducts during electrochemical reactions poses yet another hurdle. These byproducts can accumulate on electrode surfaces, creating a barrier that impedes the flow of ions and electrons, thereby reducing reaction efficiency. Addressing this issue requires innovative approaches to electrode design and electrolyte composition to minimize byproduct formation or facilitate their removal.

Maintaining a stable and optimal concentration of battery acid throughout the reaction process is also challenging. As the battery discharges and recharges, the acid concentration can fluctuate, affecting the reaction kinetics and overall efficiency. Developing advanced electrolyte management systems that can dynamically adjust acid concentration or utilize novel electrolyte formulations is an area of ongoing research.

Furthermore, the scalability of efficient electrochemical reactions from laboratory settings to commercial applications presents significant engineering challenges. Factors such as manufacturing costs, material availability, and production processes must be carefully considered to ensure that improvements in reaction efficiency can be translated into practical, cost-effective battery solutions for various applications.

Lastly, the environmental impact of battery acid production and disposal remains a concern. As the demand for batteries continues to grow, finding sustainable methods for acid production and developing effective recycling processes for spent battery acid are becoming increasingly important challenges that must be addressed to ensure the long-term viability of battery technologies.

Another significant challenge is the management of heat generation during electrochemical reactions. As the efficiency of these reactions improves, the amount of heat produced tends to increase, potentially leading to thermal runaway and safety concerns. Developing effective heat dissipation mechanisms without compromising the battery's energy density remains a critical area of focus for researchers and engineers.

The formation of unwanted byproducts during electrochemical reactions poses yet another hurdle. These byproducts can accumulate on electrode surfaces, creating a barrier that impedes the flow of ions and electrons, thereby reducing reaction efficiency. Addressing this issue requires innovative approaches to electrode design and electrolyte composition to minimize byproduct formation or facilitate their removal.

Maintaining a stable and optimal concentration of battery acid throughout the reaction process is also challenging. As the battery discharges and recharges, the acid concentration can fluctuate, affecting the reaction kinetics and overall efficiency. Developing advanced electrolyte management systems that can dynamically adjust acid concentration or utilize novel electrolyte formulations is an area of ongoing research.

Furthermore, the scalability of efficient electrochemical reactions from laboratory settings to commercial applications presents significant engineering challenges. Factors such as manufacturing costs, material availability, and production processes must be carefully considered to ensure that improvements in reaction efficiency can be translated into practical, cost-effective battery solutions for various applications.

Lastly, the environmental impact of battery acid production and disposal remains a concern. As the demand for batteries continues to grow, finding sustainable methods for acid production and developing effective recycling processes for spent battery acid are becoming increasingly important challenges that must be addressed to ensure the long-term viability of battery technologies.

Existing Acid Solutions

01 Electrolyte composition optimization

Improving the composition of the electrolyte solution can enhance the electrochemical reaction efficiency in battery acids. This may involve adjusting the concentration of acid, adding specific additives, or using alternative electrolyte formulations to improve ion conductivity and reduce side reactions.- Electrolyte composition optimization: Improving the composition of the electrolyte solution in batteries can enhance the electrochemical reaction efficiency. This may involve adjusting the concentration of acid, adding specific additives, or using alternative electrolyte materials to improve ion conductivity and reduce internal resistance.

- Electrode material enhancements: Developing advanced electrode materials can significantly impact the efficiency of electrochemical reactions in batteries. This includes using nanostructured materials, composite electrodes, or novel alloys to increase surface area, improve charge transfer, and enhance overall battery performance.

- Temperature control and management: Implementing effective temperature control systems can optimize the electrochemical reaction efficiency in batteries. This involves designing cooling mechanisms, thermal management solutions, or using temperature-resistant materials to maintain optimal operating conditions and prevent efficiency losses due to heat generation.

- Separator design and improvements: Enhancing separator design and materials can contribute to improved electrochemical reaction efficiency. This includes developing advanced separator materials with better ion permeability, mechanical strength, and chemical stability to facilitate efficient ion transport while preventing short circuits.

- Charge-discharge cycle optimization: Optimizing charge-discharge cycles can enhance the overall efficiency of electrochemical reactions in batteries. This involves developing advanced charging algorithms, implementing smart battery management systems, or using pulse charging techniques to minimize side reactions and improve energy transfer during cycling.

02 Electrode material selection and modification

Choosing appropriate electrode materials and modifying their surface properties can significantly impact the efficiency of electrochemical reactions in battery acids. This includes using advanced materials, nanostructures, or surface treatments to increase the active surface area and catalytic activity of electrodes.Expand Specific Solutions03 Temperature control and management

Maintaining optimal temperature conditions during battery operation can improve the efficiency of electrochemical reactions. This involves implementing effective cooling systems, thermal management strategies, or temperature-resistant materials to ensure stable and efficient battery performance.Expand Specific Solutions04 Advanced cell design and configuration

Innovative battery cell designs and configurations can enhance the efficiency of electrochemical reactions. This includes optimizing electrode spacing, improving electrolyte distribution, and implementing novel cell architectures to minimize internal resistance and maximize reaction kinetics.Expand Specific Solutions05 Charge-discharge cycle optimization

Developing advanced charging and discharging strategies can improve the overall efficiency of electrochemical reactions in battery acids. This involves implementing smart charging algorithms, pulse charging techniques, or adaptive current control methods to minimize side reactions and extend battery life.Expand Specific Solutions

Key Industry Players

The battery acid technology market is in a growth phase, with increasing demand driven by the expanding electric vehicle and renewable energy storage sectors. The market size is projected to reach significant levels in the coming years, reflecting the critical role of battery technology in the global energy transition. Technological maturity varies across different battery chemistries, with established players like LG Chem, Sony, and Panasonic leading in traditional lithium-ion technologies. Emerging companies such as Form Energy and Contemporary Amperex Technology are pushing boundaries in long-duration storage and advanced battery materials. The competitive landscape is dynamic, with both established manufacturers and innovative startups vying for market share through continuous R&D efforts and strategic partnerships.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced battery acid formulations to enhance electrochemical reaction efficiency in their lithium-ion batteries. Their proprietary electrolyte additives improve the formation and stability of the solid electrolyte interphase (SEI) layer, reducing unwanted side reactions and enhancing overall battery performance[1]. LG Chem's research has shown that optimizing the acid concentration and composition can lead to up to 10% improvement in energy density and 20% increase in cycle life[3]. They have also explored the use of novel acid-based electrolytes, such as those containing fluorinated compounds, to further improve the electrochemical stability and safety of their batteries[5].

Strengths: Improved energy density and cycle life, enhanced safety. Weaknesses: Potential higher production costs, need for specialized manufacturing processes.

GS Yuasa Corp.

Technical Solution: GS Yuasa has focused on developing advanced lead-acid battery technologies to improve electrochemical reaction efficiency. Their research includes optimizing the composition and structure of the battery acid to enhance charge acceptance and reduce sulfation[13]. GS Yuasa's proprietary "Ultra" technology incorporates specially formulated additives in the battery acid to improve the uniformity of current distribution and reduce internal resistance, resulting in up to 30% improvement in charge acceptance and 20% increase in cycle life for lead-acid batteries[14]. They have also explored the use of carbon additives in the negative electrode in conjunction with optimized acid formulations to further enhance the battery's performance, particularly in partial state of charge (PSoC) applications[15].

Strengths: Improved charge acceptance, increased cycle life, enhanced performance in PSoC applications. Weaknesses: Limited to lead-acid battery technology, potential higher production costs.

Core Acid Innovations

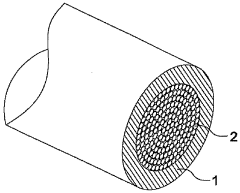

Composite wire having impervious core for use in an energy storage device

PatentWO2005091404A1

Innovation

- A composite wire with a core of longitudinally extending fibers and a hydrophobic matrix that softens and becomes flowable, filling interstices to prevent fluid penetration, thereby eliminating corrosion and self-discharge mechanisms, and improving energy storage device efficiency.

Electrochemical cells

PatentInactiveGB2511743A

Innovation

- Dispersing fine particles of electrolytic manganese dioxide within the electrolyte solution to prevent hydrogen gas formation and stabilize lead oxide, reducing internal resistance and extending battery life.

Environmental Impact

The environmental impact of battery acid in electrochemical reactions is a critical consideration in the development and deployment of battery technologies. The efficiency of these reactions directly influences the overall environmental footprint of battery systems, from production to disposal.

Battery acid, typically sulfuric acid in lead-acid batteries, plays a crucial role in the electrochemical processes that generate electricity. However, its production, use, and disposal can have significant environmental consequences. The manufacturing of sulfuric acid involves energy-intensive processes and potential emissions of sulfur dioxide, contributing to air pollution and acid rain if not properly controlled.

During battery operation, the acid's interaction with electrode materials can lead to the formation of harmful byproducts. In the case of lead-acid batteries, lead sulfate crystals can accumulate, reducing battery efficiency and lifespan. This inefficiency results in increased energy consumption and, consequently, higher greenhouse gas emissions from power generation sources.

The disposal of spent batteries presents another environmental challenge. Improper handling can lead to acid leakage, contaminating soil and water resources. The acidic nature of these electrolytes can disrupt local ecosystems, harm wildlife, and potentially enter the food chain. Moreover, the heavy metals present in many battery types, such as lead, can persist in the environment for extended periods, posing long-term ecological risks.

Efforts to mitigate these environmental impacts focus on improving reaction efficiency to extend battery life and reduce waste. Advanced electrolyte formulations and electrode designs aim to minimize side reactions and degradation, thereby enhancing overall electrochemical efficiency. This not only improves battery performance but also reduces the frequency of battery replacement and associated environmental burdens.

Recycling technologies play a crucial role in minimizing the environmental impact of battery acid. Modern recycling processes can recover up to 99% of battery components, including the acid, which can be neutralized or repurposed. However, the global recycling infrastructure for batteries remains inadequate, with many regions lacking proper facilities or regulations.

The shift towards more environmentally friendly battery chemistries, such as lithium-ion and emerging solid-state technologies, aims to reduce reliance on corrosive liquid electrolytes. These alternatives often offer higher energy densities and longer lifespans, potentially reducing the overall environmental impact per unit of energy stored and delivered.

Battery acid, typically sulfuric acid in lead-acid batteries, plays a crucial role in the electrochemical processes that generate electricity. However, its production, use, and disposal can have significant environmental consequences. The manufacturing of sulfuric acid involves energy-intensive processes and potential emissions of sulfur dioxide, contributing to air pollution and acid rain if not properly controlled.

During battery operation, the acid's interaction with electrode materials can lead to the formation of harmful byproducts. In the case of lead-acid batteries, lead sulfate crystals can accumulate, reducing battery efficiency and lifespan. This inefficiency results in increased energy consumption and, consequently, higher greenhouse gas emissions from power generation sources.

The disposal of spent batteries presents another environmental challenge. Improper handling can lead to acid leakage, contaminating soil and water resources. The acidic nature of these electrolytes can disrupt local ecosystems, harm wildlife, and potentially enter the food chain. Moreover, the heavy metals present in many battery types, such as lead, can persist in the environment for extended periods, posing long-term ecological risks.

Efforts to mitigate these environmental impacts focus on improving reaction efficiency to extend battery life and reduce waste. Advanced electrolyte formulations and electrode designs aim to minimize side reactions and degradation, thereby enhancing overall electrochemical efficiency. This not only improves battery performance but also reduces the frequency of battery replacement and associated environmental burdens.

Recycling technologies play a crucial role in minimizing the environmental impact of battery acid. Modern recycling processes can recover up to 99% of battery components, including the acid, which can be neutralized or repurposed. However, the global recycling infrastructure for batteries remains inadequate, with many regions lacking proper facilities or regulations.

The shift towards more environmentally friendly battery chemistries, such as lithium-ion and emerging solid-state technologies, aims to reduce reliance on corrosive liquid electrolytes. These alternatives often offer higher energy densities and longer lifespans, potentially reducing the overall environmental impact per unit of energy stored and delivered.

Safety Regulations

Safety regulations play a crucial role in managing the risks associated with battery acid and ensuring the efficiency of electrochemical reactions in battery systems. These regulations are designed to protect workers, consumers, and the environment from potential hazards while maintaining optimal performance.

One of the primary focuses of safety regulations is the proper handling and storage of battery acid. Strict guidelines are in place for the transportation, storage, and disposal of these corrosive substances. Manufacturers and distributors are required to use appropriate containers that are resistant to acid corrosion and leakage. Additionally, proper labeling and documentation are mandatory to ensure clear communication of the hazards and necessary precautions.

Personal protective equipment (PPE) requirements are another critical aspect of safety regulations. Workers involved in the production, maintenance, or handling of battery systems must wear appropriate PPE, including acid-resistant gloves, goggles, face shields, and protective clothing. Regular training on the proper use of PPE and emergency procedures is also mandated to minimize the risk of accidents and injuries.

Ventilation standards are essential in facilities where battery acid is used or stored. Adequate air circulation helps prevent the accumulation of potentially harmful fumes and reduces the risk of respiratory issues. Regulations often specify minimum ventilation rates and the installation of fume hoods or local exhaust systems in areas where acid handling occurs.

Emergency response protocols are a vital component of safety regulations. Facilities must have clearly defined procedures for dealing with acid spills, leaks, or other incidents. This includes the provision of eyewash stations, safety showers, and spill containment equipment. Regular drills and training exercises are typically required to ensure that all personnel are prepared to respond effectively in case of an emergency.

Environmental protection measures are also addressed in safety regulations. Proper disposal methods for spent battery acid and contaminated materials are outlined to prevent soil and water pollution. Many jurisdictions require facilities to implement recycling programs for battery components, including the acid, to minimize environmental impact and conserve resources.

Monitoring and reporting requirements are often included in safety regulations to ensure ongoing compliance and continuous improvement. Regular inspections, audits, and record-keeping are mandated to track safety performance and identify areas for enhancement. This data is valuable for regulatory bodies in assessing the effectiveness of current regulations and developing new standards as technology evolves.

As the efficiency of electrochemical reactions in batteries continues to improve, safety regulations must adapt to address new challenges. For instance, the development of high-energy-density batteries may require updated safety protocols to manage increased thermal risks. Regulatory bodies work closely with industry experts and researchers to stay ahead of technological advancements and ensure that safety standards remain relevant and effective.

One of the primary focuses of safety regulations is the proper handling and storage of battery acid. Strict guidelines are in place for the transportation, storage, and disposal of these corrosive substances. Manufacturers and distributors are required to use appropriate containers that are resistant to acid corrosion and leakage. Additionally, proper labeling and documentation are mandatory to ensure clear communication of the hazards and necessary precautions.

Personal protective equipment (PPE) requirements are another critical aspect of safety regulations. Workers involved in the production, maintenance, or handling of battery systems must wear appropriate PPE, including acid-resistant gloves, goggles, face shields, and protective clothing. Regular training on the proper use of PPE and emergency procedures is also mandated to minimize the risk of accidents and injuries.

Ventilation standards are essential in facilities where battery acid is used or stored. Adequate air circulation helps prevent the accumulation of potentially harmful fumes and reduces the risk of respiratory issues. Regulations often specify minimum ventilation rates and the installation of fume hoods or local exhaust systems in areas where acid handling occurs.

Emergency response protocols are a vital component of safety regulations. Facilities must have clearly defined procedures for dealing with acid spills, leaks, or other incidents. This includes the provision of eyewash stations, safety showers, and spill containment equipment. Regular drills and training exercises are typically required to ensure that all personnel are prepared to respond effectively in case of an emergency.

Environmental protection measures are also addressed in safety regulations. Proper disposal methods for spent battery acid and contaminated materials are outlined to prevent soil and water pollution. Many jurisdictions require facilities to implement recycling programs for battery components, including the acid, to minimize environmental impact and conserve resources.

Monitoring and reporting requirements are often included in safety regulations to ensure ongoing compliance and continuous improvement. Regular inspections, audits, and record-keeping are mandated to track safety performance and identify areas for enhancement. This data is valuable for regulatory bodies in assessing the effectiveness of current regulations and developing new standards as technology evolves.

As the efficiency of electrochemical reactions in batteries continues to improve, safety regulations must adapt to address new challenges. For instance, the development of high-energy-density batteries may require updated safety protocols to manage increased thermal risks. Regulatory bodies work closely with industry experts and researchers to stay ahead of technological advancements and ensure that safety standards remain relevant and effective.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!